Anti-freezing expansion structural body of roadbed in seasonal frozen soil region and pavement method of structural body

A technology for structures and permafrost regions, which can be applied to roads, roads, buildings, etc., and can solve problems such as long service life of roadbeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

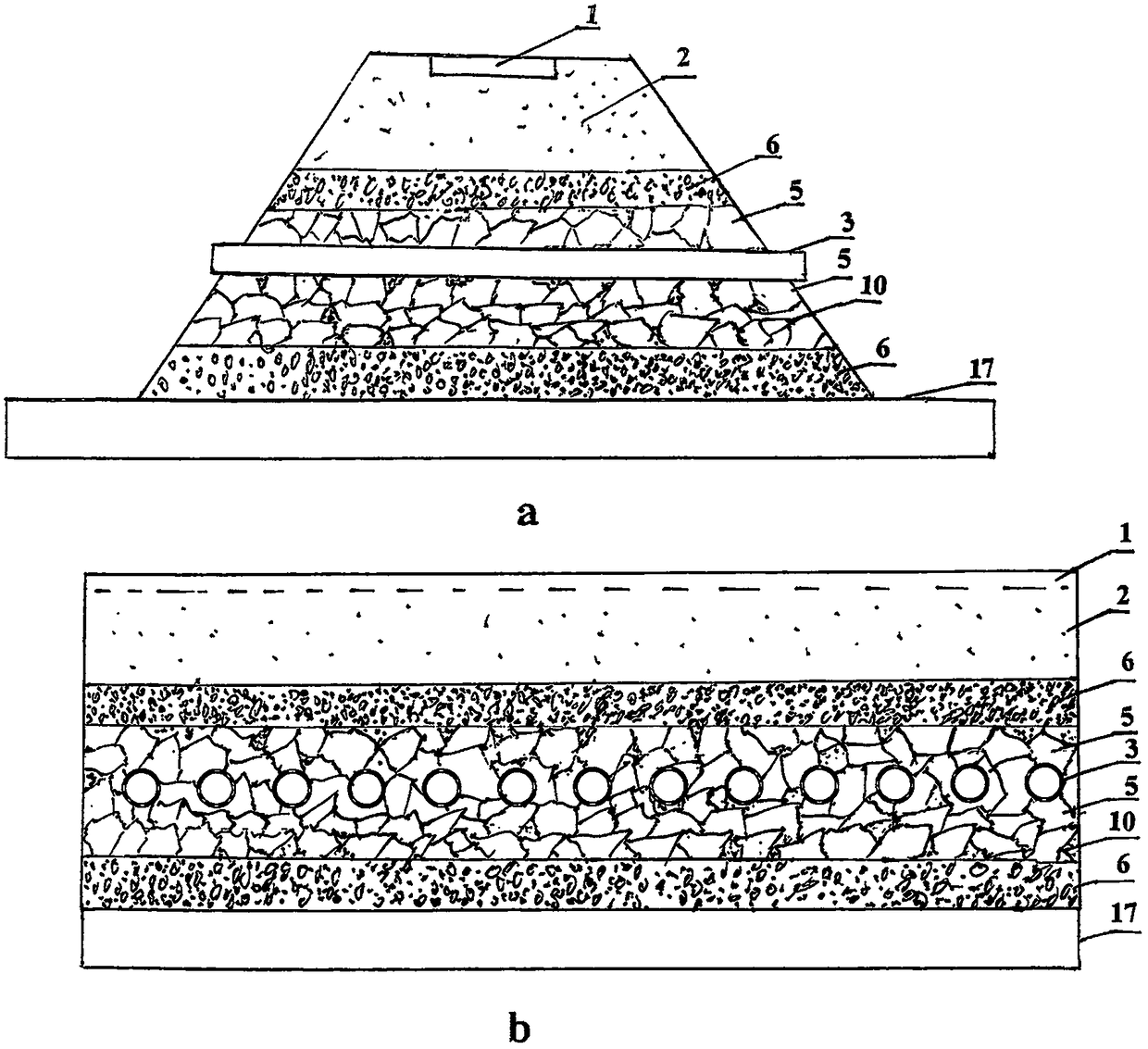

[0090] figure 1 a is a schematic cross-sectional view of the ventilation pipe (3) passing through the block stone layer (5) in the roadbed. figure 1 b is a schematic diagram of the longitudinal section of the ventilation pipe (3) passing through the block stone layer (5) in the roadbed. An embodiment of using the single-layer ventilating pipe method and the sun-proof and cooling method, the paving method is as follows: figure 1 a, in a certain experimental section of National Highway 109 where roads are built along the river in the cold region of the north, compacted crushed gravel (6) is first filled on the compacted natural surface (17), and its thickness is 0.3m; in the crushed gravel ( 6) On the layer, pave the block stone (5) coated with the coating (10) on the surface. The coating (10) is a ZS-211 reflective heat insulation coating with a film thickness of 0.30mm; the block stone (5) or It is called flaked stone (5), the particle size is 10cm~35cm, and the thickness of...

