Dispensing equipment for floodlight production

A technology for lighting and dispensing, which is applied to devices and coatings that apply liquid to the surface, which can solve the problem of low dispensing quality, difficulty in controlling the point contest and dispensing position, and inability to control the amount of dispensing and dispensing. Dispensing position and other issues to achieve the effect of improving the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

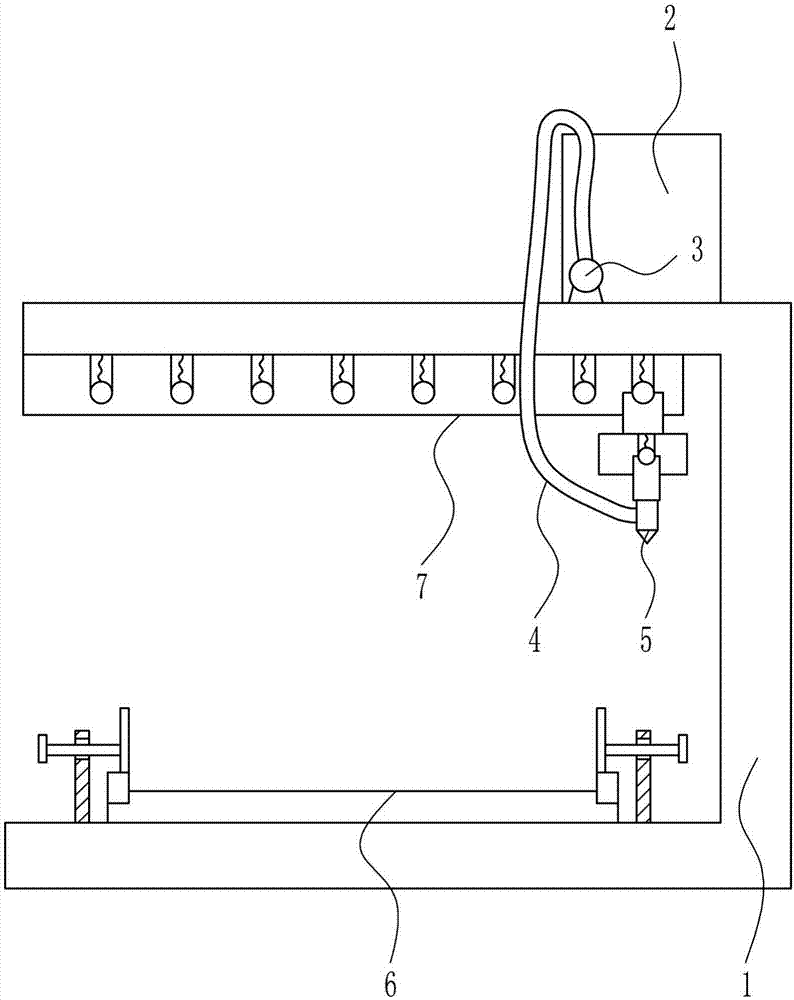

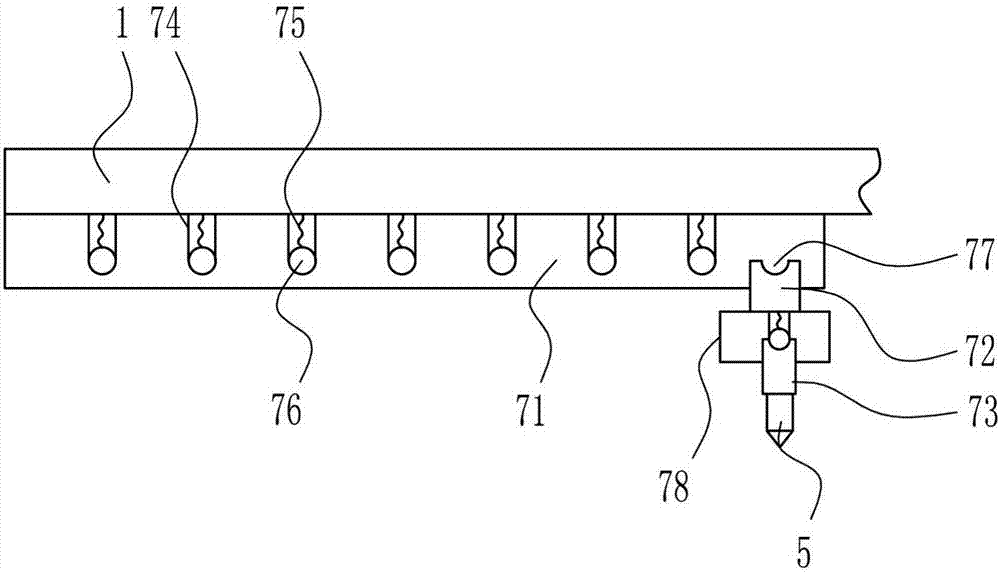

[0030] A kind of dispensing equipment for lighting production, such as Figure 1-6 As shown, it includes a mounting frame 1, a material storage box 2, a booster pump 3, a hose 4, a dispensing head 5, a fixing device 6 and a position adjustment device 7, and the bottom of the mounting frame 1 is provided with a fixing device 6, and the mounting frame 1 There is a material storage box 2 on the right side of the top, a pressure pump 3 is provided on the left side of the inner bottom of the material storage box 2, a hose 4 is connected to the pressure pump 3, and a position adjustment device 7 is installed on the top of the installation frame 1. A dispensing head 5 is provided at the bottom of the adjusting device 7 , and the hose 4 passes through the material storage box 2 and is connected with the dispensing head 5 .

Embodiment 2

[0032] A kind of dispensing equipment for lighting production, such as Figure 1-6 As shown, it includes a mounting frame 1, a material storage box 2, a booster pump 3, a hose 4, a dispensing head 5, a fixing device 6 and a position adjustment device 7, and the bottom of the mounting frame 1 is provided with a fixing device 6, and the