Method and equipment for coproducing chondroitin sulfate, II-type collagen oligopeptide and II-type collagen polypeptide through liquefying animal cartilages

A technology of chondroitin sulfate and collagen polypeptide, which is applied in the field of bone processing, can solve the problems of large equipment investment, high production cost, and complicated process, and achieve the effects of reducing production cost, reducing losses, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

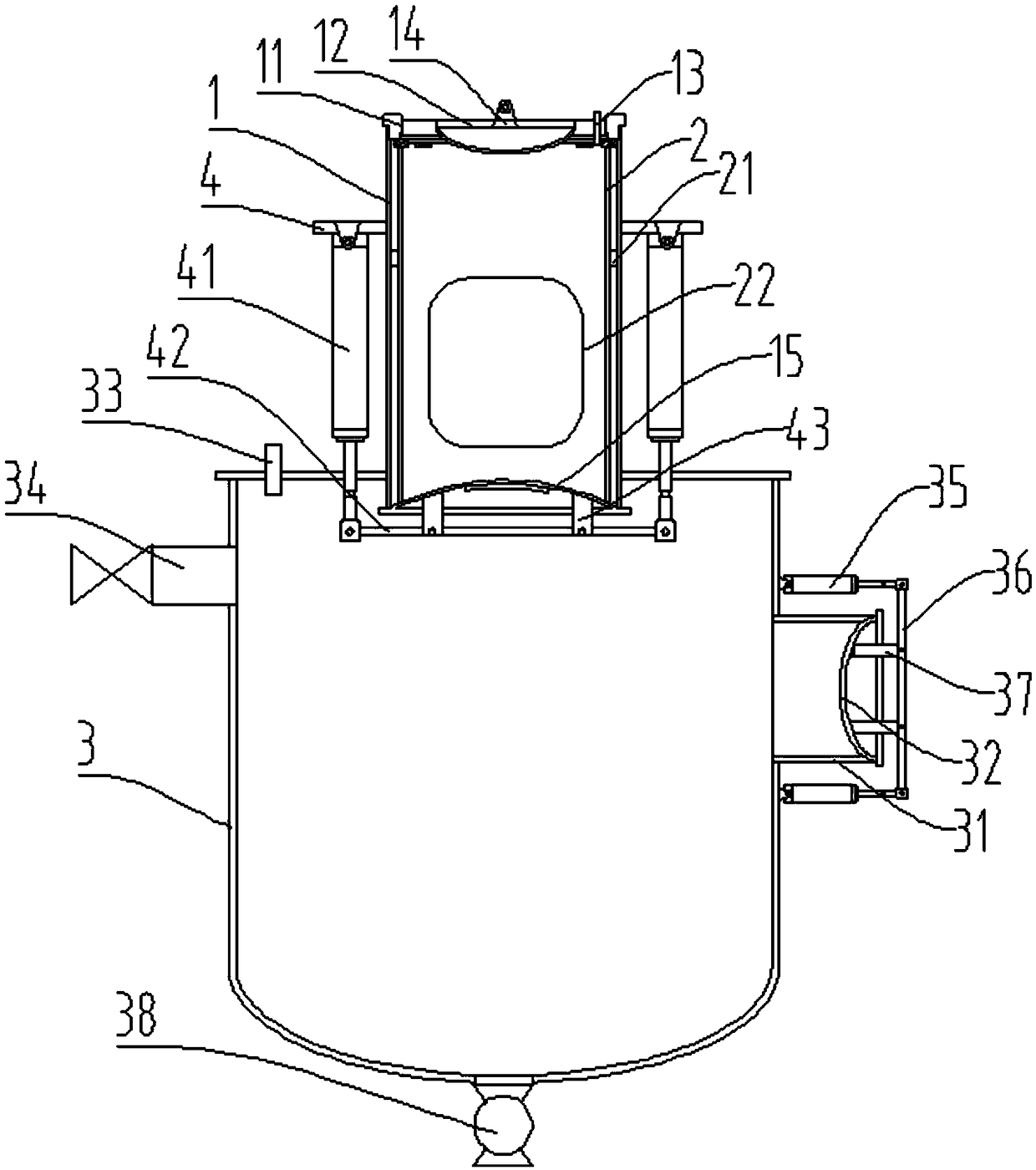

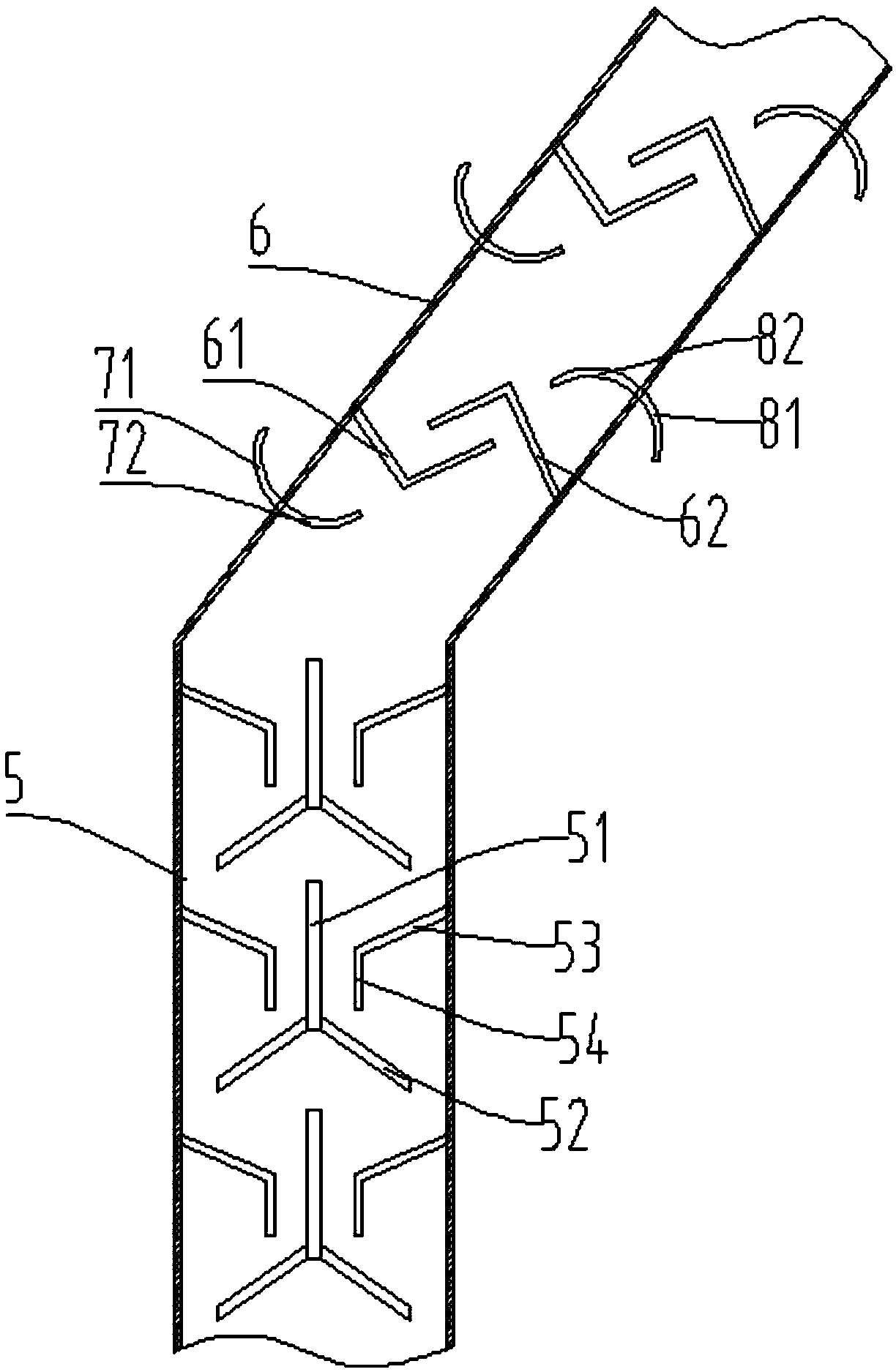

[0077] A method for co-producing chondroitin sulfate, type II collagen oligopeptide, and type II collagen polypeptide with equipment for liquefying animal cartilage, comprising the following steps:

[0078] S1. Select animal cartilage and crush it;

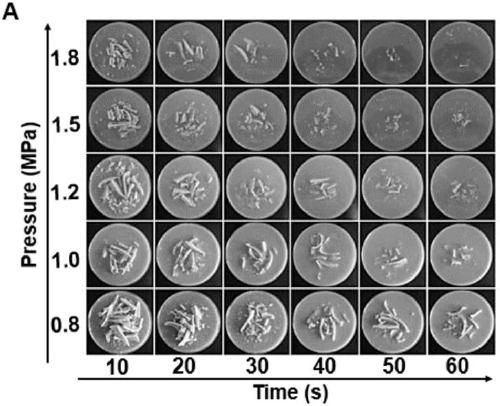

[0079] S2. Add the crushed cartilage into the first liquefaction chamber through the feeding port, close the feeding port and the lower cover, and pass saturated water vapor with a pressure of 1.0 MPa into the first liquefaction chamber through the first steam inlet for the second liquefaction chamber. For one liquefaction, the liquefaction time is 10s. At the same time, the pressure of the second liquefaction chamber is pumped to a vacuum state, and then the lower cover is opened for the first pressure relief. After the first pressure relief is completed, the second steam inlet Introduce saturated water vapor with a pressure of 0.8MPa into the second liquefaction chamber for the second liquefaction, the second liquefaction time i...

Embodiment 2

[0086] A method for co-producing chondroitin sulfate, type II collagen oligopeptide, and type II collagen polypeptide with equipment for liquefying animal cartilage, comprising the following steps:

