Automatic composite glue coating device and glue gun automatic alignment method

A technology of gluing device and composite material, applied in the direction of spraying device, liquid spraying device, etc., can solve problems such as the inability to realize spraying process, and achieve the effect of saving time and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

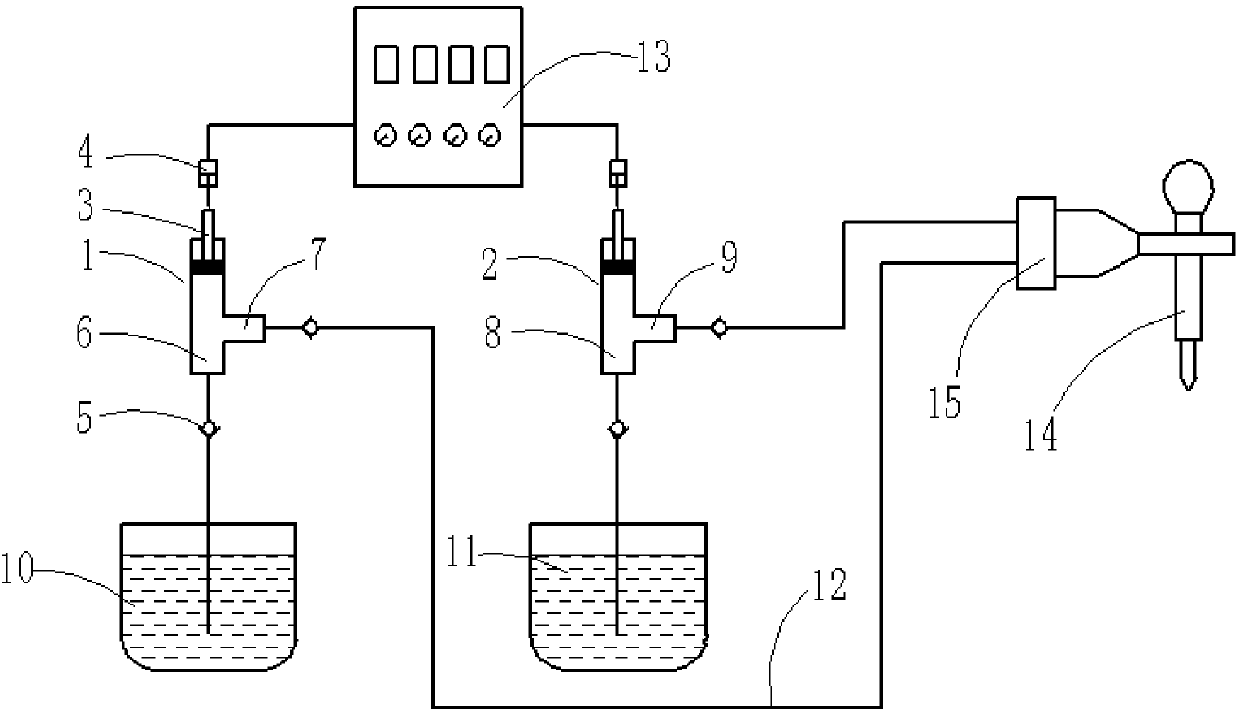

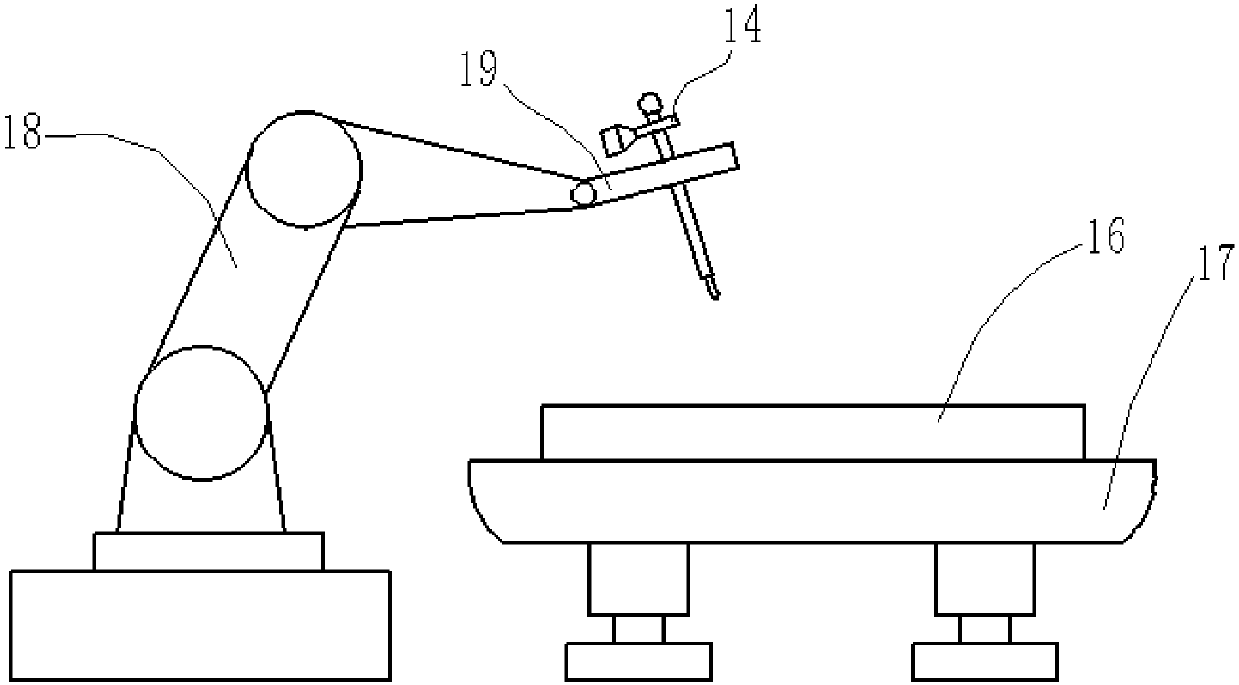

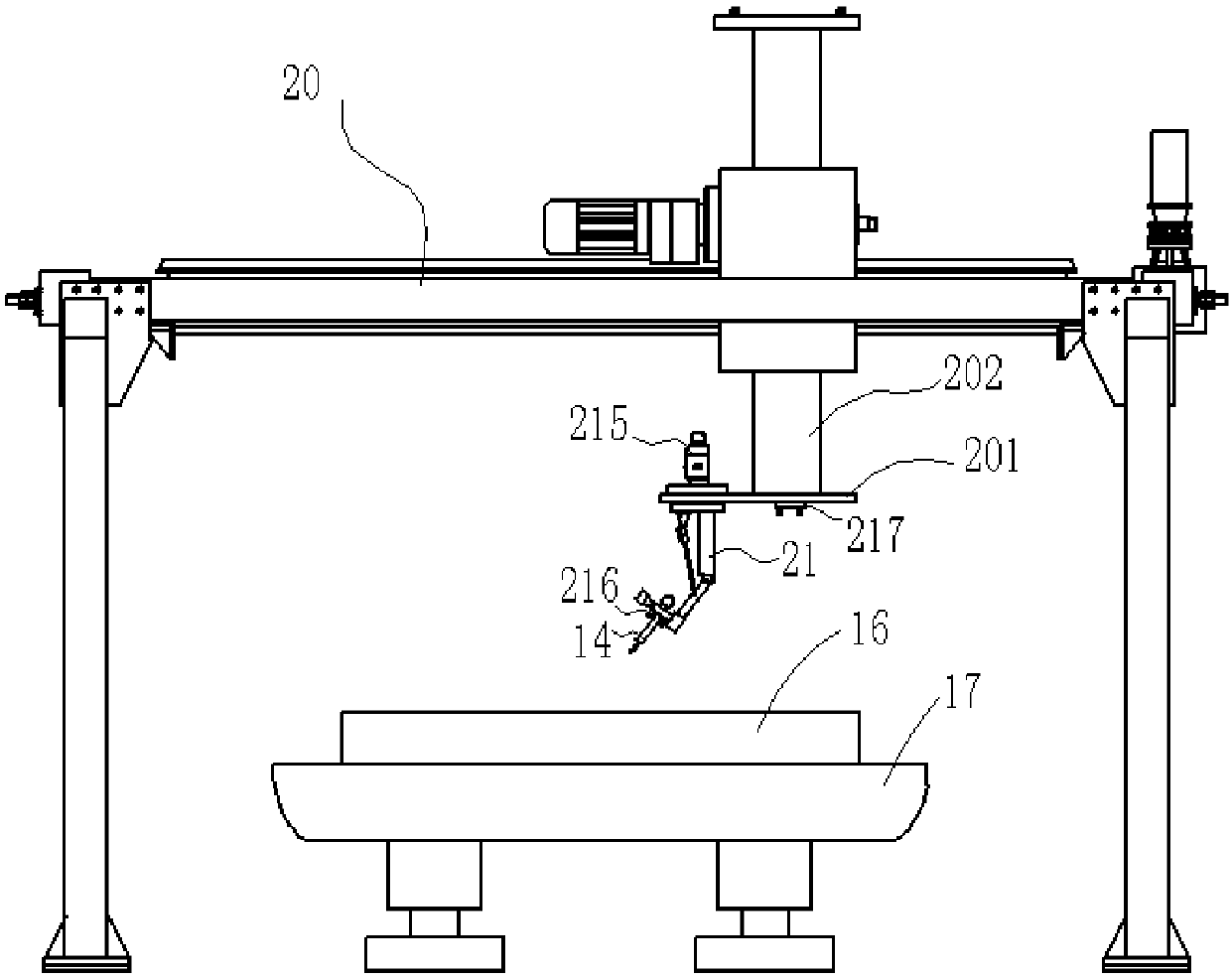

[0040] Such as Figure 1-3 As shown, an automatic gluing device for composite materials includes a first glue pump 1, a second glue pump 2, a glue gun 14, a glue gun driving device and a positioning workbench 17, and the glue gun 14 is provided with two groups Part mixing chamber 15, and has 2 input ports, the glue gun driving device includes a base and a driving system, the workpiece 16 to be glued is positioned on the positioning workbench 17, and the relative positional relationship between the positioning workbench 17 and the base of the glue gun driving device fixed.

[0041] The first glue pump 1 is a piston 3, a reciprocating cylinder 4 that drives the piston, and a container 10 filled with the first glue. The piston 3 is provided with a first passage 6 and a second passage 7 for sucking the glue. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com