Purging sealing gun for seam of color plate

A technology for sealing guns and color steel plates, which is used in building maintenance, construction, building construction, etc., can solve problems such as falling off, instability, and low efficiency, and achieve the effect of increasing reliability and avoiding excessive running of screw rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

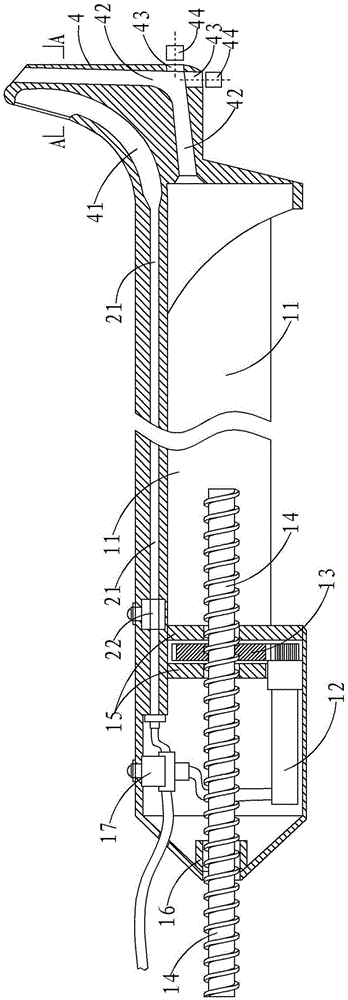

[0027] The following is attached Figure 1-5 The present invention is further described in detail.

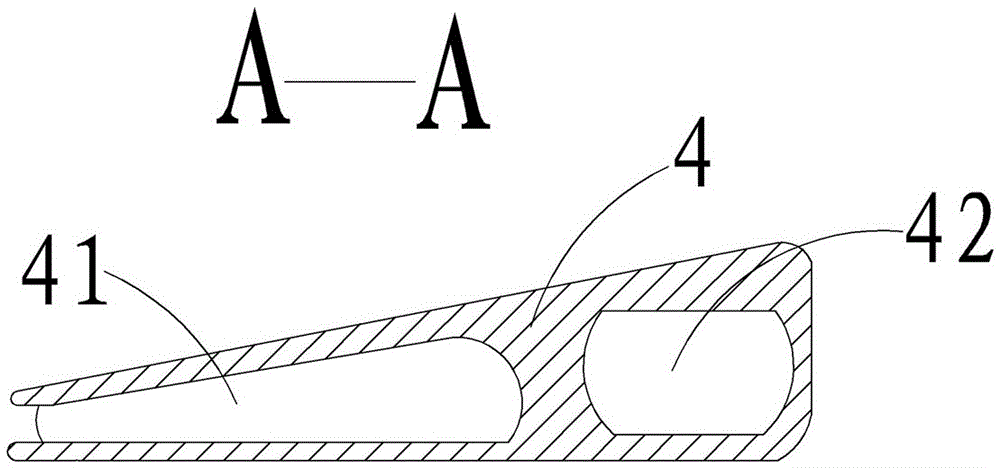

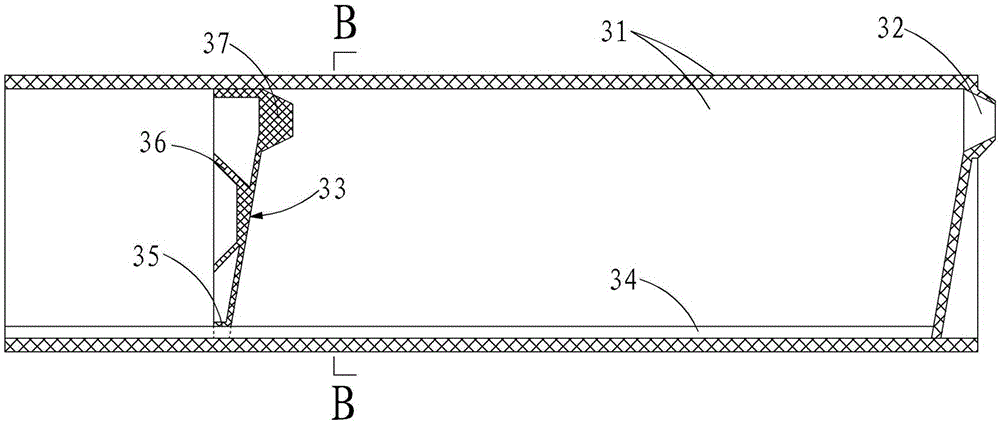

[0028] as attached Figure 1-5 Shown, a kind of color steel seam purging sealing gun, it comprises gun barrel main body, is arranged on the gun nozzle 4 of one end of gun barrel main body, is arranged on the driving mechanism inside the other end of gun barrel main body and uses with the gun barrel main body Rubber hose; the gun barrel body includes a tube body 11 with an opening on the side wall and an air duct 21 arranged axially along the tube body 11;

[0029] The drive mechanism includes a pneumatic motor 12, a drive gear 13 meshed with the drive shaft of the pneumatic motor 12, and a threaded screw 14 threaded through the center of the drive gear 13; the drive gear 13 is arranged on the pipe body through two splints 15 11, the screw rod 14 is arranged along the axial direction of the pipe body 11, the pneumatic motor 12 is fixedly arranged on the inner wall of the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com