Electronic element guide rail type glue dispensing equipment for LED lamp production

A technology of electronic components and LED lights, which is applied in coatings and devices for coating liquid on the surface, etc. It can solve the problems of poor dispensing effect, slow dispensing speed, cumbersome operation, etc., to prolong the service life and ensure the quality , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

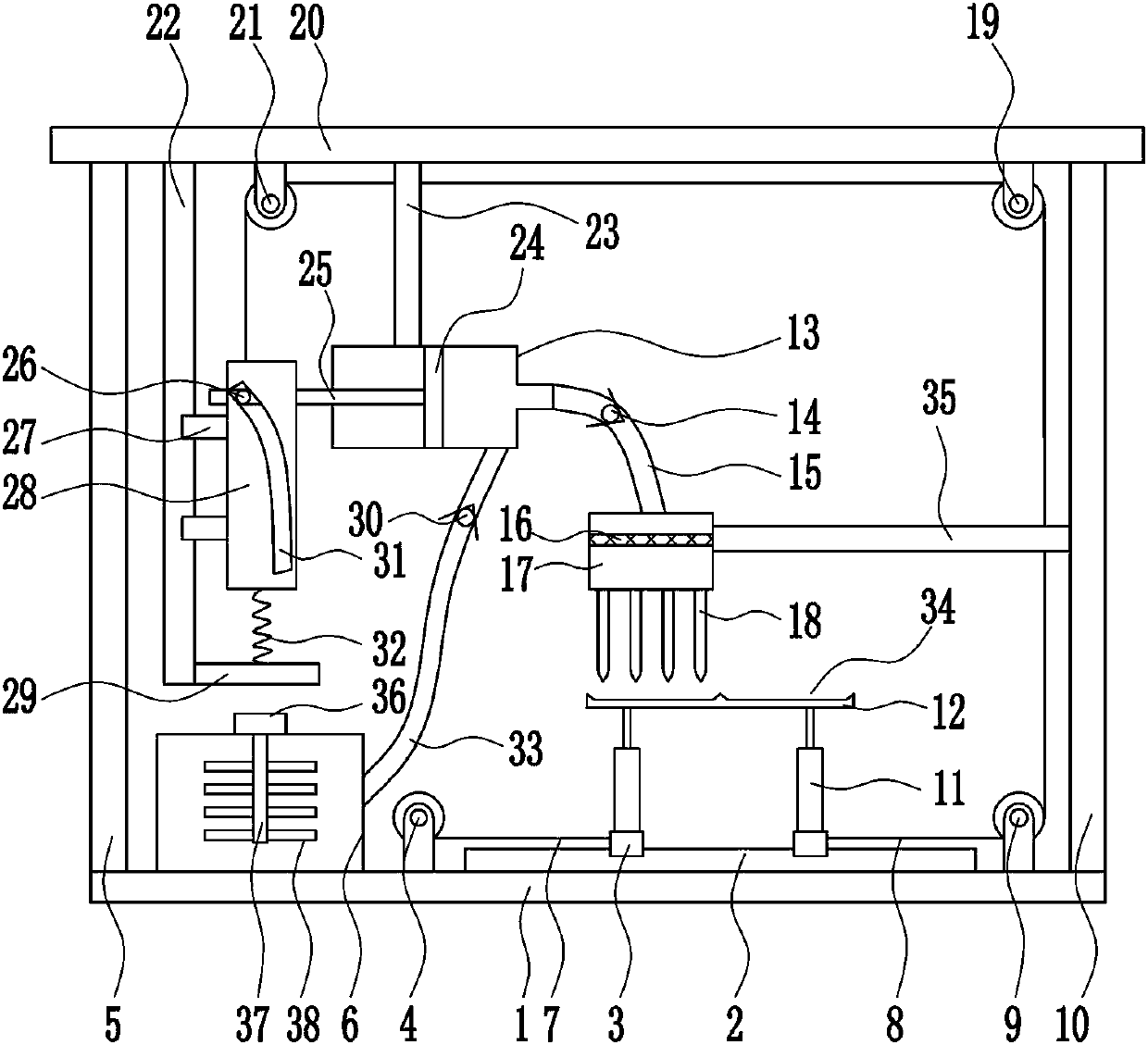

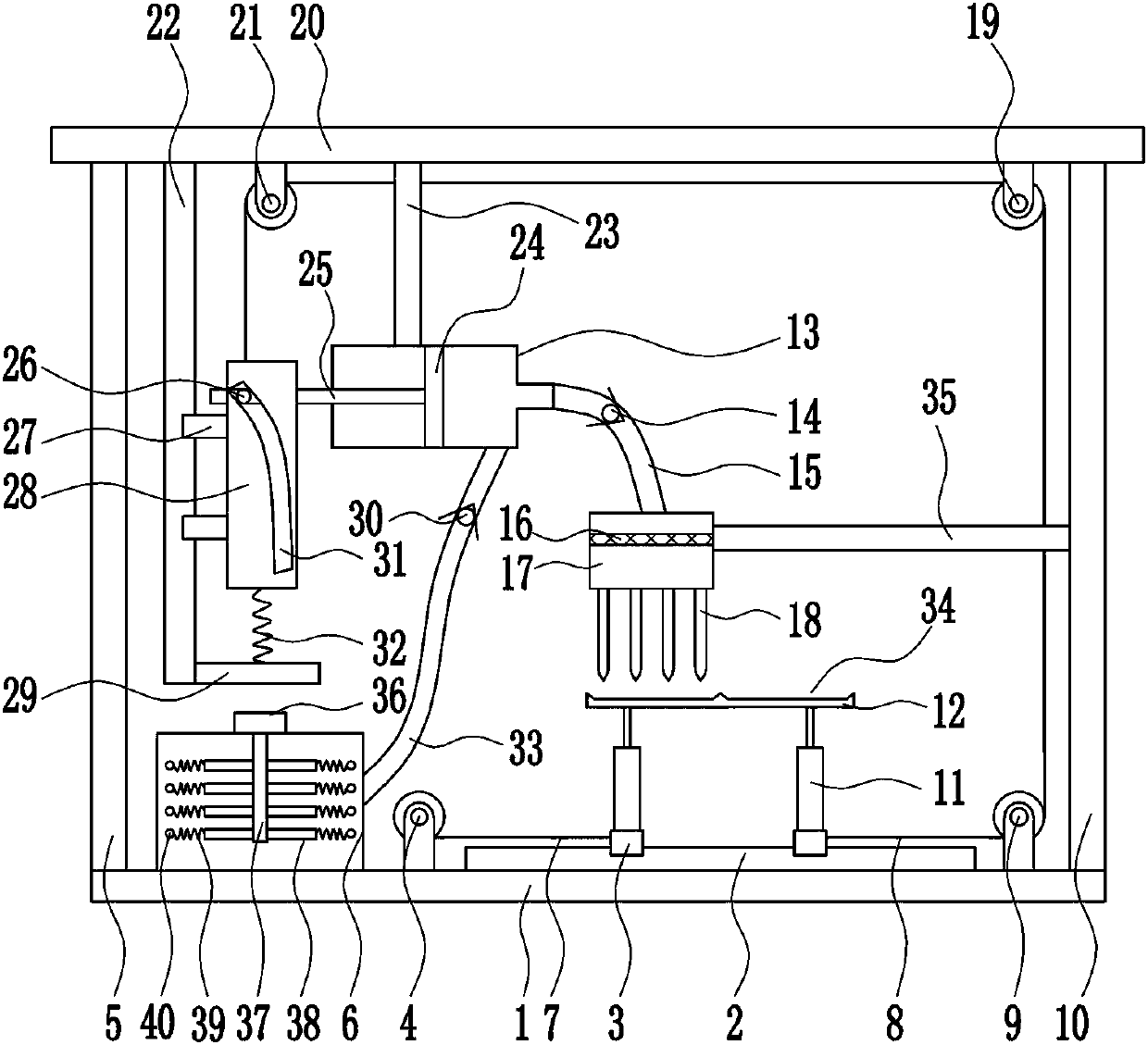

