Production method for non-annealed medium carbon cold heading steel hot-rolled wire rod

A production method and carbon cold heading technology are applied in the production field of annealing-free medium carbon cold heading steel hot-rolled wire rods, which can solve the problems of increasing investment in super-heavy-duty finishing rolling units, and achieve the enhancement of competitive advantages, reduction of drawing amount, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

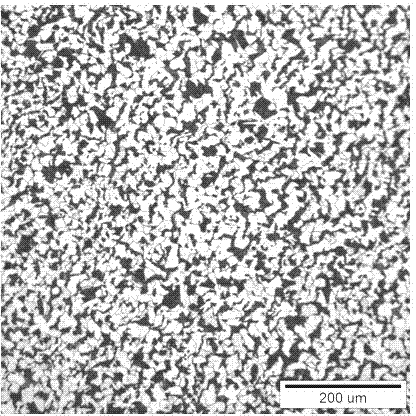

Image

Examples

Embodiment 1

[0025] Embodiment 1: The production method of the annealing-free medium-carbon cold-heading steel hot-rolled wire rod is as follows.

[0026] (1) Molten steel is smelted and continuously cast into slabs. The components are as follows by weight percentage: C 0.19%, Si 0.06%, Mn 0.63%, Cr 0.95%, P 0.013%, S 0.005%, the rest is iron and inevitable impurities .

[0027] (2) The billet is opened after being slowly cooled for 72 hours, and the hot rolled billet after the billet is slowly cooled for 72 hours.

[0028] (3) Heat the slow-cooled hot-rolled billet to 1160℃ for 120min; then dephosphorize with high-pressure water. The dephosphorization temperature is 1140℃, and the phosphorus removal water pressure is required to be at least 10MPa.

[0029] (4) The hot rolled billet after dephosphorization is subjected to 6+8 passes of rough and intermediate rolling, 4 passes of pre-finishing rolling, and 8 passes of finishing rolling; the finishing rolling temperature is 970℃, and the coiling tem...

Embodiment 2

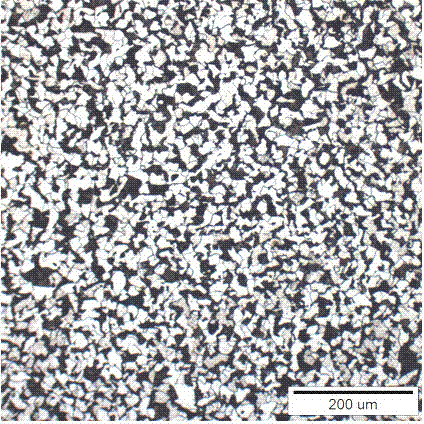

[0032] Embodiment 2: The production method of the annealing-free medium-carbon cold-heading steel hot-rolled wire rod is as follows.

[0033] (1) Molten steel is smelted and continuously cast into steel billets. Its components are as follows by weight percentage: C 0.20%, Si 0.09%, Mn 0.64%, Cr 0.93%, P 0.016%, S 0.005%, the rest is iron and inevitable impurities .

[0034] (2) The billet is opened after being slowly cooled for 75 hours, and the hot-rolled billet after the billet is slowly cooled for 73 hours.

[0035] (3) The hot-rolled billet is heated to 1175℃ for 110min; then high-pressure water is used for dephosphorization. The dephosphorization temperature is 1150℃, and the dephosphorization water pressure is at least 10MPa.

[0036] (4) The hot-rolled billet after dephosphorization is subjected to 6+8 passes of rough and intermediate rolling, 4 passes of pre-finishing rolling, 8 passes of finishing rolling, and the finishing rolling temperature is 980℃. After finishing rolling...

Embodiment 3

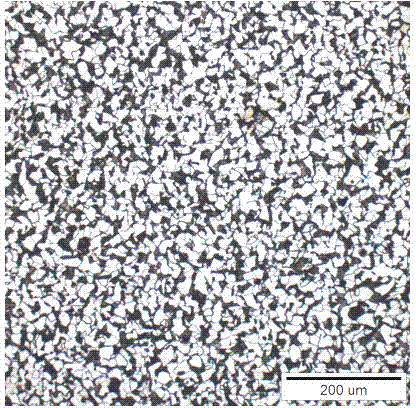

[0039] Embodiment 3: The production method of the annealing-free medium-carbon cold-heading steel hot-rolled wire rod is as follows.

[0040] (1) Molten steel is smelted and continuously cast into slabs. Its components are as follows by weight percentage: C 0.18%, Si 0.04%, Mn 0.66%, Cr 0.95%, P 0.012%, S 0.007%, the rest is iron and inevitable impurities .

[0041] (2) The billet is opened after slow cooling for 72 hours, and the hot rolled billet after the billet is slowly cooled for 70 hours.

[0042] (3) Heat the hot-rolled billet to 1155°C for a holding time of 135min; then dephosphorize with high-pressure water. The dephosphorization temperature is 1130°C, and the phosphorus removal water pressure is required to be at least 10MPa.

[0043] (4) The hot-rolled billet after dephosphorization is subjected to 6+8 passes of rough and intermediate rolling, 4 passes of pre-finishing rolling, 8 passes of finishing rolling, and the finishing rolling temperature is 990℃. After finishing ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com