[0087] S1. Select animal cartilage and crush it;

[0088] S2. Add the crushed cartilage into the first liquefaction chamber through the feeding port, close the feeding port and the lower cover, and pass saturated water vapor with a pressure of 1.4MPa into the first liquefaction chamber through the first steam inlet for the second liquefaction chamber. For one liquefaction, the liquefaction time is 35s. At the same time, the pressure of the second liquefaction chamber is evacuated to a vacuum state, and then the lower cover is opened for the first pressure relief. After the first pressure relief is completed, the second steam inlet Introduce saturated water vapor with a pressure of 1.1MPa into the second liquefaction chamber for the second liquefaction, the second liquefaction time...

Embodiment 3

[0095] A method for co-producing chondroitin sulfate, type II collagen oligopeptide, and type II collagen polypeptide with equipment for liquefying animal cartilage, comprising the following steps:

[0096] S1. Select animal cartilage and crush it;

[0097] S2. Add the crushed cartilage into the first liquefaction chamber through the feeding port, close the feeding port and the lower cover, and pass saturated water vapor with a pressure of 1.8 MPa into the first liquefaction chamber through the first steam inlet to carry out the second liquefaction process. For one liquefaction, the liquefaction time is 60s. At the same time, the pressure of the second liquefaction chamber is pumped to a vacuum state, and then the lower cover is opened for the first pressure relief. After the first pressure relief is completed, the second steam inlet is used. Introduce saturated water vapor with a pressure of 1.5MPa into the second liquefaction chamber for the second liquefaction, the second l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com