Embodiment 2

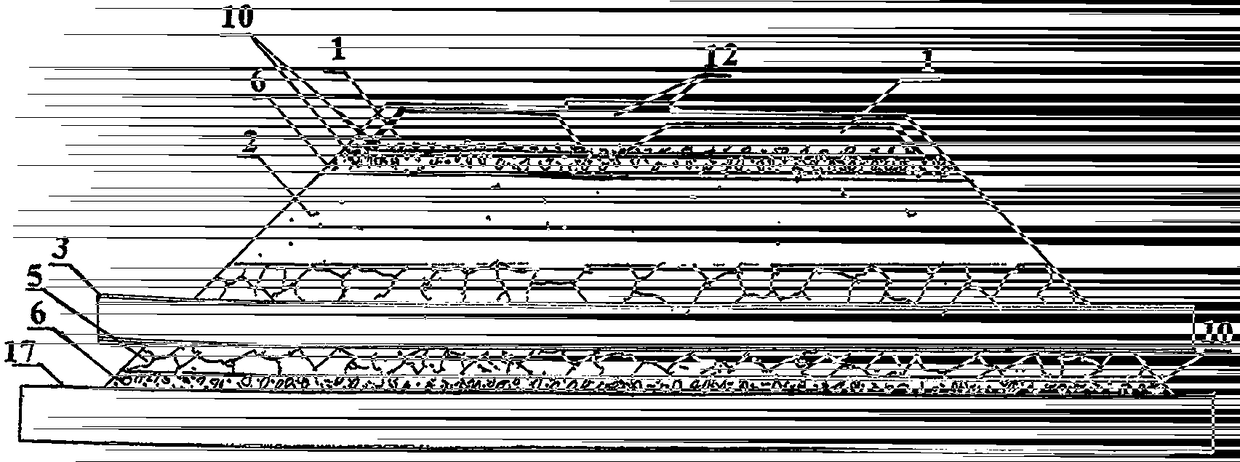

[0093] figure 2 It is a schematic diagram of a transverse section of a highway subgrade with embedded ventilation pipes (3) and crushed stones and block stones.

[0094] An embodiment of using the single-layer ventilating pipe method and the sun-proof and cooling method, the paving method is: first fill the crushed stone (6) in the compacted crushed gravel on the compacted natural ground surface (17), and its particle size is 5mm ~70mm, first pave the thickness of 0.25m, and then pave the coating layer (10) on the surface of the crushed stone (6) with a thickness of 5cm is SPUA material, spray S-402 with JHPK-A9000 Jinghua Parker new polyurethane spraying machine Anti-corrosion and thermal insulation polyurea coating, the coating layer (10) is 2mm thick, and the thermal conductivity is 0.02-0.03W / m.k; of course, it can also be coated with ZS-1 type thermal insulation coating at room temperature, with a film thickness of 0.2mm-0.5mm; On the crushed stone (6) layer, pave a lay...

