Aluminum-coated precursor as well as preparation method and application thereof

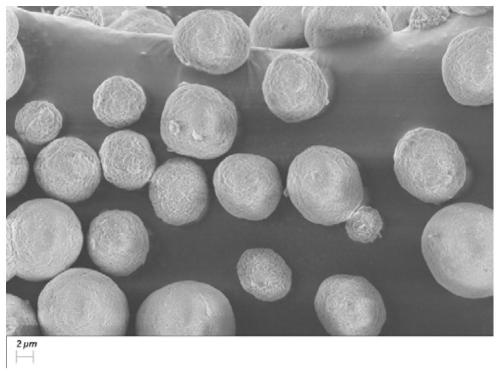

A technology of precursor and aluminum coating, which is applied in the field of aluminum coating precursor and its preparation, can solve the problems of poor sphericity, low vibration, small particle size, etc., and achieve improved sphericity, uniform particle size distribution, vibration The effect of high solid density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

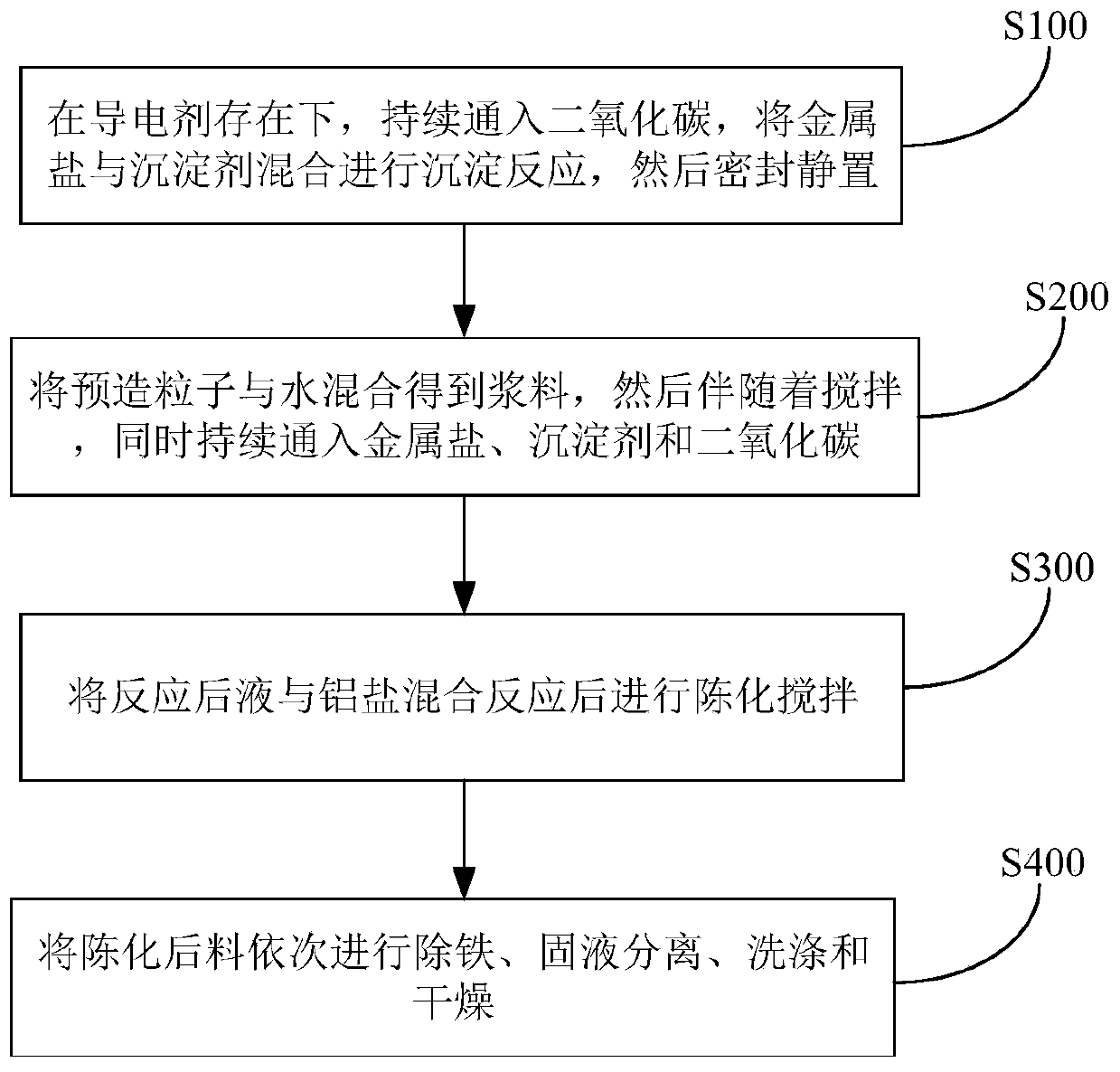

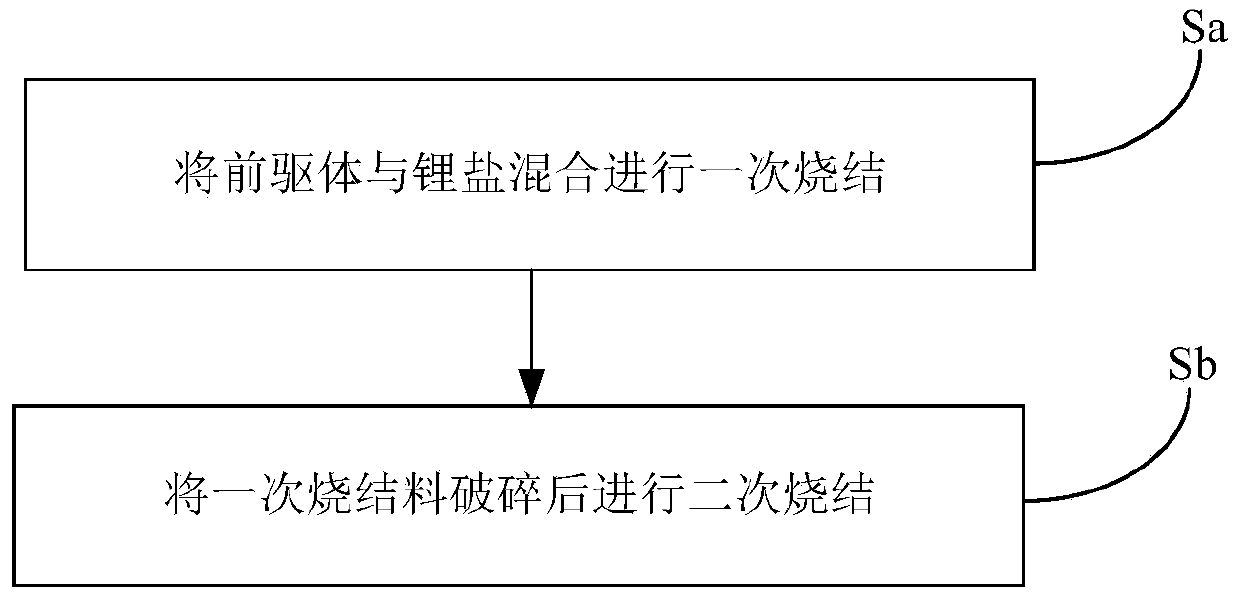

[0075]According to the method for preparing an aluminum-coated precursor according to an embodiment of the present invention, firstly, in the presence of a conductive agent, carbon dioxide is continuously introduced, and then a metal salt and a precipitant are added. The continuous introduction of carbon dioxide can adjust the pH of the system and maintain the pH of the system. The inert environment prevents metal elements from being oxidized during the co-precipitation process, and can improve the sphericity of the precursor, while the conductive agent can improve the rate performance of the material, and then the slurry obtained by mixing the prefabricated particles with water is continuously passed through Add metal salts, precipitants, carbon dioxide and complexing agents. Complexing agents can reduce the reaction speed of the system and inhibit the formation of new particles in the system. Metal salts and precipitants use small prefabricated particles as crystal seeds in th...

Embodiment 1

[0087] The method for preparing the aluminum-coated precursor is as follows:

