High-nickel ternary single crystal material and preparation method thereof

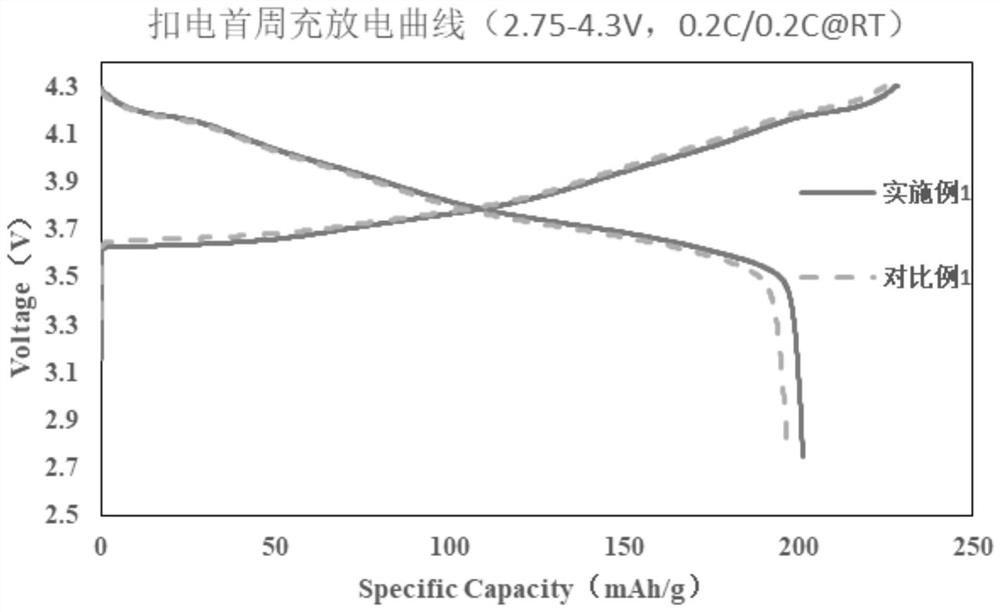

A single crystal material, high nickel technology, used in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of poor material performance, high surface fine powder, poor single crystal morphology, etc., and achieve less lithium distribution. , the effect of full sintering and full shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

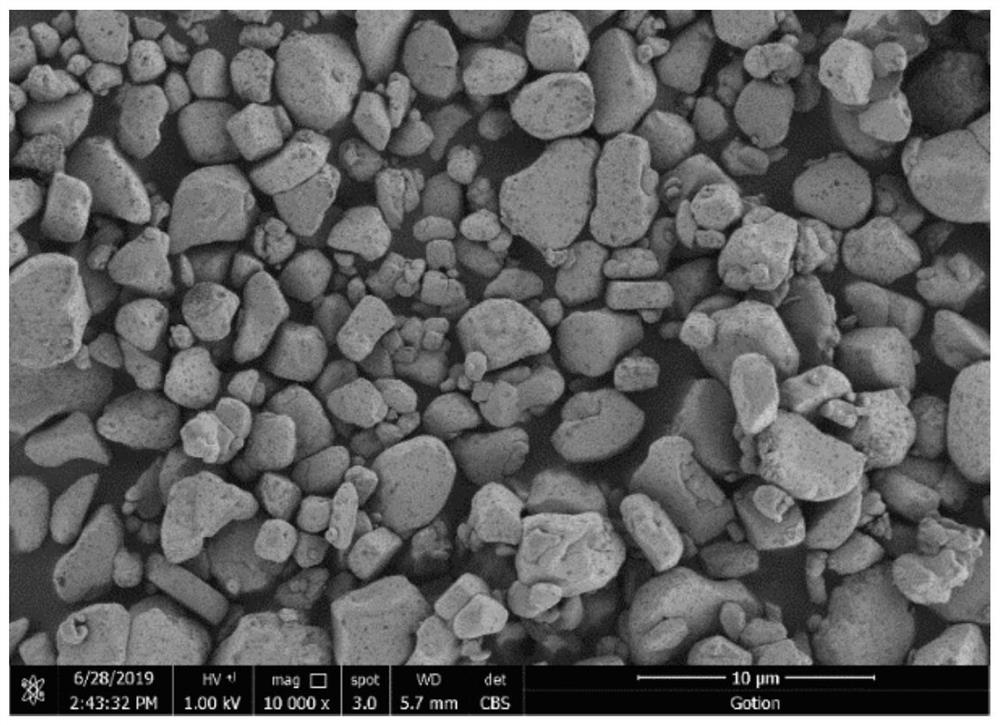

Embodiment 1

[0033] A method for preparing a high-nickel ternary single crystal material, comprising the steps of:

[0034](1) Preparation of nickel-cobalt-manganese salt solution, precipitant solution and complexing agent solution: the battery-grade soluble nickel sulfate, cobalt sulfate, and manganese sulfate accurately weighed according to the stoichiometric ratio of 83:12:5 were added to deionized water After passing nitrogen gas to remove oxygen, 50L2mol / L nickel-cobalt-manganese salt solution was obtained, which was labeled as A1 solution after filtration; the battery-grade flake NaOH powder was added to deionized water to form a 10mol / L sodium hydroxide solution, which was labeled as A1 solution after filtration. Precipitant A2 solution; dilute battery-grade ammonia water to make 18g / L ammonia solution, which is labeled as complexing agent A3 solution after filtration;

[0035] (2) A1, A2, A3 solutions are added into the reaction kettle concurrently, and the inert gas nitrogen is pa...

