Patents

Literature

31results about How to "High braking precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

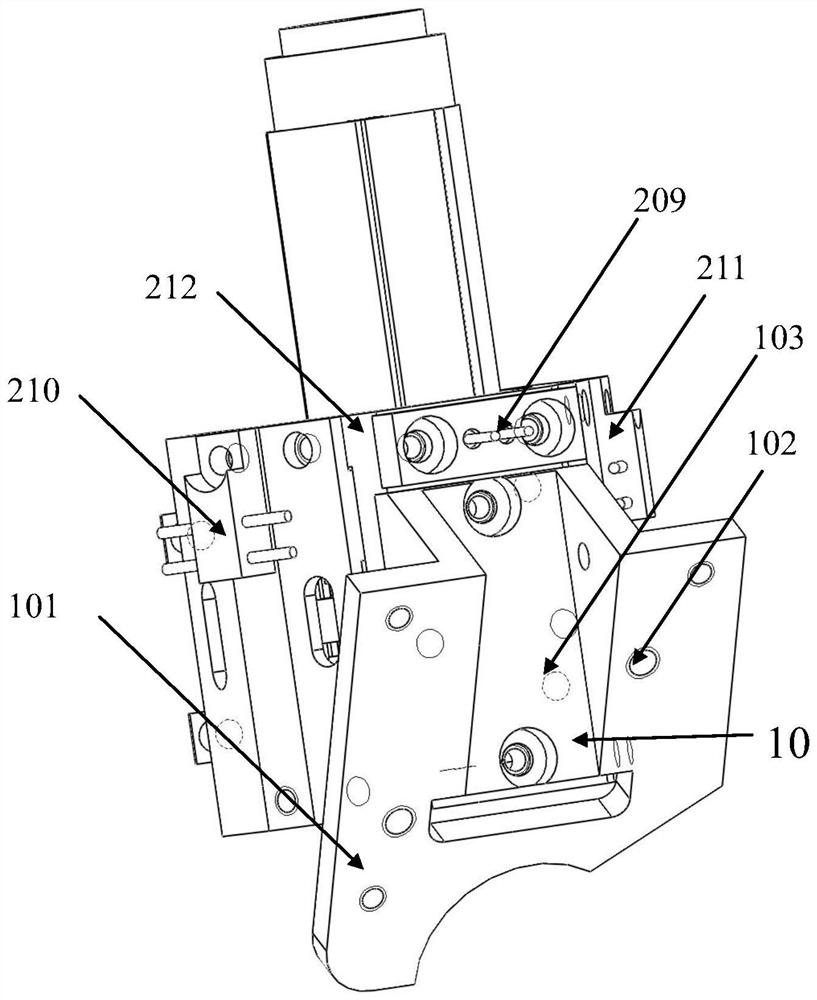

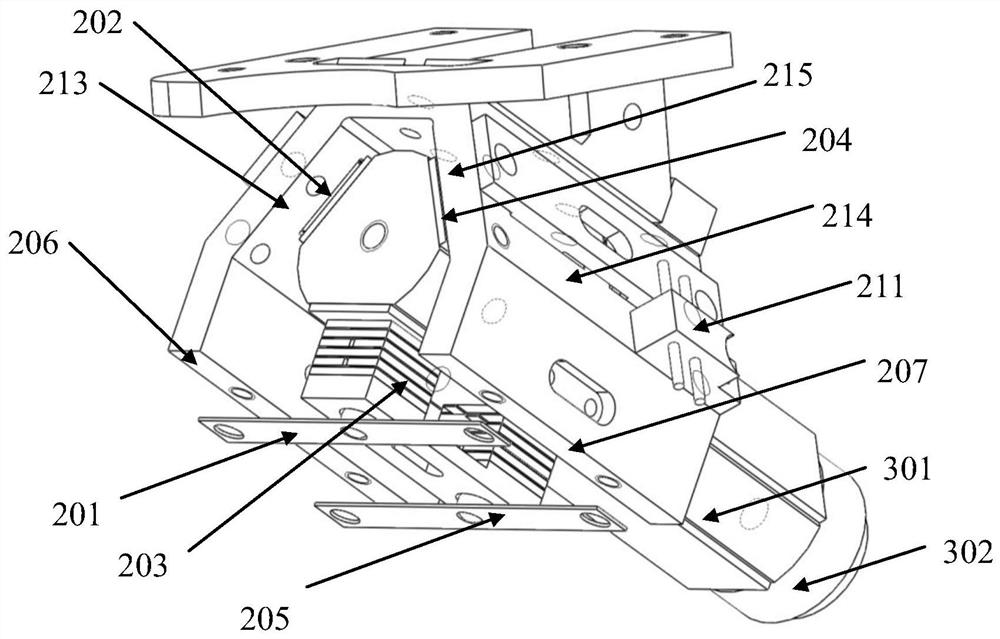

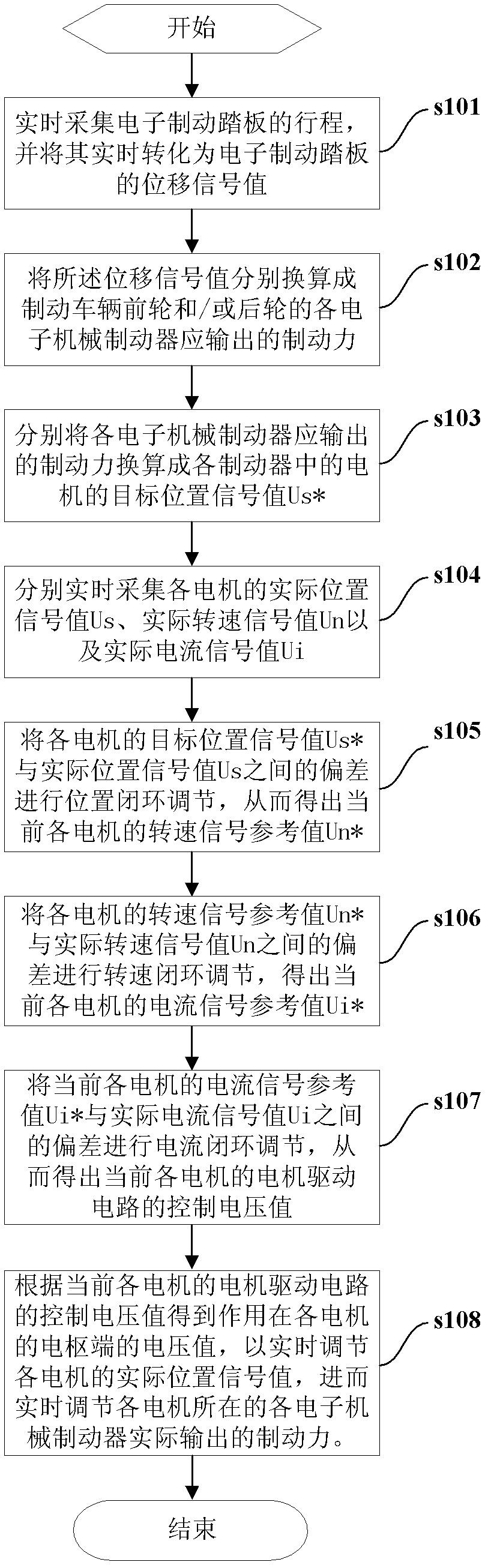

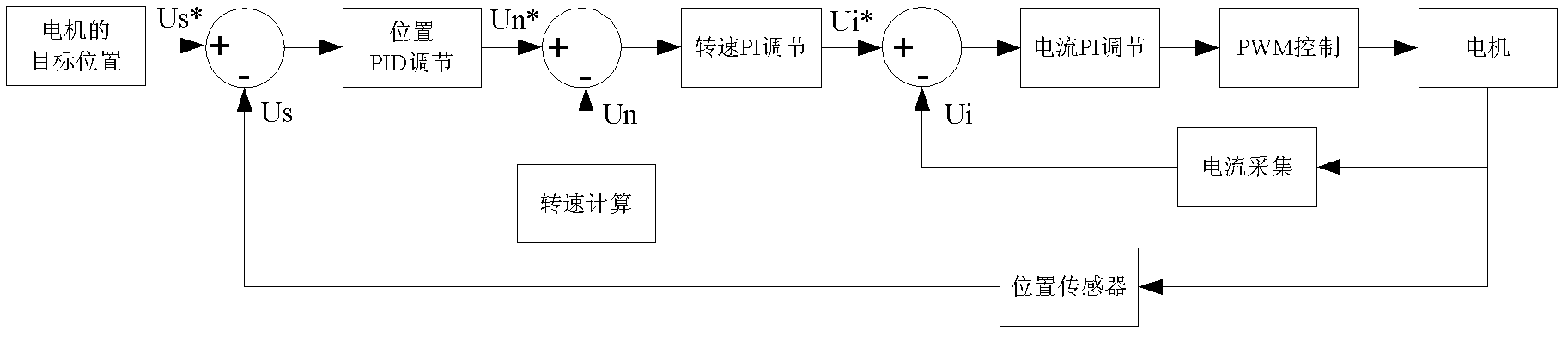

Brake force real-time adjusting method based on brake-by-wire system and adjusting device

ActiveCN102582600AHigh braking precisionBrake force adjustmentElectrodynamic brake systemsBraking systemsAutomotive engineeringBrake force

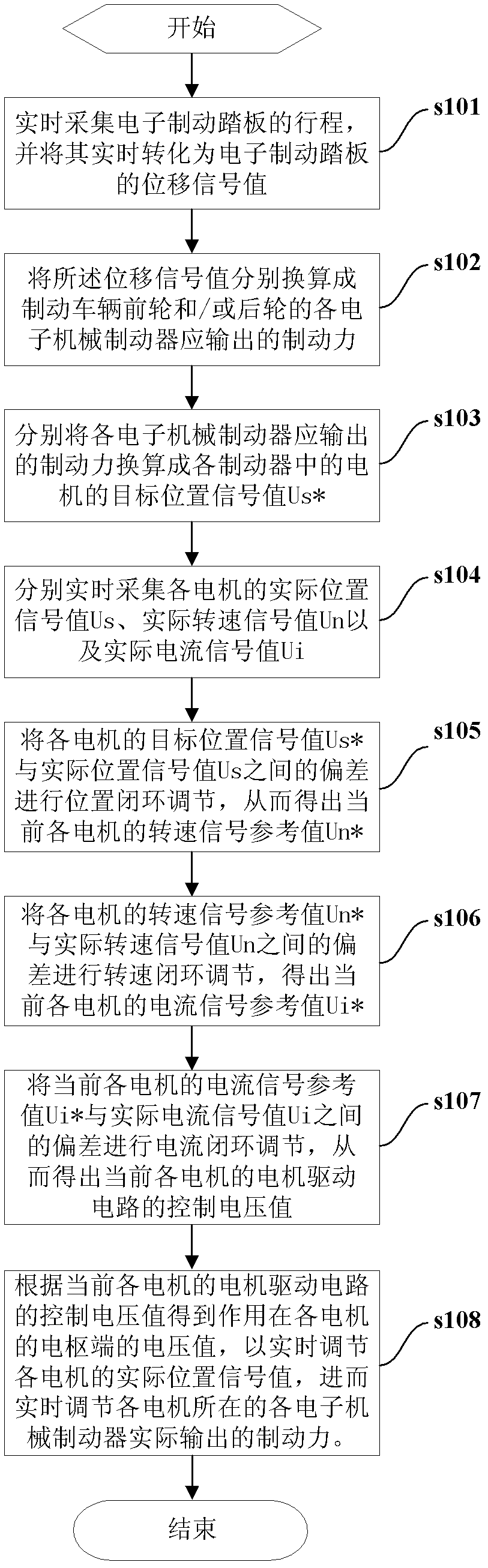

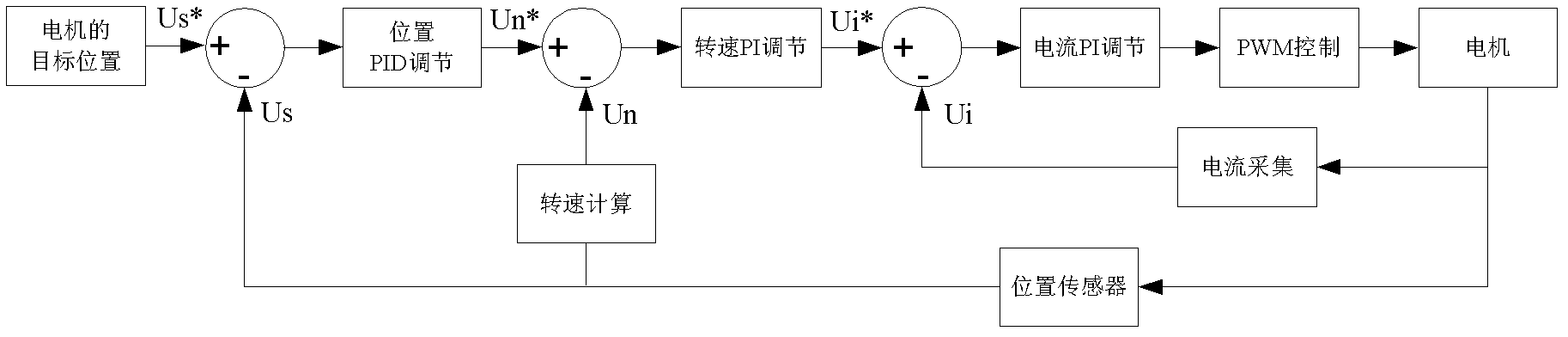

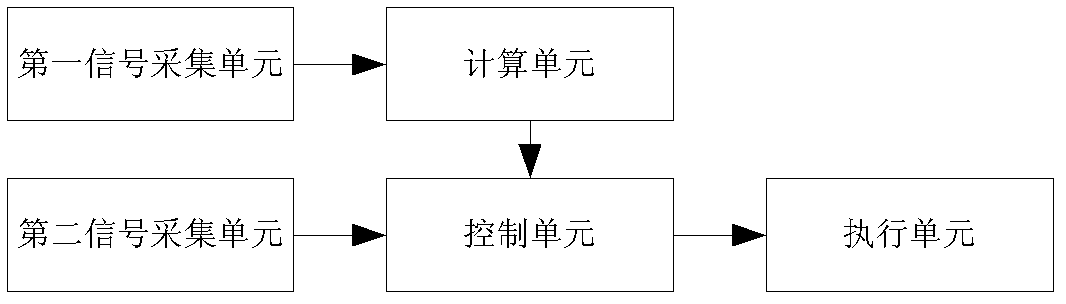

The invention provides a brake force real-time adjusting method based on a brake-by-wire system. The brake force real-time adjusting method comprises following steps: respectively obtaining objective position signal values of motors in various electronic and mechanical brakes of front wheels and / or rear wheels of a brake vehicle according to strokes of electronic brake pedals; respectively acquiring actual position signal values, actual rotation speed signal values and actual current signal values of the motors in real time; and respectively realizing real-time closed-loop control for positions, rotation speeds and current of the motors according to deviation between the objective position signal values and the actual position signal values of the motors, the actual rotation speed signal values and the actual current signal values, and accordingly adjusting actually outputted brake force of the electronic and mechanical brakes with the motors in real time. Correspondingly, the invention provides a brake force real-time adjusting device. The brake force real-time adjusting method and the adjusting device can suppress fluctuation generated when brake force is adjusted in real time in the prior art, stability of the brake-by-wire system is improved, and a braking effect is good.

Owner:CHERY AUTOMOBILE CO LTD

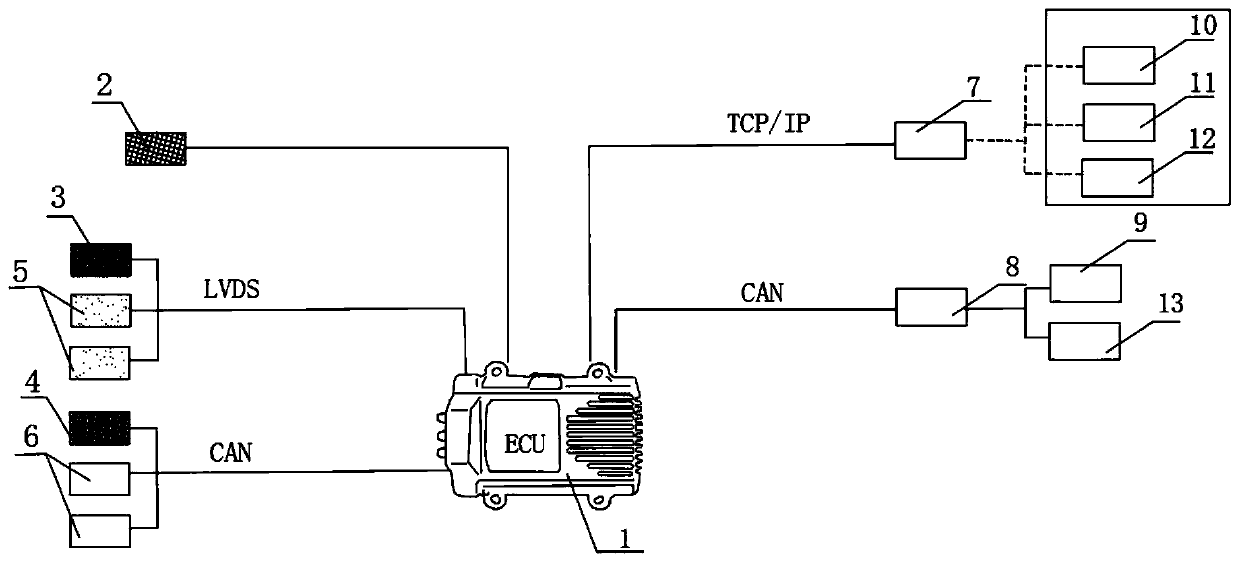

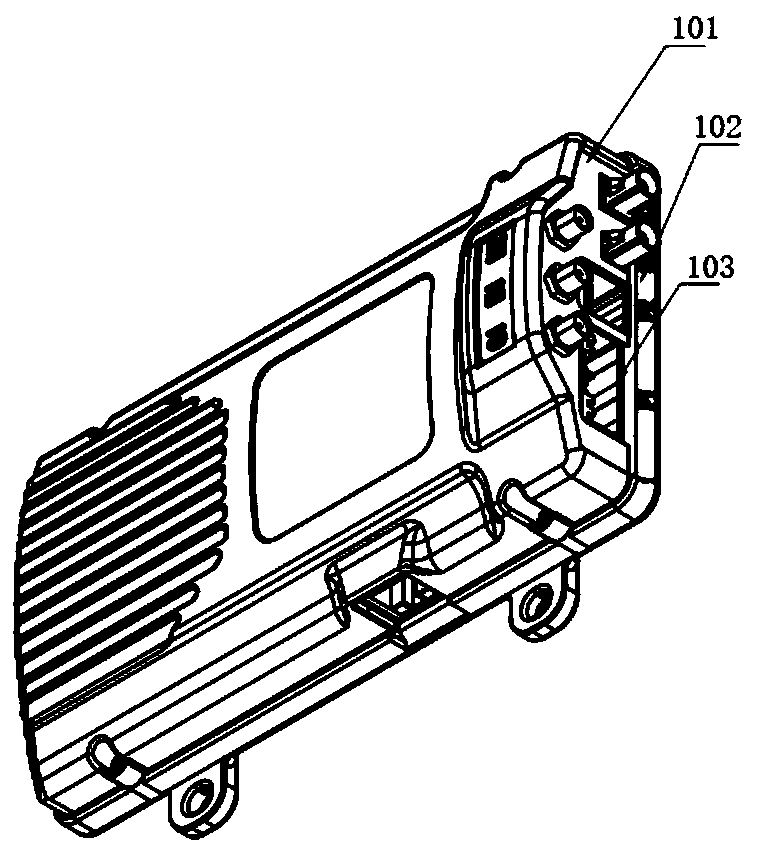

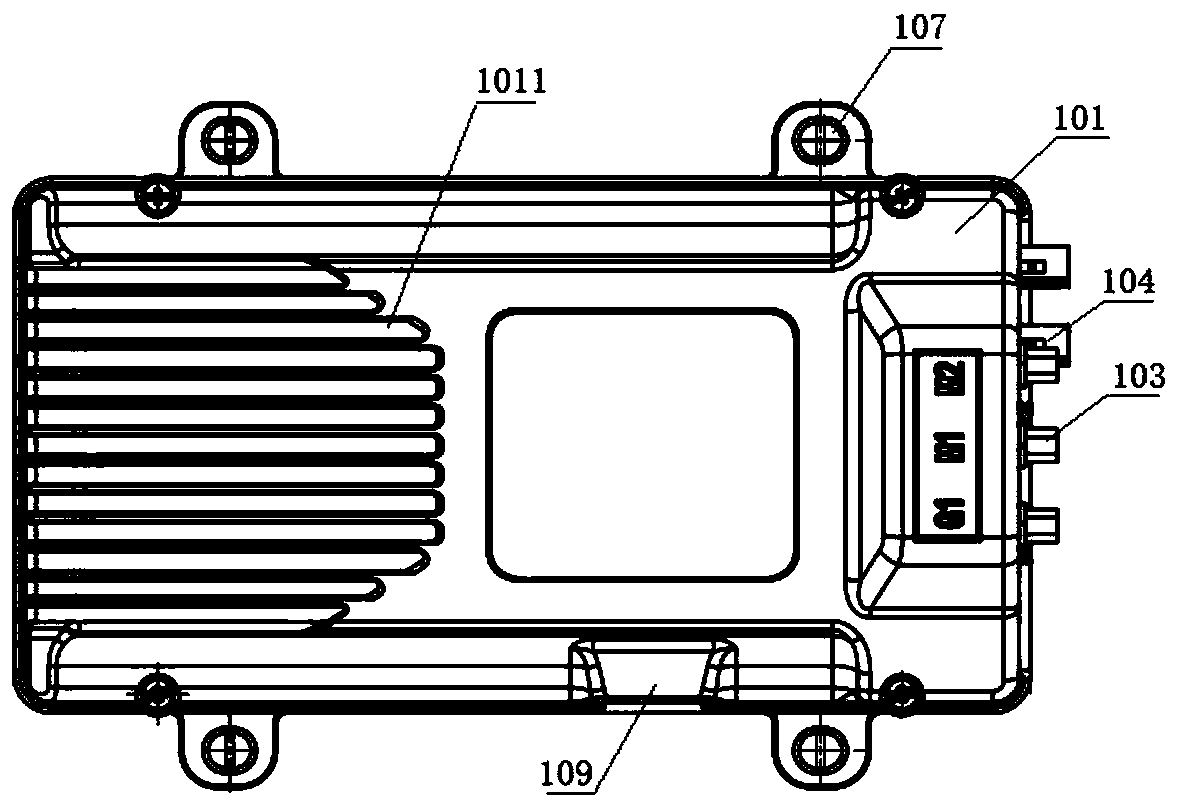

Collision mitigation system and method for bus

PendingCN111169444AAssurance controlAutomatic controlBraking action transmissionAutomatic initiationsDriver/operatorBlind zone

The invention discloses a collision relieving system and method for a bus, and relates to the technical field of automobile collision prevention. The system comprises a first millimeter-wave radar, asecond millimeter-wave radar, a display screen prompter, a first front-facing camera, a second front-facing camera and a fusion host. The first millimeter-wave radar and the second millimeter-wave radar are respectively used for acquiring reflection radar waves of a lane right ahead and lanes on two sides of a vehicle in real time for the image sensor to perform data information identification, and the first front camera and the second front camera are respectively used for acquiring image data of identified targets of the lane right ahead and the lanes on two sides. According to the invention, a driver is ensured not to correctly operate under special conditions, and meanwhile, the control of the automobile is automatically realized, so that the safety of the automobile and the driver isprotected, the accuracy and high efficiency of collision obstacles possibly existing in front are ensured, the recognition blind area is smaller, and the automatic emergency collision braking accuracyis higher.