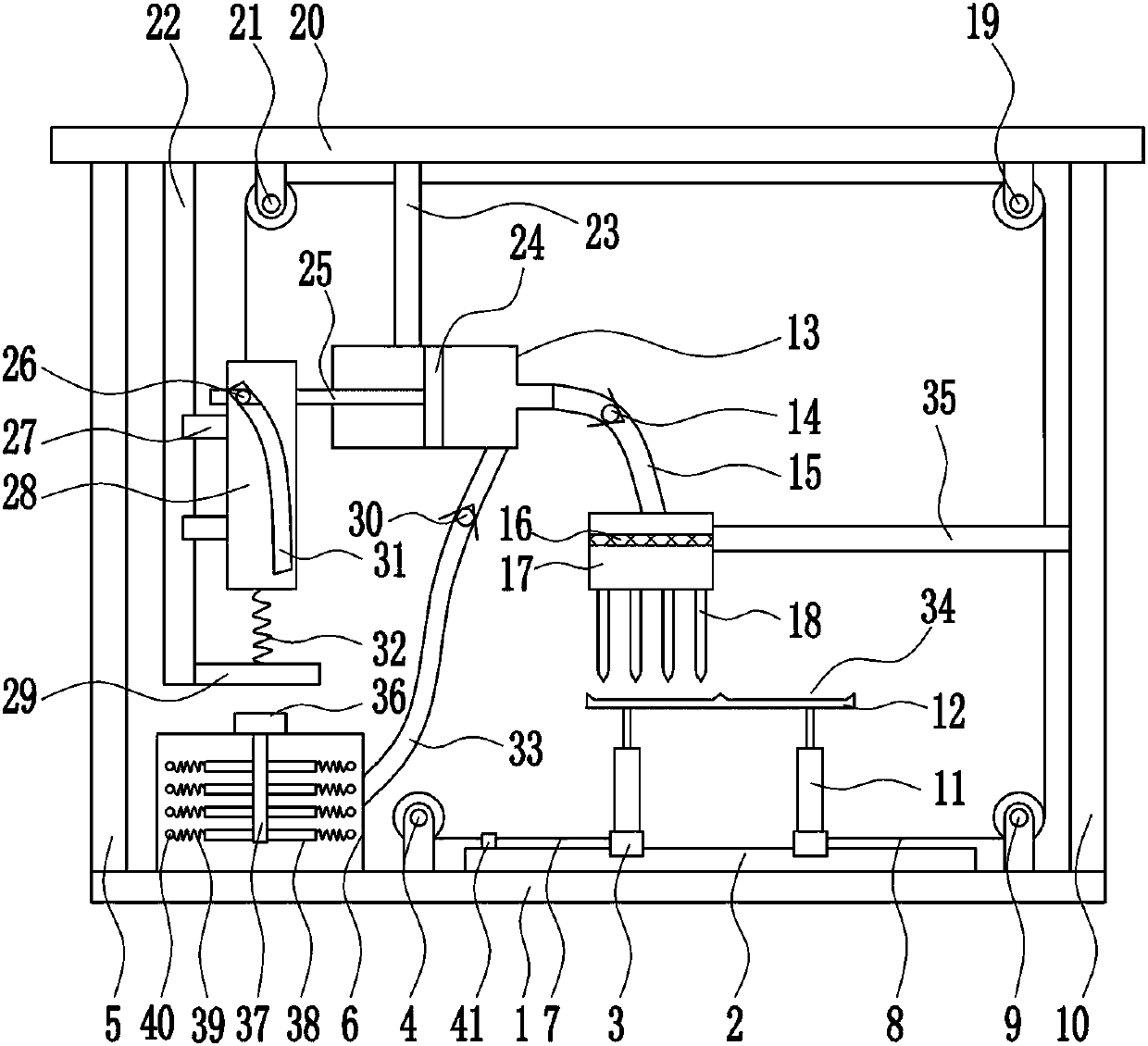

[0035] A guide rail type dispensing equipment for electronic components used in the production of LED lamps, such as Figure 1-5 As shown, it includes a bottom plate 1, a first slide rail 2, a first slider 3, an electric reel 4, a left frame 5, a storage tank 6, a first pull wire 7, a second pull wire 8, and a first fixed pulley 9 , right frame 10, electric push rod 11, placement plate 12, cylinder body 13, first one-way valve 14, first hose 15, mesh plate 16, dispensing tank 17, dispensing head 18, second fixed pulley 19 , top plate 20, the third fixed pulley 21, the second slide rail 22, the first connecting rod 23, the piston 24, the first push rod 25, the sliding shaft 26, the second slider 27, the moving block 28, the fixed plate 29, the first Two one-way valves 30, the first spring 32, the second hose 33 and the second connecting rod 35, the left side frame 5 is welded on the left side of the bottom plate 1, and the left side of the bottom plate 1 is connected with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com