Milling and turning composite electric spindle assembly and corresponding numerical control machining equipment

An electric spindle and spindle technology, applied in the field of CNC machine tools, can solve problems such as high maintenance or maintenance costs, affecting continuous production, and reducing service life, and achieving reduced maintenance or maintenance costs, good protection effect, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

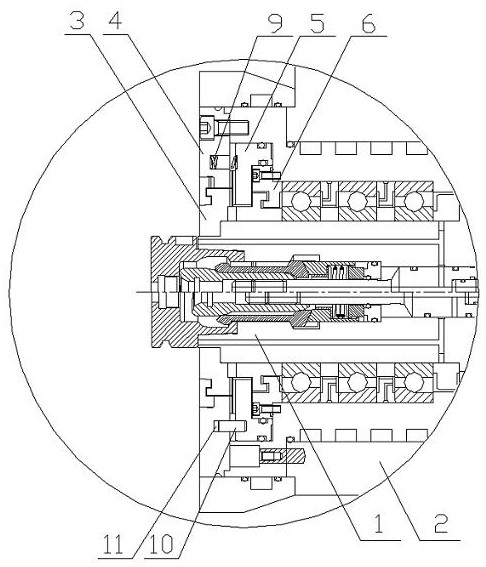

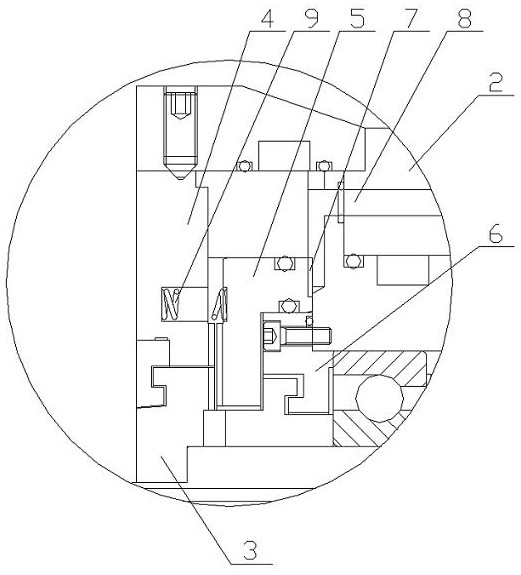

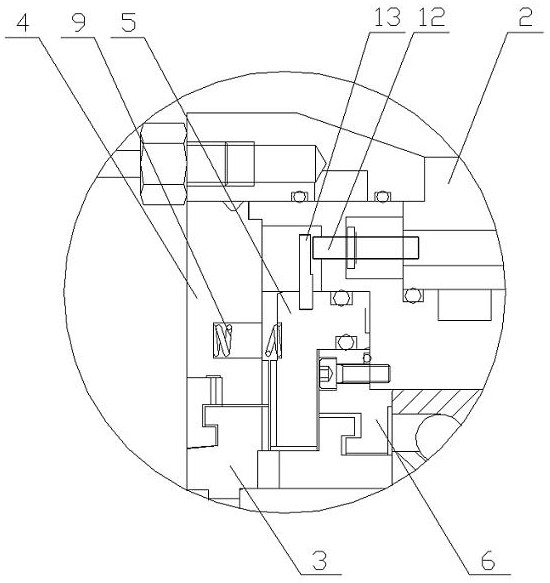

[0032] see Figure 1 to Figure 7, the present invention discloses a milling and turning composite electric spindle assembly, which includes a spindle 1 and a spindle housing (components containing the housing) 2, and also includes a spindle brake mechanism, which is arranged on the spindle The front end of the front end includes a rotating toothed plate 3, a positioning toothed plate 4 and a moving toothed plate 5. The rotating toothed plate 3, the positioning toothed plate 4 and the moving toothed plate 5 are all annular, and their central axes are all located on the axis of the main shaft. A three-gear mechanism is formed. The rotating toothed disc is coaxially fixed on the front end of the main shaft and rotates synchronously with the main shaft. The positioning toothed disc is coaxially sleeved on the outside of the rotating toothed The housings are fixed together, and there is a rotation gap between the inner circle and the outer circle of the rotating toothed disc. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com