Method for making low-temperature adhesive plate vacuum glass and apparatus thereof

A technology of vacuum glass and production method, applied in the field of flat vacuum glass, can solve the problems of difficult deep processing of products, insufficient heating of glass, and no guarantee of vacuum degree, and achieves flexible and diverse specifications, low production cost, and small equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

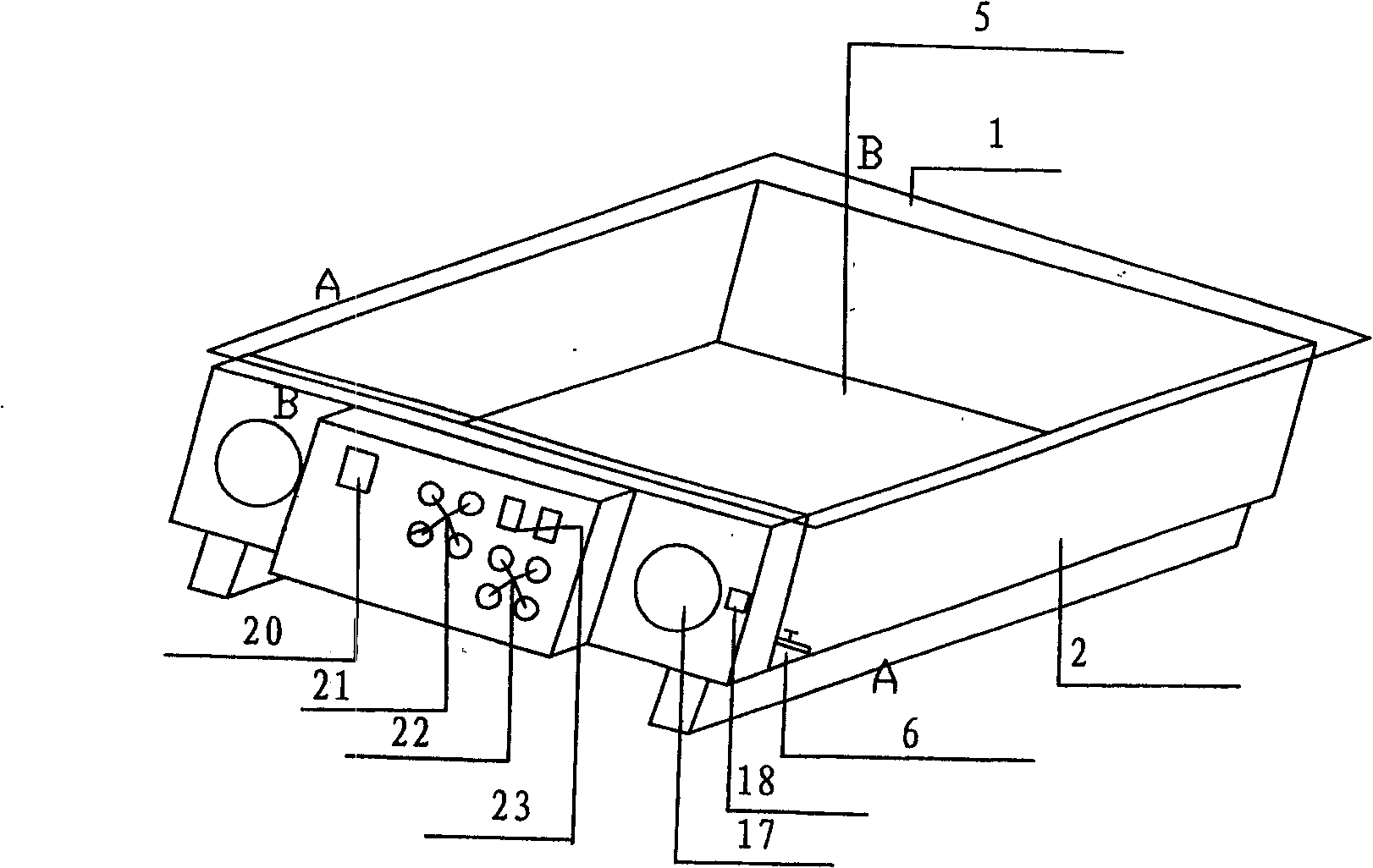

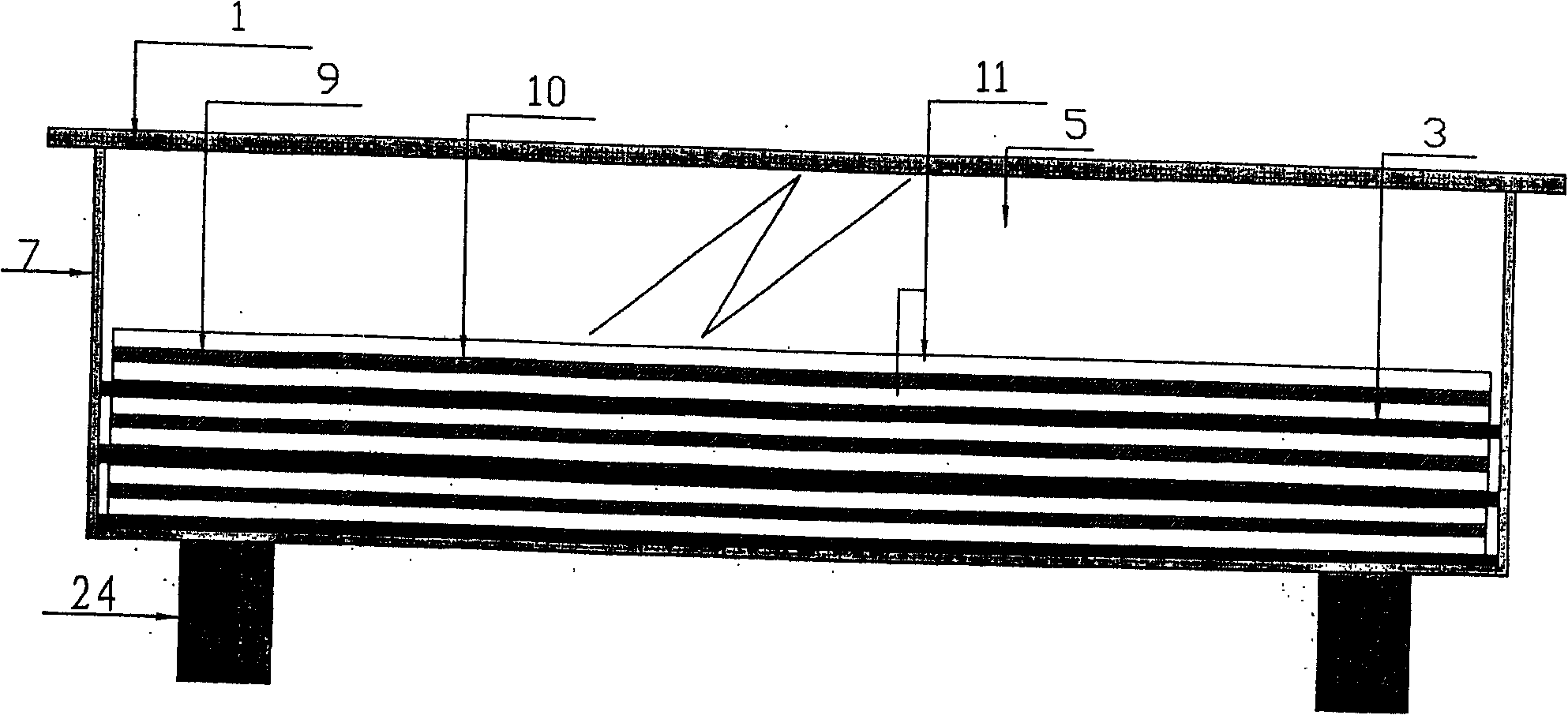