mounting frame 1 There is a material storage box 2 on the right side of the top, a pressure pump 3 is provided on the left side of the inner bottom of the material storage box 2, a hose 4 is connected to the pressure pump 3, and a position adjustment device 7 is installed on the top of the installation frame 1. A dispensing head 5 is provided at the bottom of the adjusting device 7 , and the hose 4 passes through the material storage box 2 and is connected with the dispensing head 5 .

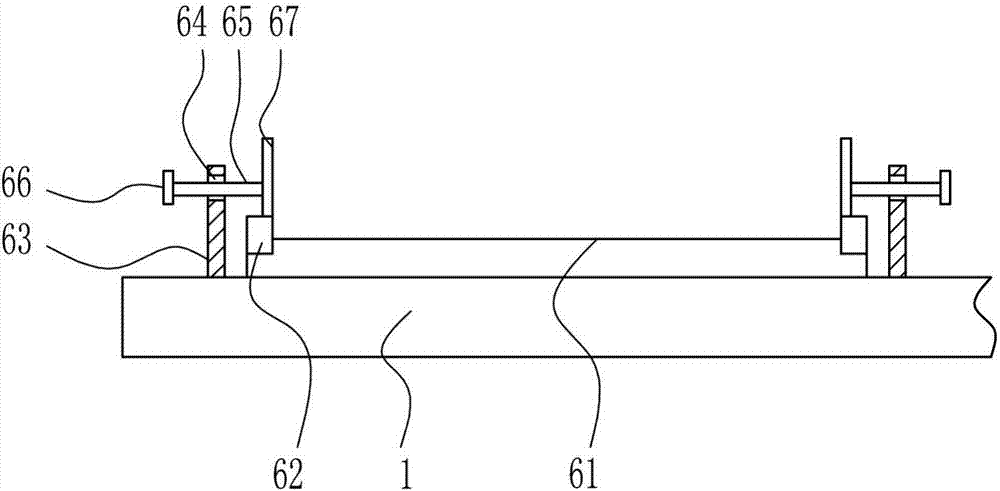

[0033] The fixing device 6 includes a first slide rail 61, a first slide block 62, a vertical plate 63, a bolt 65, a runner 66 and a pressing plate 67. The bottom...

Embodiment 3

[0035] A kind of dispensing equipment for lighting production, such as Figure 1-6 As shown, it includes a mounting frame 1, a material storage box 2, a booster pump 3, a hose 4, a dispensing head 5, a fixing device 6 and a position adjustment device 7, and the bottom of the mounting frame 1 is provided with a fixing device 6, and the mounting frame 1 There is a material storage box 2 on the right side of the top, a pressure pump 3 is provided on the left side of the inner bottom of the material storage box 2, a hose 4 is connected to the pressure pump 3, and a position adjustment device 7 is installed on the top of the installation frame 1. A dispensing head 5 is provided at the bottom of the adjusting device 7 , and the hose 4 passes through the material storage box 2 and is connected with the dispensing head 5 .

[0036] The fixing device 6 includes a first slide rail 61, a first slide block 62, a vertical plate 63, a bolt 65, a runner 66 and a pressing plate 67. The bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com