Optical module automatic chip mounting and assembling machine

An optical component, automatic patch technology, applied in the direction of optical components, connecting components, mechanical equipment, etc., can solve the problems of slow efficiency, difficult to control product position positioning, poor stability and consistency, etc., to improve product quality, improve Accuracy and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

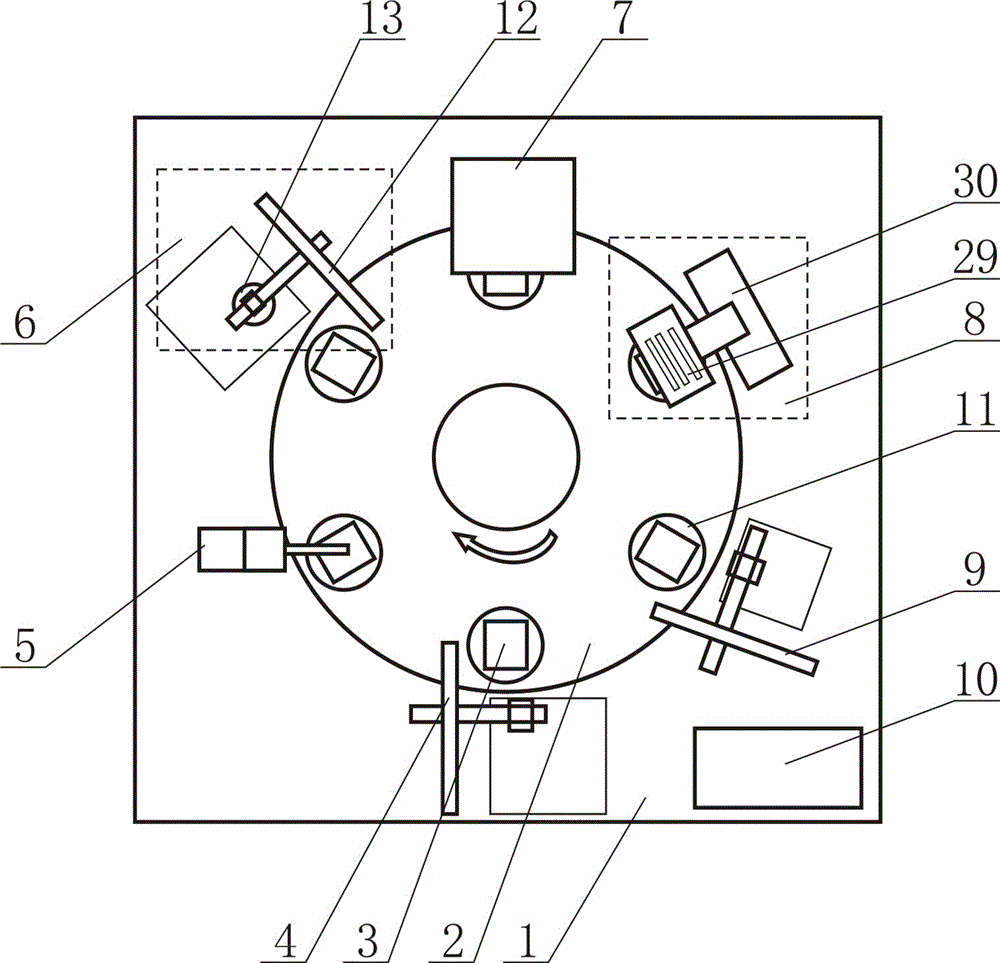

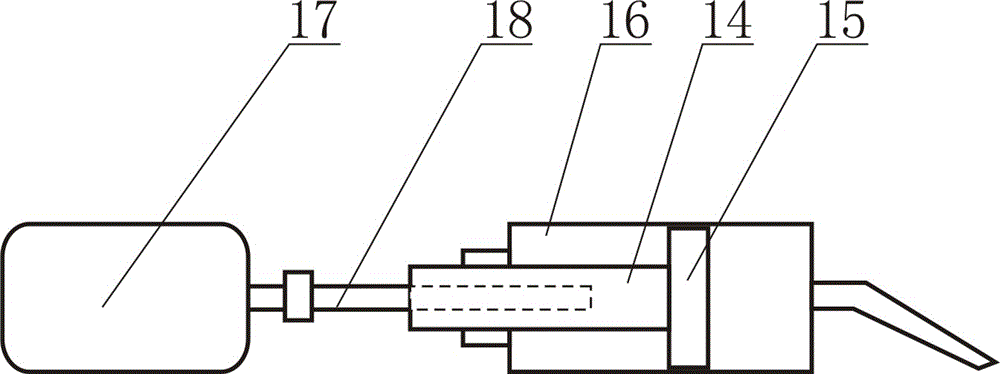

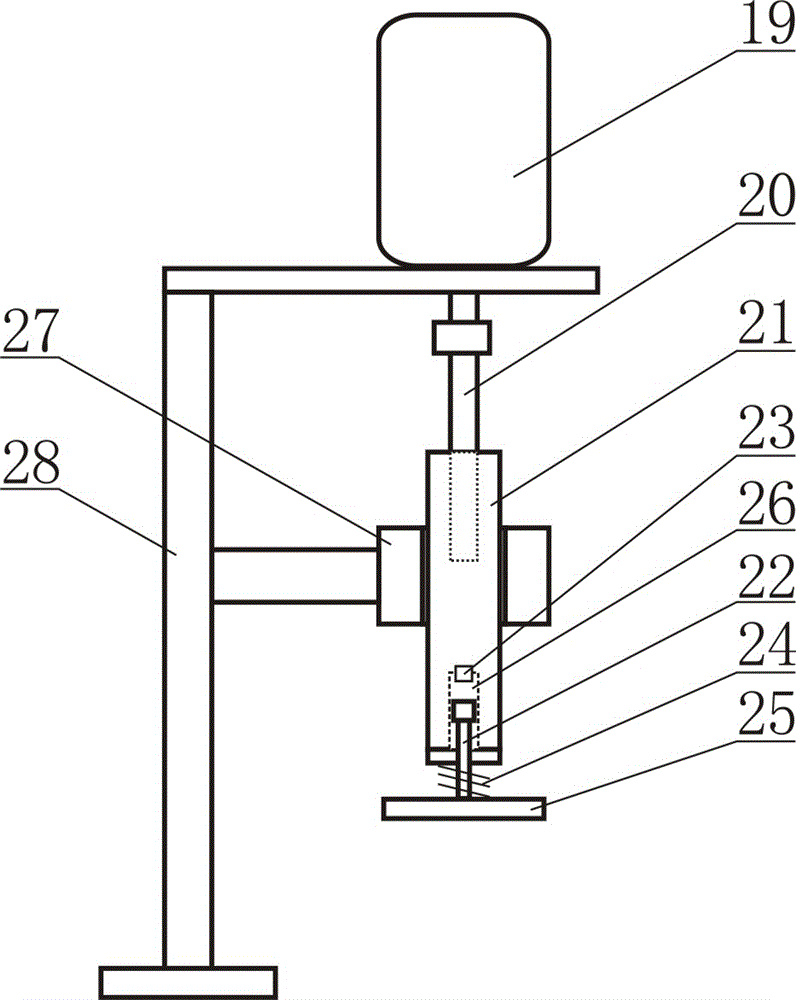

[0017] Such as figure 1 As shown, the automatic patch assembly machine for optical components includes a workbench 1 and an intermittent turntable 2 arranged on the workbench 1. On the intermittent turntable 2, there are six jigs 3 evenly distributed along its periphery. A glass prism feeding manipulator 4, a dispensing device 5, a filter feeding device 6, a patch pressing device 7, UV curing device 8, finished product take-out manipulator 9 and controller 10; under the control of controller 10, glass prism feeding manipulator 4 puts the glass prism into the fixture 3 on the intermittent turntable 2, and the intermittent turntable 2 rotates One station, the glass prism in the tooling fixture 3 is transferred to the dispensing station, the glue dispensing device 5 injects glue onto the glass prism in the tooling fixture 3, the intermittent turntable 2 rotates a station, and the glue in the tooling fixture 3 The glass prism is transferred to the filter feeding station. The filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com