Magnesium-aluminum ramming material for rh furnace

A technology of ramming material and magnesium aluminum, which is applied in the field of refractory materials, can solve problems such as temperature fluctuations, furnace wall damage, and accelerated furnace lining damage, and achieve the effects of improving thermal shock resistance, improving high-temperature performance, and improving medium-temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

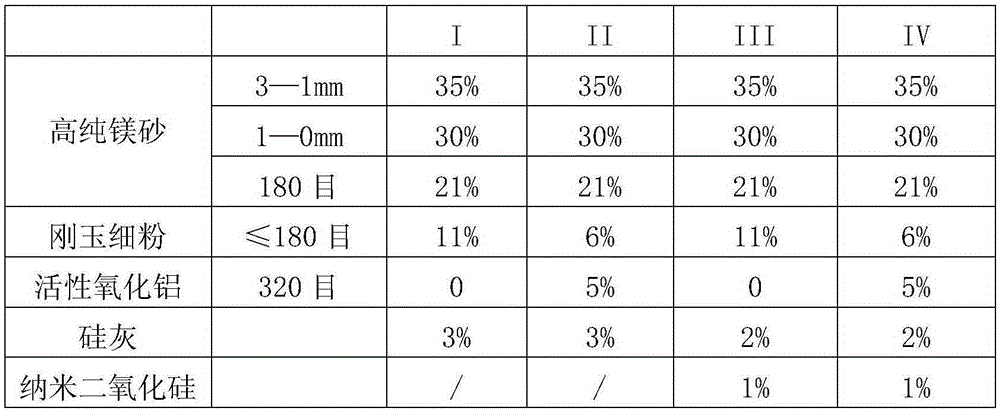

[0013] Example 1. The introduction of PT-10 increases the plasticity of magnesium-aluminum ramming materials (as shown in Table 1)

[0014] Table 2

[0015]

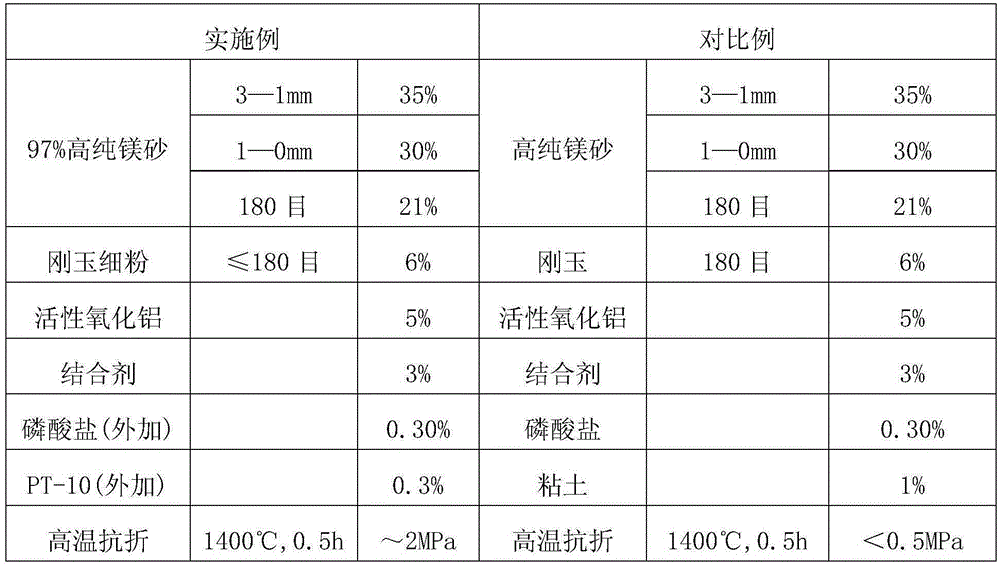

Embodiment 2

[0016] Embodiment 2. has improved the high-temperature performance of material:

[0017]

Embodiment 3

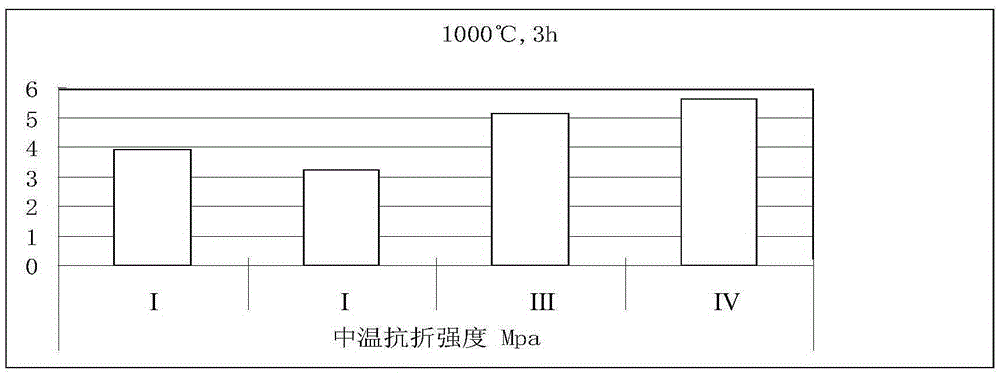

[0018] Embodiment 3. Due to the high activity of nano-silica, nano-silica is used, which can promote the reaction of activated alumina and magnesium oxide fine powder to produce magnesia-aluminum spinel at a lower temperature, which can be produced at low temperature. Certain sintering, thus improving the medium temperature strength of the material (Table 4).

[0019] Table 4

[0020]

[0021] It should be emphasized that:

[0022] ①Due to the decreasing reserves of high-grade chrome ore, the price of fused magnesia-chrome sand continues to rise. In the case of equivalent service life, the price advantage of the magnesium-aluminum ramming material described in the present invention is more obvious. In addition, The environmental protection of the magnesium-aluminum ramming material makes the magnesium-aluminum ramming material have a good cost performance, so it will have a good application prospect.

[0023] ②The amount of PT-10 added in the above-mentioned examples is j...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com