Product laminating, corner positioning and cutting mechanism

A technology of cutting mechanism and corner positioning, which is applied in packaging and other directions, can solve the problems of unsightly packaging, blocking sealing and tangent lines, etc., and achieve the effect of beautiful product appearance and high lamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

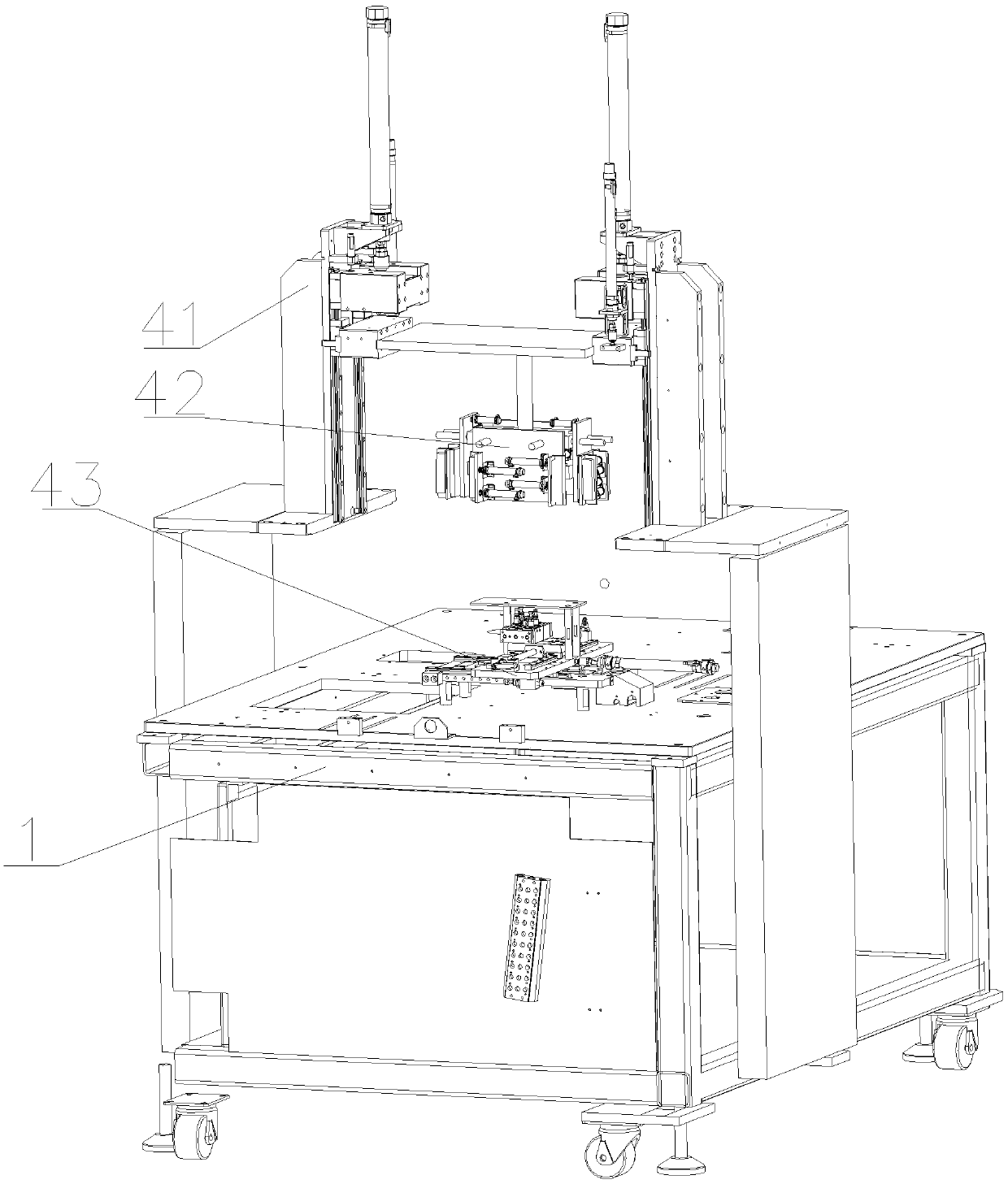

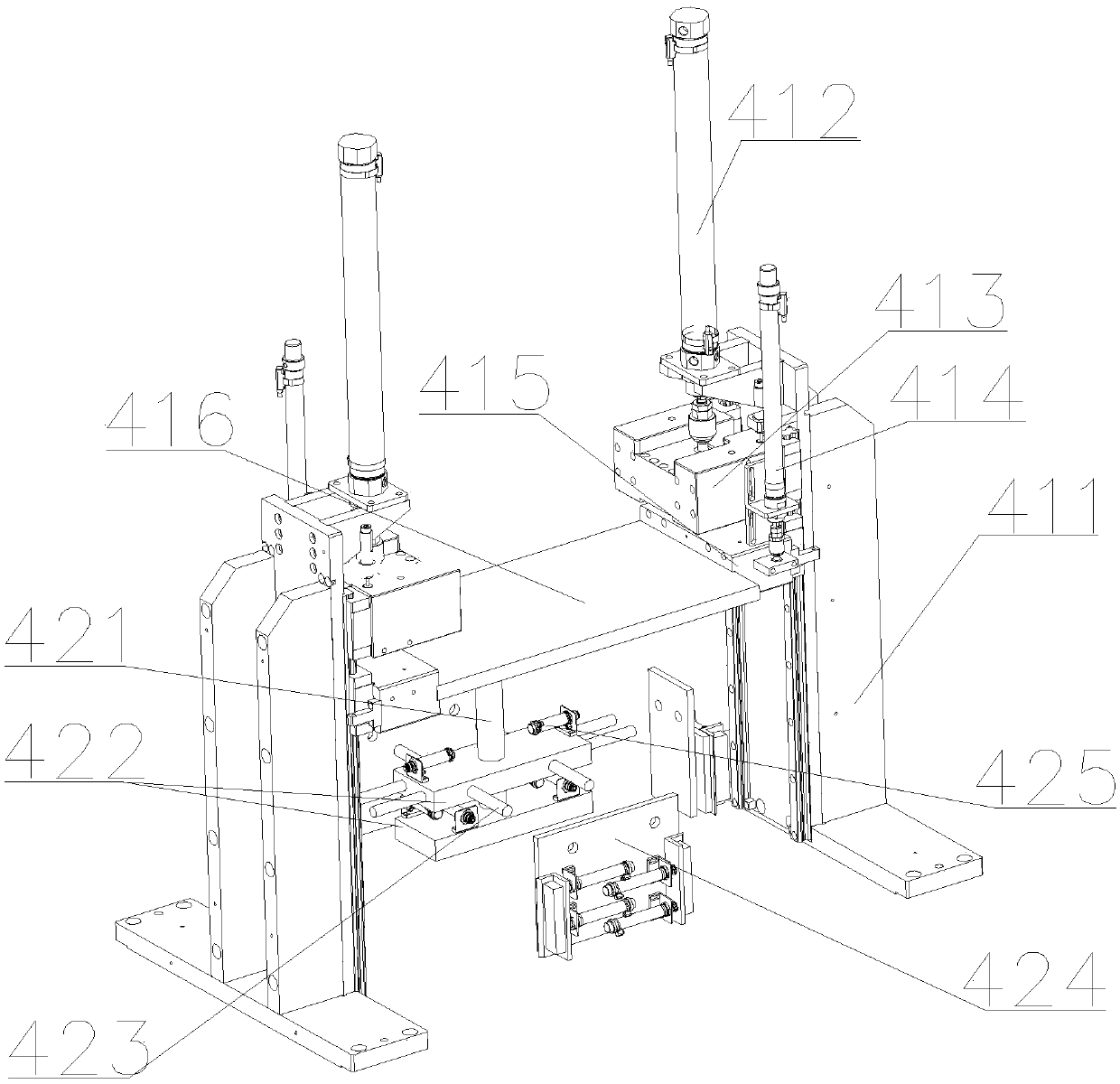

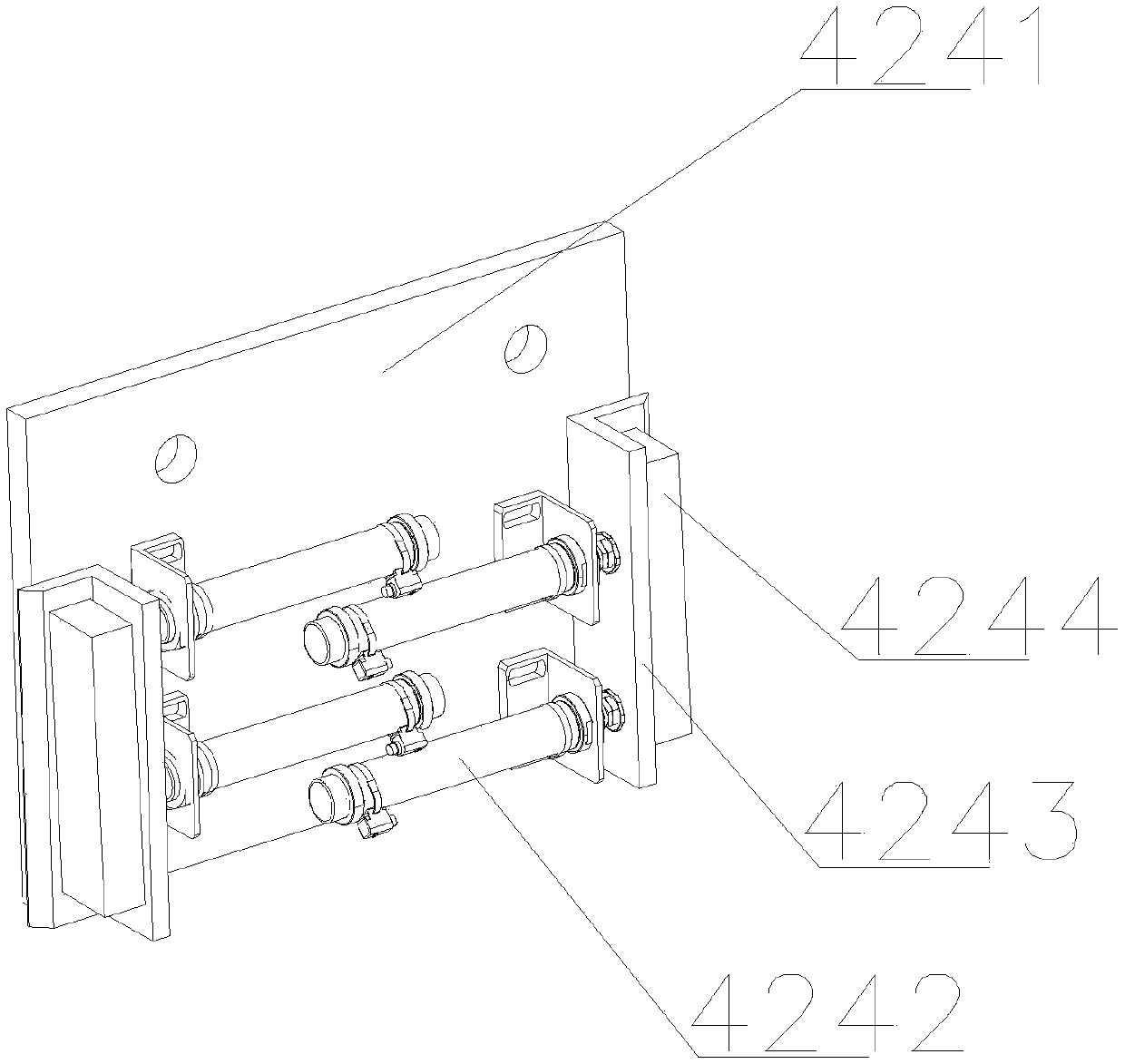

[0016] refer to figure 1 A corner positioning and shearing mechanism for product coating in the present invention includes a corner positioning and shearing lifting mechanism 41, a corner positioning and shearing actuator 42, and a corner positioning and shearing seat 43. The corner positioning and shearing actuator 42 is arranged on the corner positioning and shearing lifting mechanism 41 , and the corner positioning and shearing seat 43 is arranged on the workbench 1 below the corner positioning and shearing actuator 42 . The corner positioning shear lifting mechanism 41 comprises a corner positioning shear lifting seat 411, a first corner positioning shear lifting cylinder 412, a first corner positioning shear lifting seat 413, a second corner positioning shear lift Cylinder 414, the second corner positioning shear lifting seat 415 and corner positioning shear lifting platform 416, the first corner positioning shear lifting cylinder 412 is arranged on the top of the corner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com