Glue outlet amount control device and method

A technology for controlling the device and the amount of glue output, applied to the device and coating of the surface coating liquid, can solve the problems of increasing production cost, wasting glue, low efficiency, etc., and achieving the effect of improving the utilization rate and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

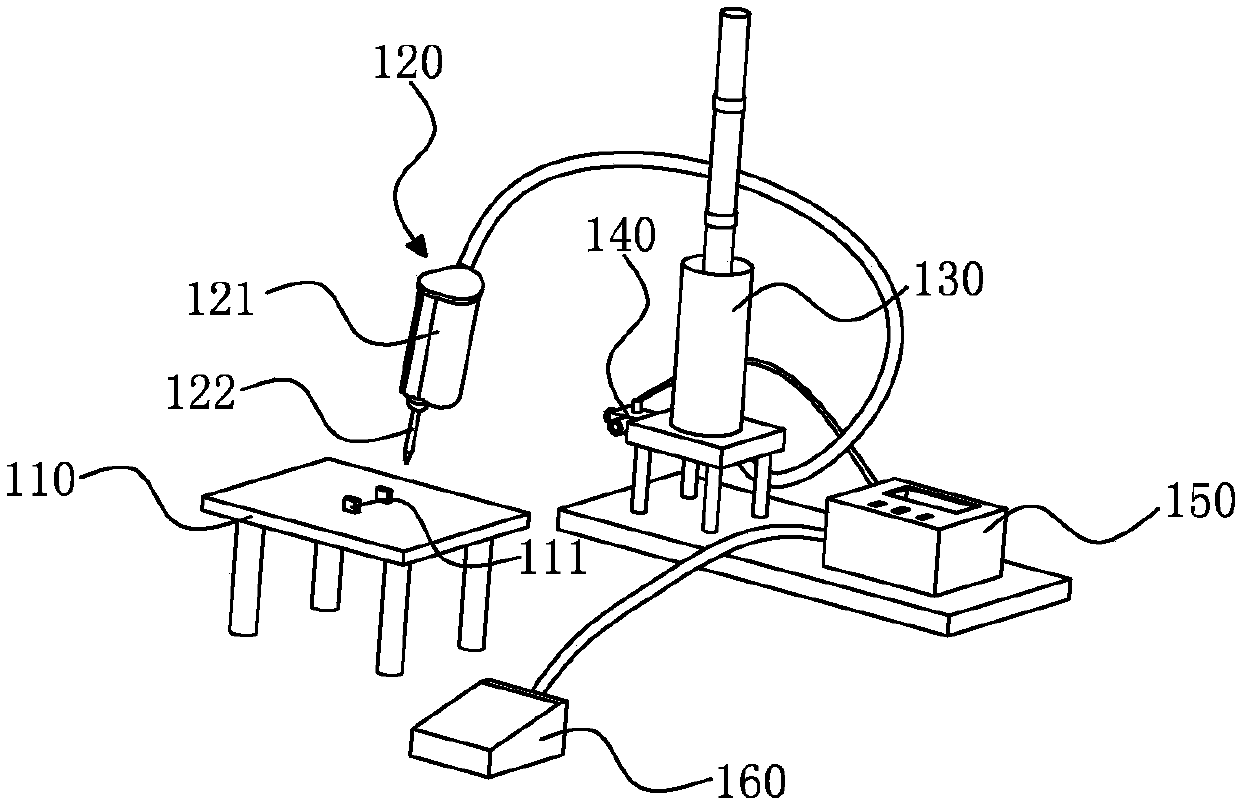

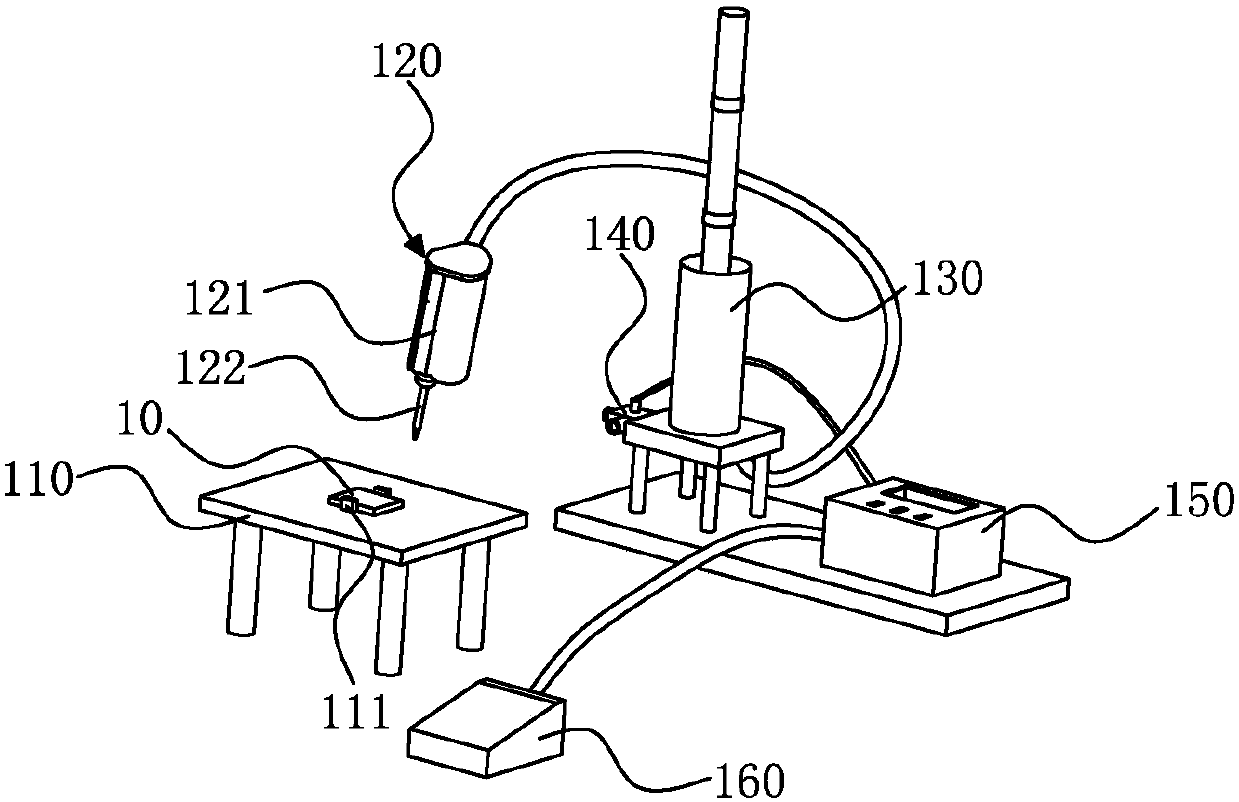

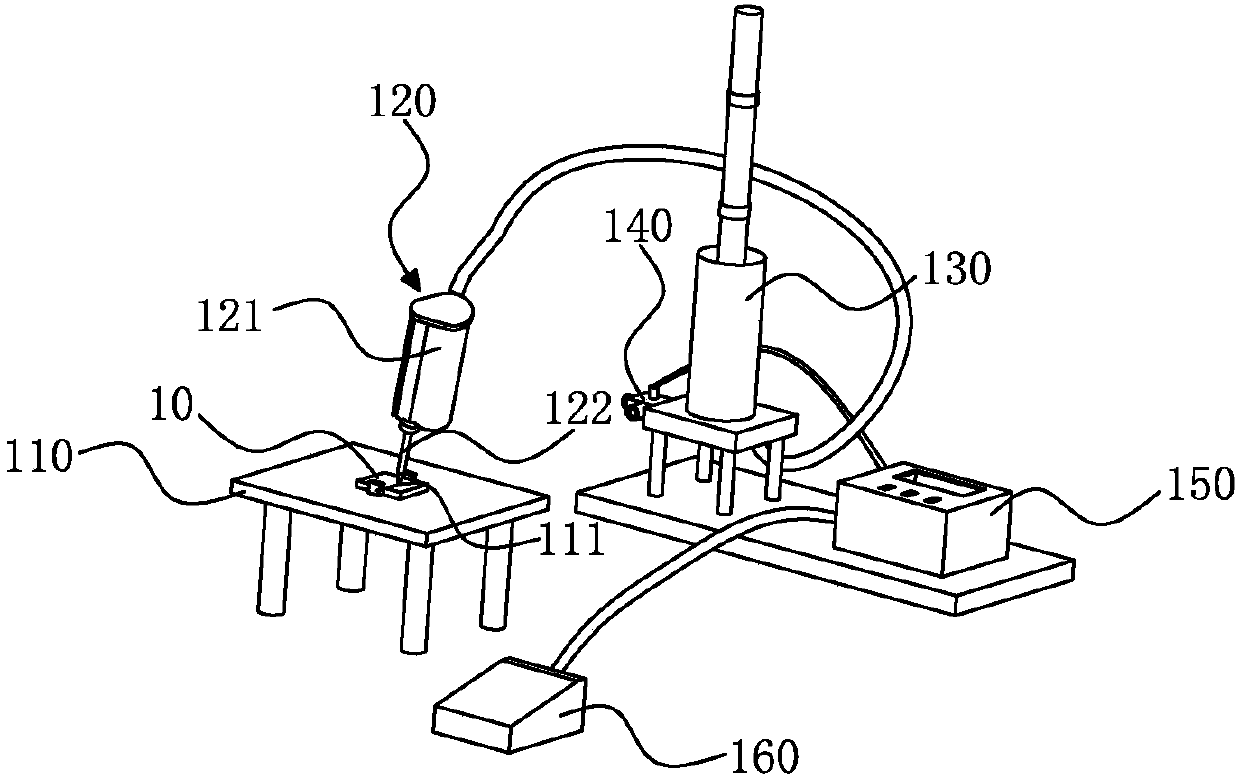

[0029] see figure 1 , figure 1 A schematic structural view of the glue output control device of the present invention is shown.

[0030] The glue output control device 100 of the present invention is used to dispense glue to the product 10, and the device includes:

[0031] Workbench 110, which is used to place product 10;

[0032] Glue dispensing head 120, which is located on one side of the workbench 110, the dispensing head 120 has a glue storage barrel 121 and a glue outlet 122;

[0033] Inflatable cylinder 130, which is located on one side of the dispensing head 120, the air outlet of the inflatable cylinder 130 is connected to the glue storage barrel 121 of the dispensing head 120;

[0034] A control valve 140, which is arranged on the inflatable cylinder 130, and the control valve 140 controls the opening and closing of the inflatable cylinder 130;

[0035] A timer 150, which is arranged on one side of the inflation cylinder 130, and the timer 150 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com