Cold repairing material for asphalt road surfaces as well as preparation method and application of cold repairing material

A technology of cold patching and asphalt, which is applied in the field of emergency maintenance and daily maintenance of designed roads, and can solve problems such as difficult construction, difficult operation, and seasonal influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

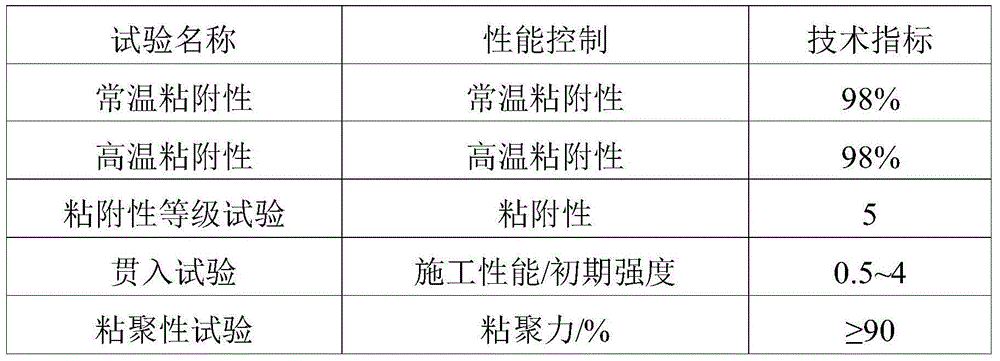

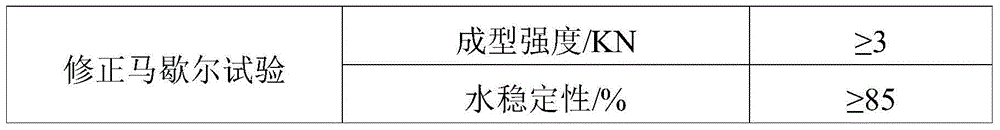

[0036] Get 70 parts of petroleum pitch and 20 parts of diesel oil, mix and stir to obtain the mixture, then add 3 parts of cold patching additives (pine tree extract-terpene (n=2, C10H16, α-pinene, β-pinene) to the evenly stirred mixture ene) and eucalyptus extract m-isoprene as the main component of the terpene-based macromolecular polymer), mix and stir evenly, make cold repair cement, and aggregate (meet the requirements of Table 1), according to the oil-stone ratio 4:100 for mixing, after stirring evenly, package and transport to the maintenance construction site, pour the product into the pit, and use manual leveling and tamping or car tires for compaction, rolling compaction and leveling.

Embodiment 2

[0038] Get 77 parts of petroleum pitch and 22 parts of diesel oil, mix and stir to obtain the mixture, then add 3.3 parts of cold patching additives (pine tree extract-terpene (n=2, C10H16, α-pinene, β-pinene terpene) and Populus trifoliate isoprene as the main component of the terpene-based macromolecular polymer), mixed and stirred evenly to prepare the cold patch cement, and the aggregate (in line with the requirements of Table 1), according to The oil-stone ratio is 6:100 for mixing. After stirring evenly, the product is packaged and transported to the maintenance construction site. The product is poured into the pit, and it is manually leveled and tamped or compacted by car tires, rolled and compacted and leveled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com