Owner:上海峰华人工智能科技有限公司

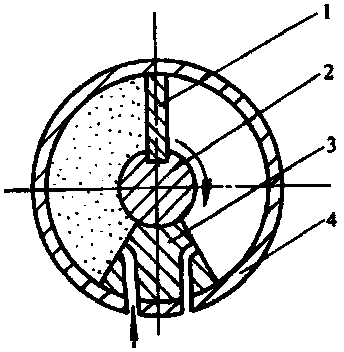

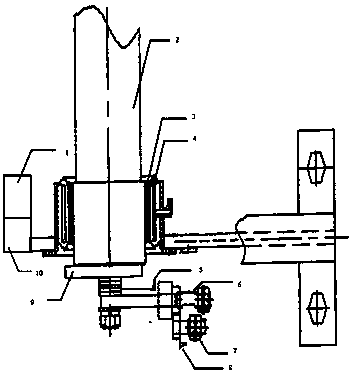

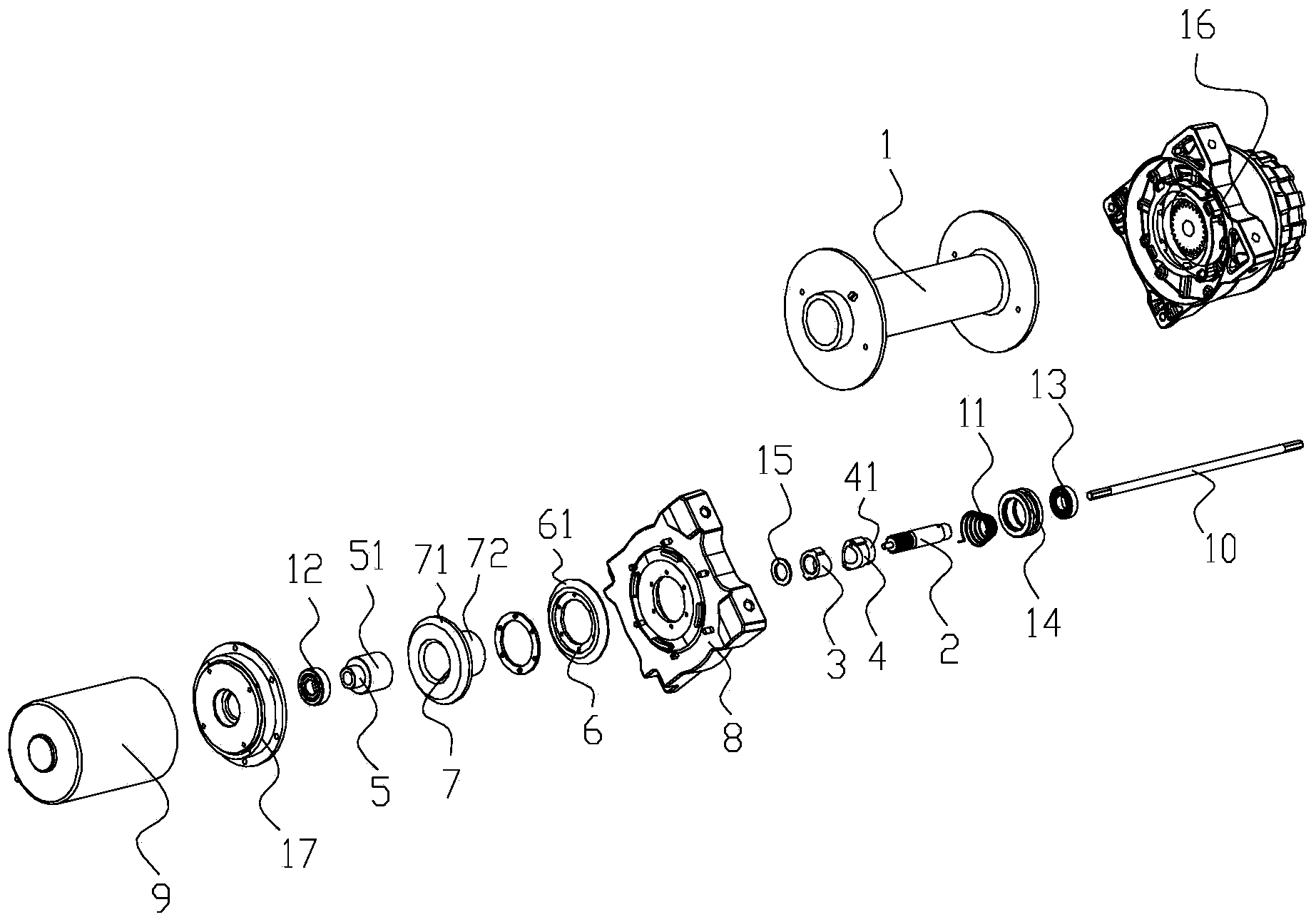

Single-vane type oscillating cylinder

InactiveCN103867518AReduce volumeSimple structureFluid-pressure actuatorsPulp and paper industryStator

The invention discloses a single-vane type oscillating cylinder, comprising vanes, a rotor, a stator and a cylinder body, the vanes, rotor and stator are arranged in the cylinder body, the rotor is arranged at the bottom of the vane, and the stator is arranged at the bottom of the rotor. The single-vane type oscillating cylinder is small in size, simple in structure, light in weight and higher in braking precision.

