A suction device

A suction device and shooting device technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as scrapping, product position error, lack of positioning detection of suction cups, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

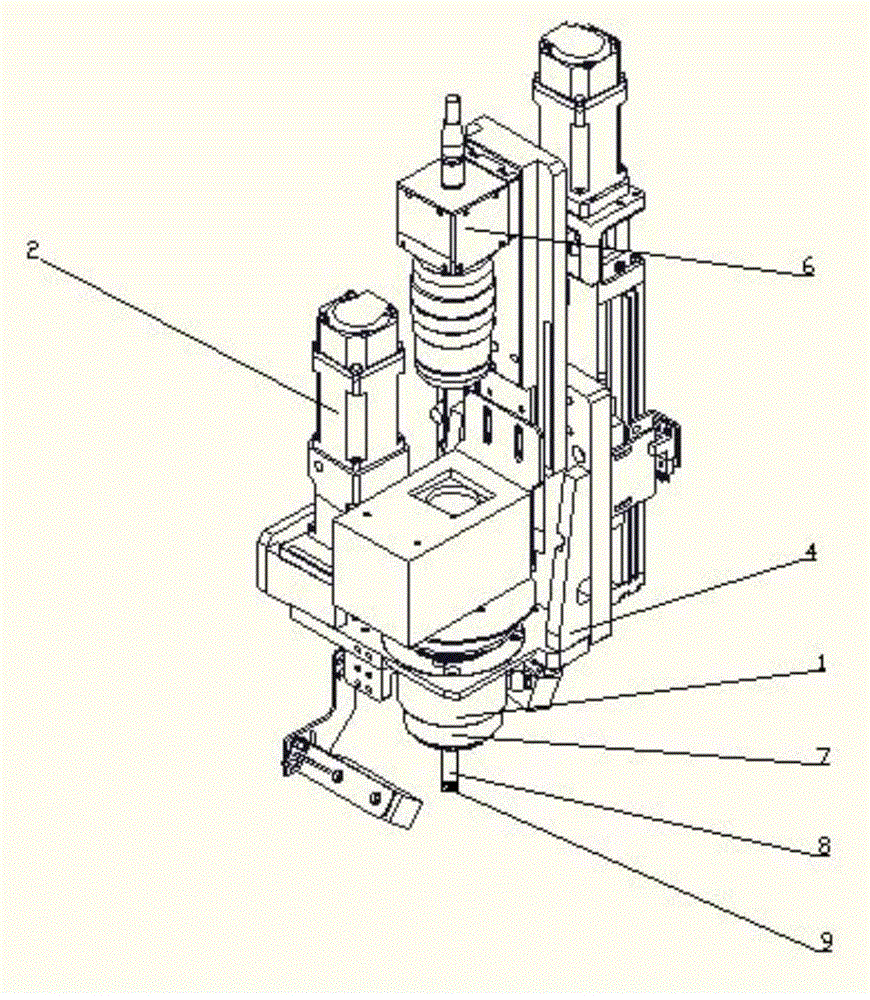

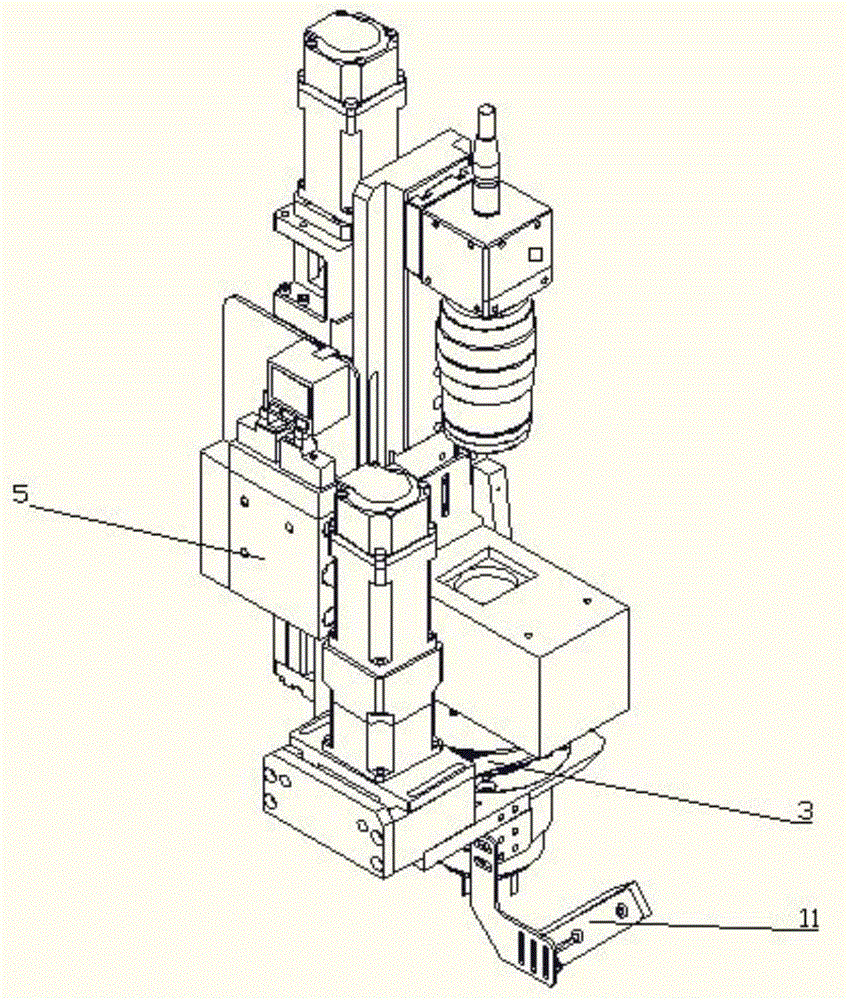

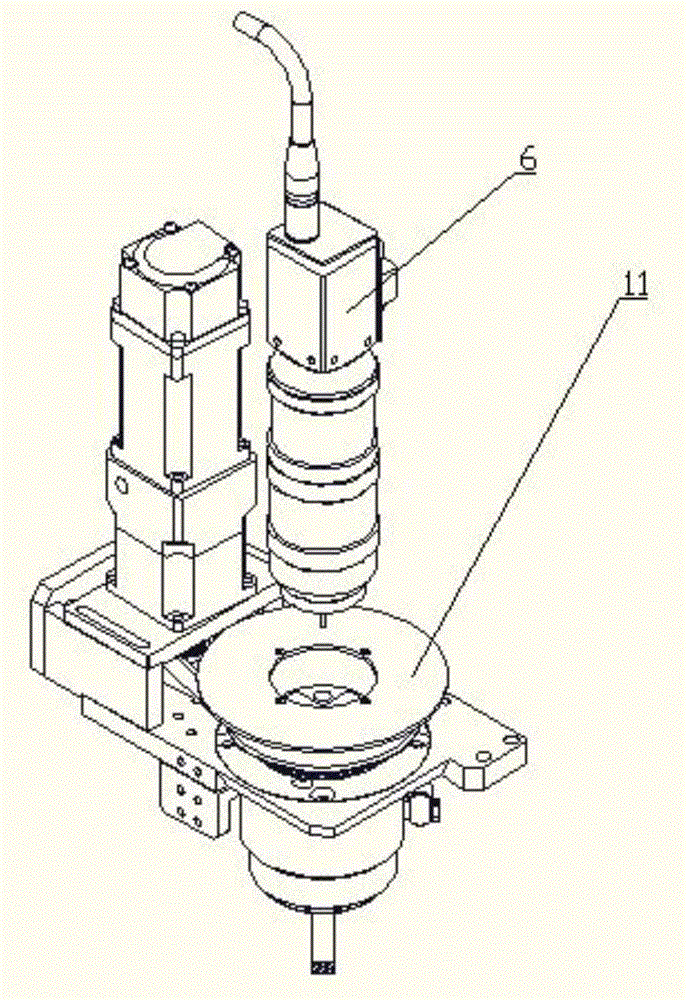

[0030] Such as figure 1 , 2 , A suction device shown in 3 and 4 is characterized in that it includes a suction head assembly 1, a photographing device 6, a belt 3, and a fixed table 4, and the suction head assembly 1 is provided with a suction head 7 and a vacuum negative pressure device 5. The suction head assembly 1 and the photographing device 6 are fixed on the fixed table 4, the belt 3 is fixed on the suction head assembly 1, the vacuum negative pressure device 5 is connected with the suction The head assembly 1 is connected, and the photographing device 6 is located on the upper part of the suction head assembly 1 .

[0031] Further, the suction head assembly 1 is connected, and the motor 2 can drive the suction head assembly 1 to rotate through the belt 3 .

[0032] Further, the photographing device 6 is coaxial and concentric with the suction head assembly 1 .

[0033] Further, the suction head assembly 1 includes a suction head 7, and the center of the suction head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com