[0088] (1) Nickel sulfate, cobalt sulfate, and manganese sulfate are mixed according to the molar ratio of nickel, cobalt, and manganese to 0.2:0.18:0.6 to obtain a mixed metal salt, and the concentration of nickel sulfate, cobalt sulfate, and manganese sulfate in the mixed metal salt is 400g / L, and then in the presence of conductive agent glucose, carbon dioxide is continuously introduced at a flow rate of 0.1L / min, and then the mixed metal salt is quickly mixed with a sodium hydroxide solution with a concentration of 200g / L (mixing is completed within 10 seconds) , wherein the molar ratio of the mixed metal salt to sodium hydroxide is 1:2.0, and based on the total amount of 1L mixed metal salt and sodium hydroxide, the amount of conductive agent glucose is 20g), and then sealed at 30 degrees Celsius for 12 hours , to obtain prefabricated particles with a particle size of 1.2 microns;

[0089] (2)...

Embodiment 2

[0097] The method for preparing the aluminum-coated precursor is as follows:

[0098] (1) Mix nickel chloride, cobalt chloride, and manganese chloride according to the molar ratio of nickel, cobalt, and manganese to 0.2:0.09:0.7 to obtain a mixed metal salt, and nickel chloride, cobalt chloride, and chlorine in the mixed metal salt The concentration of manganese oxide is 300g / L, and then in the presence of the conductive agent fructose, carbon dioxide is continuously introduced at a flow rate of 0.5L / min, and then the mixed metal salt is quickly mixed with a sodium hydroxide solution with a concentration of 50g / L (Complete mixing within 10 seconds, wherein, the mol ratio of mixed metal salt and sodium hydroxide is 1: 3.5, based on the total amount of 1L mixed metal salt and sodium hydroxide simultaneously, the consumption of conductive agent fructose is 30g), then at 80 Celsius sealed and left standing for 18 hours to obtain prefabricated particles with a particle size of 1.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com