Owner:DALIAN QIANBAO CAST IRON FOUNDRY

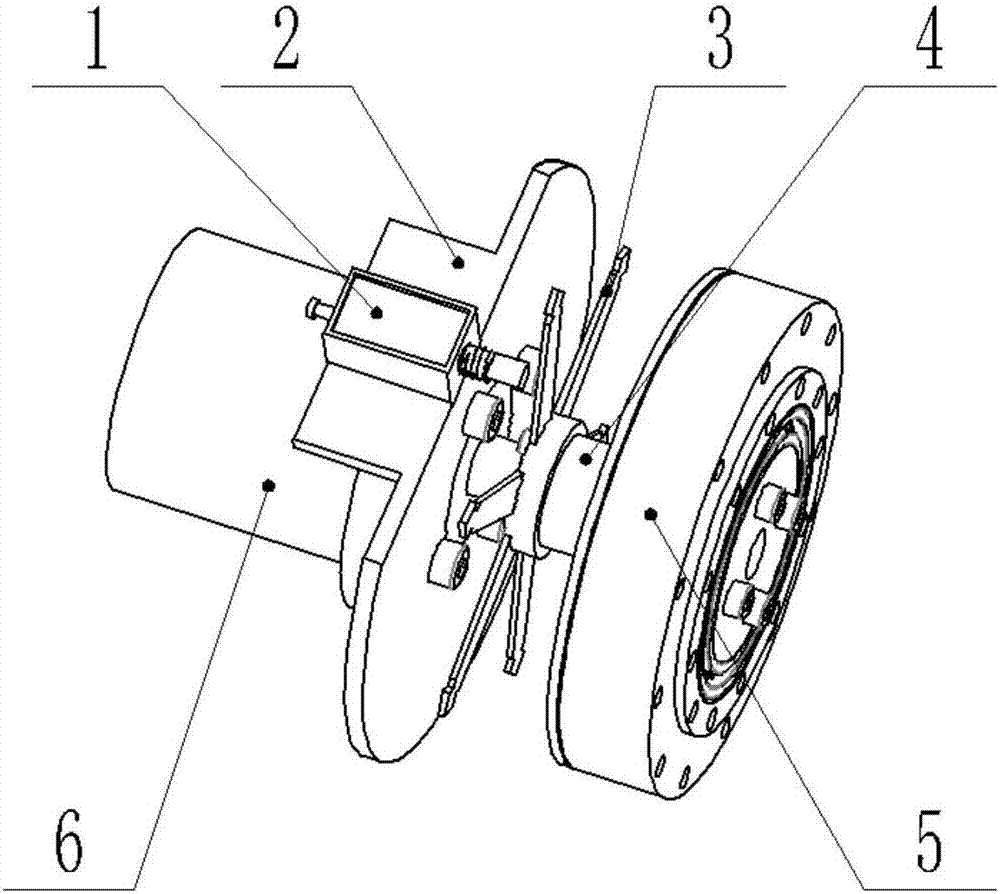

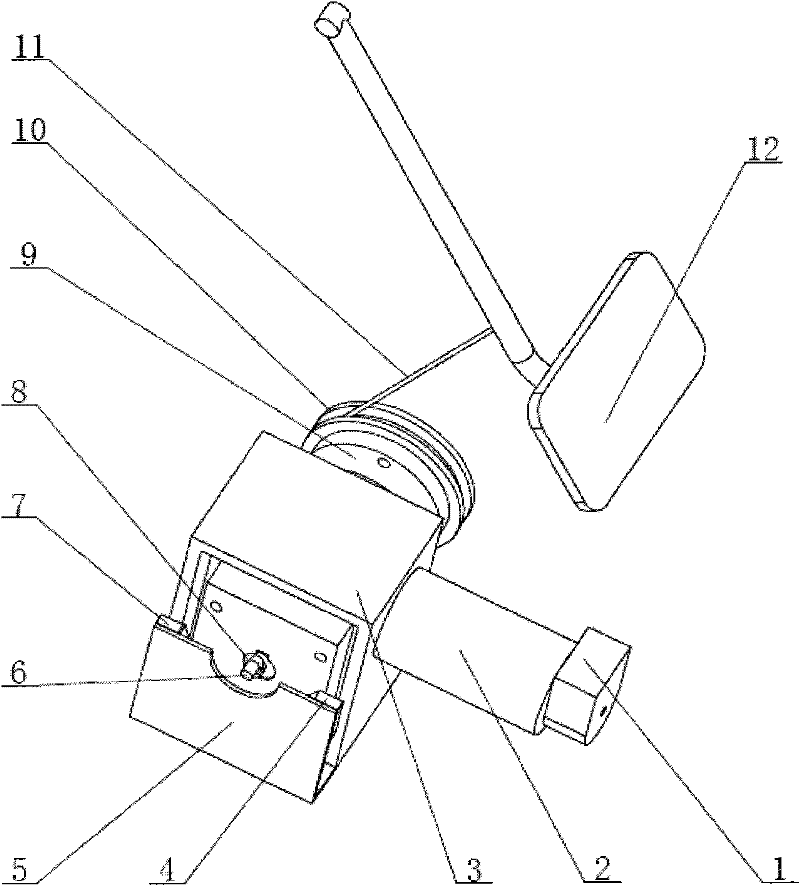

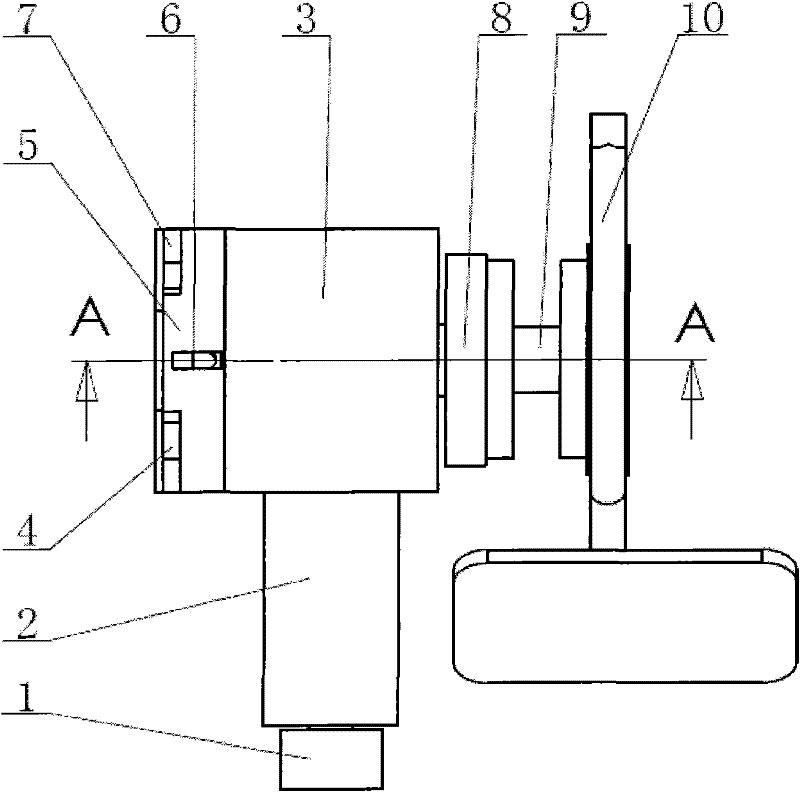

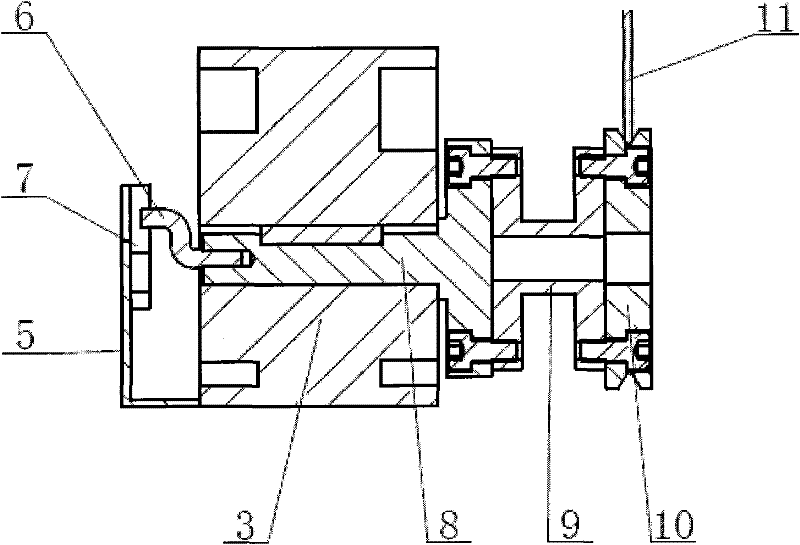

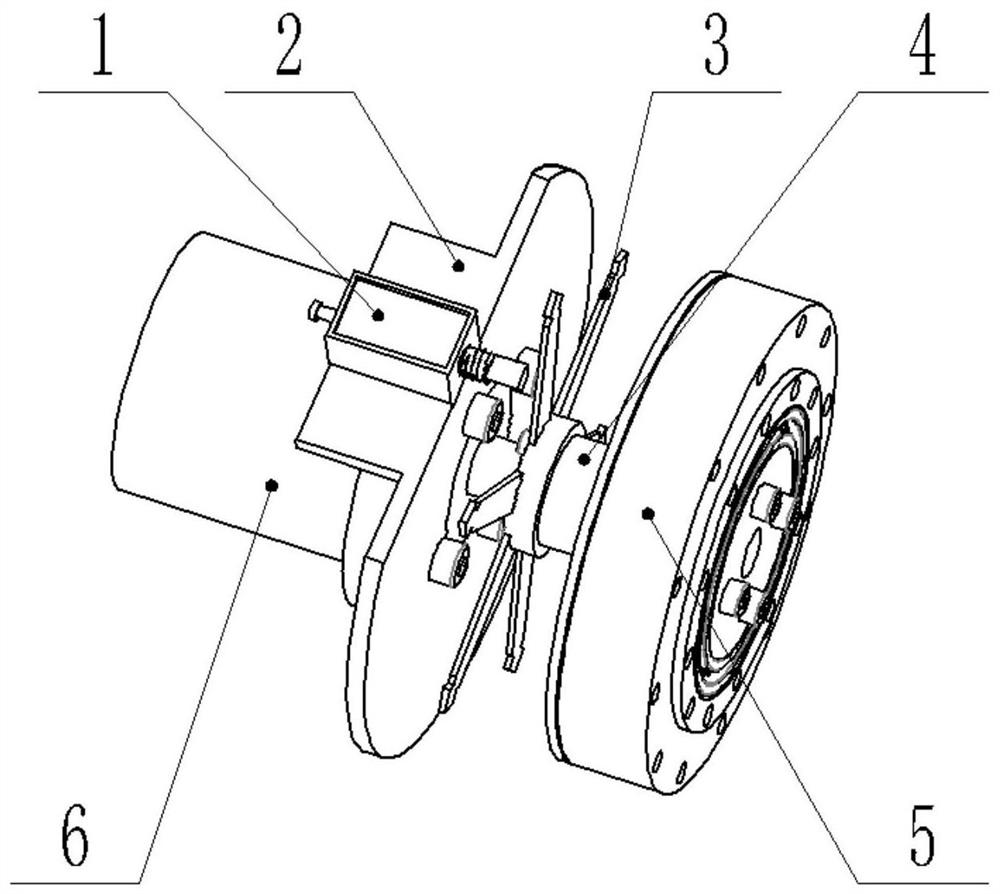

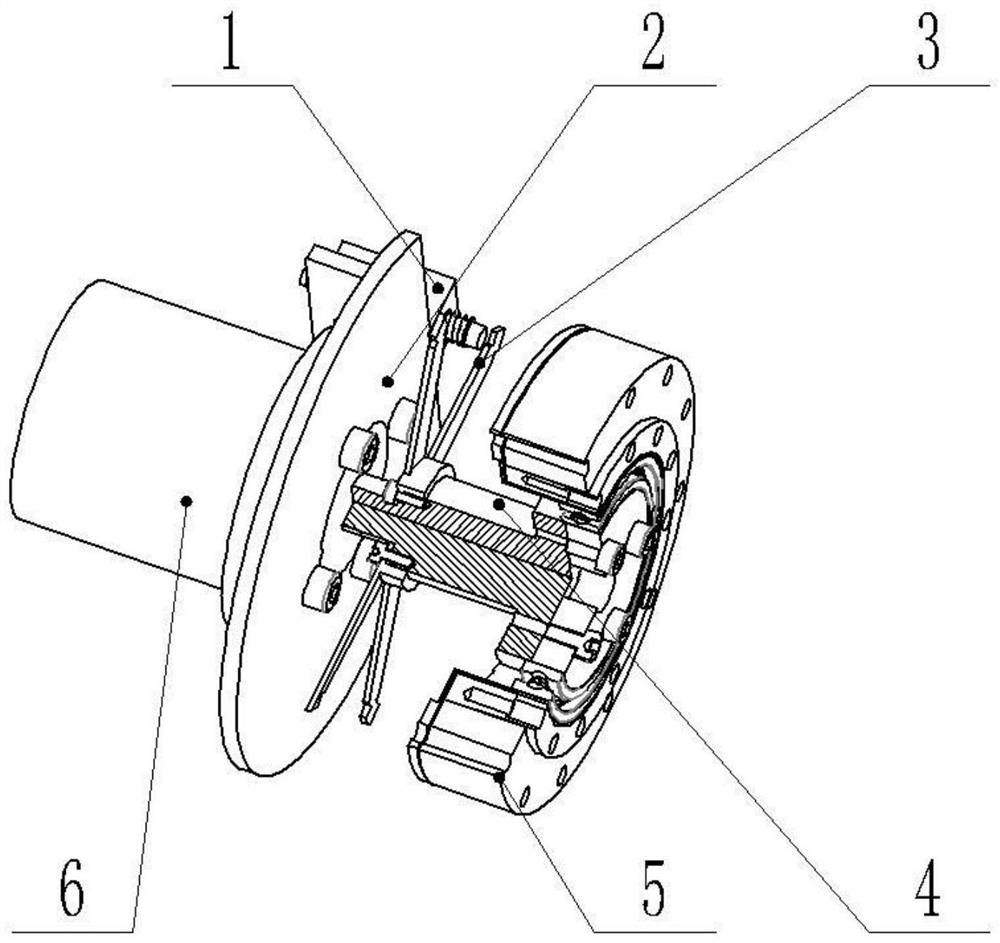

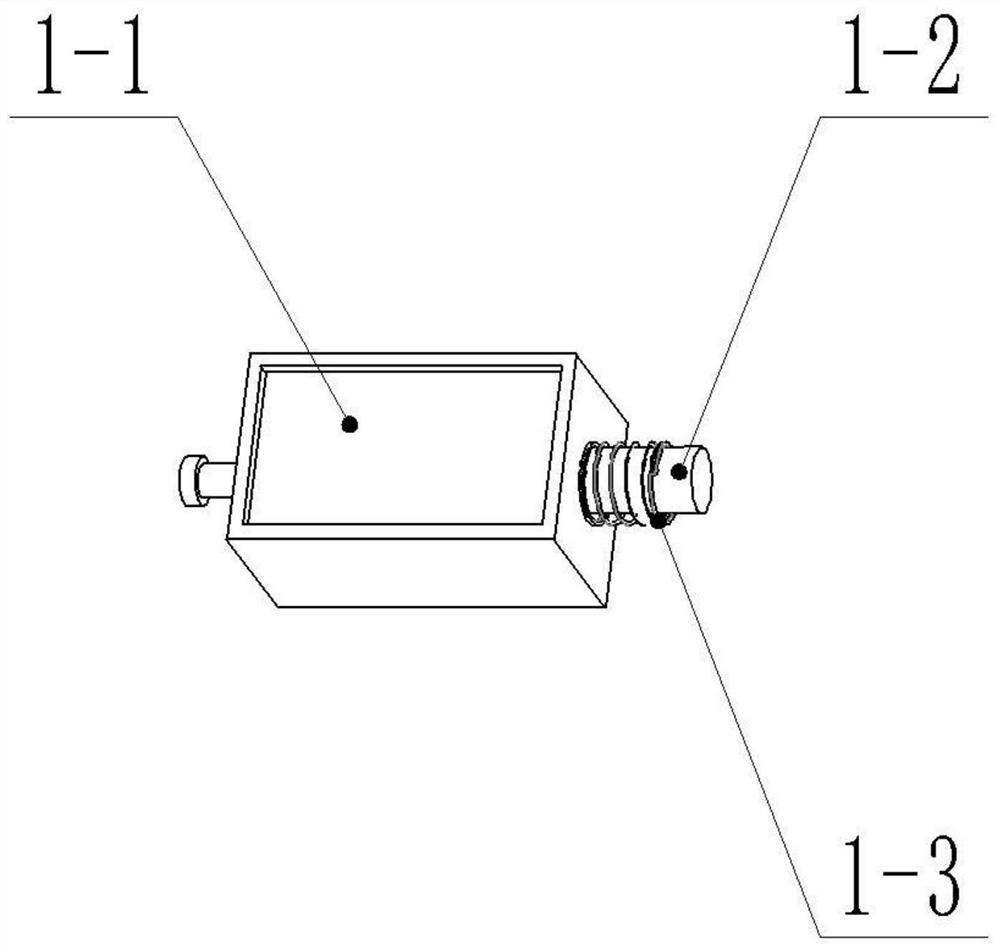

High-precision brake mechanism

ActiveCN107401565ALow installation requirementsEasy to installBrake actuating mechanismsActuatorsEngineeringMechanical engineering

The invention relates to a high-precision brake mechanism which comprises a brake switch, a brake disc, a switch connecting frame, a rotating shaft and a drive device; the drive device is connected with the input end of the rotating shaft. The high-precision brake mechanism is characterized in that the brake disc is mounted on a shaft shoulder of the rotating shaft and performs rotary motion along the rotating shaft; the brake switch comprises an electromagnetic switch, a reset spring and an iron core and is mounted on the switch connecting frame; the iron core is inserted in a columnar through hole in the electromagnetic switch, and the connection between the electromagnetic switch and the iron core is completed by the reset spring; the brake disc comprises a fixed base and six disc teeth with the same structure; the six disc teeth are uniformly distributed on the cylindrical side surface of the fixed base by taking the fixed base as a center, each of the disc teeth is from the connecting end of the fixed base to the tail end of the disc tooth, and the width of each of the disc teeth gradually reduces; V-shaped grooves are symmetrically formed in the two sides at the tail end of each of the disc teeth; the fixed base is in the shape of a cylinder with a cover-sealed bottom end.

Owner:HEBEI UNIV OF TECH

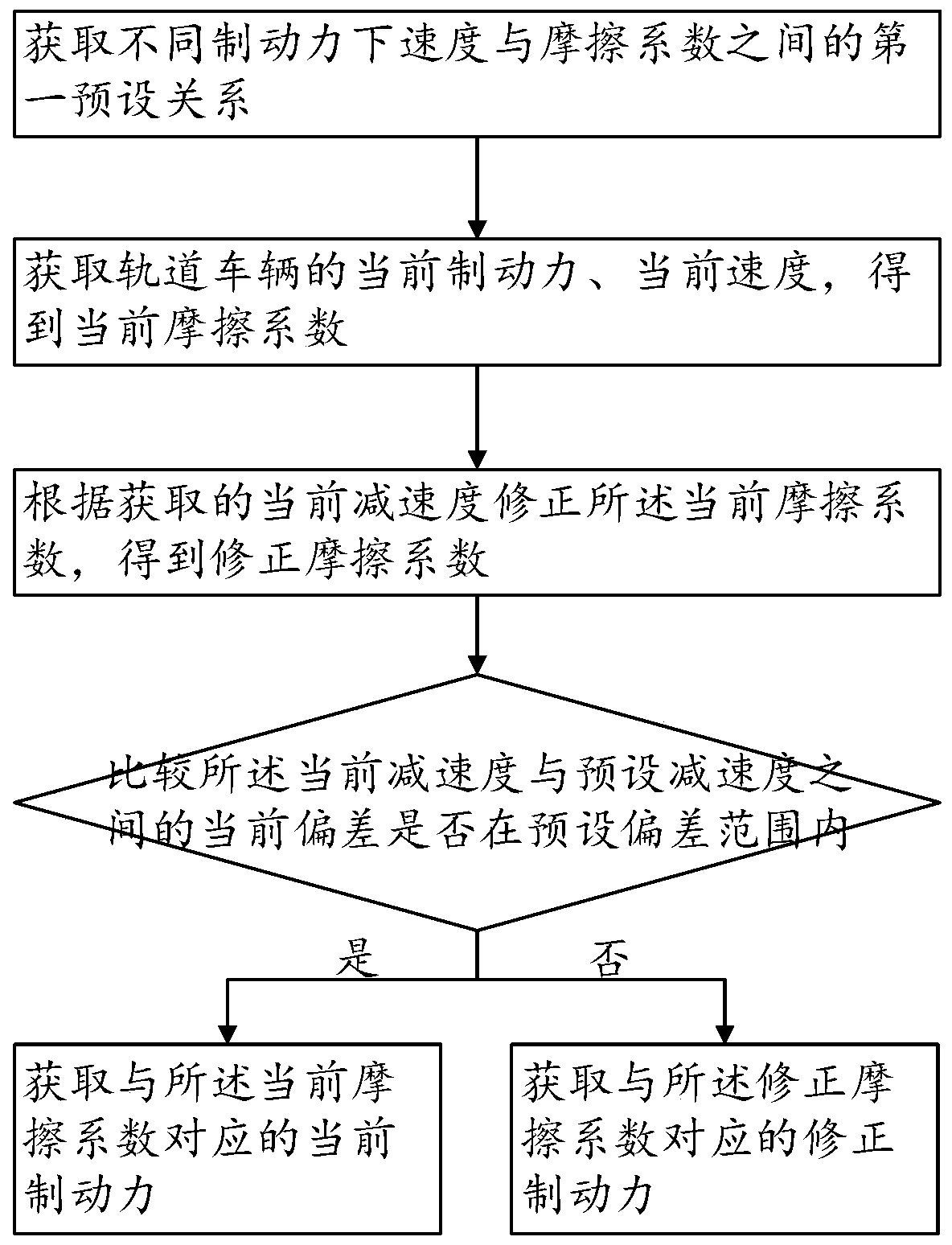

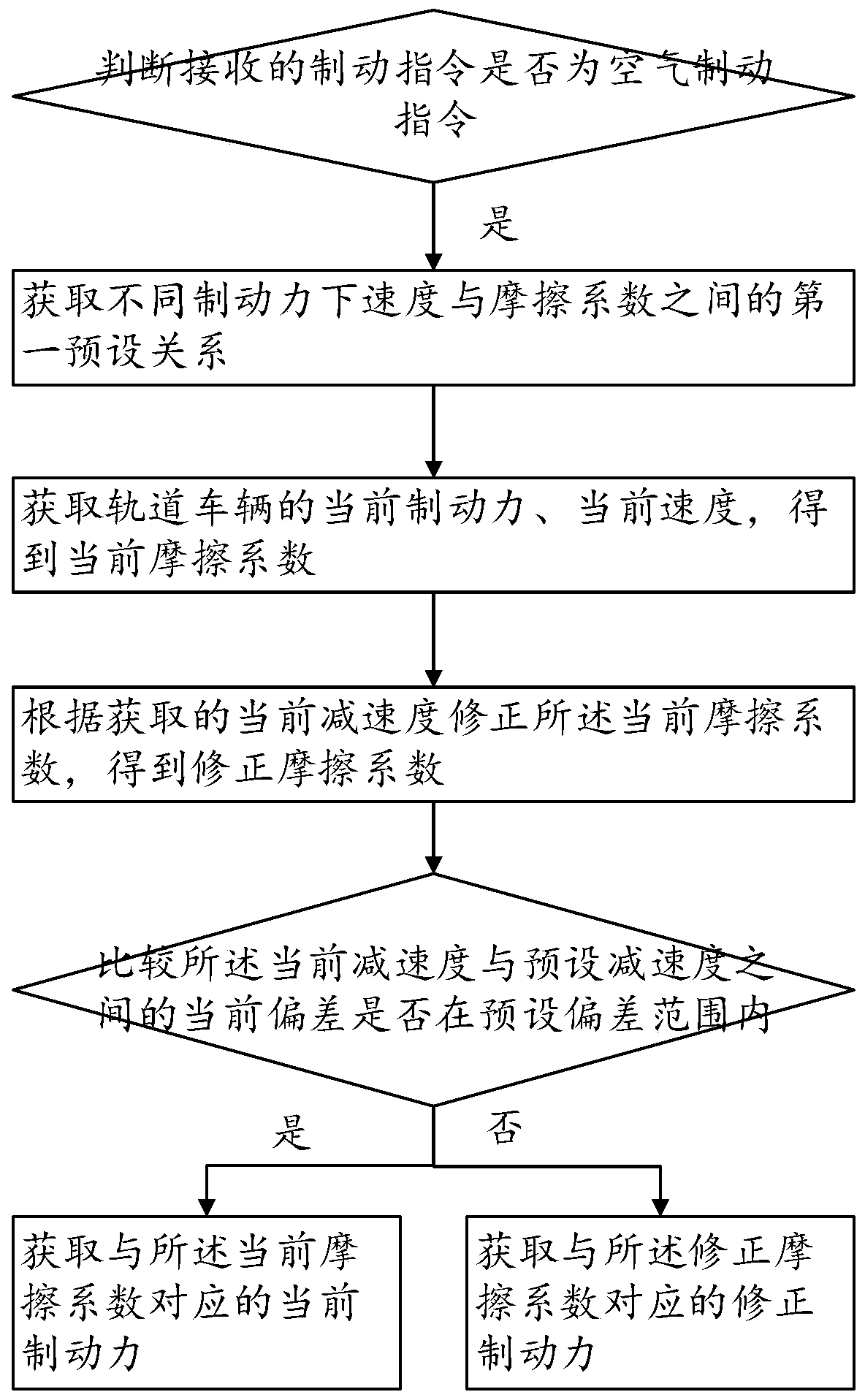

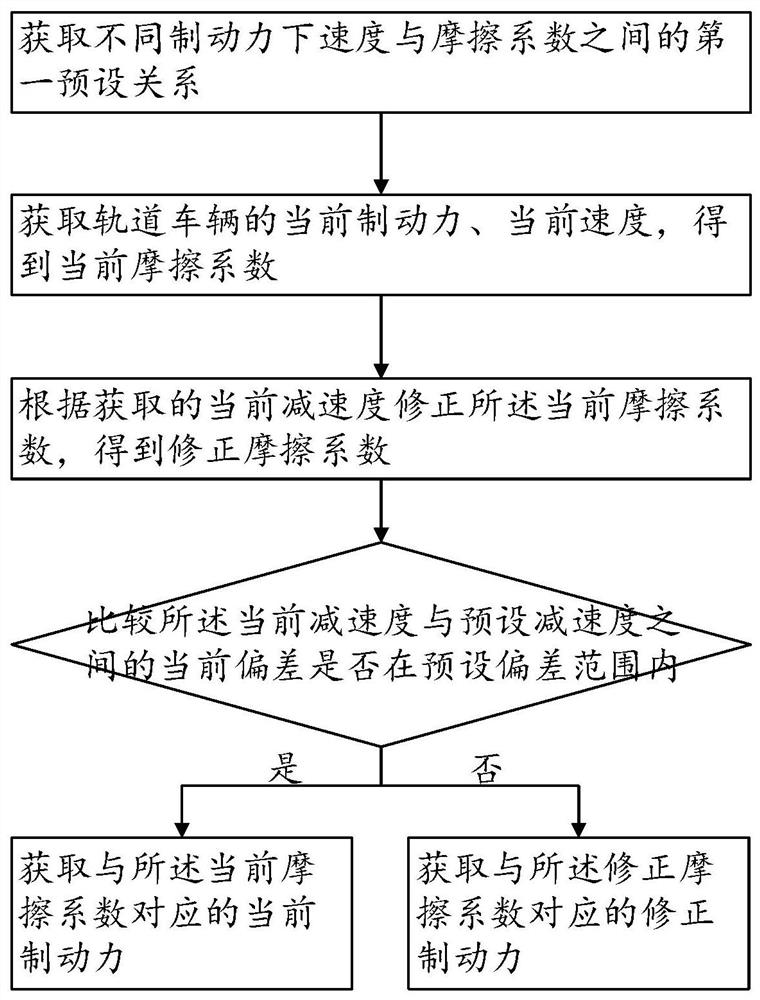

Railway vehicle air brake parking control method and system

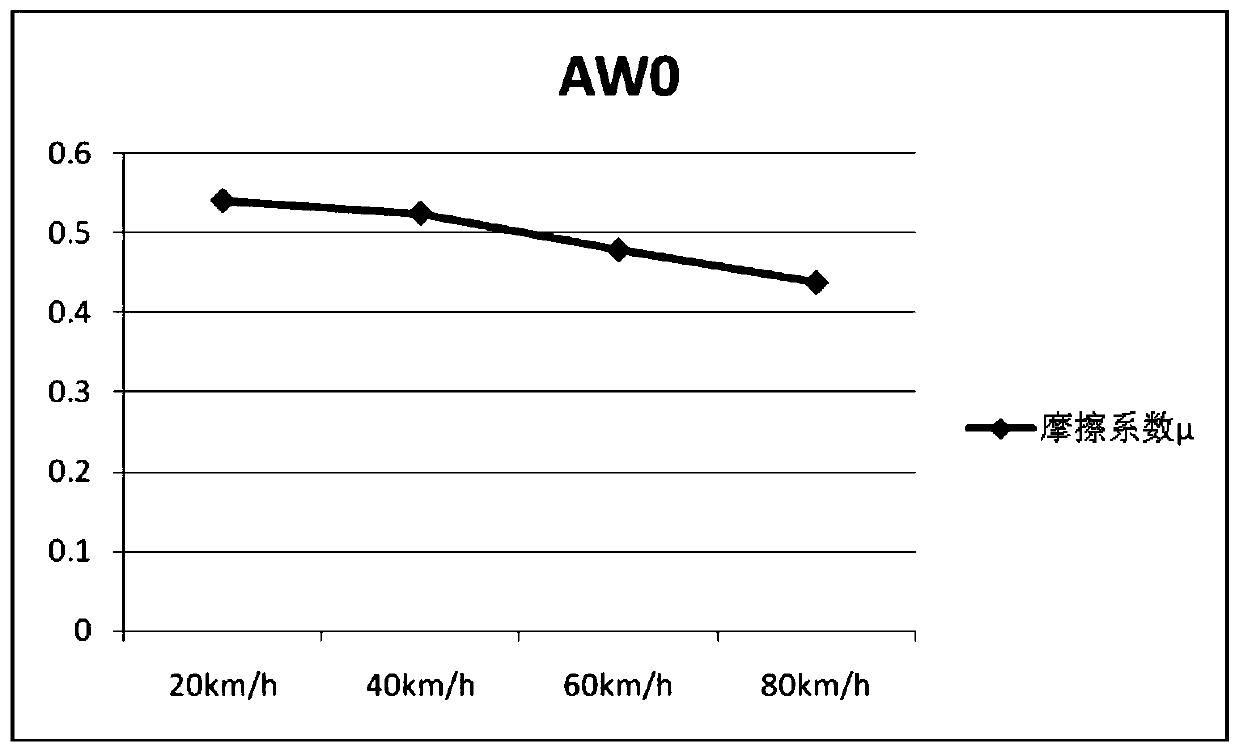

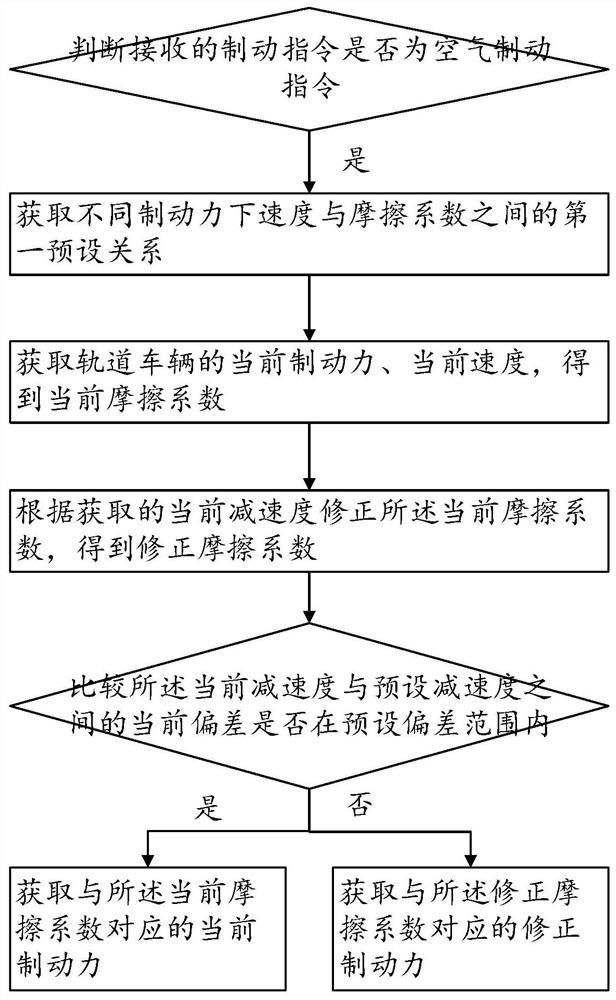

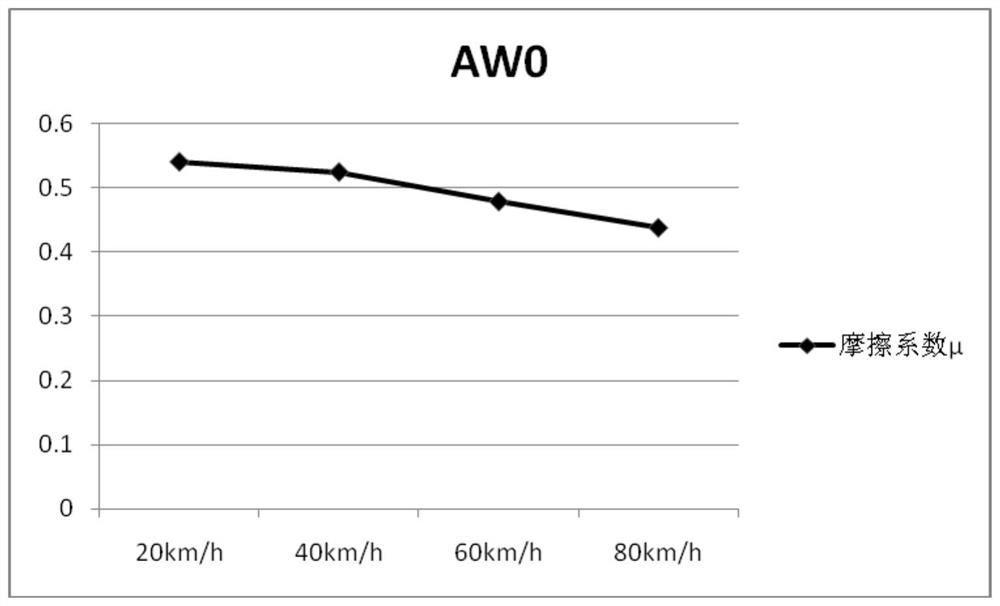

The invention discloses a railway vehicle air brake parking control method. The method comprises: obtaining a first preset relation between the speed and the friction coefficient under different brakeforces; obtaining the current braking force and the current speed of the rail vehicle to obtain the current friction coefficient; correcting the current friction coefficient according to the obtainedcurrent deceleration to obtain a corrected friction coefficient; comparing whether a current deviation between the current deceleration and a preset deceleration is within a preset deviation range, and if so, obtaining a current braking force corresponding to the current friction coefficient; and if not, obtaining a corrected braking force corresponding to the corrected friction coefficient. Thecurrent friction coefficient is accurately obtained according to the current speed and the current braking force, the current friction coefficient is corrected to obtain the corrected friction coefficient, and the accurate friction coefficient is selected between the current friction coefficient and the corrected friction coefficient according to the current deceleration, so that the braking forceis closer to an accurate value, and the braking precision is higher. The invention further discloses a railway vehicle air brake parking control system.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

