High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

A composite water reducer and polycarboxylate-based technology, applied in the field of building materials, can solve the problem that the wall can only be controlled within a range of less than 5%, the wall loses its bearing capacity and thermal insulation performance, and the freeze-thaw resistance performance is not ideal, etc. problems, to achieve uniform and stable storage, good slump protection effect, and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

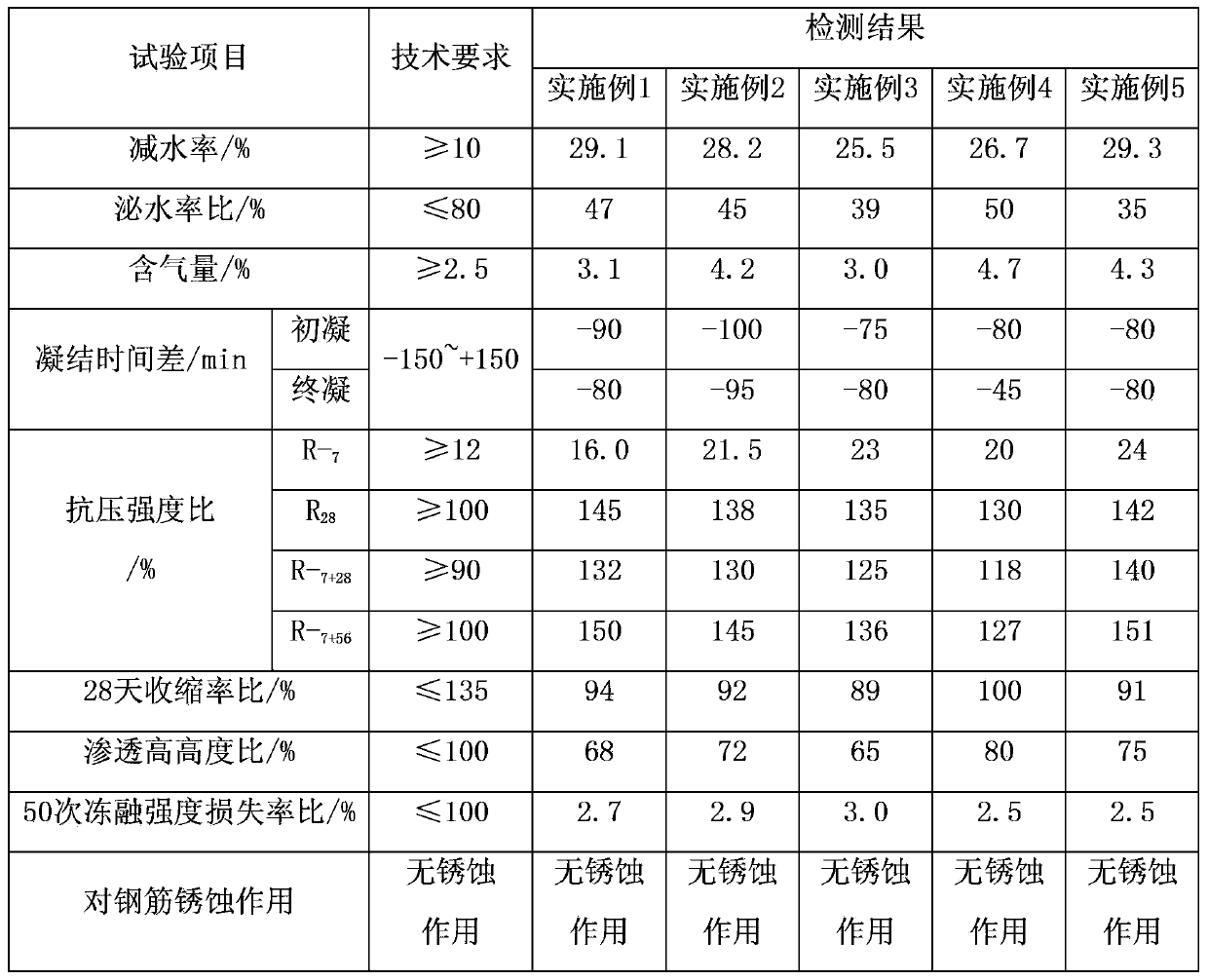

Examples

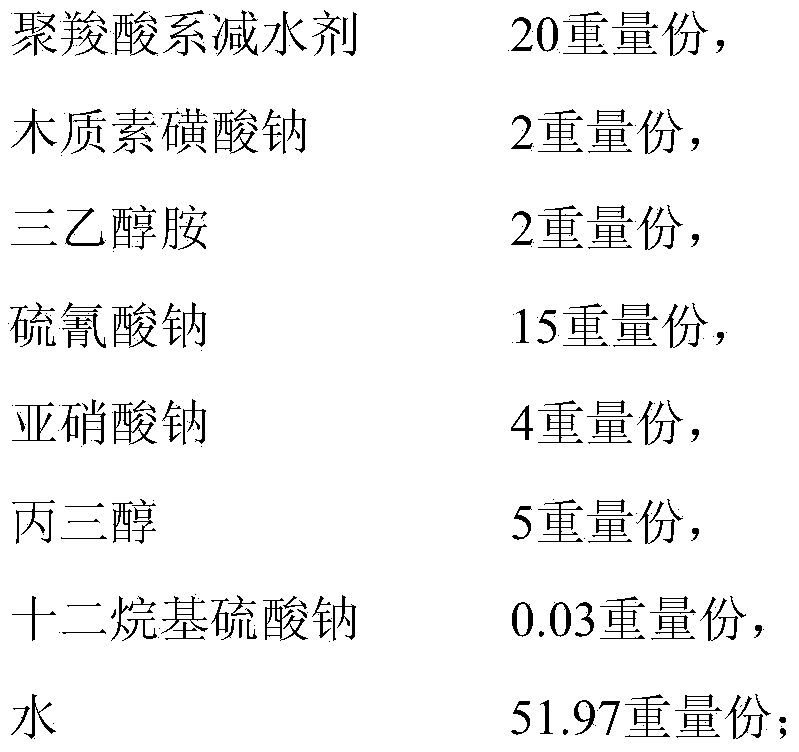

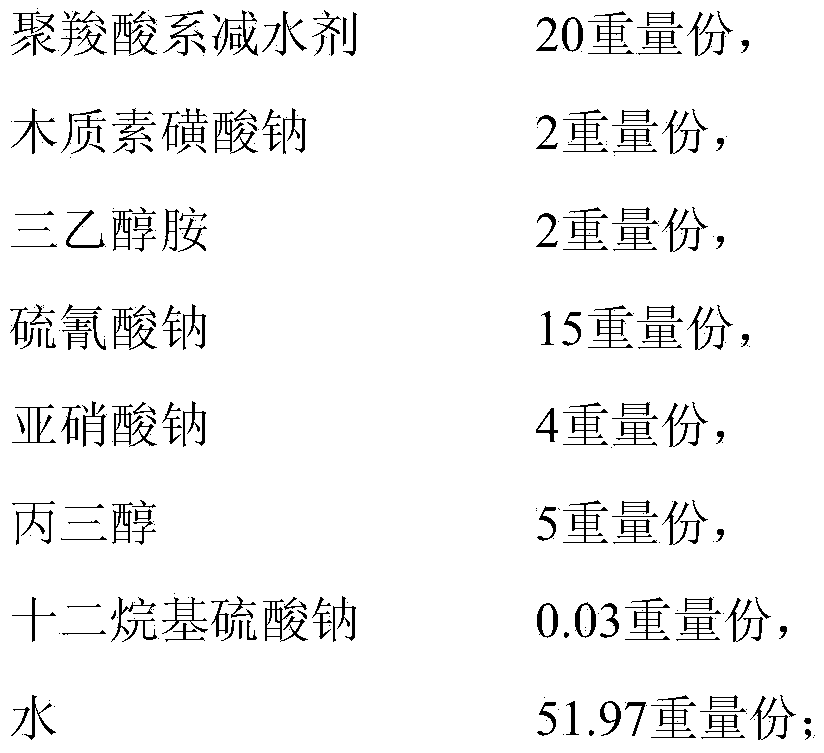

Embodiment 1

[0054] Example 1 Preparation of composite water reducer of the present invention

[0055] Take LonS-Mw water-reducing polycarboxylic acid mother liquor (acrylic acid, 40% solid content, manufacturer Sichuan Jilong Chemical Building Materials Co., Ltd., production batch number 20121207-0) 187.5kg, sodium lignosulfonate 15kg, water 536.1kg and mix After uniformity, sequentially add 21kg of triethanolamine, 150kg of sodium thiocyanate, 40kg of calcium nitrite, 50kg of glycerol, and 0.4kg of sodium lauryl sulfate (K12) and stir evenly to obtain the product. The dosage of the obtained composite water reducer is 1.6-2.1wt% of the cementitious material in the concrete.

