Ceramic material as well as preparation method and application thereof

A technology of ceramic materials and ceramic slurry, which is applied in the direction of electrical components, fixed capacitor dielectrics, circuits, etc., can solve the problems of multilayer ceramic capacitors such as reduced cost and processing difficulty, weak strength, etc., to promote sintering, improve compactness, and improve The effect of flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The ceramic material of the invention can be applied in the preparation of multilayer ceramic capacitors. In some embodiments, the preparation method includes the following steps:

[0041] (1) The raw materials of ceramic slurry are mixed and ball-milled to obtain ceramic slurry, wherein the raw materials of ceramic slurry include ceramic material, binding agent and solvent of the present invention;

[0042] (2) casting the above-mentioned ceramic slurry to form a layer of film, drying to obtain a ceramic dielectric layer;

[0043] (3) forming an internal electrode layer on the surface of the ceramic dielectric layer obtained in step (2) by a printing process;

[0044] (4) Laminating, pressing, debinding and sintering the above-mentioned ceramic dielectric layer printed with internal electrodes to obtain a ceramic chip;

[0045] (5) Coating conductive paste for external electrodes on both ends of the ceramic chip, and baking at a temperature of 600-900°C to form exter...

Embodiment 1~26

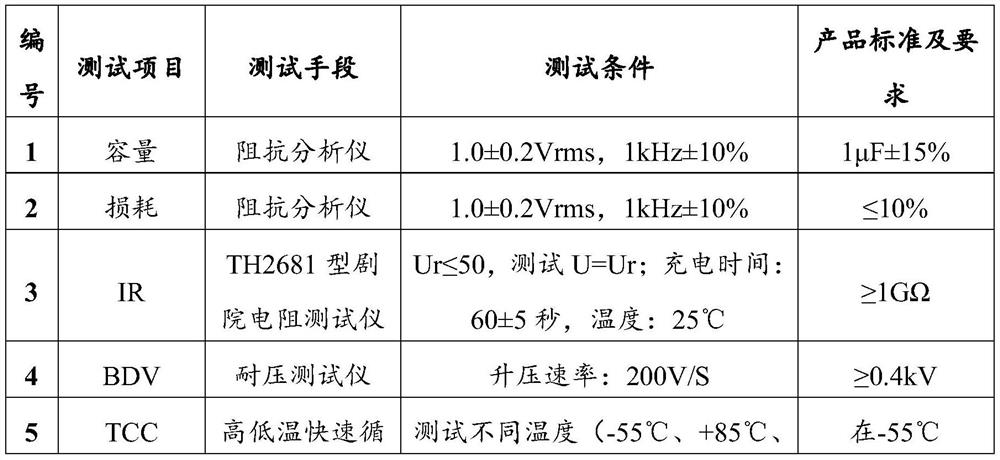

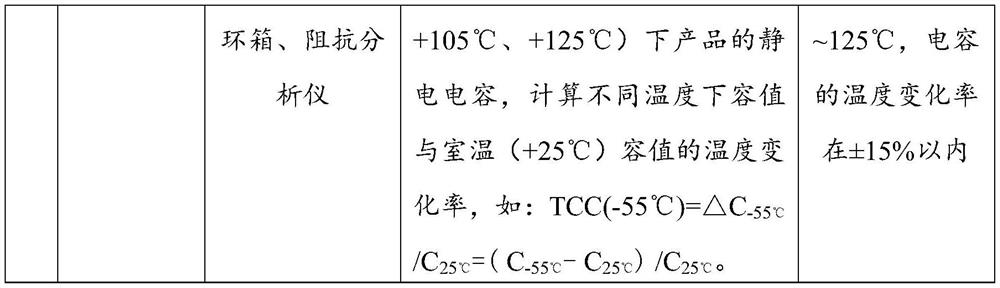

[0060] Embodiment 1~26 and comparative example 1~12

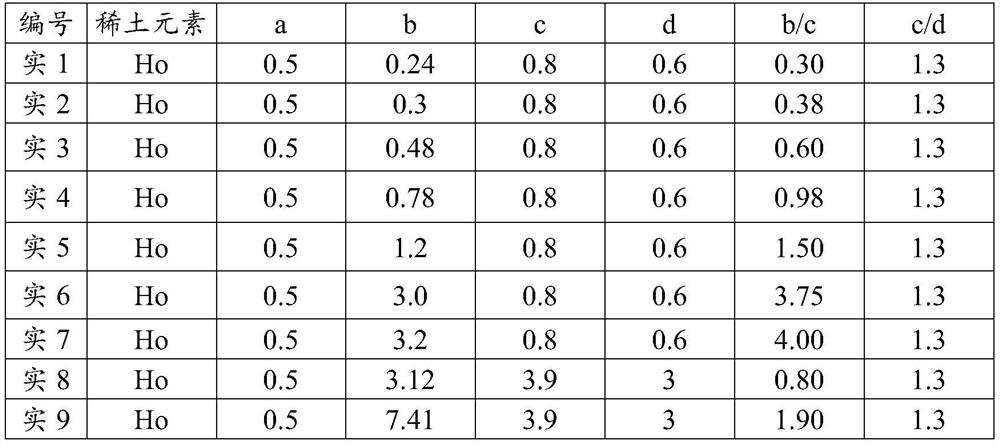

[0061] Embodiments 1-26 (abbreviated as real 1-26) and comparative examples 1-12 (abbreviated as pair 1-12) respectively provide a kind of ceramic material, these ceramic materials comprise barium titanate compound, rare earth element and Sintering aids, in which barium titanate compounds are (Ba 1-x-y Ca x Sr y ) m (Ti 1-p-q Zr p f q )O 3 , x are all 0, y are all 0, p are all 0, q are all 0, m are all 1, these barium titanate compounds are all prepared by solid phase method, and they are powders made in the same batch; Note that the molar ratio of rare earth elements to barium titanate compounds is a%, the molar ratio of MgO to barium titanate compounds is b%, and MnO 2 The molar ratio with barium titanate compound is c%, SiO 2 The molar ratio to the barium titanate compound is d%, and the values of a, b, c, d, b / c and c / d are shown in Table 2.

[0062] Table 2

[0063]

[0064]

[0065] The preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com