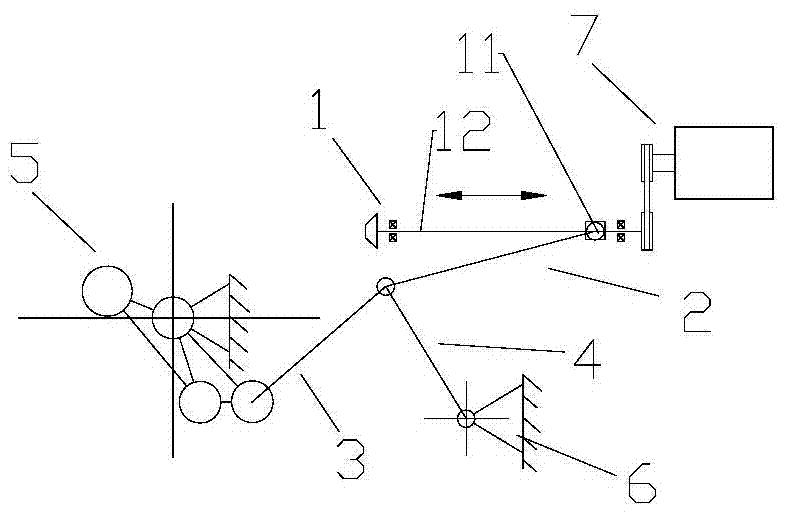

High speed rail braking method and system based on multiple intelligent bodies

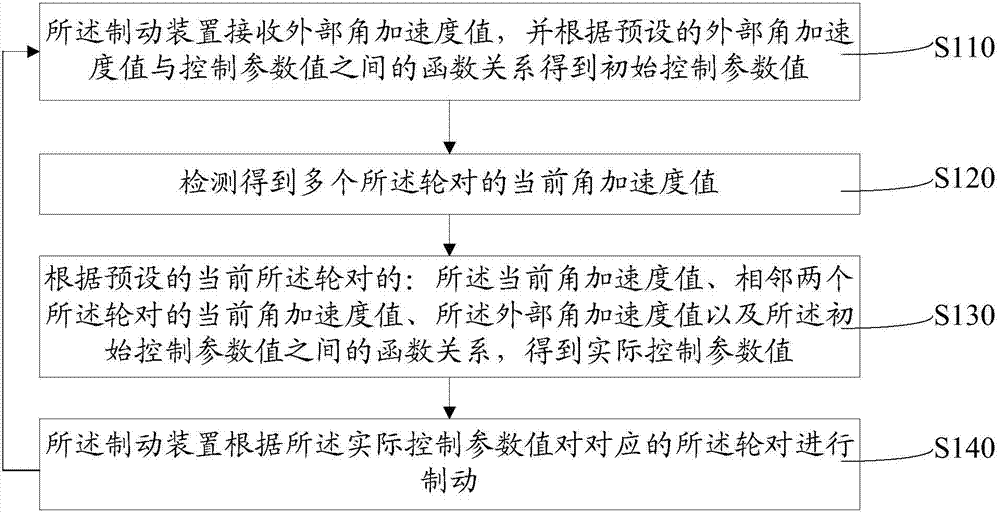

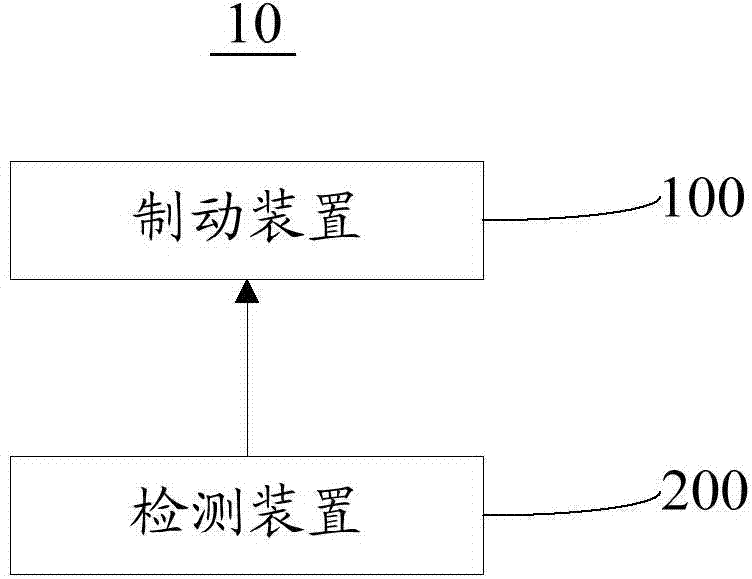

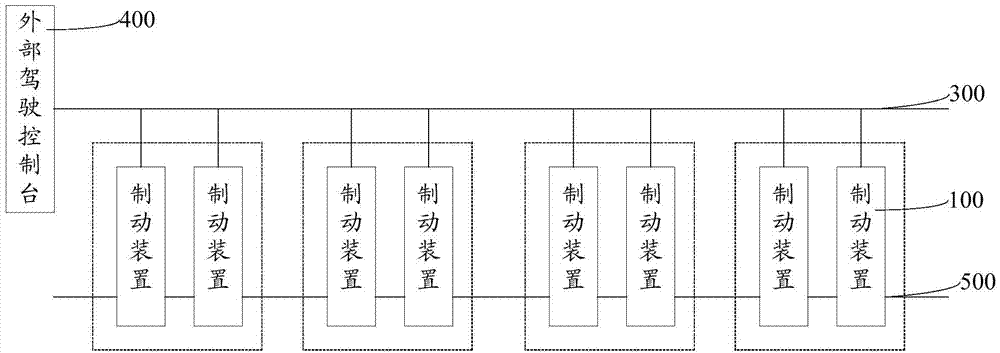

InactiveCN104842983AHigh braking precisionSmall deviation in braking effectBraking systemsTime delaysControl parameters

The invention discloses a high speed rail braking method and a high speed rail braking system based on multiple intelligent bodies. The high speed rail braking method based on the multiple intelligent bodies includes the following step: step S110, using a braking device to receive external angle acceleration magnitude, and obtaining initial control parameter value according to a preset function relationship between the external angle acceleration magnitude and a control parameter value, and further includes the following steps: step S120, obtaining current angle acceleration magnitude of a plurality of wheel sets through detection; step S130, obtaining an actual control parameter value of each current wheel set according to a function relationship among the current angle acceleration magnitude, the current angle acceleration magnitude of two adjacent wheel sets, the external angle acceleration magnitude and the initial control parameter value of each current wheel set, which are preset; step S140, using the breaking device to brake the corresponding wheel sets according to the actual control parameter values, and returning to the step S110. The high speed rail braking method based on the multiple intelligent bodies can simultaneously consider influence factors between time delay constraint and each wheel set, and difference between braking effects of the high speed rail braking method based on the multiple intelligent bodies and expected braking effects is small, and furthermore braking accuracy is high.

