Preparation method of rare earth oxide doped alumina-based high-performance metal melt hydrogen determination probe material

A technology of rare earth oxides and substrates, applied in the field of electrochemistry and analysis and detection, can solve problems such as instability and inability to apply hydrogen content measurement, and achieve high strength, good chemical stability and thermal stability, and high proton migration number Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Roughly weigh a certain mass of analytically pure Al 2 o 3 and Yb 2 o 3 , respectively placed in clean zirconia crucibles, covered with a crucible lid, placed in a muffle furnace, set the heating rate at 5°C / min, and baked at 500°C for 8h to dry the medicine.

[0049] Al by molar ratio 2 o 3 : Yb 2 o 3 =1.999:0.001 ratio, take a proper amount of dried powder, mix them into a ball mill tank, add absolute ethanol, and prepare a slurry with a solid content of 20-30wt%, using alumina grinding balls, balls The mass ratio is 2:1, the mass ratio of large balls, medium balls and small balls is 3:4:3, using a planetary ball mill, set the speed at 300r / min, and ball milled for 96h, then transfer the slurry to an evaporating dish, and Put it in an explosion-proof constant temperature oven and dry it at 200°C to get blocky powder. After rough grinding in agate mortar, sieve with 200-mesh standard sieve to get pre-ground powder.

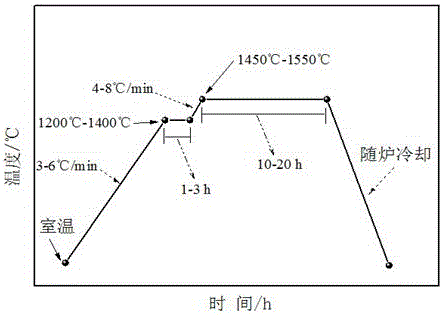

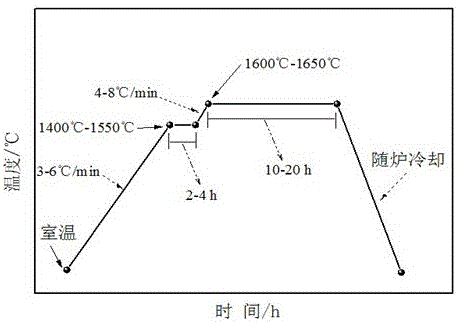

[0050] The above-mentioned pre-grinded powde...

Embodiment 2

[0056] Roughly weigh a certain mass of analytically pure Al 2 o 3 and Pr 2 o 3 , respectively placed in clean zirconia crucibles, covered with a crucible lid, placed in a muffle furnace, set the heating rate at 5°C / min, and baked at 600°C for 7h to dry the medicine.

[0057] Al by molar ratio 2 o 3 : Pr 2 o 3 =1.997:0.003 ratio, respectively take an appropriate amount of the above-mentioned dried powders, mix them into a ball mill tank, add a certain amount of absolute ethanol, and prepare a slurry with a solid content of 20-30 wt %. Aluminum grinding balls, the mass ratio of balls to materials is 2:1, the mass ratio of large balls, medium balls and small balls is 3:4:3, a planetary ball mill is used, the speed is set at 350r / min, ball milling is 72h, and then the slurry is The material was transferred to an evaporating dish, and dried in an explosion-proof constant temperature oven at 200°C to obtain block powder, which was coarsely ground in an agate mortar and sieved...

Embodiment 3

[0064] Roughly weigh a certain mass of analytically pure Al 2 o 3 and Sm 2 o 3 , respectively placed in clean zirconia crucibles, covered with a crucible lid, placed in a muffle furnace, set the heating rate at 5°C / min, and baked at 700°C for 6h to dry the medicine.

[0065] Al by molar ratio 2 o 3 : Sm 2 o 3 =1.99:0.01 ratio, take an appropriate amount of the above-mentioned dried powders, mix them into a ball mill tank, add a certain amount of absolute ethanol, and prepare a slurry with a solid content of 20-30 wt %. Aluminum grinding balls, the mass ratio of balls to materials is 2:1, the mass ratio of large balls, medium balls and small balls is 3:4:3, using a planetary ball mill, set the speed at 400r / min, ball milled for 48h, and then the slurry The material was transferred to an evaporating dish, and dried in an explosion-proof constant temperature oven at 200°C to obtain block powder, which was coarsely ground in an agate mortar and sieved with a 200-mesh standa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com