Embodiment 3

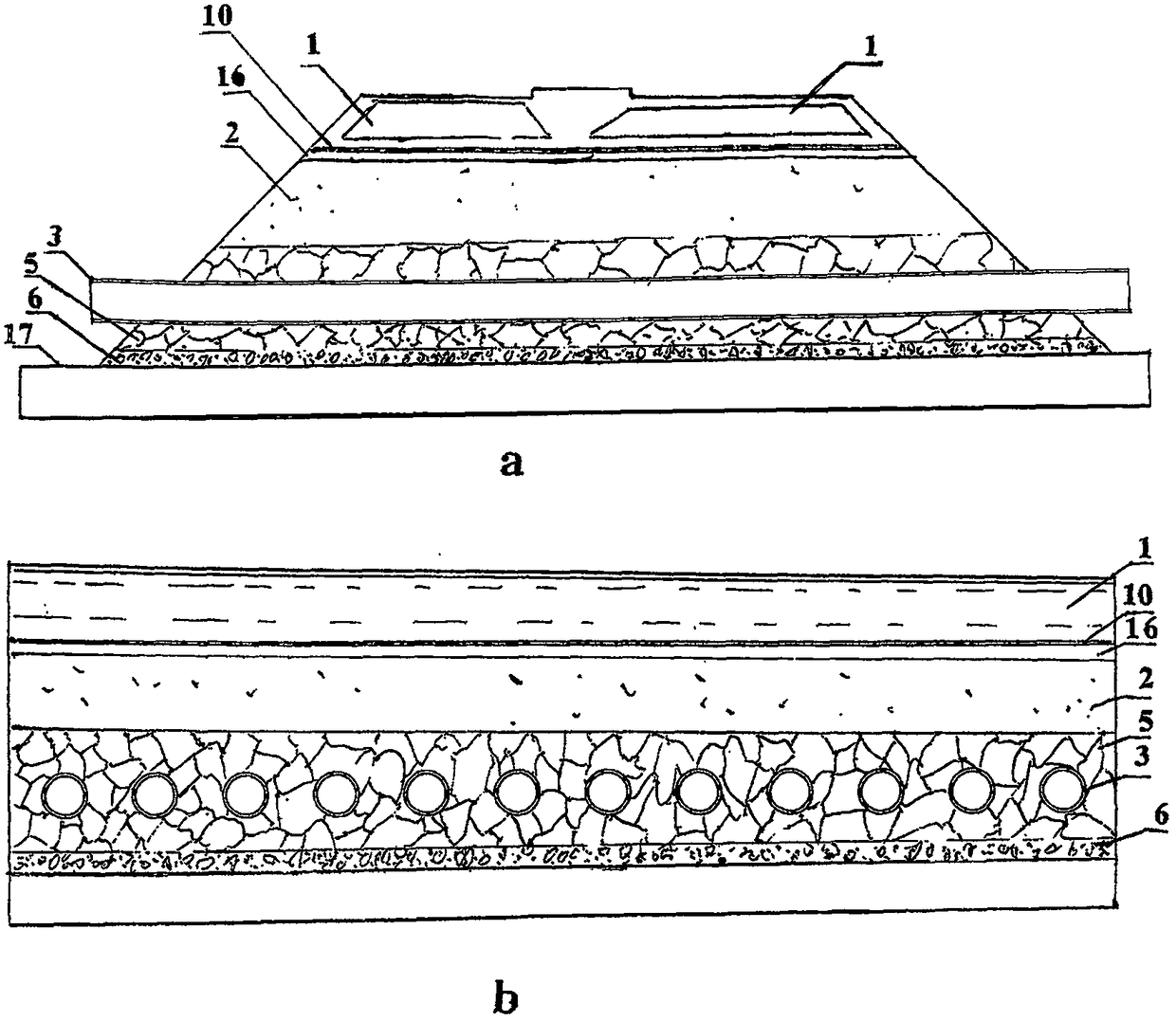

[0097] image 3 a. image 3 b. It is respectively the horizontal and vertical cross-sectional schematic diagrams of the roadbed embedded ventilation pipe (3) and crushed stones, block stones and sun-proof and cooling body (16). An embodiment of comprehensively using the single-layer ventilation pipe method, the interlayer method and the sun-proof and cooling method, the paving method is: completely in accordance with figure 2 The subgrade structure and the method of embodiment 2 are paved. which with figure 2 Slightly different: in image 3 Medium-use sunscreen cooling body (16) instead figure 2 Crushed stones (6) coated with a coating layer (10) on the middle surface. In order to save space, first illustrate the structure of the sun-proof cooling body (16) in the present embodiment: the sun-proof cooling body (16) is formed in a part of hole-shaped ventilation plate (4), block stone (5), crushed gravel (6), concrete body (7), on the surface of geosynthetic material (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com