Owner:陈磊

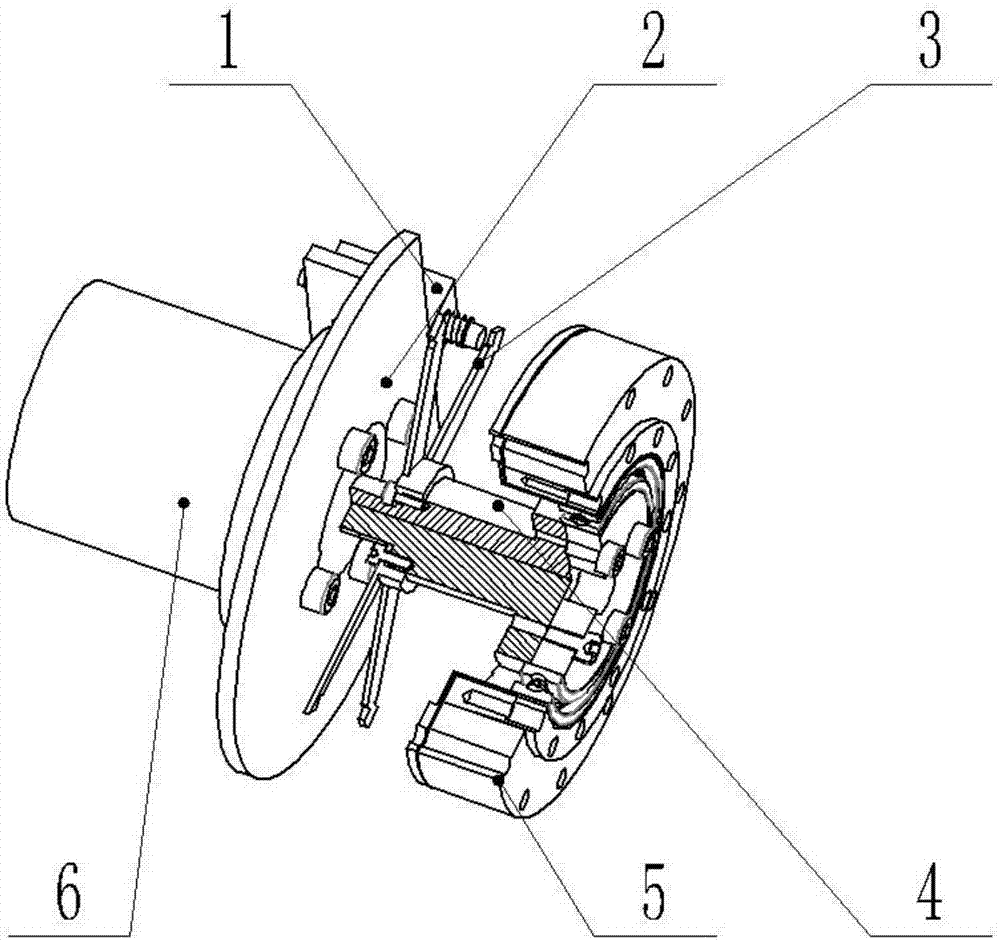

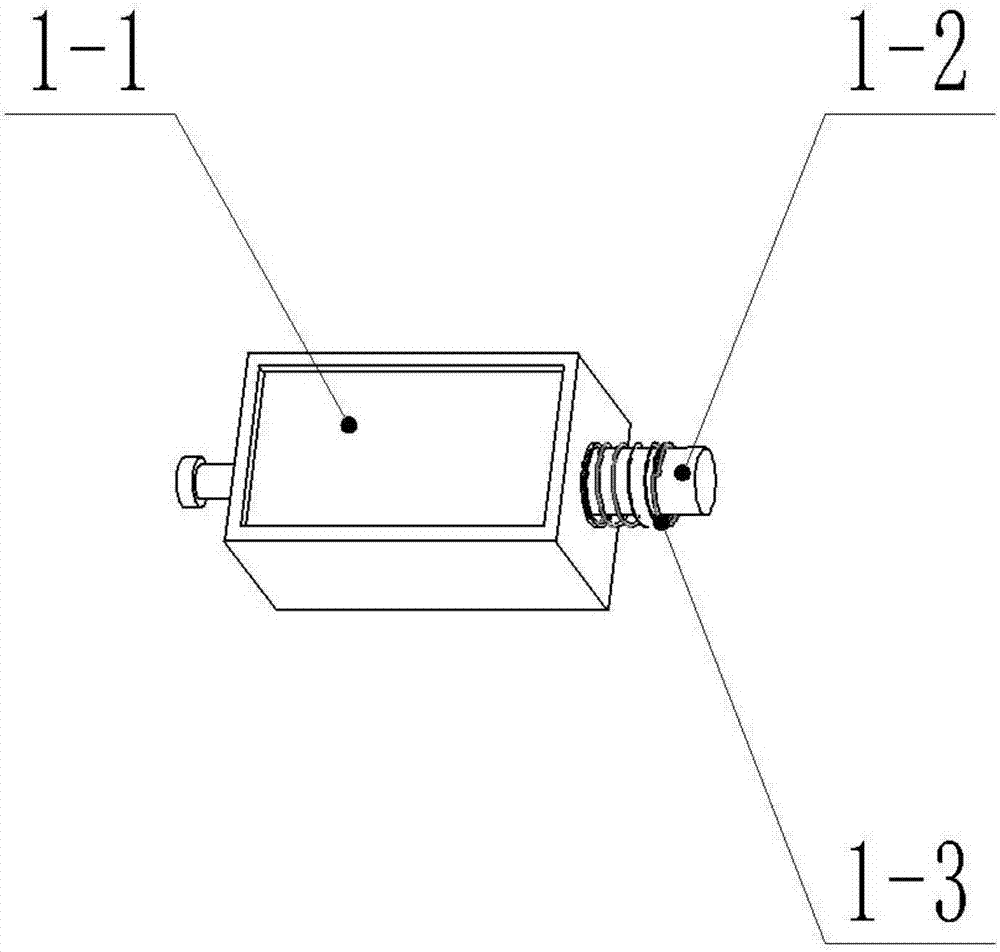

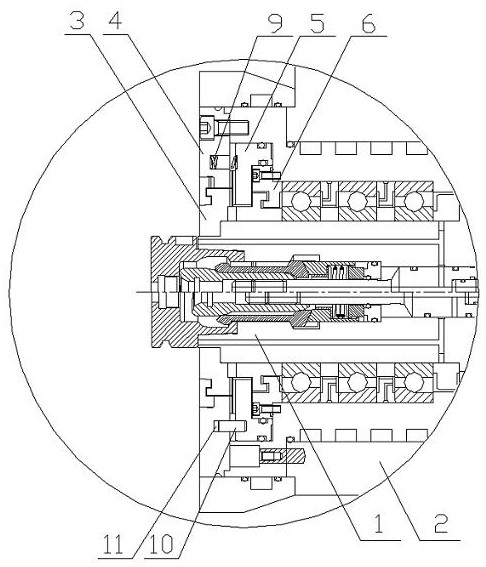

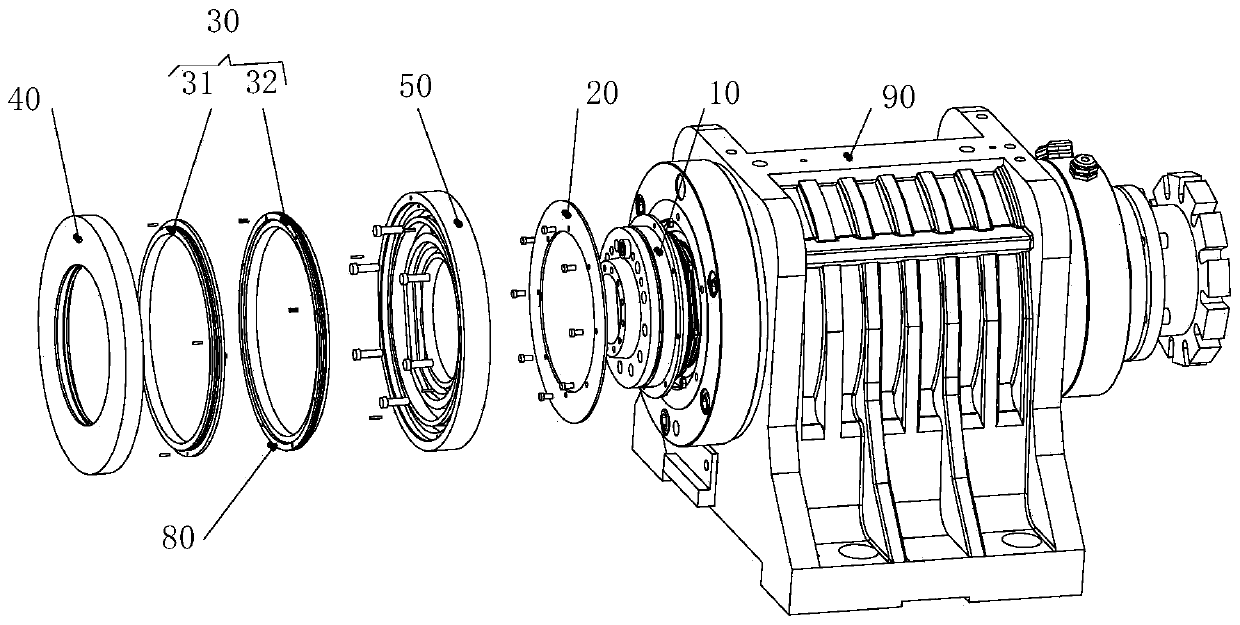

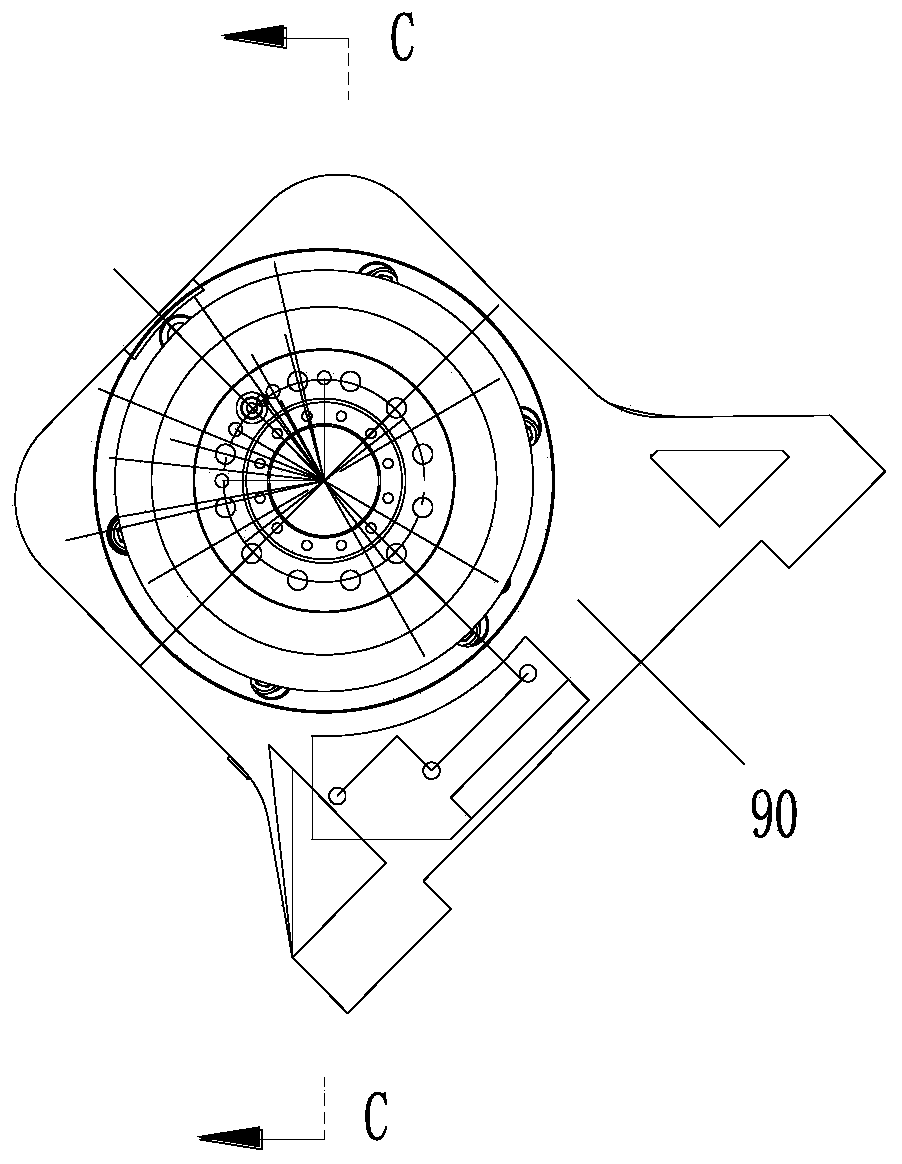

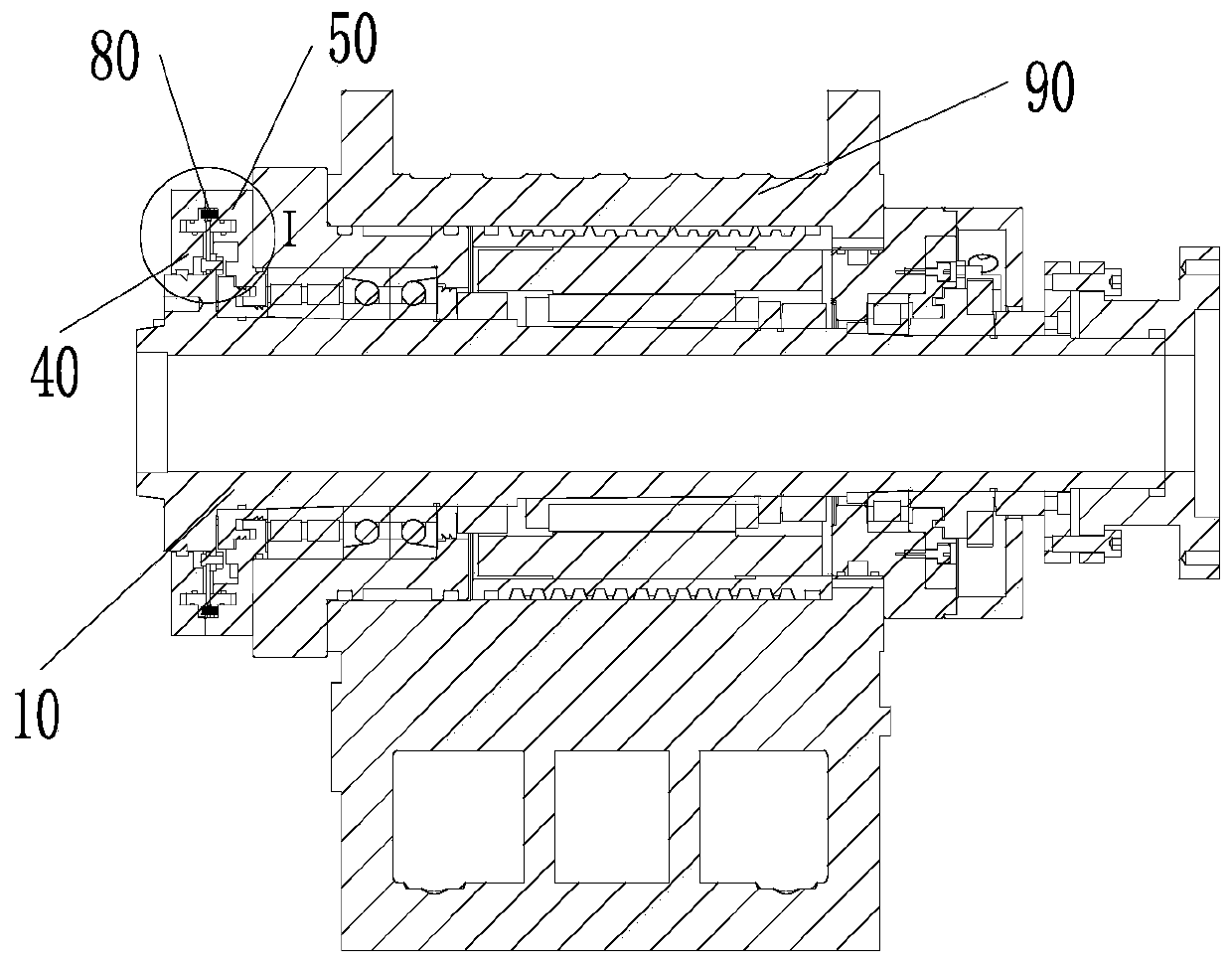

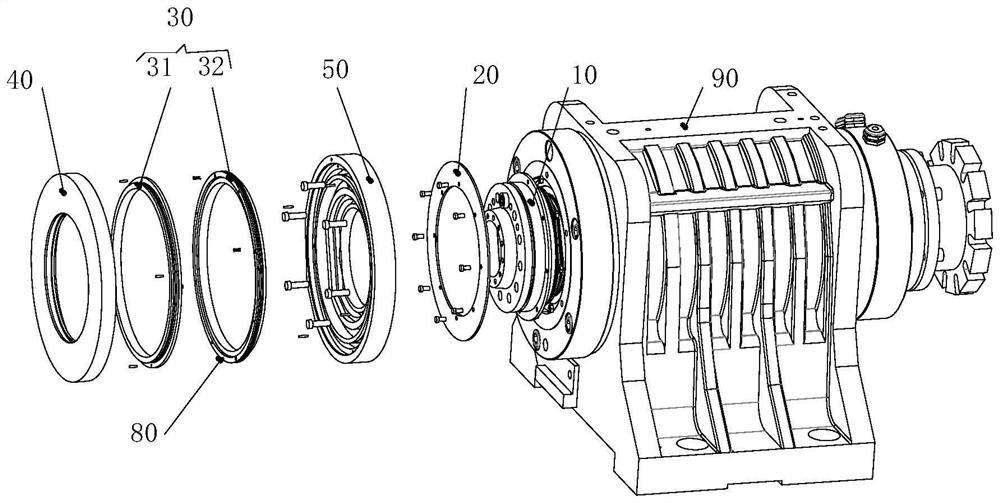

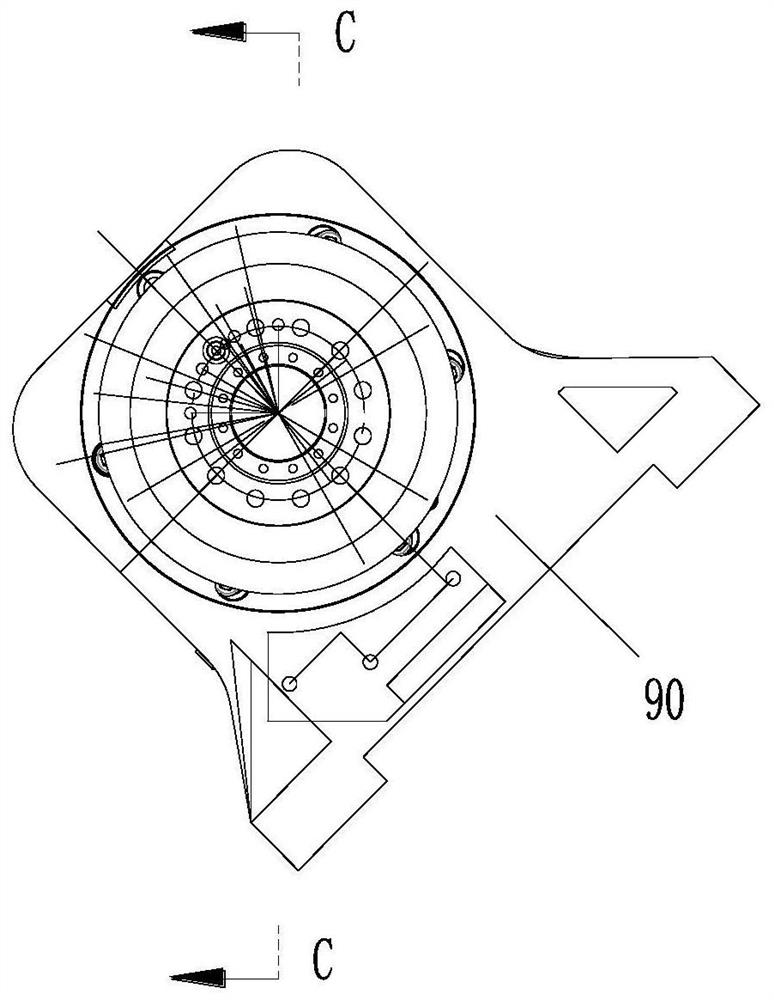

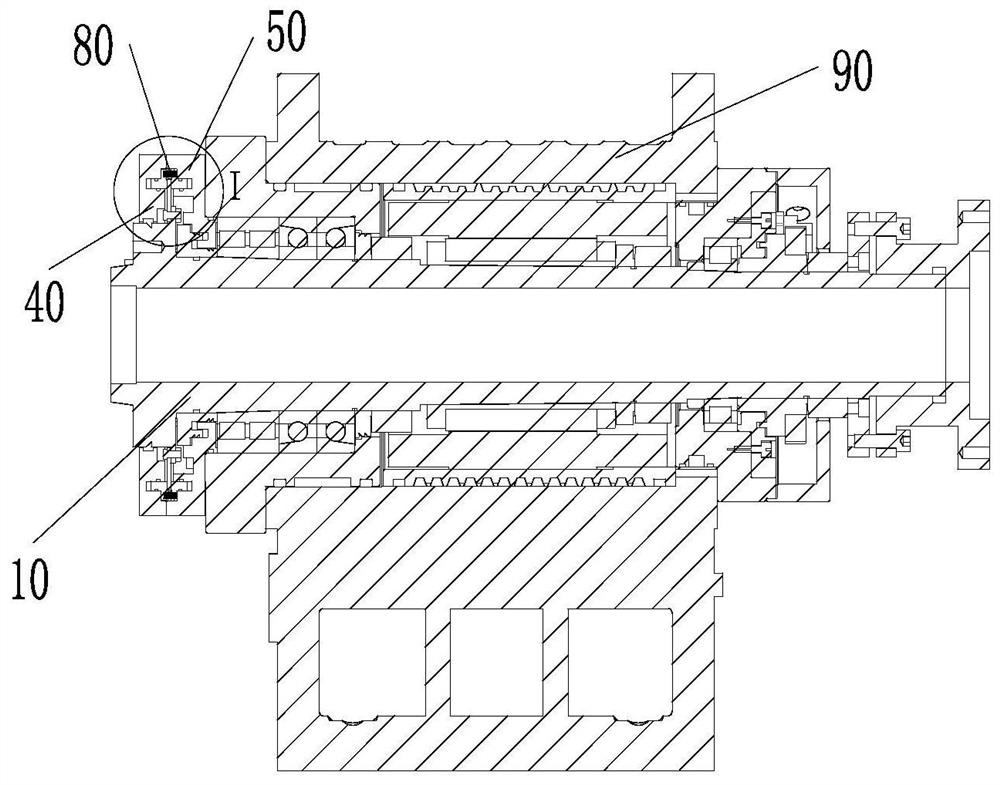

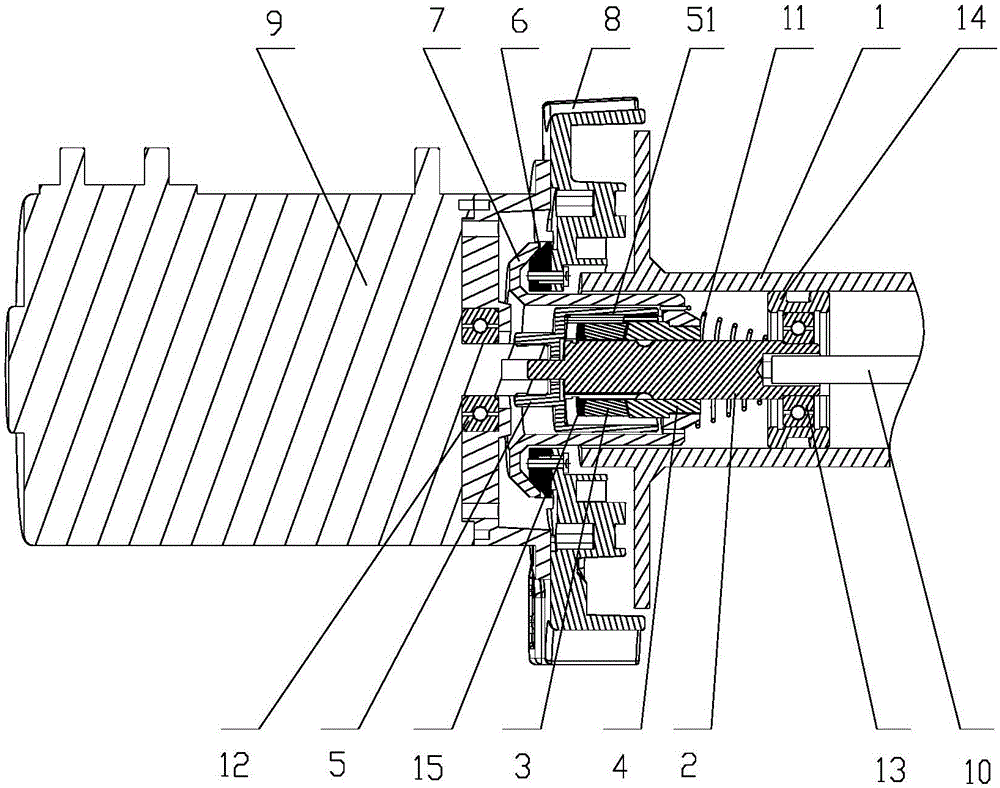

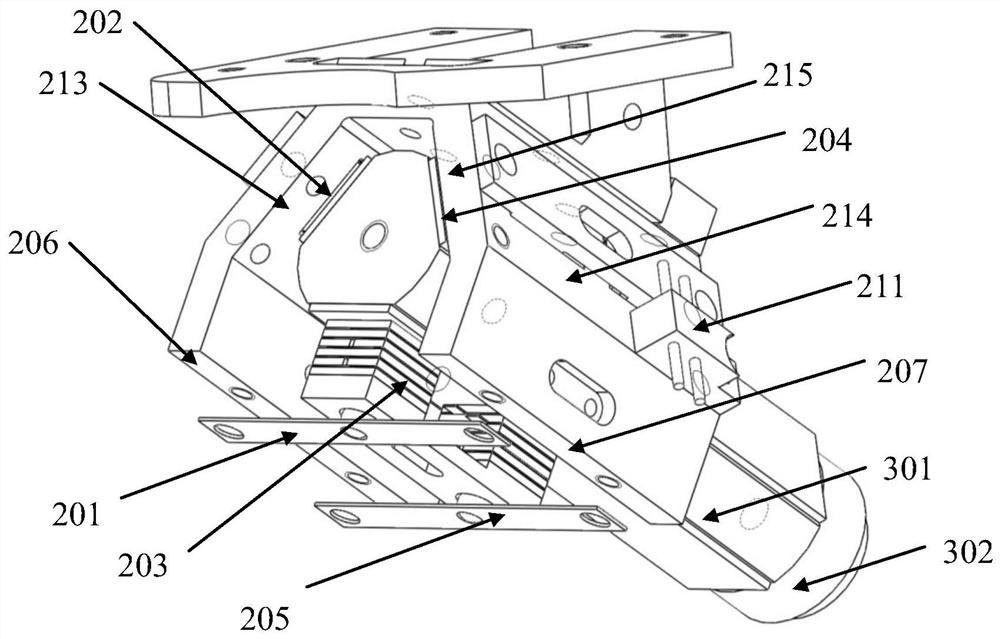

Milling and turning composite electric spindle assembly and corresponding numerical control machining equipment

InactiveCN111673097AReduce torqueAvoid deformation damageLarge fixed membersDriving apparatusNumerical controlEngineering

The invention relates to a milling and turning composite electric spindle assembly and numerical control machining equipment. The milling and turning composite electric spindle assembly comprises a spindle, a spindle shell and a spindle braking mechanism. The spindle braking mechanism comprises a rotary toothed disc, a positioning toothed disc and a movable toothed disc, the rotary toothed disc coaxially and fixedly sleeves the front end of the spindle, the positioning toothed disc coaxially sleeves the outer side of the rotary toothed disc and is provided with a rotating clearance, the positioning toothed disc is fixedly connected to the front end of the spindle shell, the movable toothed disc is mounted between the spindle shell and a front bearing flange in a sleeving mode and is slidably and hermetically matched with the spindle shell and the front bearing flange, an annular oil cavity is formed in the rear surface of the movable toothed disc, the structure and number of end teethof each toothed disc are the same, the end teeth of the rotary toothed disc and the positioning toothed disc are located on the rear end surface, and the end teeth of the movable toothed disc are located on the front end surface. The spindle braking mechanism is installed at the front end of the spindle and is close to a cutting point, the braking effect is good, the torque applied to the spindleis small during braking, so that the spindle meets the braking requirement without particularly large rigidity, and the deformation damage of the spindle caused by frequent braking can be effectivelyavoided.

Owner:北京东方精益机械设备有限公司

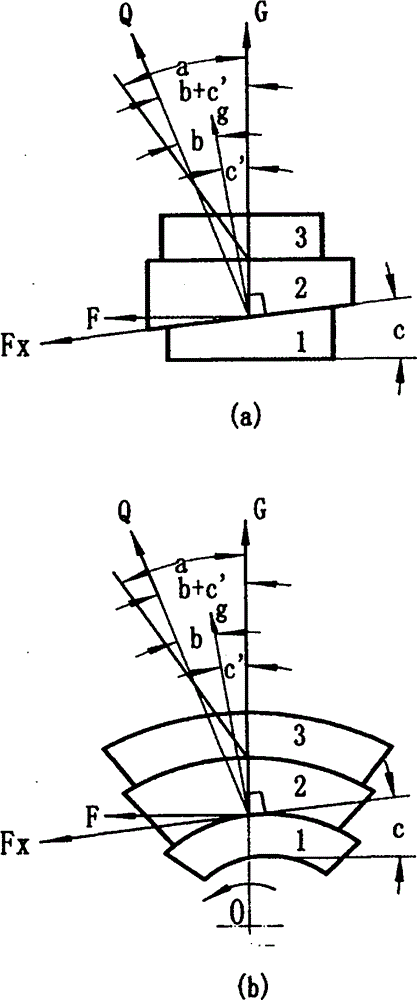

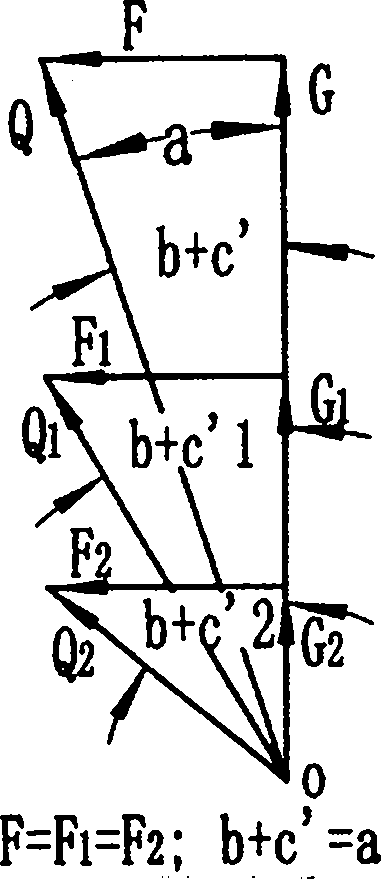

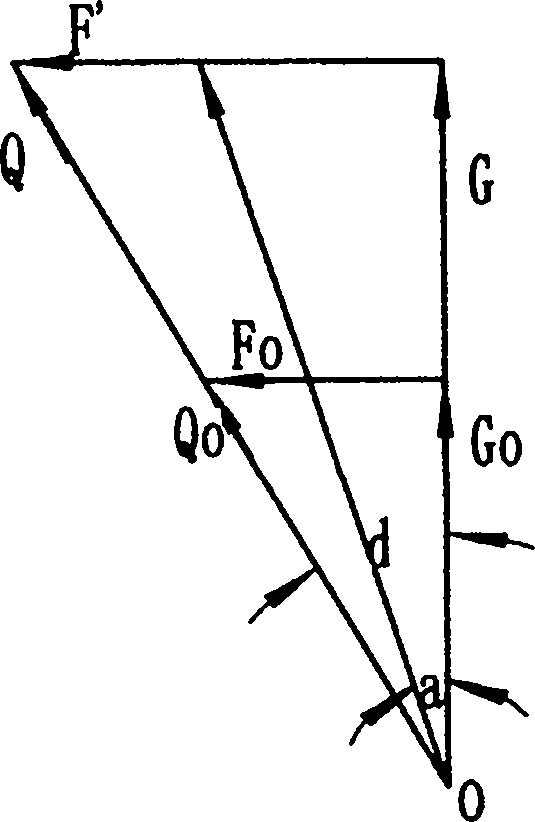

Friction difference brake method

InactiveCN104595388ASimple structureImprove energy savingBrake typesRolling resistanceFriction angle

The invention relates to a friction difference brake method. Friction difference three element parts are adopted for mechanical brake including linear brake and rotation brake, the friction difference three element parts comprise a drive part, a friction difference part and a target part, the friction difference part is connected with the drive part or a rack through an elasticity keeping part and a brake controller, the drive part is fixedly installed on the rack, and the friction difference part is installed on the drive part in a floating mode. The friction coefficient between the friction difference part and the target part is larger than that between the friction difference part and the drive part by over one time, and a sliding or rolling friction mode is adopted between the drive part and the friction difference part. When b+c <=a, the friction difference self-locking brake is in a complete brake form; when 90 degrees >b+c >a and b+c is a definite value, the friction difference self-locking brake is in a definite proportion speed reduction brake form; when 90 degrees >b+c >=a and b+c is adjusted randomly within the range, wherein a is the friction angle between the friction difference part and the target part, b is the friction angle between the friction difference part and the drive part, c is the drive angle, b+c is a friction difference angle, the friction difference self-locking brake is in a whole journey brake form.

