Preparation method of graphene sulfide

A technology of sulfided graphene and graphene, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of harsh equipment requirements, unfavorable large-scale production, long reaction time, etc., and achieve excellent anti-wear reduction. The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

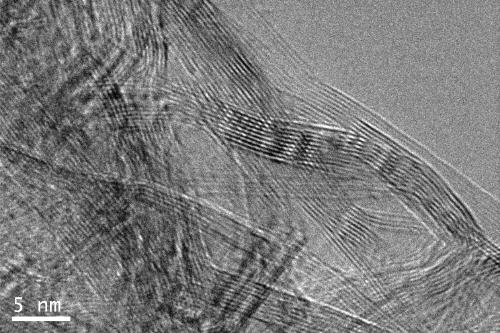

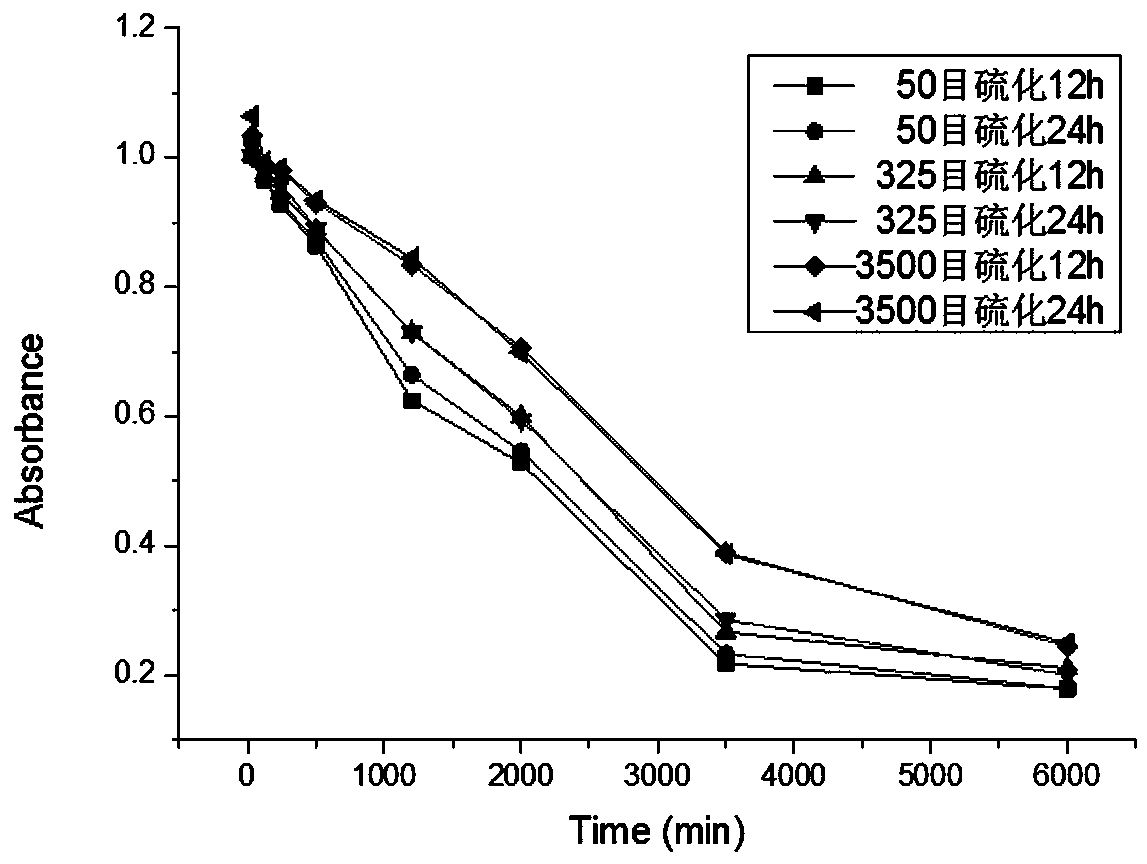

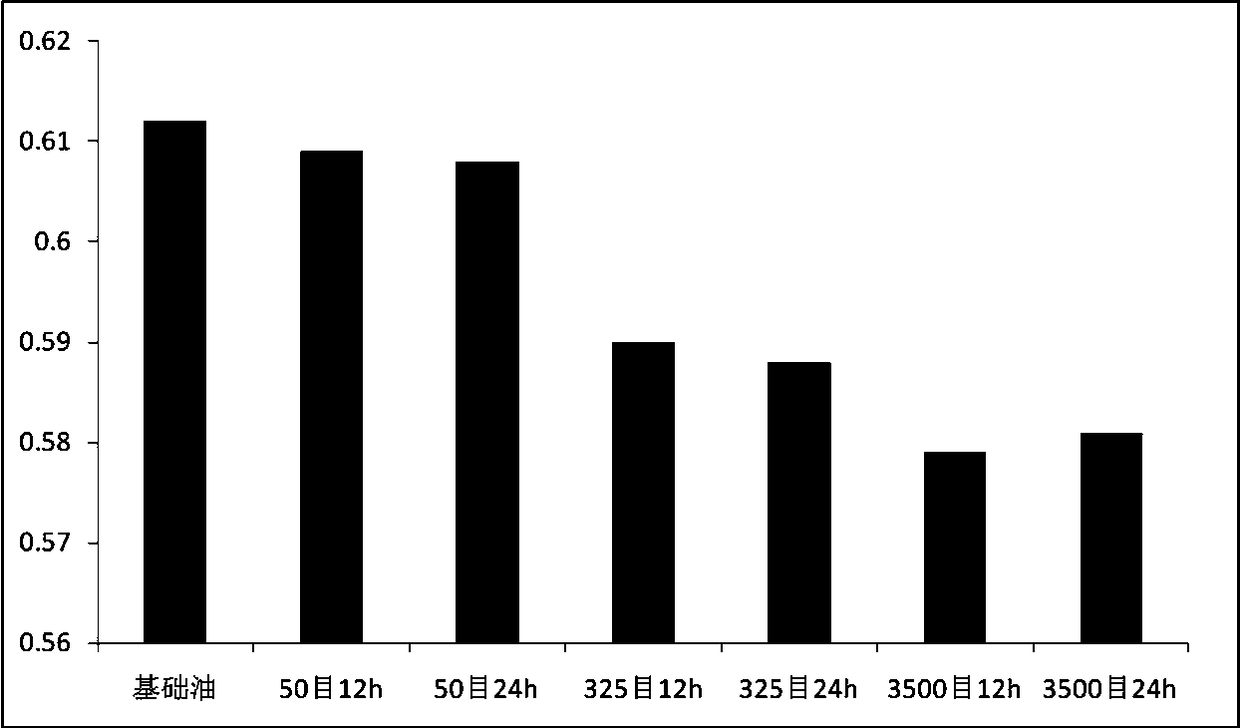

Image

Examples

Embodiment 1

[0025] 1. Oxidation of graphene

[0026] (1) Take 1 g of 50-mesh graphene powder in a flask, add 46 ml of concentrated sulfuric acid (98%H 2 SO 4 ) and 0.5 g sodium nitrate (NaNO 3 ), at 35 o Stir for 2min under heating condition in C water bath;

[0027] (2) Stir the mixture in an ice bath for 15 min to lower the temperature to 0 o C;

[0028] (3) Add 3 g potassium permanganate (KMnO 4 ), the temperature is controlled at 20 o React in C for 5 minutes, after the reaction is stable, at 35 o C water bath heating condition was stirred for 24 h, and the graphene oxide product was obtained after centrifugation and filtration.

[0029] 2. Vulcanization of graphene oxide

[0030] (1) Take 100 mg of graphene oxide and graphene in 100 ml DMF, and ultrasonically treat it for 1 h to make it uniformly dispersed;

[0031] (2) Centrifuge at 1000 rpm for 10 min to remove precipitated impurities;

[0032] (3) Put it in the flask again, add 300 mg of P with a mass fraction of 99% 4...

Embodiment 2

[0037] 1. Oxidation of graphene

[0038] (1) Take 1 g of 50-mesh graphene powder in a flask, add 46 ml of concentrated sulfuric acid (98%H 2 SO 4 ) and 0.5 g sodium nitrate (NaNO 3 ), at 35 o Stir for 2min under heating condition in C water bath;

