Lengthened type wrench joining structure

An elongated and rectangular technology, applied in the field of lengthened wrench combination structure, can solve the problems of high raw material cost, burden of production cost, shrinking into the handle body, etc., to achieve beautiful product appearance, stimulate purchase desire, and stable combination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

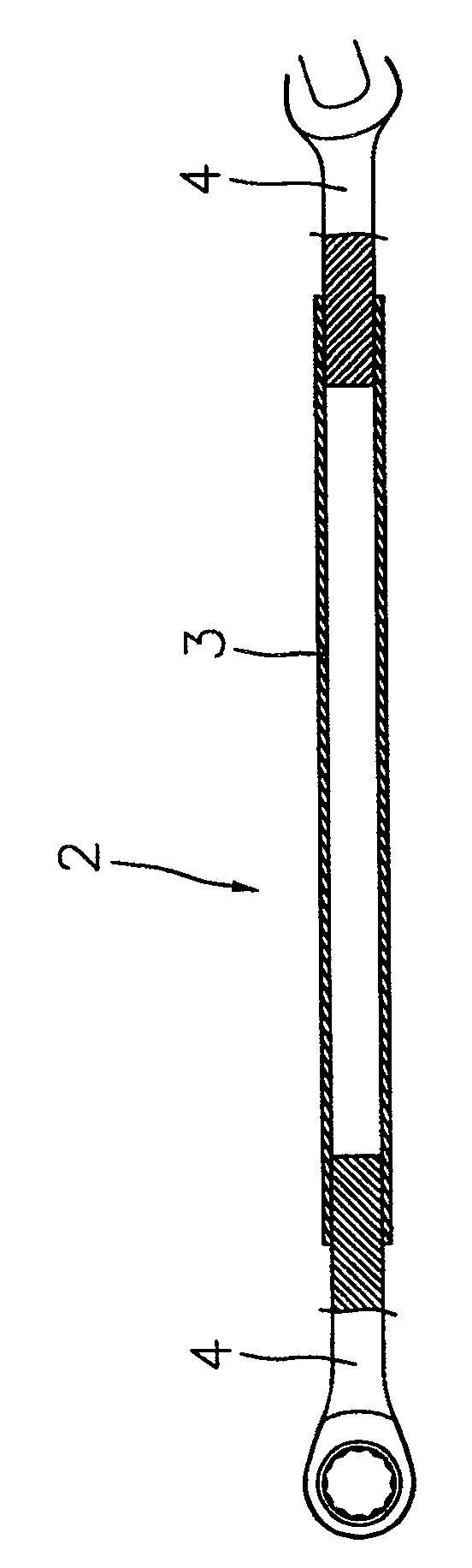

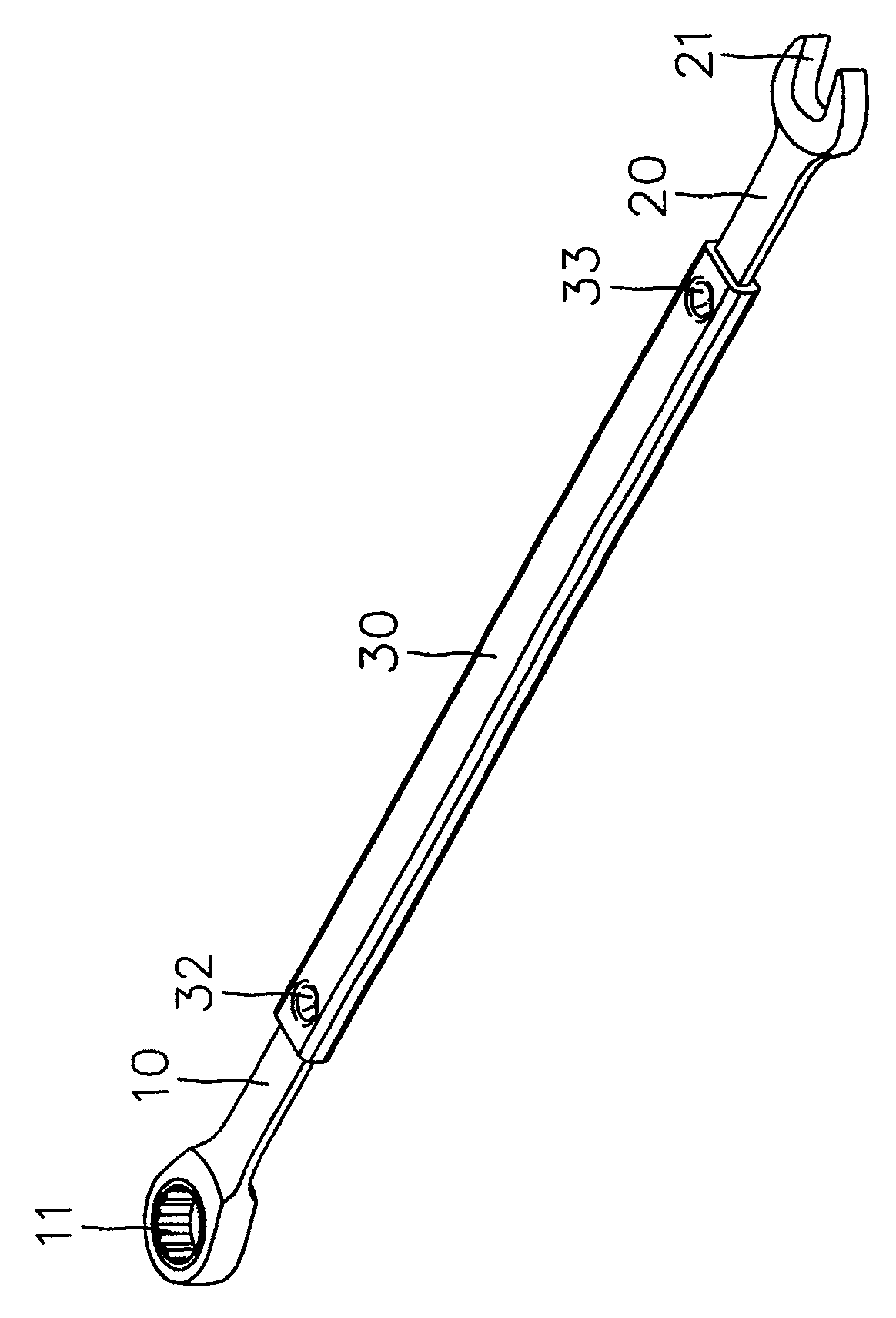

[0017] Refer to image 3 , The present invention includes a first pulling member 10, a second pulling member 20 and an extension member 30; among them:

[0018] Please refer to Figure 4 versus Figure 5 The first pulling member 10 has a first end and a second end. The first end is provided with a pulling portion 11, and the pulling portion 11 is used to turn a screw or a nut. The second end of the first puller 10 forms a connecting portion 12, and the first puller 10 defines a consolidation groove 13 penetrating the upper and lower sides of the connecting portion 12.

[0019] The second flipping member 20 has a first end and a second end. The first end is provided with a flipping portion 21, and the flipping portion 21 is used to turn a screw or a nut. The second end of the second puller 20 forms a connecting portion 22, and the second puller 20 defines a fixing groove 23 penetrating the upper and lower sides of the connecting portion 22.

[0020] The extension member 30 has a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com