Owner:韩树海

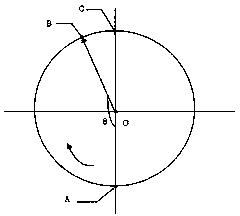

Textile mechanical device with automatic positioning function

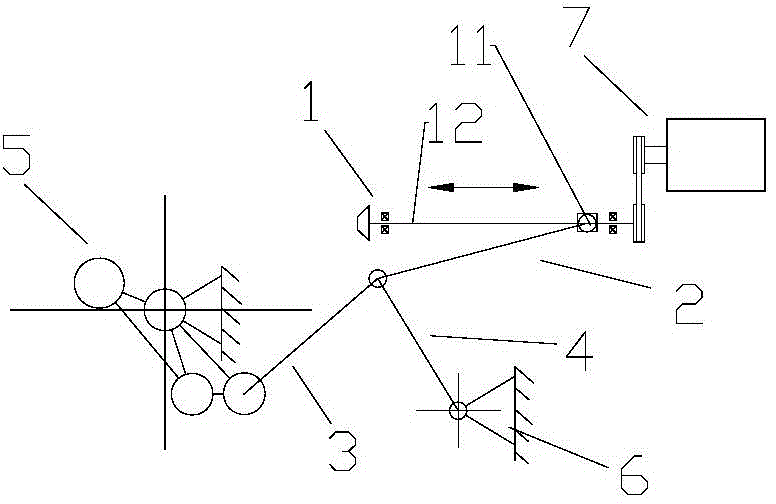

InactiveCN107447373ARequirements for realizing automatic positioningSmall moment of inertiaNeedling machinesClutch controlMotor drive

The invention relates to a textile mechanical device capable of automatic positioning. When the main motor drives the main shaft to slow down slowly under the control of the frequency converter, the bottom dead center sensor starts to detect the number of times the crank reaches the bottom dead center. When the number of points is less than 30 times per minute, under the control of the controller, the positioning gear controlled by the clutch is started, and the positioning gear starts to work; at the same time, when the bottom dead center sensor detects that the crank reaches the bottom dead center, the counting sensor starts to record the positioning The number of rotations of the gear, when the number of rotations of the positioning gear reaches a certain value, the controller starts the stop signal, and the frequency converter of the main motor stops. At this time, the crank just stops at the top dead center position, which plays the role of automatic positioning.

Owner:RUGAO WANLI CHEM IND

A braking device for an unmanned vehicle

InactiveCN101797917BEnsure safetyGuaranteed not to affect each otherAutomatic initiationsControl devicesEngineeringControl theory

The invention relates to a braking device for an unmanned vehicle. The device includes a motor, a reducer, an encoder and a sensing mechanism; the reducer is a worm gear reducer, the input end of which is connected to the motor, and the rear output shaft of the motor is connected to the encoder; one end of the output shaft of the reducer is connected to The sensor contact, the other end of which is connected to the torque sensor, and the other end of the torque sensor is connected to the wire wheel wound with steel wire; the two sides of the upper part of the sensor fixing frame connected to the reducer housing are respectively equipped with a zero position sensor and a pole position sensor , the contacts of the two sensors are respectively located inside the circular trajectory of the sensor contacts. The invention adopts the worm gear mechanism to effectively keep the vehicle in the braking state; the limit sensor and the torque limiter realize effective braking and ensure the safety of the vehicle; the steel wire ensures that the unmanned driving mode and the manual driving mode do not affect each other . The utility model has the advantages of simple and compact structure, low cost, strong versatility, and does not destroy the structure of the original vehicle.

Owner:中国人民解放军炮兵学院

Automatic locating structure for textile machine

InactiveCN106676758ASmall moment of inertiaReduce control errorNeedling machinesClutch controlMotor drive

The invention relates to an automatic locating structure for a textile machine. When a main motor drives a spindle to slowly slow down under control of a frequency converter, a bottom dead center sensor starts to detect the frequency that a crank reaches a bottom dead center; when it is detected that the frequency that the crank reaches the bottom dead center is below 30 times per minute, a locating gear controlled by a clutch is started under control of a controller, and the locating gear starts to work; meanwhile, when the bottom dead center sensor detects that the crank reaches the bottom dead center, a counting sensor starts to record the number of turns of rotation of the locating gear, when the number of turns of rotation of the locating gear reaches a certain value, the controller starts a shutdown signal, the frequency converter of the main motor stops, the crank exactly stops at a top dead center at this moment, and the function of automatic locating is achieved.

Owner:杨配媛

Spindle structure and machine tool with same

ActiveCN111014735ASolve the technical problem of poor positioning accuracyRealize brake operationLarge fixed membersBrakeEngineering

The invention provides a spindle structure and a machine tool with the same. The spindle structure comprises a spindle core, a brake disc and a brake assembly, wherein the brake disc is arranged on the spindle core so that the brake disc is driven to rotate by the spindle core, and the brake disc is arranged in a manner of being bulged out of the spindle core; the brake assembly comprises a firstbrake part and a second brake part, the first brake part is movably arranged at one side of the brake disc, and the second brake part is movably arranged at the other side of the brake disc; the brakeassembly has a brake state and an avoiding state, and when the brake assembly is in the brake state, the first brake part and the second brake part are arranged on the brake disc in a clamping manner, so that the spindle core stops rotating; and when the brake assembly is in the avoiding state, the first brake part and the second brake part are arranged in a manner of being spaced from the brakedisc to avoid the brake disc; and the spindle core is provided with a drive section and a connection section which are oppositely arranged, the connection section is used for being connected with an element to be connected, and the brake assembly and the brake disc are arranged on the connection section. The technical problem of low location accuracy of a spindle structure in the prior art duringbrake is solved.

Owner:GREE ELECTRIC APPLIANCES INC

Spindle structure and machine tool with it

ActiveCN111014735BSolve the technical problem of poor positioning accuracyRealize brake operationLarge fixed membersBrakeStructural engineering

The invention provides a spindle structure and a machine tool with the same. The spindle structure comprises a spindle core, a brake disc and a brake assembly, wherein the brake disc is arranged on the spindle core so that the brake disc is driven to rotate by the spindle core, and the brake disc is arranged in a manner of being bulged out of the spindle core; the brake assembly comprises a firstbrake part and a second brake part, the first brake part is movably arranged at one side of the brake disc, and the second brake part is movably arranged at the other side of the brake disc; the brakeassembly has a brake state and an avoiding state, and when the brake assembly is in the brake state, the first brake part and the second brake part are arranged on the brake disc in a clamping manner, so that the spindle core stops rotating; and when the brake assembly is in the avoiding state, the first brake part and the second brake part are arranged in a manner of being spaced from the brakedisc to avoid the brake disc; and the spindle core is provided with a drive section and a connection section which are oppositely arranged, the connection section is used for being connected with an element to be connected, and the brake assembly and the brake disc are arranged on the connection section. The technical problem of low location accuracy of a spindle structure in the prior art duringbrake is solved.

Owner:GREE ELECTRIC APPLIANCES INC

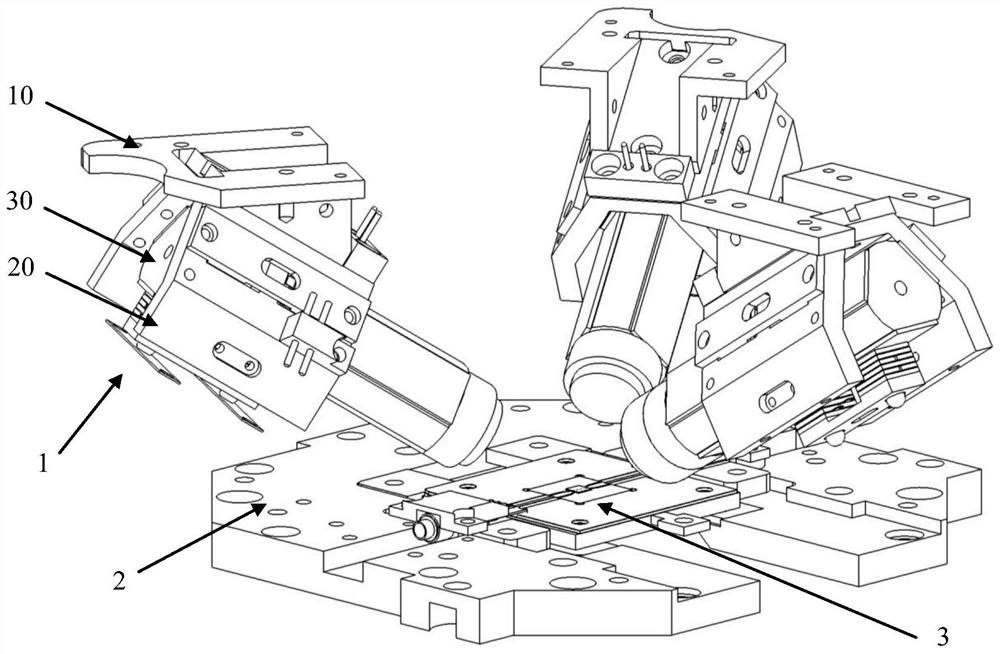

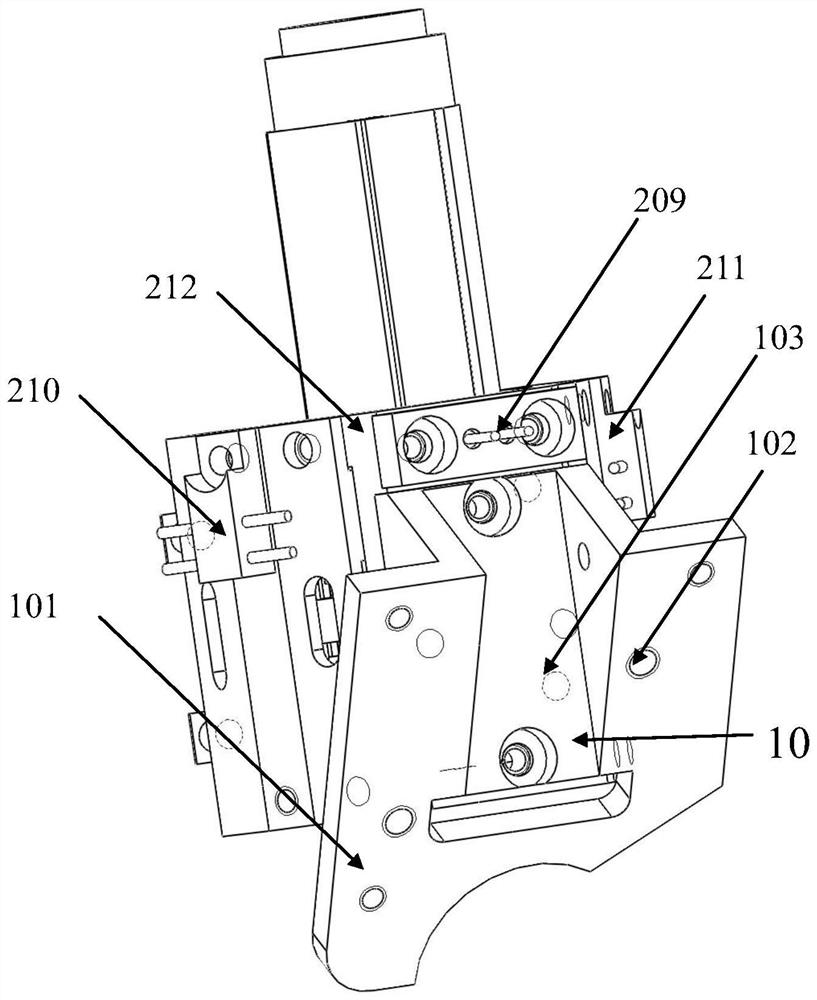

Electric control vector magnetic field device and mounting method thereof

ActiveCN112466594ACompact structureHigh braking precisionPermanent magnetsPhysicsMagnetic field magnitude

The invention relates to the technical field of precision actuation, in particular to an electric control vector magnetic field device and an installation method thereof. The device comprises: a sample table, wherein a sample support is arranged on the sample table; a magnetic field control mechanism which comprises a moving part and a driving part for driving the moving part to do precise linearmotion, wherein a permanent magnet is loaded at the end part of the moving part, and the extension lines of the moving direction and the polarization direction of the permanent magnet are orthogonal to the center of the sample support. Precise actuation of the permanent magnet in one direction is controlled through the magnetic field control mechanism, the permanent magnet is accurately controlledto be close to or away from a sample on the sample support, and therefore the magnetic field intensity of the sample is accurately controlled. The electric control vector magnetic field device is compact in structure, high in braking precision and large in magnetic field regulation and control range.

Owner:PEKING UNIV

Brake force real-time adjusting method based on brake-by-wire system and adjusting device

ActiveCN102582600BHigh braking precisionBrake force adjustmentElectrodynamic brake systemsBraking systemsLoop controlElectric machinery

The invention provides a brake force real-time adjusting method based on a brake-by-wire system. The brake force real-time adjusting method comprises following steps: respectively obtaining objective position signal values of motors in various electronic and mechanical brakes of front wheels and / or rear wheels of a brake vehicle according to strokes of electronic brake pedals; respectively acquiring actual position signal values, actual rotation speed signal values and actual current signal values of the motors in real time; and respectively realizing real-time closed-loop control for positions, rotation speeds and current of the motors according to deviation between the objective position signal values and the actual position signal values of the motors, the actual rotation speed signal values and the actual current signal values, and accordingly adjusting actually outputted brake force of the electronic and mechanical brakes with the motors in real time. Correspondingly, the invention provides a brake force real-time adjusting device. The brake force real-time adjusting method and the adjusting device can suppress fluctuation generated when brake force is adjusted in real time in the prior art, stability of the brake-by-wire system is improved, and a braking effect is good.

Owner:CHERY AUTOMOBILE CO LTD

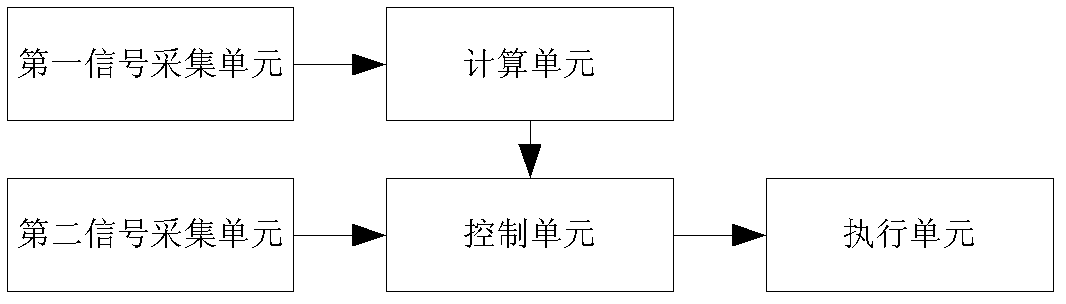

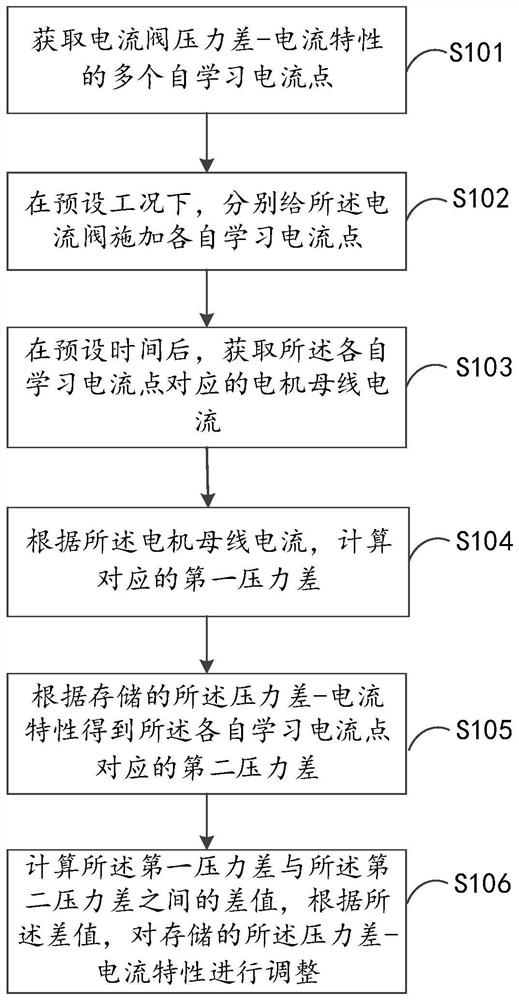

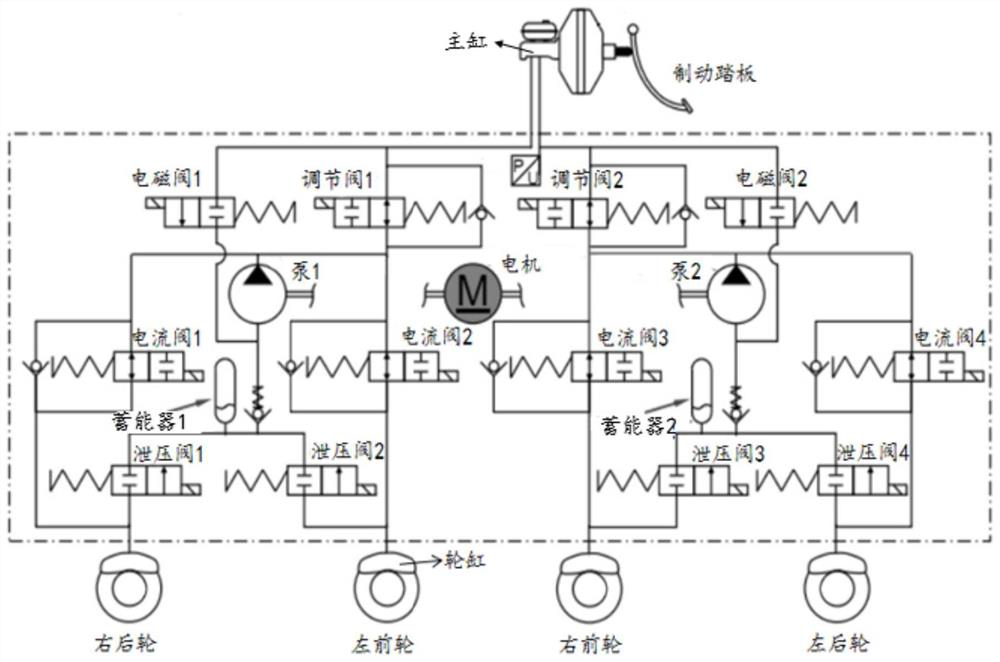

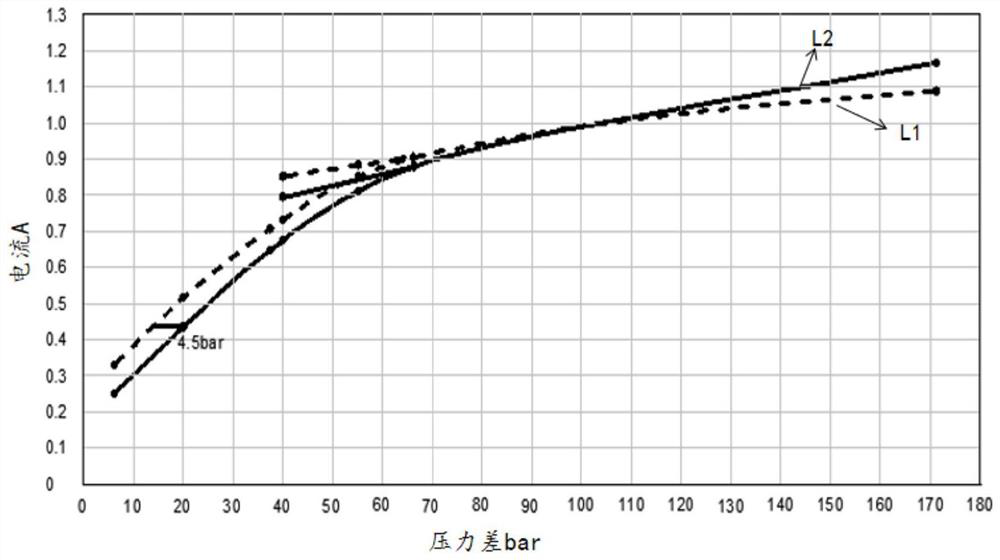

A self-learning method and system for current valve pressure difference-current characteristics

ActiveCN112389418BLow manufacturing process costHigh braking precisionBraking action transmissionControl devicesManufacturing technologyControl system

The present invention provides a self-learning method and system for the pressure difference-current characteristic of a current valve. The self-learning method is applied to the self-learning system, including: obtaining multiple self-learning current points of the pressure difference-current characteristic; Under the set working conditions, apply respective learning current points to the current valves; after a preset time, obtain the motor bus currents corresponding to the respective learning current points; calculate the corresponding first pressure difference according to the motor bus currents ; Obtain the second pressure difference corresponding to the respective learning current points according to the stored pressure difference-current characteristics; calculate the difference between the first pressure difference and the second pressure difference, and according to the difference , to adjust the stored pressure difference-current characteristics. The invention adjusts the pressure difference-current characteristics of the current valve through a self-learning method, thereby reducing the manufacturing process cost of the current valve while improving the braking accuracy of the electronic stability control system.