Embodiment 2

[0056] Example 2 Preparation of composite water reducer of the present invention

[0057] Take LonS-Mw water-reducing polycarboxylic acid mother liquor (acrylic acid, 40% solid content, manufacturer Sichuan Jilong Chemical Building Materials Co., Ltd., production batch number 20121214-0) 250kg, sodium lignosulfonate 12kg, water 425kg and mix evenly , sequentially add 26kg of triisopropanolamine, 180kg of sodium nitrite, 50kg of calcium formate, 55kg of ethylene glycol, and 2.0kg of triterpene saponins and stir evenly to obtain final product. The dosage of the obtained composite water reducer is 1.1-1.7wt% of the cementitious material in the concrete.

Embodiment 3

[0058] Example 3 Preparation of composite water reducer of the present invention

[0059] Take VF-1 standard polycarboxylate mother liquor (40% solid content, manufacturer Sichuan Lujia Stone Technology Development Co., Ltd., production batch number 20121210-01) 245kg, sodium lignosulfonate 20kg, water 432kg, after mixing evenly, sequentially Add 23 kg of diethanolamine, 175 kg of calcium nitrate, 55 kg of calcium formate, and 50 kg of propylene glycol and stir evenly to obtain the product. The dosage of the obtained composite water reducer is 1.2-1.8wt% of the cementitious material in the concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com