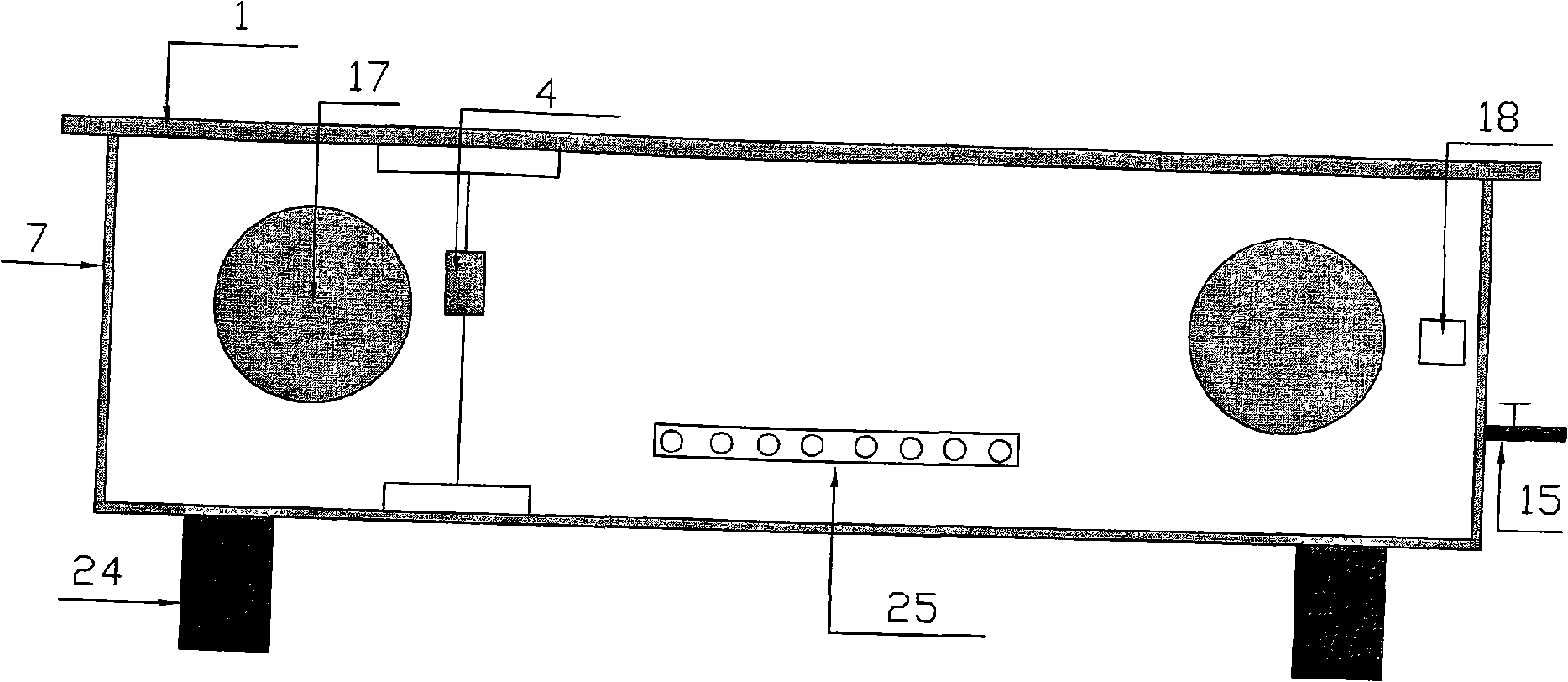

[0027] like figure 1 , 2 , Shown in 3 and 4, a kind of equipment of flat vacuum glass, comprises the vacuum box body 2 that is made up of box body bottom plate, box body wall 7, sealing cover 1, and vacuum box body 2 inside is vacuum chamber 5, and vacuum box body 2 The upper cover or one side is used as a sealing cover to open the sealing cover 1. In the vacuum chamber 5, a heating device 3 and a glue injection machine 4 that can be operated by remote control to move up and down, back and forth, and left and right are arranged. In the vacuum box 2 A vacuuming pipeline 6 and a vacuum valve 15 connected to an external vacuum pump are arranged on the top. The sealing cover 1 is a flexible sealing cover, specifically a silica gel plate or a rubber plate.

[0028] The bottom plate of the box body and the box body wall 7 are all made of metal, and a sight glass 17 that can observe the internal sealing position is installed on one side of the box body wall 7, and a device for supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com