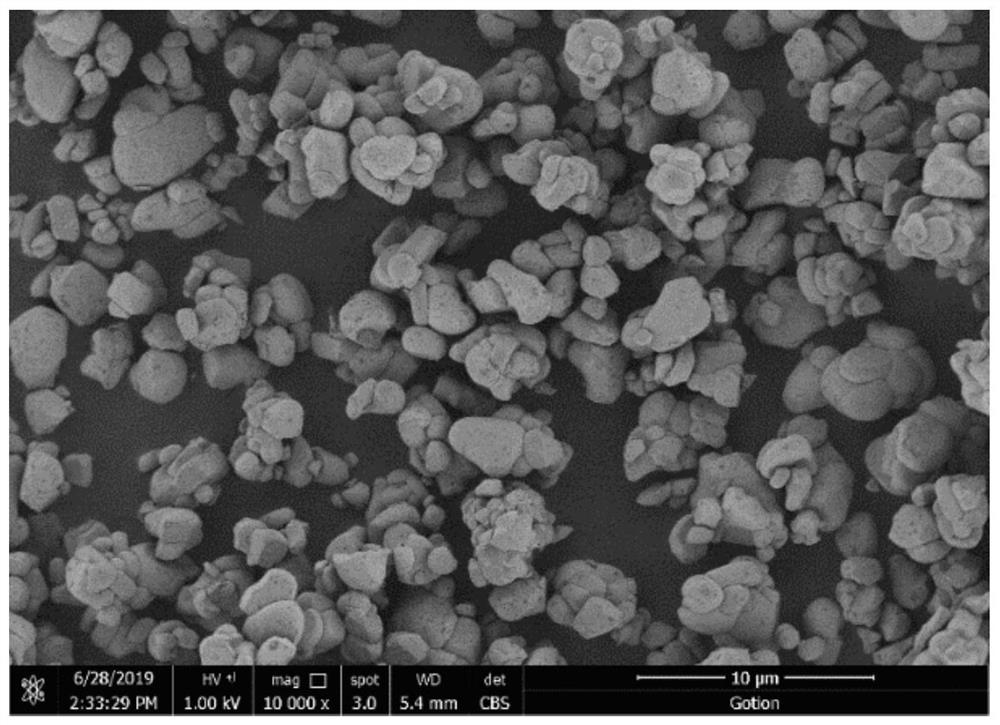

Embodiment 2

[0051] A method for preparing a high-nickel ternary single crystal material, comprising the steps of:

[0052] (1) Preparation of nickel-cobalt-manganese salt solution, precipitant solution and complexing agent solution: the battery-grade soluble nickel sulfate, cobalt sulfate, and manganese sulfate accurately weighed according to the stoichiometric ratio of 80:10:10 were added to deionized water After passing nitrogen gas to remove oxygen, 50L2mol / L nickel-cobalt-manganese salt solution was obtained, which was labeled as A1 solution after filtration; the battery-grade flake NaOH powder was added to deionized water to form a 10mol / L sodium hydroxide solution, which was labeled as A1 solution after filtration. Precipitant A2 solution; dilute battery-grade ammonia water to make 18g / L ammonia solution, which is labeled as complexing agent A3 solution after filtration;

[0053] (2) A1, A2, A3 solutions are added into the reaction kettle concurrently, and the inert gas nitrogen is ...

Embodiment 3

[0064] A method for preparing a high-nickel ternary single crystal material, comprising the steps of:

[0065] (1) Preparation of nickel-cobalt-manganese salt solution, precipitant solution and complexing agent solution: the battery-grade soluble nickel sulfate, cobalt sulfate, and manganese sulfate accurately weighed according to the stoichiometric ratio of 70:10:20 were added to deionized water After passing nitrogen gas to remove oxygen, 50L2mol / L nickel-cobalt-manganese salt solution was obtained, which was labeled as A1 solution after filtration; the battery-grade flake NaOH powder was added to deionized water to form a 10mol / L sodium hydroxide solution, which was labeled as A1 solution after filtration. Precipitant A2 solution; dilute battery-grade ammonia water to make 18g / L ammonia solution, which is labeled as complexing agent A3 solution after filtration;

[0066] (2) A1, A2, A3 solutions are added into the reaction kettle concurrently, and the inert gas nitrogen is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com