Sintering heat preservation device, sintering machine and sintering method thereof

A thermal insulation device and sintering material technology, which is applied in the field of sintering thermal insulation devices, can solve problems such as uneven air volume, large gas consumption, and wind grabbing, and achieve the effects of reducing the rate of return ore, improving sintering quality, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

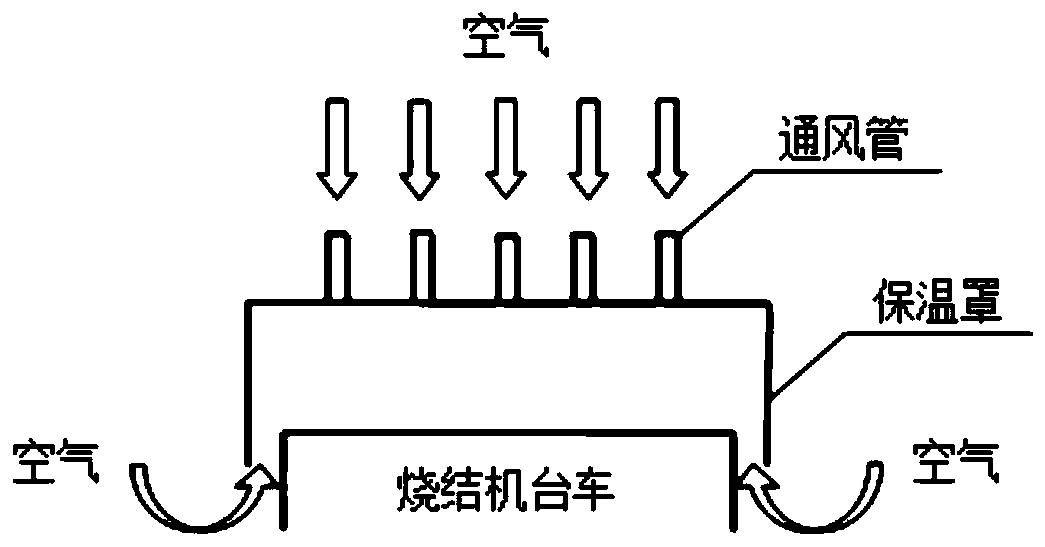

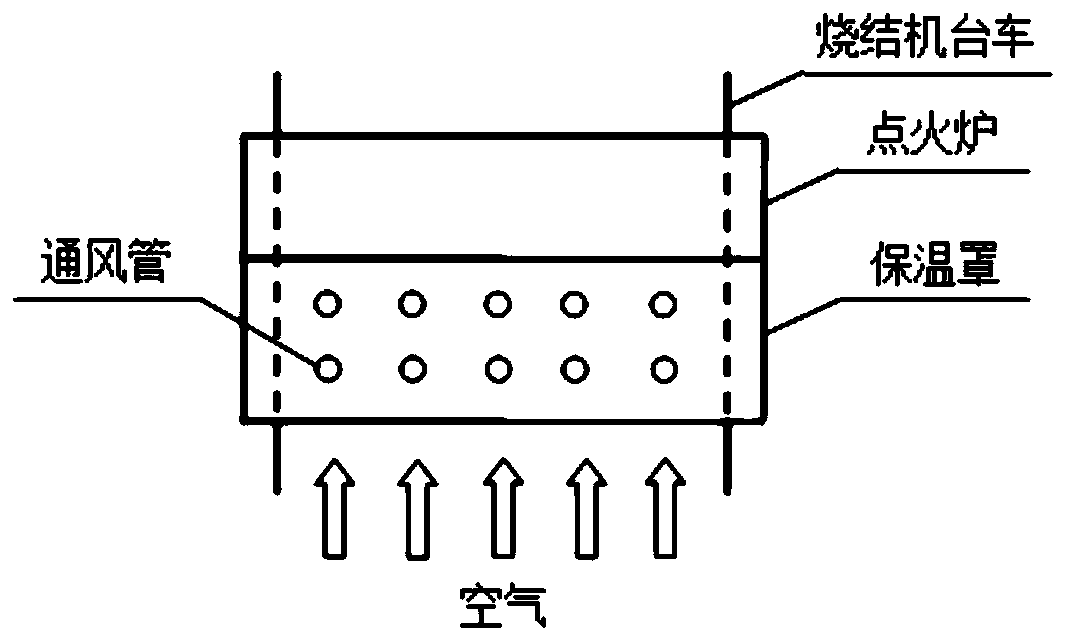

[0054] In sintering production, after the sintering material is ignited, the sintering material needs to be kept warm. In the prior art, a heat preservation furnace or a heat preservation cover is generally installed after the ignition furnace to keep the sintered material surface away from the ignition furnace 2. However, simply taking the form of a heat preservation cover can reduce a large amount of heat loss on the surface of the sintered material, but its air or oxygen supply is relatively insufficient, and under the action of the negative pressure of the exhaust system under the sintering trolley, the sintered material will Grab the wind from the ignition furnace 2 above the surface, which affects the work of the ignition furnace. However, if air is introduced through openings on the insulation cover, or from the rear of the insulation cover or the gaps on both sides, it is easy to cause rapid cooling of the sintered material surface, affect the sintering quality, and inc...

Embodiment 2

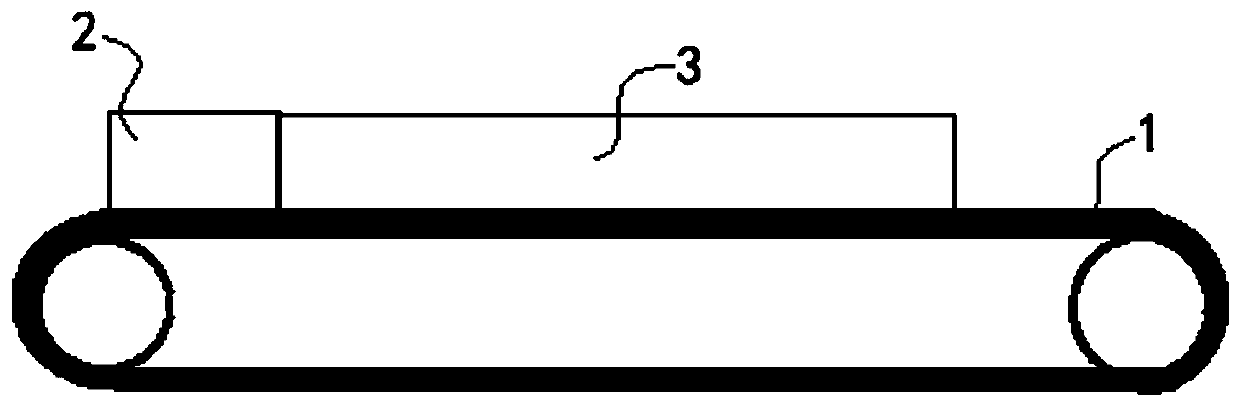

