Multifunctional dispensing equipment for solar battery pieces

A solar cell, multi-functional technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of affecting the dispensing position, excessive glue output, glue waste, etc., to ensure integrity and guarantee The effect of tightness and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

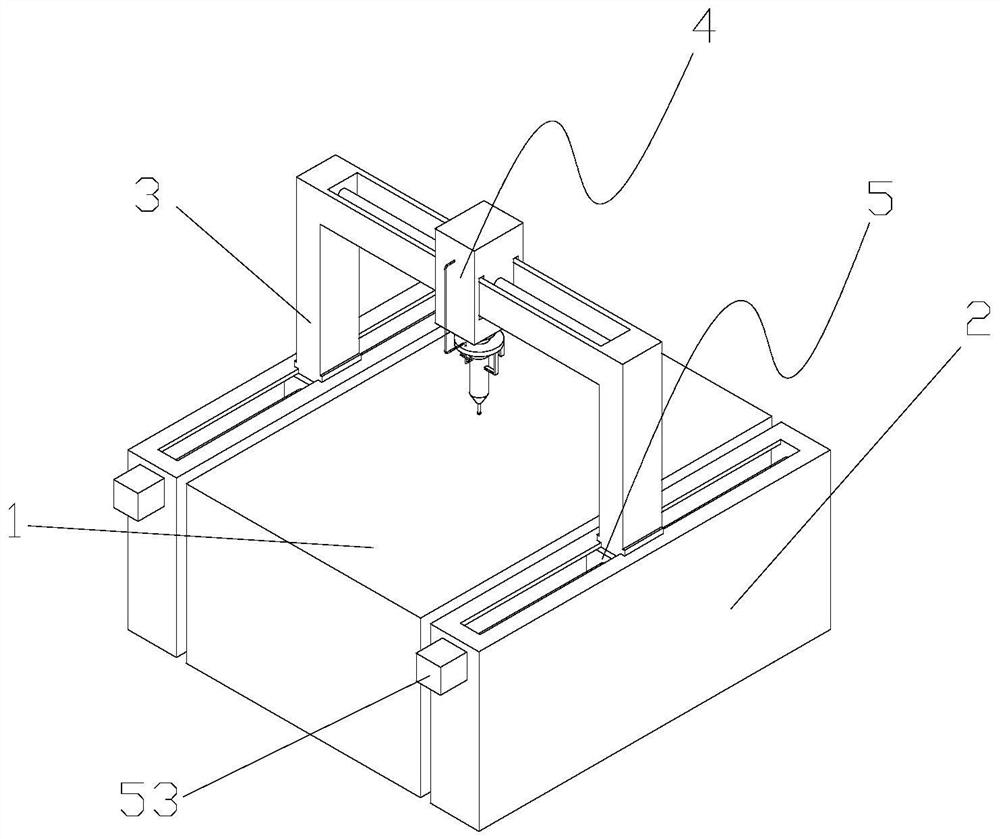

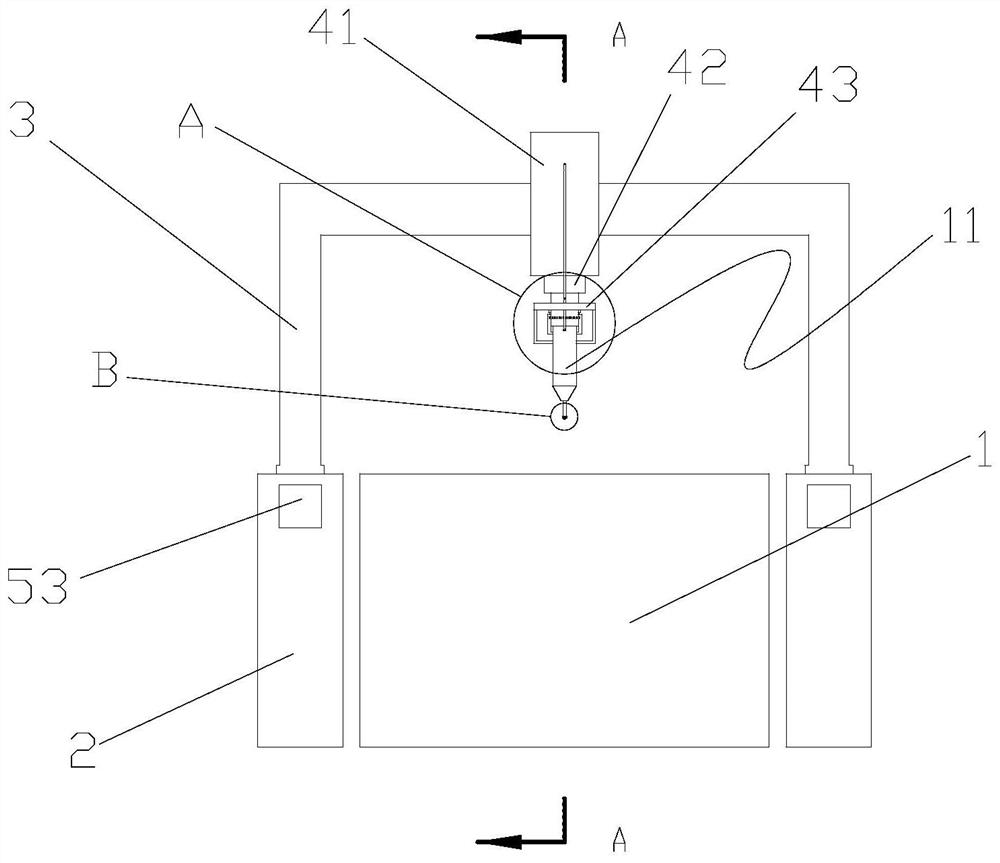

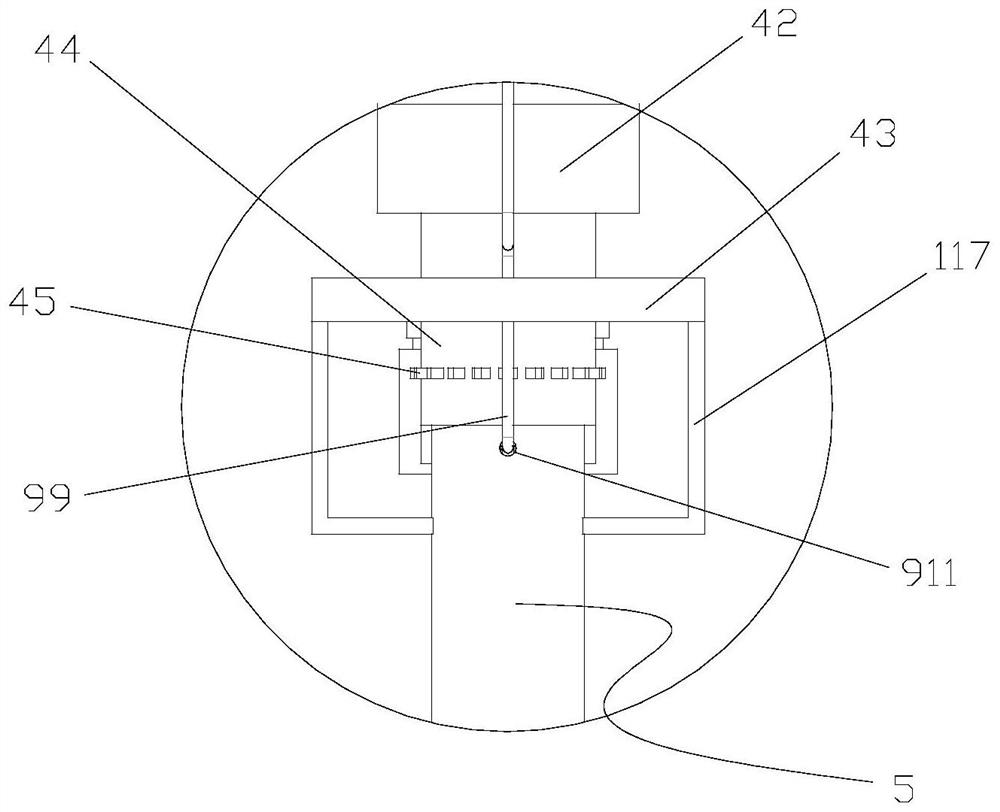

[0032] like Figure 1-15 As shown, a multifunctional dispensing equipment for solar cells includes a conveying platform 1, a frame 2, a working frame 3, a dispensing device 4, and a transmission structure 5; the conveying platform 1 is set on the ground, and the frame 2 is set on the On both sides of the conveying platform, the working frame 3 is arranged on the frame, the dispensing device 4 is arranged on the working frame, the transmission structure 5 is used to control the dispensing device, and the conveying platform is used to transport the solar panels , this is the prior art and will not be repeated here. The frame is provided with two working frames arranged on both sides of the conveyor table as an inverted U-shaped structure; the dispensing device 4 includes a moving block 41, a first cylinder 42, a fixed Disk 43, connecting block 44, glue gun 5, telescopic structure 6, transmission gear 45, adjustable power assembly 7; moving block 41 can move back and forth on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com