Steel structural system circular tube compression bar and machining device and method thereof

A processing device and steel structure technology, applied in the field of construction steel structure, can solve problems such as low production efficiency and complicated manufacturing process, and achieve the effects of high production efficiency, high product quality and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

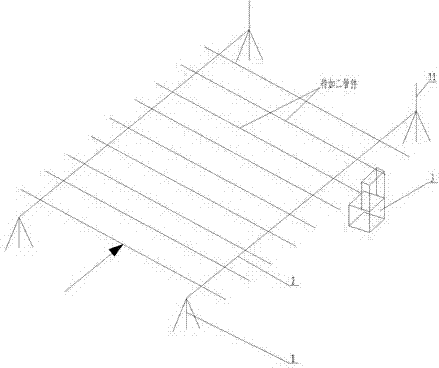

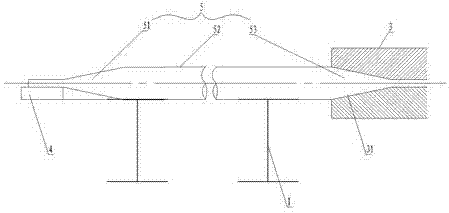

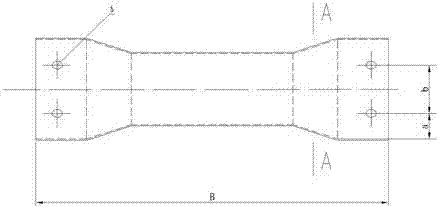

[0027] The processing device of the steel structure system circular pipe compression rod in this embodiment, combined with figure 1 , including a bracket 1, a motor, a feeding table 2 and a flattening mold 3, the feeding table 2 is located on the bracket 1, and the feeding table 2 is driven by a motor, which drives the round tube pressure bar to move left and right on the bracket 1, and the flattening mold 3 Located on one side of the support 1 , one end of the flattening die 3 facing the feeding platform 2 is provided with a tapered feeding opening 31 . Wherein, a leveling plate 4 is provided on the end of the feeding table 2 far away from the flattening mold 3, and the height of the leveling plate 4 is the same as the minimum height of the feeding port 31, and is used for leveling the rod to be processed.

[0028] The device is used to process the steel structure system round pipe pressure rod, the pipe to be processed is placed on the feeding table 2, the motor is started, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com