[0064] like image 3 As shown, a sintering machine is mainly used for sintering operations in metallurgical sintering plants, sintering various ore powders into blocks, and partially eliminating harmful impurities in the ore. It includes a sintering trolley 1, an ignition furnace 2 and a heat preservation device. Among them, the sintering trolley 1 is the main operating part of the sintering machine, and the sintering material is ignited, sintered, cooled, etc. on the sintering trolley, and an exhaust system is installed below it, usually using an exhaust fan and other devices. The ignition furnace 2 is installed above the feed end of the sintering trolley 1, and is used to ignite the sintering material. The thermal insulation device adopts a sintering thermal insulation device in Example 1, which can supply sufficient oxygen to the sintered material layer while maintaining thermal insulation, and improve the quality of the upper part of the sintered material layer and the un...

Embodiment 3

[0066] A kind of sintering method of sintering machine, adopts the sintering machine of embodiment 2 to carry out sintering work, comprises the steps:

[0067] 1. Turn on the ignition furnace 2. The ignition temperature is 900-1150°C. After the sintering material is distributed on the sintering trolley, the sintering trolley 1 transports the sintering material through the ignition furnace 2 at a running speed of 1.0-2.5m / min to ignite. The embodiment takes 2m / min. It should be noted that the running speed of the sintering trolley 1 needs to be selected according to the actual working conditions, but generally does not exceed the above range; after that, the sintering material enters the heat preservation cover 3, and the length of the heat preservation cover 3 is based on the actual The production process is set, generally kept within 2-10m, and 6m is taken in this embodiment.

[0068] 2. The lower part of the heat exchanger 31 receives heat radiation from the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com