Preparation method of dispersion type gas permeable brick for ladle

A technology of breathable bricks and shaped steels, applied in the field of refractory materials, can solve the problems of poor thermal shock resistance, poor mechanical properties and air permeability, and slag erosion resistance of breathable bricks, so as to achieve improved slag erosion resistance, improved mechanical properties, and improved resistance to slag erosion. The effect of thermal shock performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

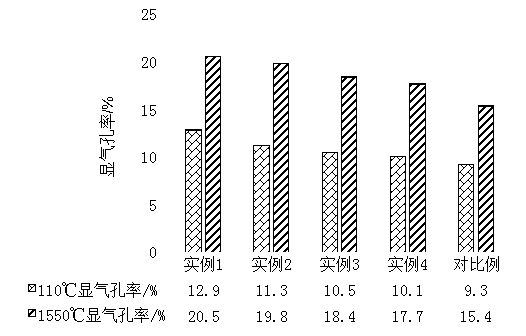

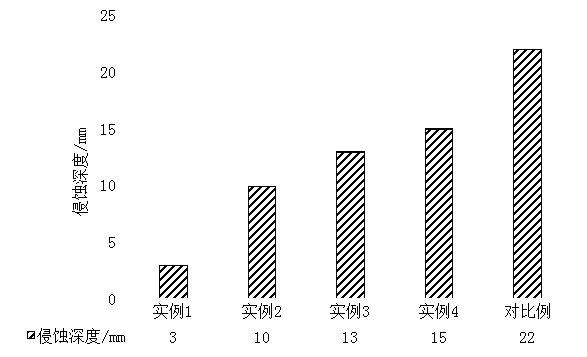

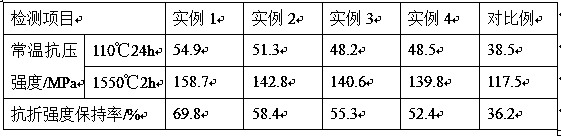

Examples

example 1

[0024]Mix rice husk fiber and calcium carbonate powder into the ball mill according to the mass ratio of 3:1, and add potassium permanganate powder with 0.5 times the mass of rice husk fiber, quartz sand and rice husk fiber with 0.3 times the mass of rice husk fiber to the ball mill 4 times the mass of zirconia ball milling beads, ball milled and mixed for 45 minutes, passed through a 180-mesh sieve, and the additive was obtained; the corundum mixture and zirconia powder were mixed at a mass ratio of 25:2, and an additive of 0.40 times the mass of the corundum mixture was added, and the corundum mixture was Dispersant with a mass of 0.10 times the mass of corundum and water with a mass of 0.15 times the corundum are stirred and mixed for 50 minutes at a temperature of 55°C and a rotational speed of 260r / min to obtain a mixture, which is then moved into a mold and vibrated to form a billet ; Under the condition that the temperature is 40°C, the billet is maintained at a constant...

example 2

[0026] Mix quartz sand and calcium carbonate powder into the ball mill according to the mass ratio of 1:1, and add potassium permanganate powder with 1.5 times the mass of quartz sand and zirconia ball milling beads with 12 times the mass of quartz sand to the ball mill, and mix for 45 minutes. Pass through a 180-mesh sieve to obtain additives; mix the corundum mixture and zirconia powder at a mass ratio of 25:2, add additives 0.40 times the mass of the corundum mixture, dispersant 0.10 times the mass of the corundum mixture, and water 0.15 times the mass of the corundum , at a temperature of 55°C and a rotational speed of 260r / min, stir and mix for 50 minutes to obtain a mixture, move the mixture into a mold, and vibrate to form a billet; Keep away from light for 36 hours, remove the mold, move the demoulded billet into the calciner, raise the temperature to 600°C at a heating rate of 60°C / h, keep the heat for 8 hours, cool to room temperature with the furnace, and discharge t...

example 3

[0028] Mix the rice husk fiber and calcium carbonate powder in a mass ratio of 3:1 and add them to the ball mill. Quartz sand with 0.3 times the mass of rice husk fiber and zirconia ball milling beads with 4 times the mass of rice husk fiber are ball milled for 45 minutes and passed through a 180-mesh sieve. To obtain additives; mix the corundum mixture and zirconia powder at a mass ratio of 25:2, add additives 0.40 times the mass of the corundum mixture, dispersant 0.10 times the mass of the corundum mixture, and water 0.15 times the mass of the corundum, at a temperature of 55 ℃, the rotation speed is 260r / min, after stirring and mixing for 50 minutes, the mixture is obtained, and the mixture is moved into the mold, and vibrated to form a billet; the billet is maintained at a constant temperature and protected from light for 36 hours at a temperature of 40°C. Remove the mold, move the demoulded billet into the calciner, raise the temperature to 600°C at a heating rate of 60°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com