Suction device with a dirt collection chamber, a spinning machine, and a method

A suction device, spinning machine technology, used in textiles and papermaking, etc., can solve problems such as inability to remove sticky dirt, expensive suction devices, adverse effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

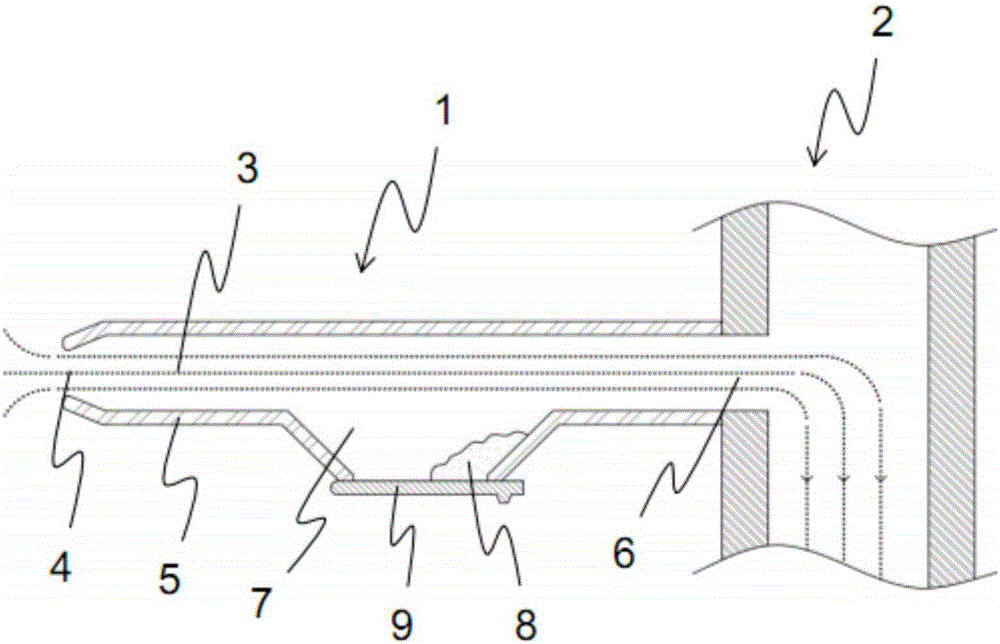

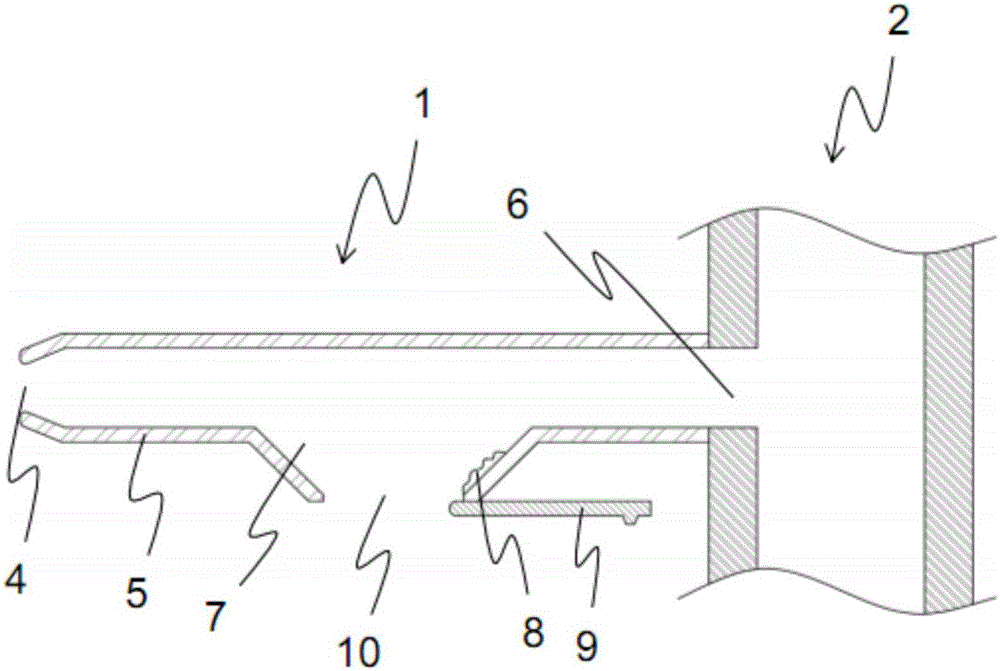

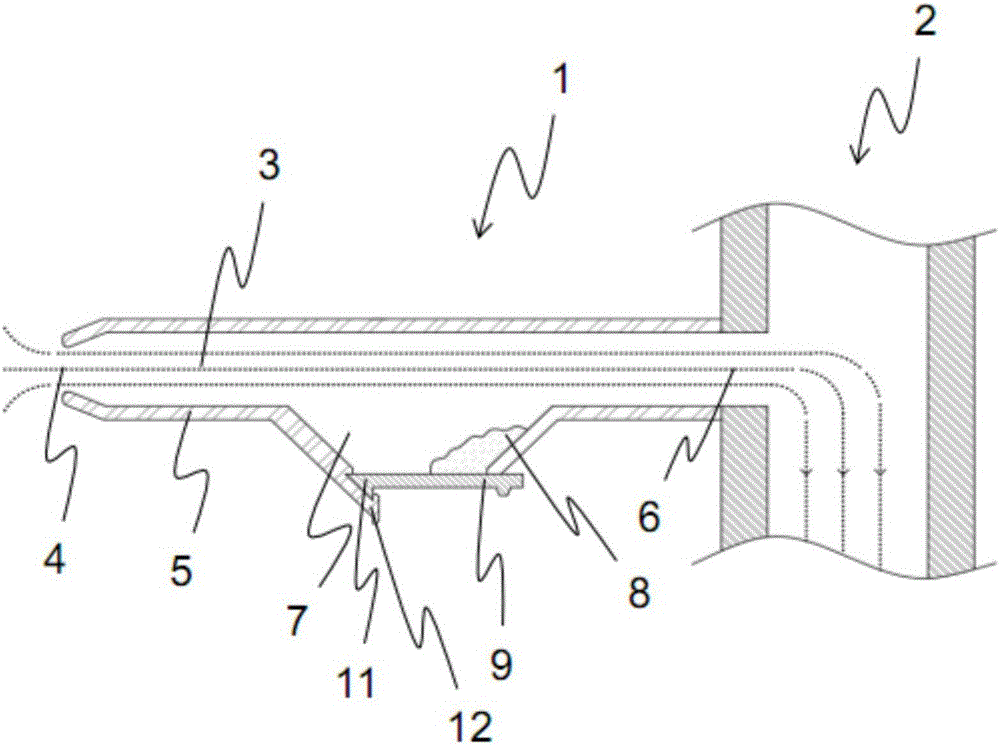

[0065] Figure 1a A longitudinal section through the suction device 1 and the partial vacuum device 2 connected to the suction device 1 is shown. A suction air flow 3 which can guide loose fibres, dirt and fibrous structures (not shown here) enters the suction device 1 through a suction opening 4 . The suction flow 3 continues along a line section 5 through a connection opening 6 into the partial vacuum device 2 . Furthermore, a dirt collection chamber 7 is shown, in the region of which the suction flow 3 is significantly reduced. Dirt 8 thus accumulates in the dirt collection chamber 7 without clogging in other areas of the pipe section 5 . Dirt collection chamber one side is designed with movable slide block 9. Slider 9 is in the working position in this figure.

[0066] After a certain amount of dirt 8 has accumulated in the dirt collection chamber 7, the suction device 1 must be cleaned. To do this move slider 9 to Figure 1b In the cleaning position shown, the dirt c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com