[0039] (2) Stir the mixture in an ice bath for 15 min to lower the temperature to 0 o C;

[0040] (3) Add 3 g potassium permanganate (KMnO 4 ), the temperature is controlled at 20 o React in C for 5 minutes, after the reaction is stable, at 35 o C water bath heating condition was stirred for 24 h, and the graphene oxide product was obtained after centrifugation and filtration.

[0041] 2. Vulcanization of graphene oxide

[0042] (1) Take 100 mg of graphene oxide and graphene in 100 ml DMF, and ultrasonically treat it for 1 h to make it uniformly dispersed;

[0043] (2) Centrifuge at 1000 rpm for 10 min to remove precipitated impurities;

[0044] (3) Put it in the flask again, add 300 mg of P with a mass fraction of 99% 4...

Embodiment 3

[0048] 1. Oxidation of graphene

[0049] (1) Take 1 g of 325-mesh graphene powder in a flask, add 46 ml of concentrated sulfuric acid (98%H 2 SO4 ) and 0.5 g sodium nitrate (NaNO 3 ), at 35 o Stir for 2min under heating condition in C water bath;

[0050] (2) Stir the mixture in an ice bath for 15 min to lower the temperature to 0 o C;

[0051] (3) Add 3 g potassium permanganate (KMnO 4 ), the temperature is controlled at 20 o React in C for 5 minutes, after the reaction is stable, at 35 o C water bath heating condition was stirred for 24 h, and the graphene oxide product was obtained after centrifugation and filtration.

[0052] 2. Vulcanization of graphene oxide

[0053] (1) Take 100 mg of graphene oxide and graphene in 100 ml DMF, and ultrasonically treat it for 1 h to make it uniformly dispersed;

[0054] (2) Centrifuge at 1000 rpm for 10 min to remove precipitated impurities;

[0055] (3) Put it in the flask again, add 300 mg of P with a mass fraction of 99% 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com