Silver clay and method for producing silver products using the silver clay

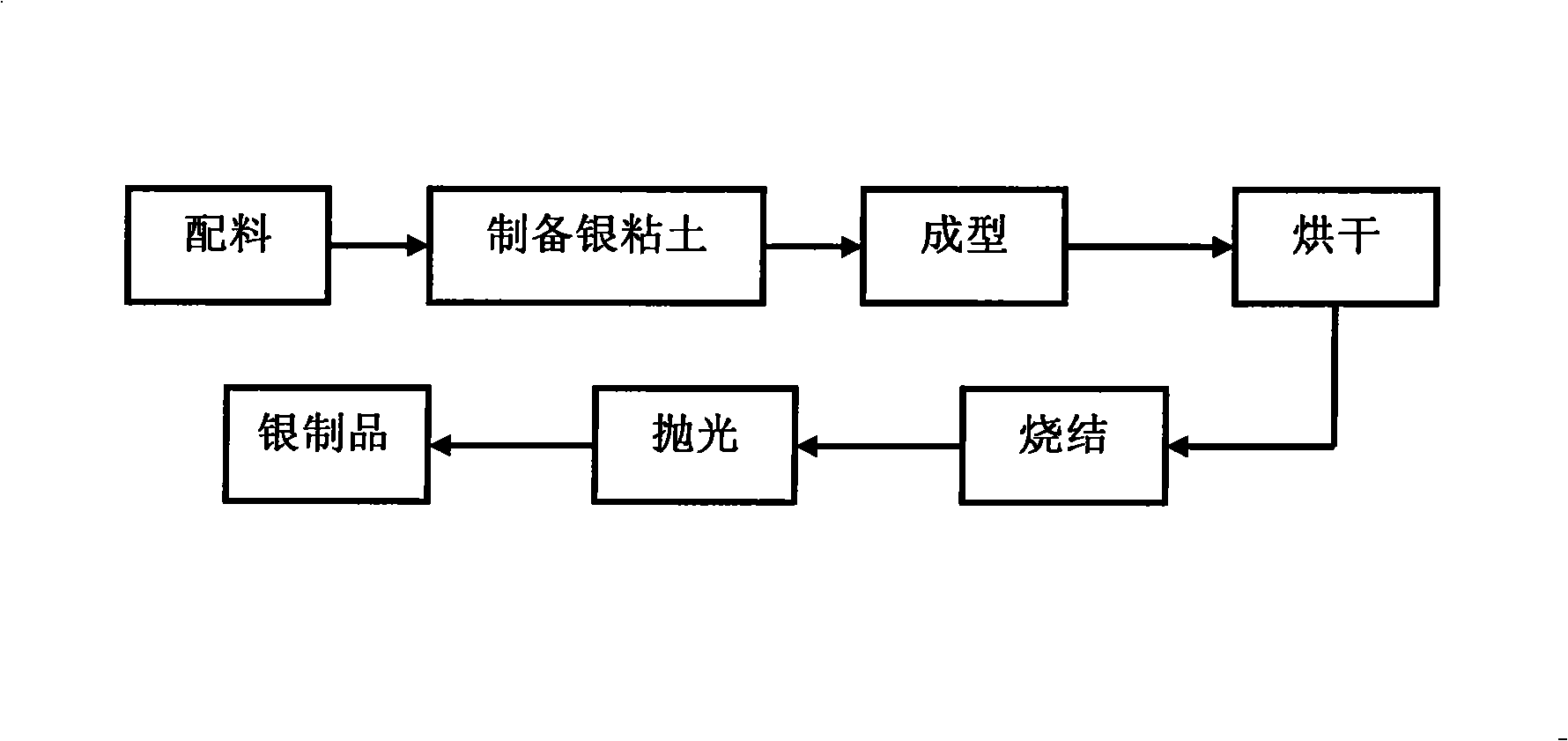

A production method and technology for silver products, which are applied in the field of preparation of silver clay for low-temperature sintering and its products, can solve problems such as the inability to be widely used in a wide range, and achieve the effect of simple and easy steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare silver powder in the following proportions: 30% by mass of silver micropowder with an average particle diameter of 0.286 μm, and 70 mass percent of silver micropowder with an average particle diameter of 1.21 μm;

[0036] Silver powder, bismuth powder and methyl cellulose as a binder are planetary ball milled at a speed of 1000r / min for 10 minutes in a ball mill jar, then olive oil and water are added as fats and oils, and silver clay is obtained after mixing evenly. The content of each component in the silver clay is: 80% by mass of silver powder, 1% by mass of bismuth powder, 7% by mass of binder, 1% by mass of oil, and the rest is water;

[0037] The silver clay is molded under 10MPa using a hydraulic press;

[0038] Bake the molded silver clay at 95°C for 12 hours to obtain a blank;

[0039] Put the blank into the resistance sintering furnace, and use the intelligent temperature regulator to control the heating program of the resistance furnace, so that the...

Embodiment 2

[0042] Silver powder is prepared in the following proportions: 40% by mass of silver micropowder with an average particle diameter of 0.5 μm, and 60 mass percent of silver micropowder with an average particle diameter of 2.5 μm;

[0043] Silver powder, bismuth powder and methyl cellulose as a binder are planetary ball milled in a ball mill jar at a speed of 1000r / min for 30 minutes, then olive oil and water are added as fats and oils, and silver clay is obtained after mixing evenly. The content of each component in the silver clay is: 70% by mass of silver powder, 0.8% by mass of bismuth powder, 5% by mass of binder, 2% by mass of oil, and the rest is water;

[0044] The silver clay is molded under 10MPa using a hydraulic press;

[0045] Bake the molded silver clay at 80°C for 12 hours to obtain a blank;

[0046] Put the blank into the resistance sintering furnace, and use the intelligent temperature regulator to control the heating program of the resistance furnace, so that ...

Embodiment 3

[0049] Prepare silver powder in the following proportions: 35% by mass of silver micropowder with an average particle diameter of 0.137 μm, and 65 mass percent of silver micropowder with an average particle diameter of 1 μm;

[0050] Silver powder, bismuth powder and methyl cellulose as a binder are planetary ball milled at a speed of 1000r / min for 60 minutes in a ball mill jar, then olive oil and water are added as fats and oils, and silver clay is obtained after mixing evenly. The content of each component in the silver clay is: 75% by mass of silver powder, 0.3% by mass of bismuth powder, 8% by mass of binder, 1.5% by mass of oil, and the rest is water;

[0051] The silver clay is molded under 10MPa using a hydraulic press;

[0052] Bake the molded silver clay at 100°C for 12 hours to obtain a blank;

[0053] Put the blank into the resistance sintering furnace, and use the intelligent temperature regulator to control the heating program of the resistance furnace, so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com