Owner:上海拿森汽车电子有限公司

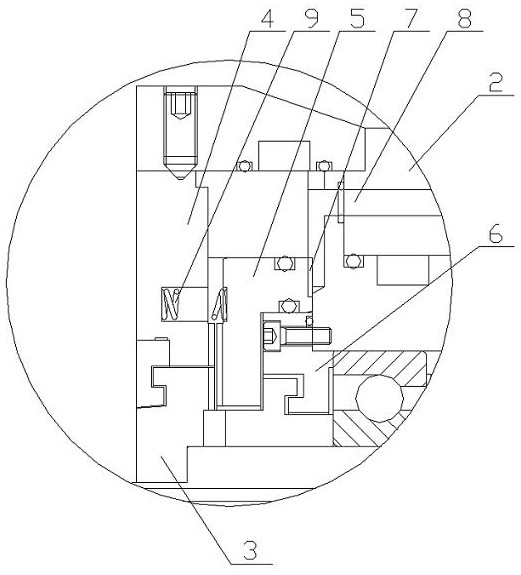

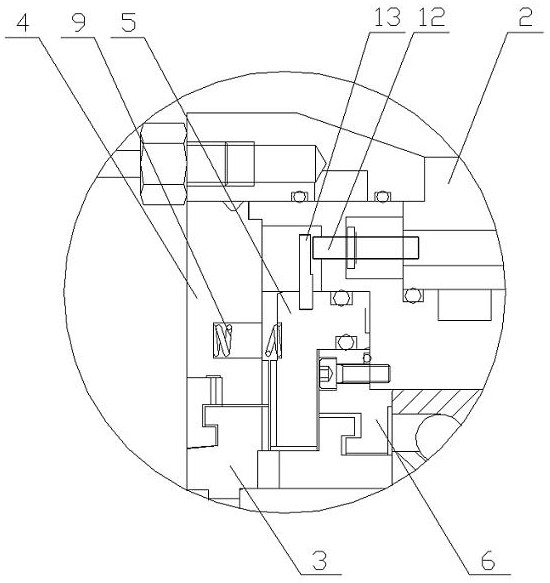

A High Precision Braking Mechanism

ActiveCN107401565BEasy to installPrevent radial slippageBrake actuating mechanismsActuatorsRotational axisEngineering

The invention relates to a high-precision braking mechanism, which includes a brake switch, a brake disc, a switch connection frame, a rotating shaft and a driving device; the driving device is connected to the input end of the rotating shaft, and is characterized in that the brake disc It is installed on the shoulder of the rotating shaft and rotates with the rotating shaft; the brake switch is installed on the switch connecting frame; the brake switch includes an electromagnetic switch, a return spring and an iron core, and the iron core is inserted into the electromagnetic The connection between the electromagnetic switch and the iron core is completed by the return spring; the brake disc includes a fixed base and six disc teeth with the same structure; the six disc teeth are used to fix the base The base is evenly distributed on the side of the cylinder of the fixed base, and the width of each tooth is gradually reduced from the connection end of the fixed base to the end of the tooth; the ends of the teeth are symmetrically arranged with V-shaped grooves on both sides; The fixed base is cylindrical with a bottom end capped.

Owner:HEBEI UNIV OF TECH

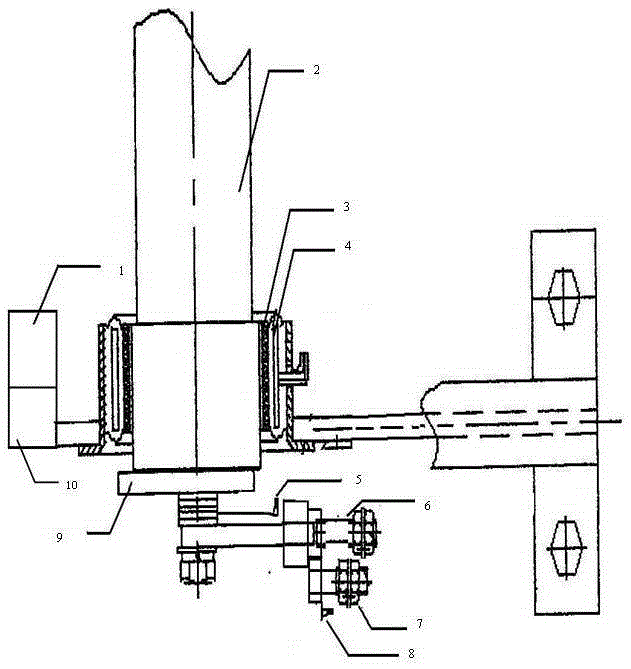

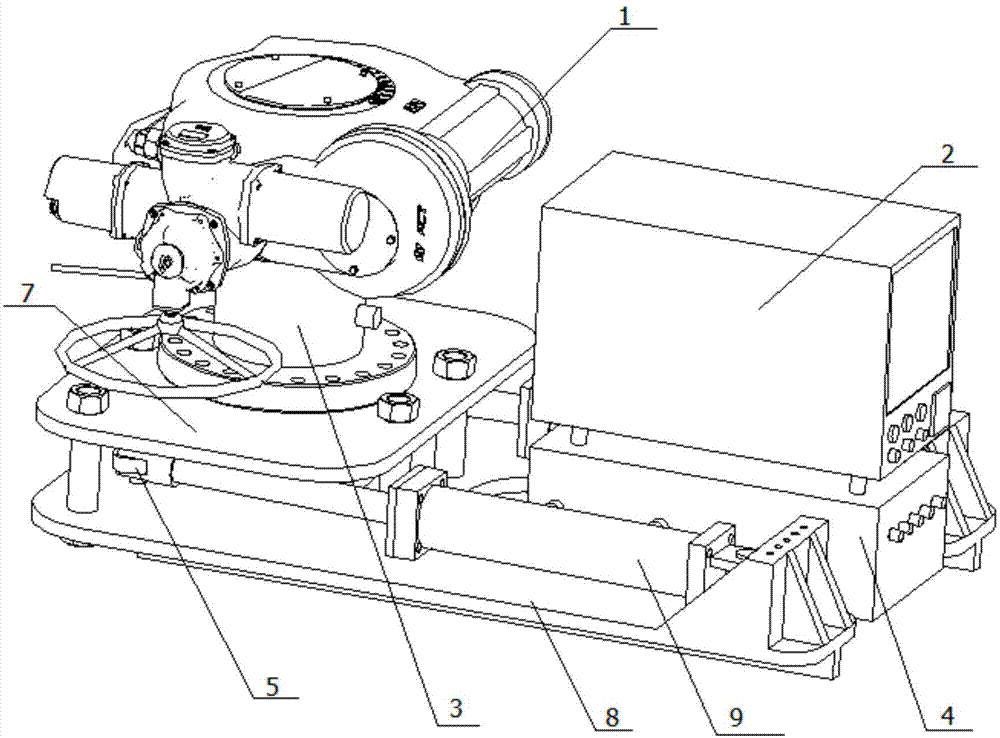

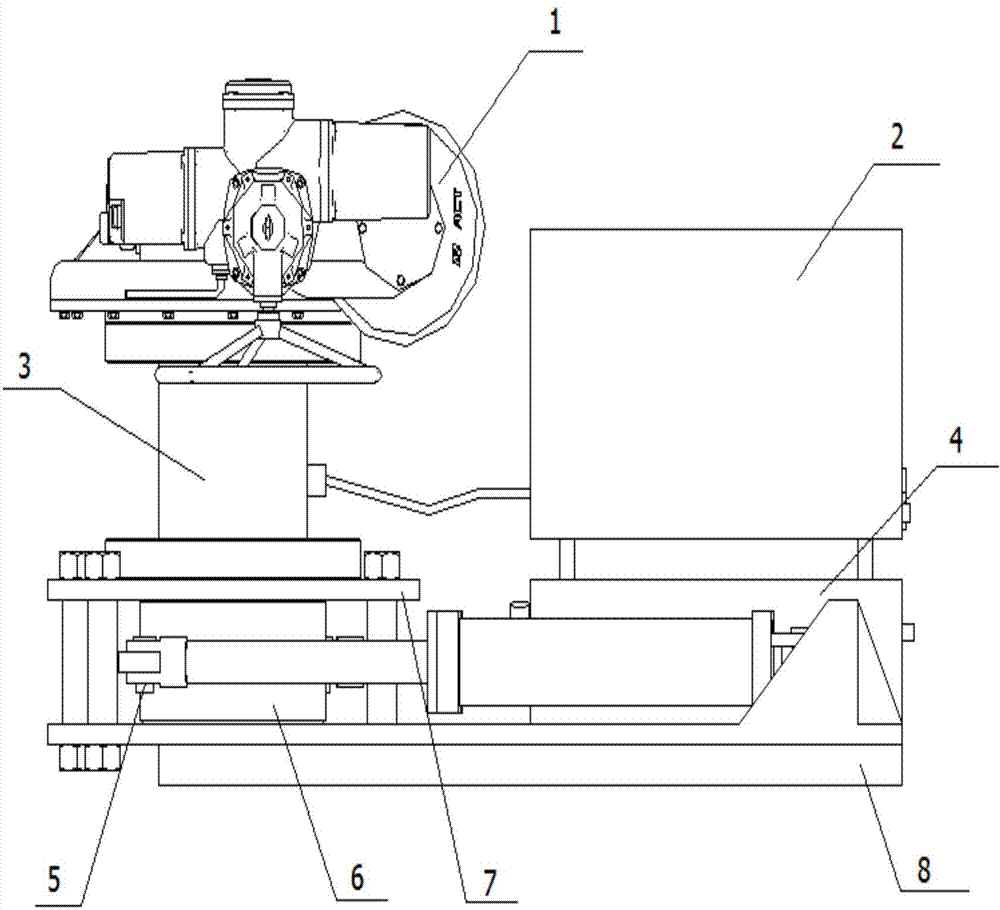

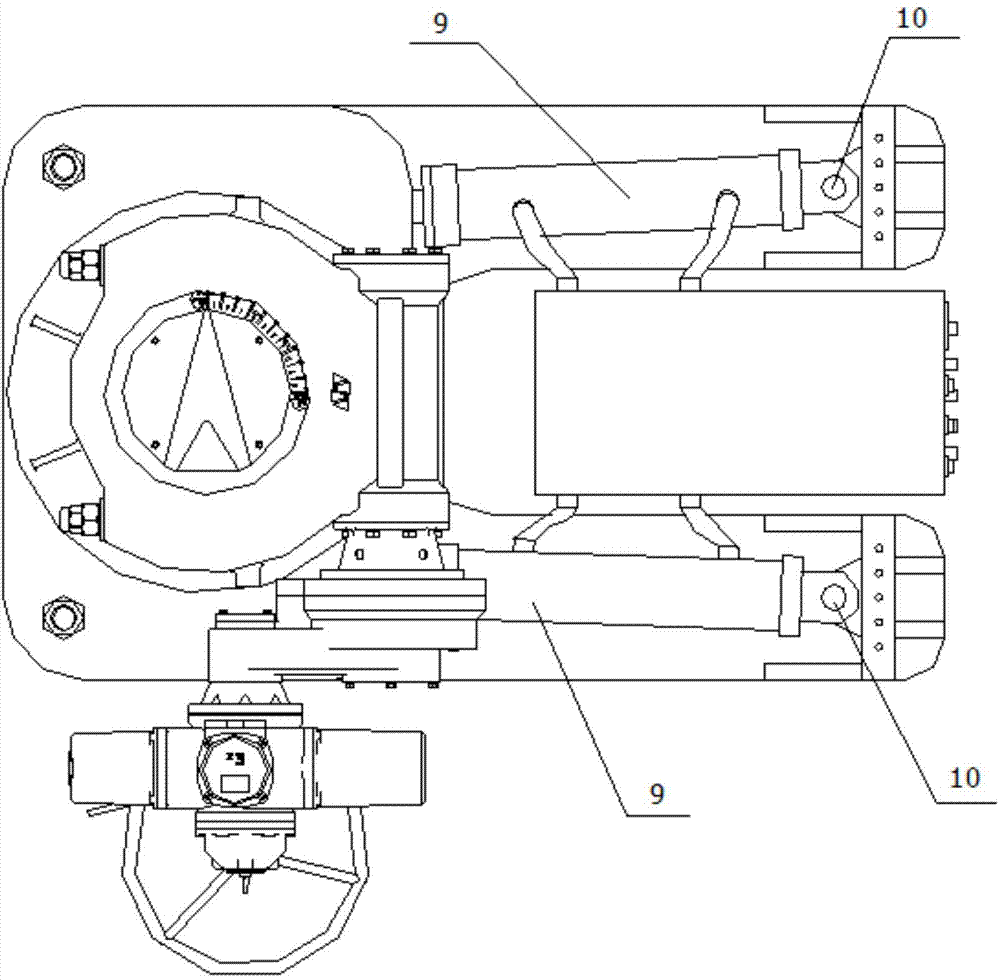

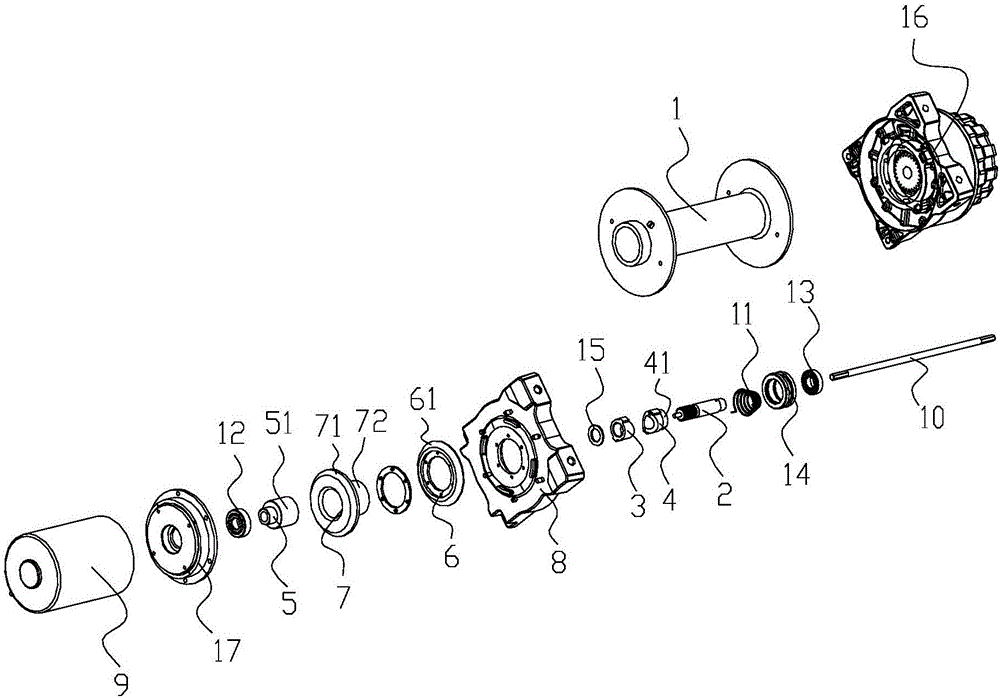

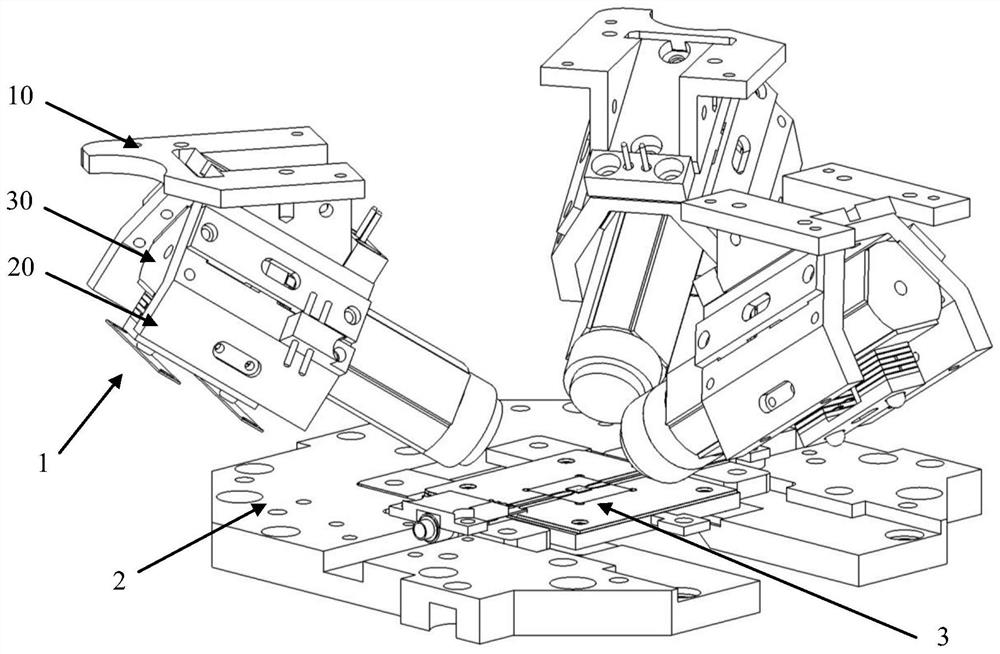

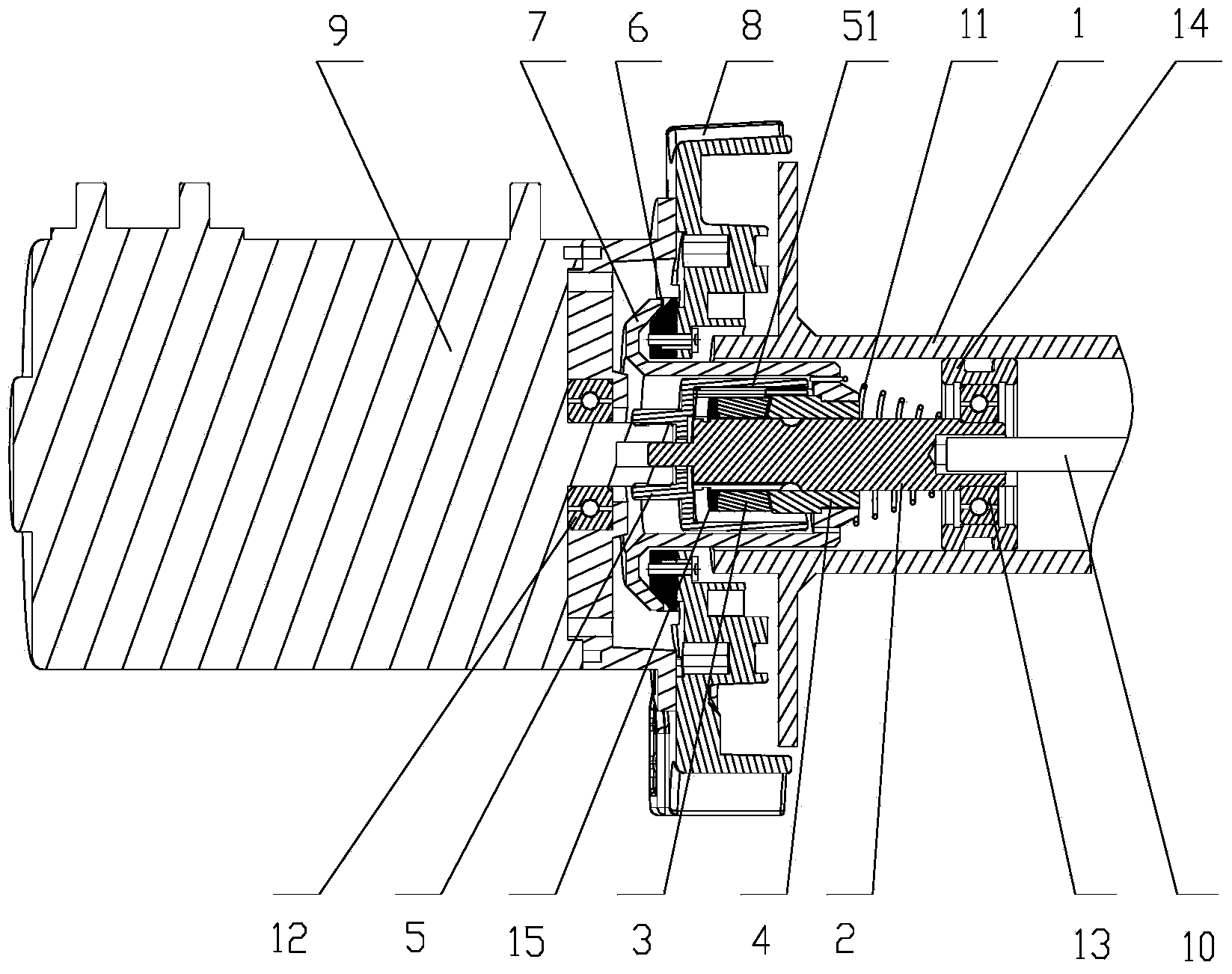

Torque detecting device of large-torque electric actuating mechanism

ActiveCN103487184BReal-time displayAccurate torque detectionWork measurementTorque measurementDrive shaftControl theory

The invention provides a torque detecting device of a large-torque electric actuating mechanism. The torque detecting device of the large-torque electric actuating mechanism comprises the large-torque electric actuating mechanism, a fixing mechanism, a torque detecting mechanism and a braking mechanism. The large-torque electric actuating mechanism comprises an electric actuating component and an output shaft connected with the electric actuating component. The fixing mechanism comprises a base and a base plate which is located above the base and fixed with the base. The torque detecting mechanism comprises a reactive force torque sensor located below the electric actuating component. One end of the reactive force torque sensor is fixedly connected with the electric actuating component, and the other end of the reactive force torque sensor is fixed with the base plate. The braking mechanism comprises a transmission shaft and a braking component. One end of the transmission shaft is connected with the output shaft, and the other end of the transmission shaft is connected with the braking component. According to the torque detecting device of the large-torque electric actuating mechanism, real-time display of on-line torque curves of the large-torque electric actuating mechanism can be achieved, accurate precision data are provided for analysis, experiments and tests of the large-torque electric actuating mechanism, and the braking is stable and low in noise in the braking detecting process.

