rice cooker

A technology for electric rice cookers and liners, which is applied in pressure cookers, special materials for cooking utensils, cooking utensils, etc., and can solve problems such as difficult surface treatment, easy corrosion, and peeling off of corrosion-resistant surface treatment layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

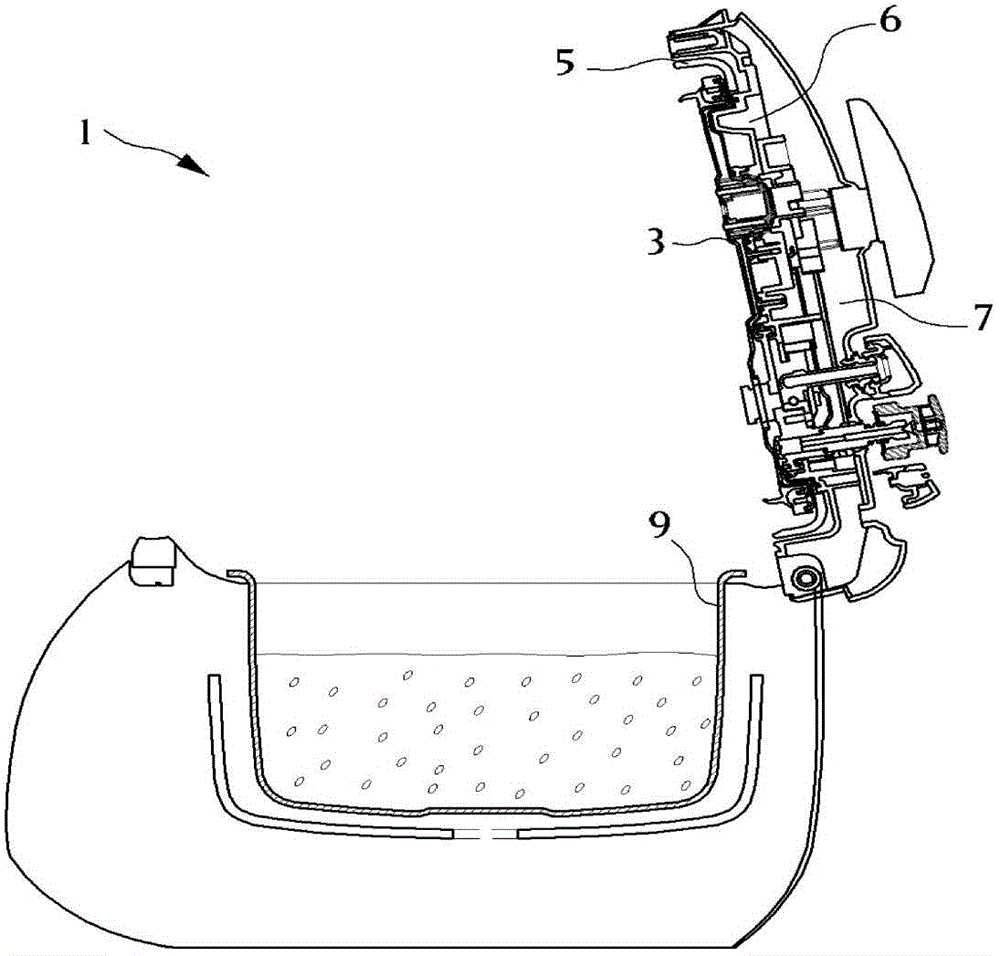

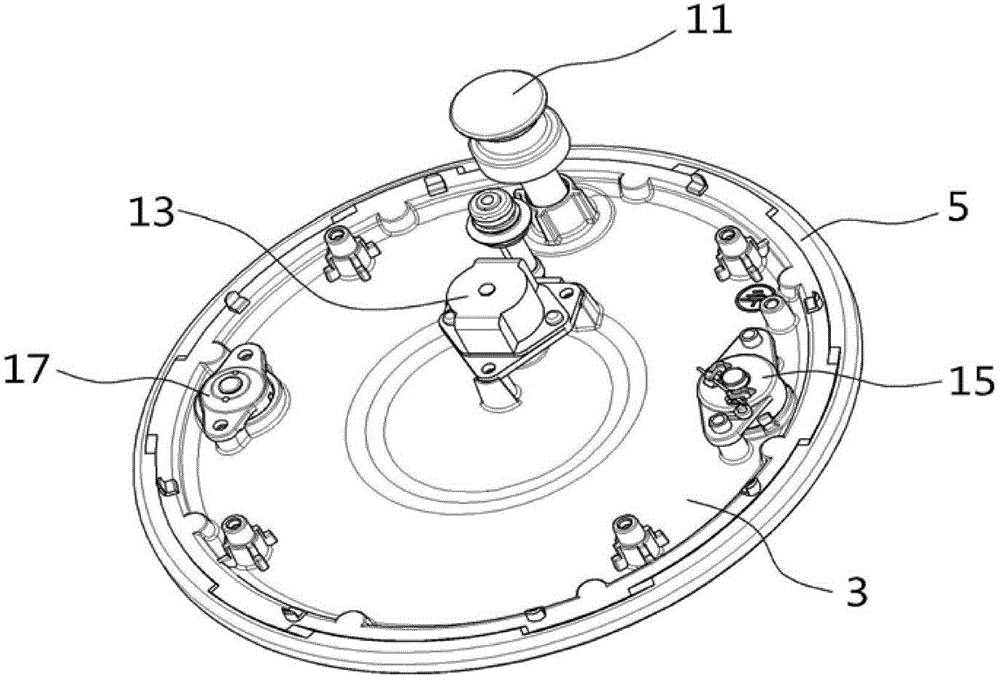

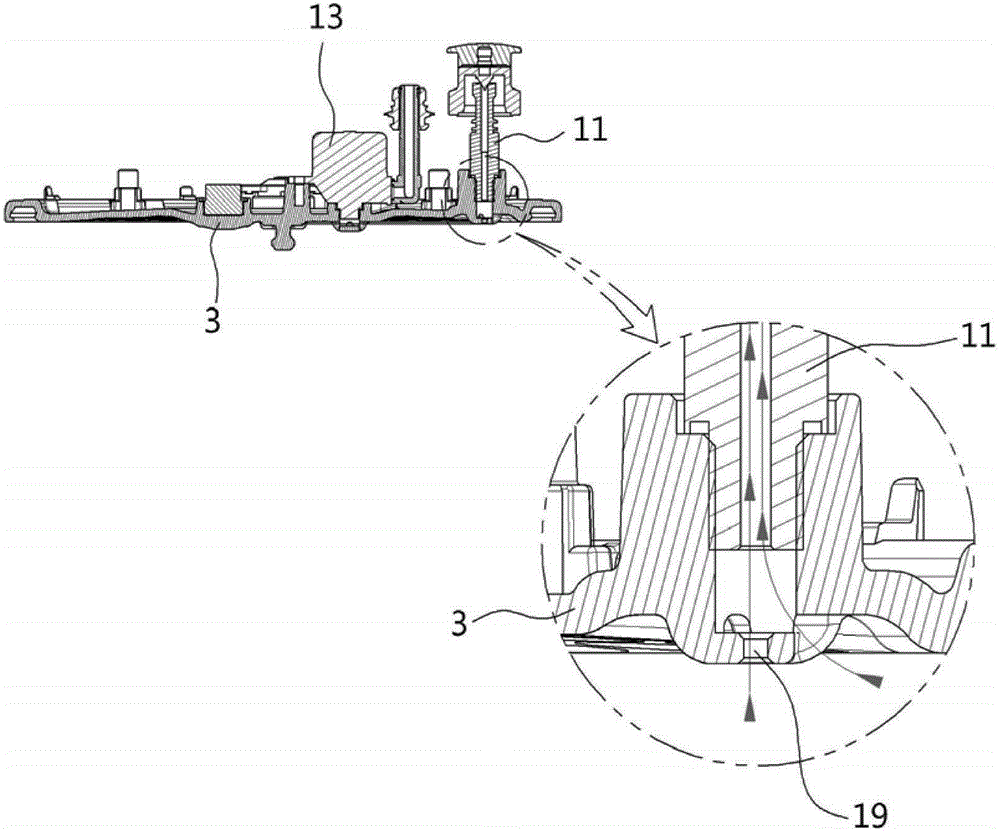

[0029] Hereinafter, an electric rice cooker and a manufacturing method thereof according to preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0030] Figure 4a It is a perspective view showing a top heating stainless steel plate combined with a control bracket of an electric rice cooker according to an embodiment of the present invention, Figure 4b It is a perspective view showing a top heating stainless steel plate combined with a control bracket and a locking ring of an electric rice cooker according to an embodiment of the present invention.

[0031] Such as Figure 4a and Figure 4b As shown, the rice cooker of the present invention is composed of a top heating stainless steel plate 100 , a pressure response working unit and a control bracket 110 .

[0032] Here, the top heating stainless steel plate 100 is preferably made of stainless steel, is combined with the lower surface of the lid, and is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com