Positioning fastener of manual tool

A technology of positioning and hand tools, which is applied in the manufacture of tools, wrenches, screwdrivers, etc., can solve the problems of limited service life, limited effect of structural clamping, difficulty in achieving high positioning effect, etc., and achieve stable and reliable joint structure and safe joint sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the structure, characteristics and other purposes of the present invention, the following preferred embodiments are attached with drawings for detailed description as follows, but the embodiments described in this illustration are for illustration purposes, not for patent applications The only limitation on .

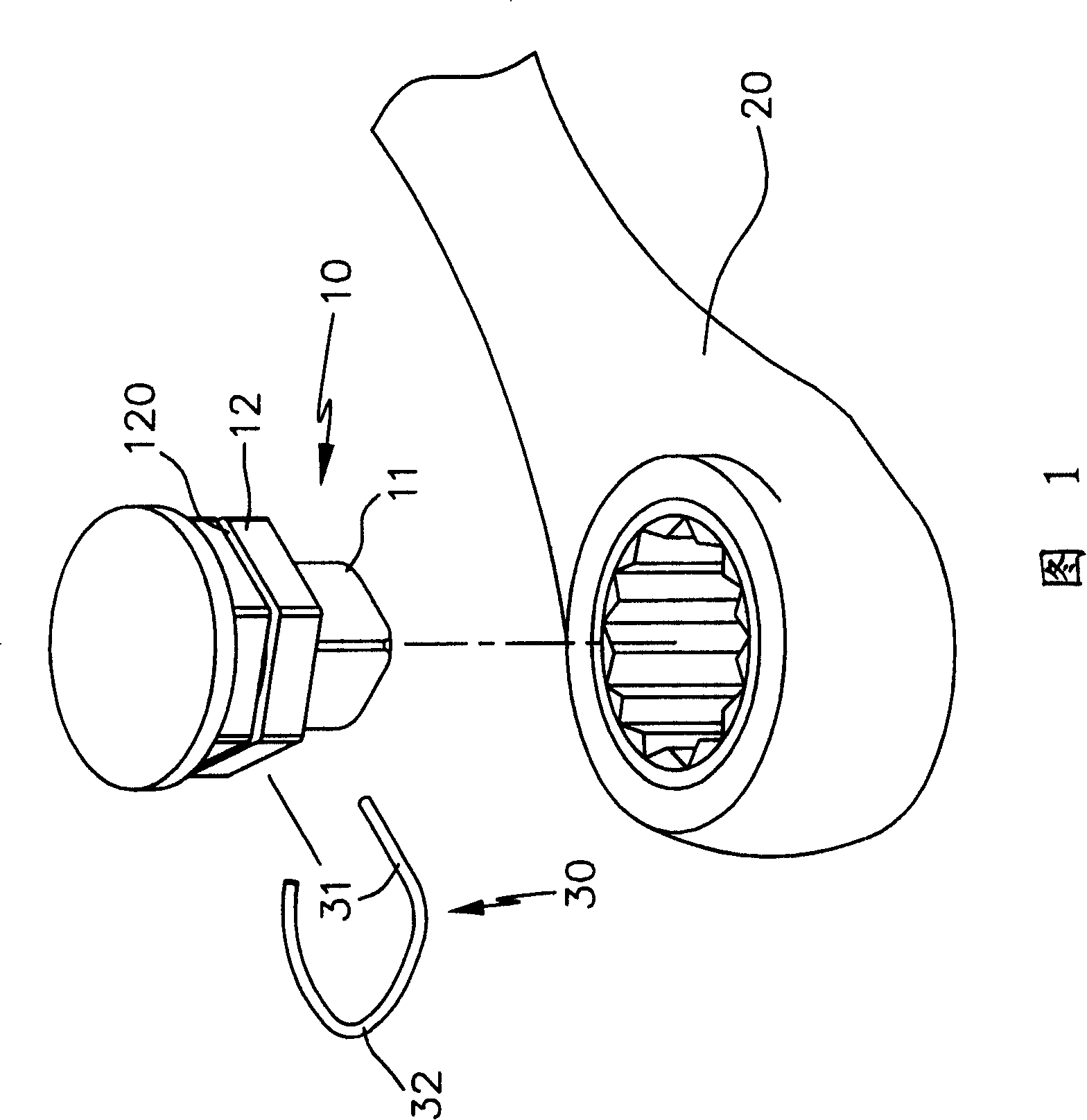

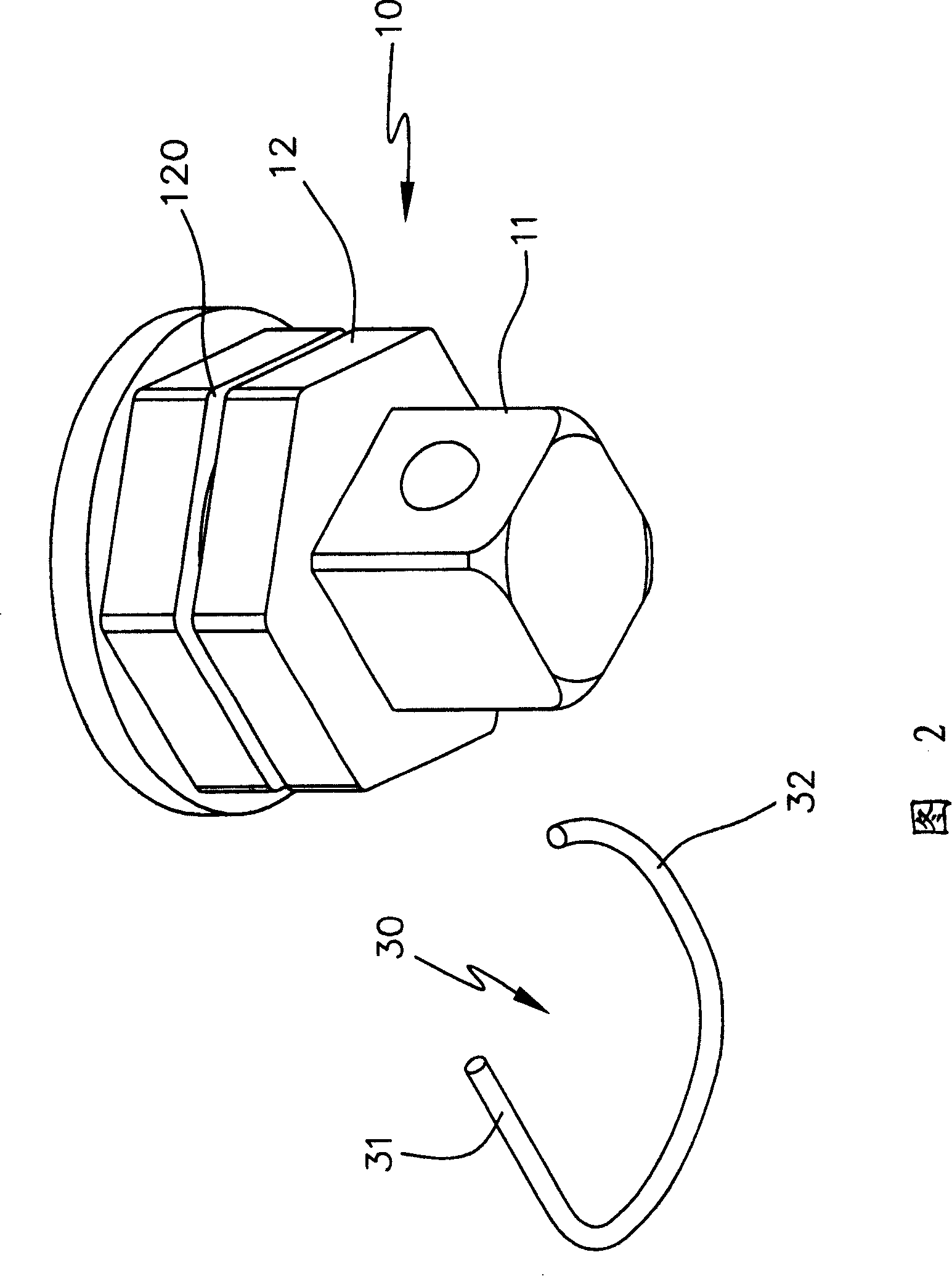

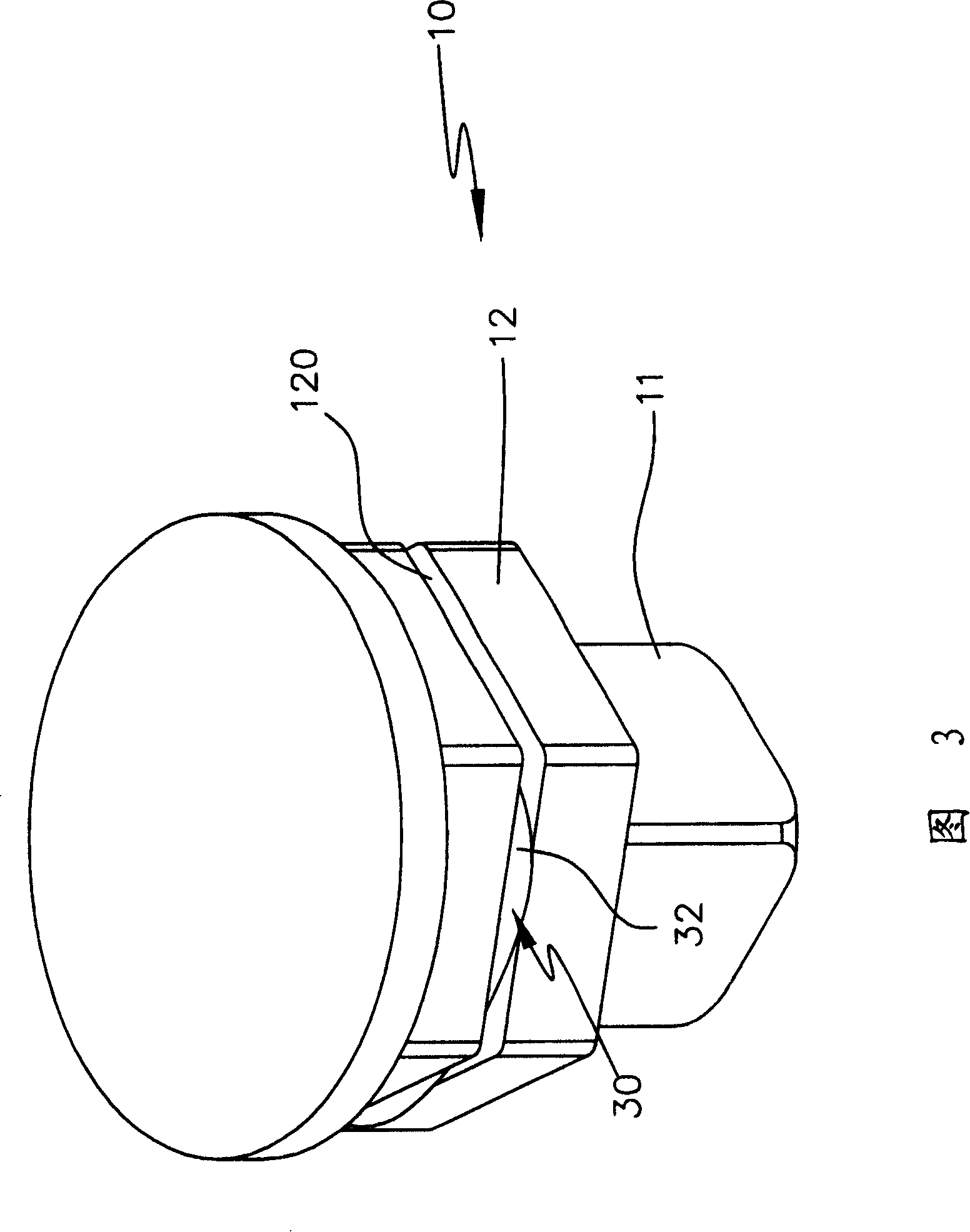

[0024] Please refer to Figs. 1-4, the joint 10 of the present invention can be socketed with various tools 20, and its joint 10 has a driving end 11, and its driving end 11 is adjacent to a set of sleeves seated on the tool 20. Fitting portion 12, and the outer diameter of fitting portion 12 is recessed with a positioning groove 120, for an elastic semi-circular fastening member 30 to be snapped in and positioned, and partly protrudes from positioning groove 120 to match with the opposite tool 20 The end surface is elastically snapped and positioned.

[0025] Among them, the joint 10 mainly has a driving end 11 for driving other wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com