Owner:TIANJIN AIKETE MEASUREMENT CONTROL TECH

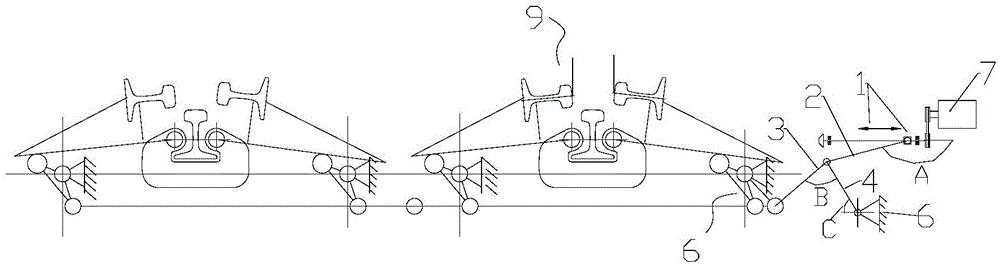

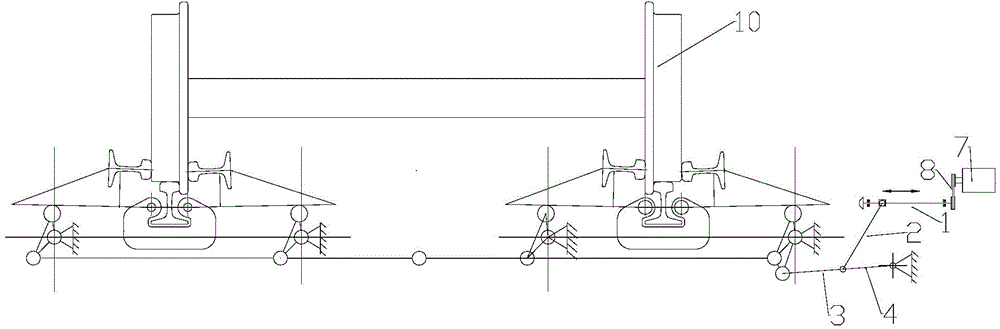

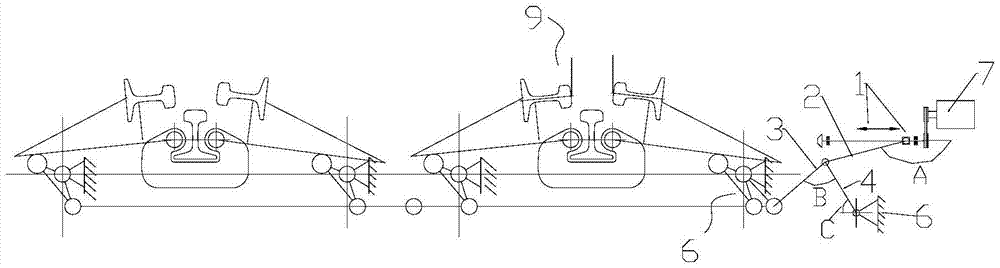

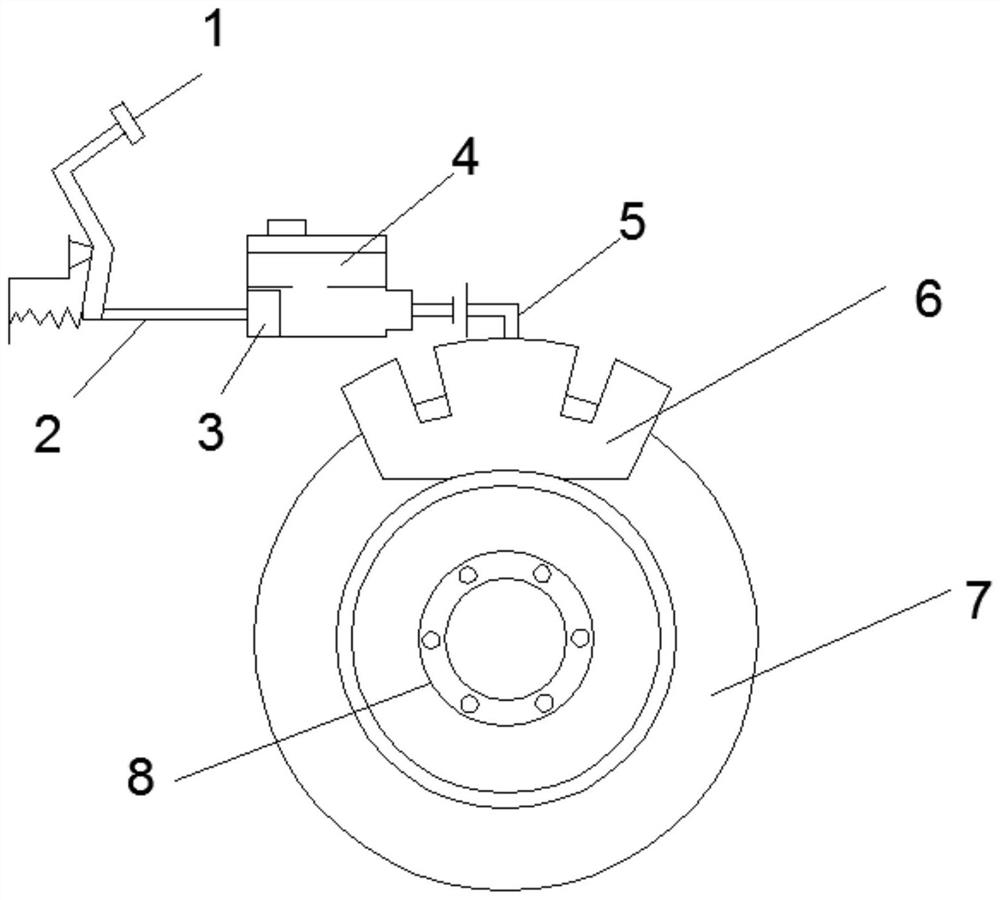

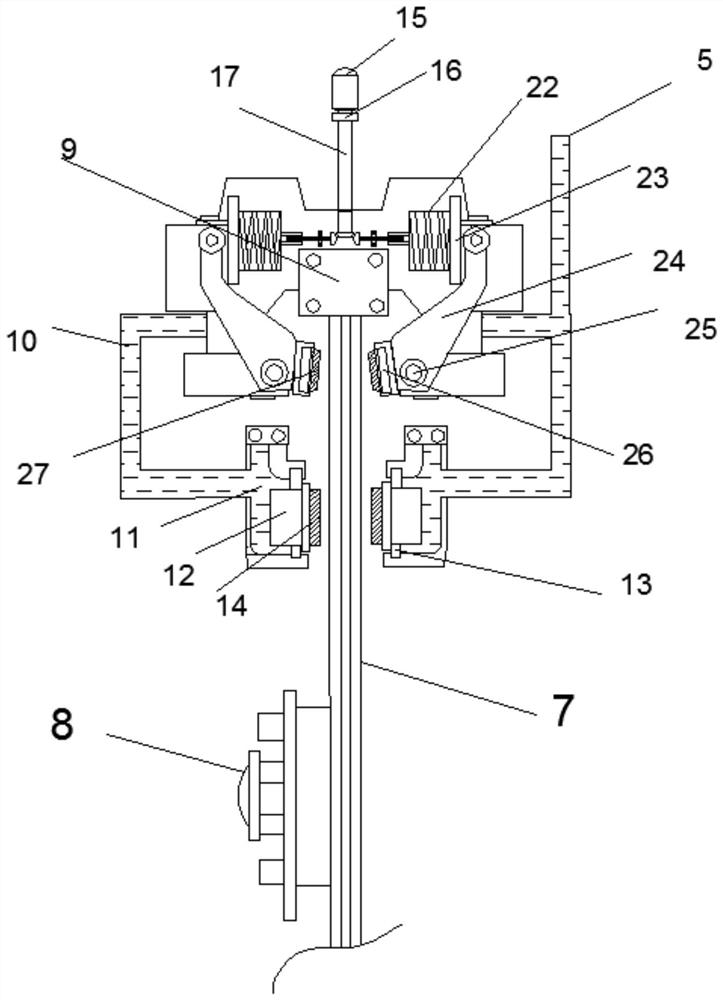

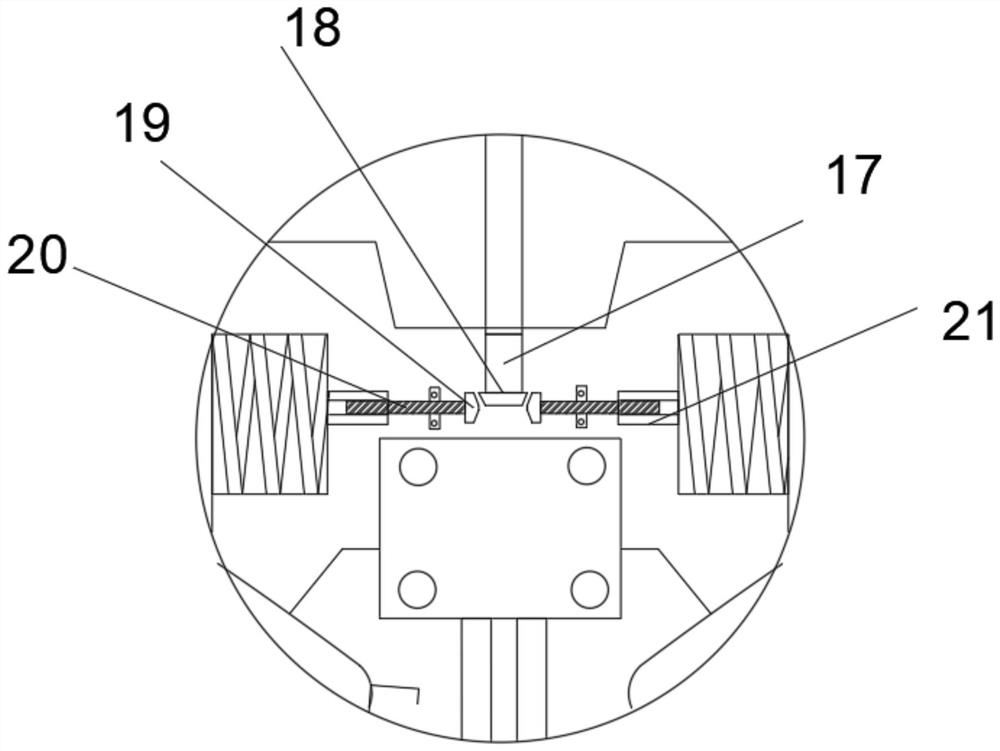

Decelerating brake method and device of electric vehicle and application of lead screw transmission mechanism

InactiveCN104802824ALarge thrustThere will be no problem of large shock and vibrationBraking action transmissionRail brake actuationLinear motionReduction drive

The invention discloses a method for realizing decelerating brake of a rail electric vehicle. The method comprises a step of arranging a pedestal, vehicle inner and outer brake calipers, a motor, a big crankshaft and a link transmission mechanism, and also comprises the following steps: (1) flexibly connecting the motor with a translation mechanism to convert the rotation of the motor into linear motion, pushing the link transmission mechanism through the translation mechanism via a transmission link to relieve and brake wheels of the rail electric vehicle; (2) meanwhile moving the transmission link under pushing of the translation mechanism to realize an effect of increasing thrust to naturally slow down a brake end point, and acting most of impact force stressed on the transmission link on the translation mechanism and a mounting seat thereof when the transmission link is close to or at the brake end point. The invention also discloses an electric vehicle decelerator device and application of the lead screw transmission mechanism. The brake process is stable, inadequate brake caused by kinematic accumulative error can be effectively avoided, the impact and the vibration to the motor are effectively reduced, a motor shaft is protected, and the brake precision is improved.

Owner:FOSHAN ANJIELUN TECH CO LTD

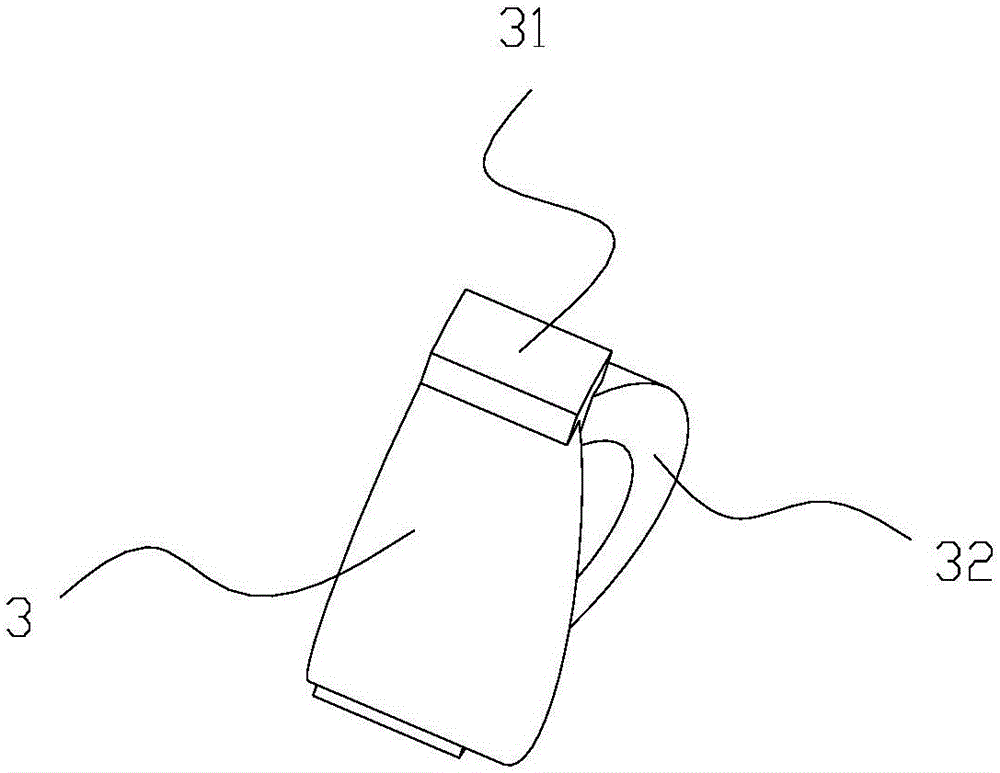

a brake device

The invention discloses a brake apparatus which comprises a rotary drum, a spline shaft, a cam with an internal spline, a cam with an internal circular hole, a coupling, a brake pad and a conical brake disc. The spline shaft is inserted into the rotary drum, the conical brake disc is matched with the brake pad, the rotary drum is connected with a motor by a support, the brake pad is fixedly arranged on the support, a conical surface is arranged at the peripheral edge of the brake pad, the conical brake disc comprises a conical disc and a sleeve, the conical disc runs in with the conical surface, the sleeve is integrally connected with the conical disc, one end of the sleeve is positioned in the rotary drum and is fixedly connected with the cam with the internal circular hole, a tower torsion spring is arranged at the tail end of the spline shaft, and two ends of the tower torsion spring are respectively connected with the spline shaft and the sleeve. The brake apparatus has the advantages that the rotary drum is small in size and low in cost; the brake apparatus is high in brake precision, and the brake stability can be improved; the problem that an existing rotary drum generates heat in no-load states can be effectively solved, and accordingly the mechanical performance of the brake apparatus can be improved.

Owner:NINGBO ZHONGHUANG MACHINE & ELECTRICS

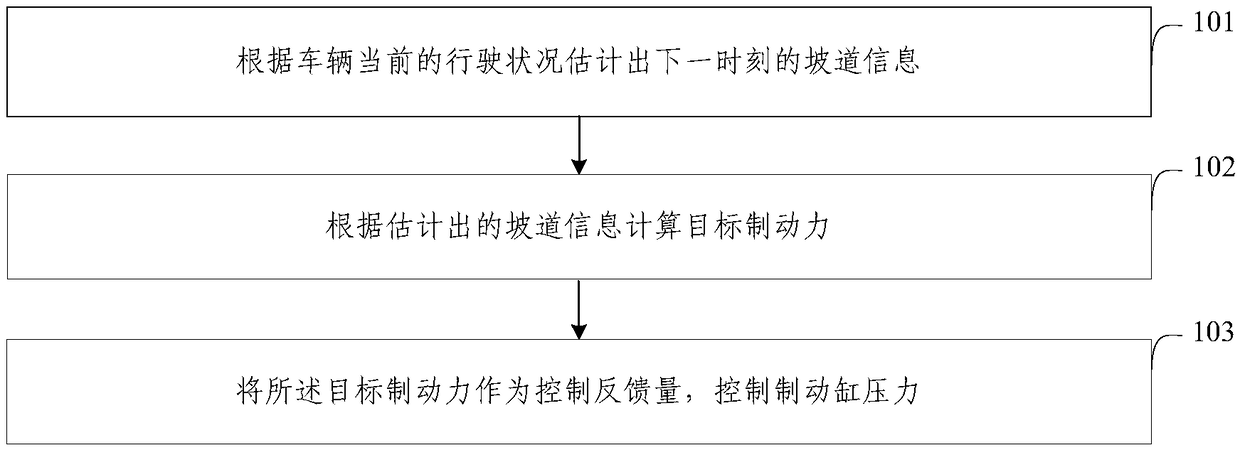

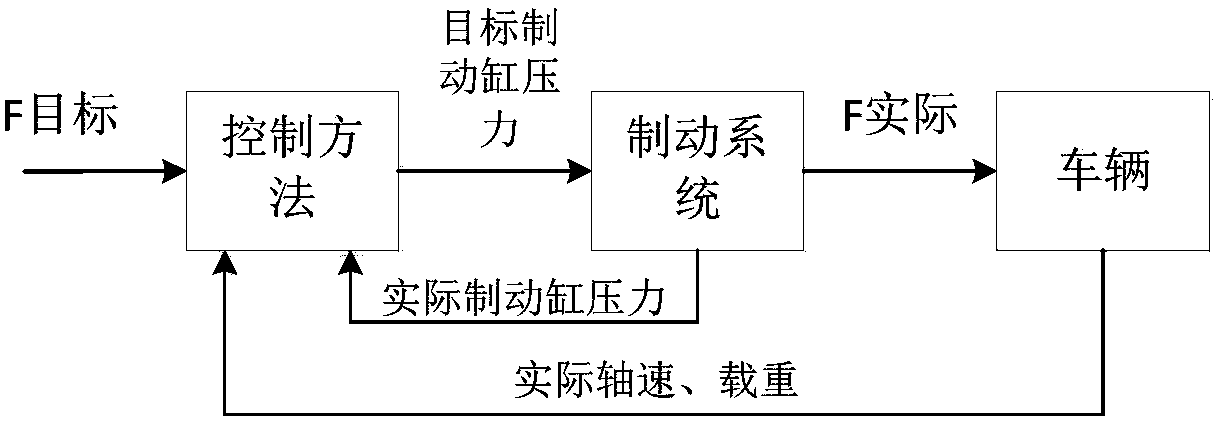

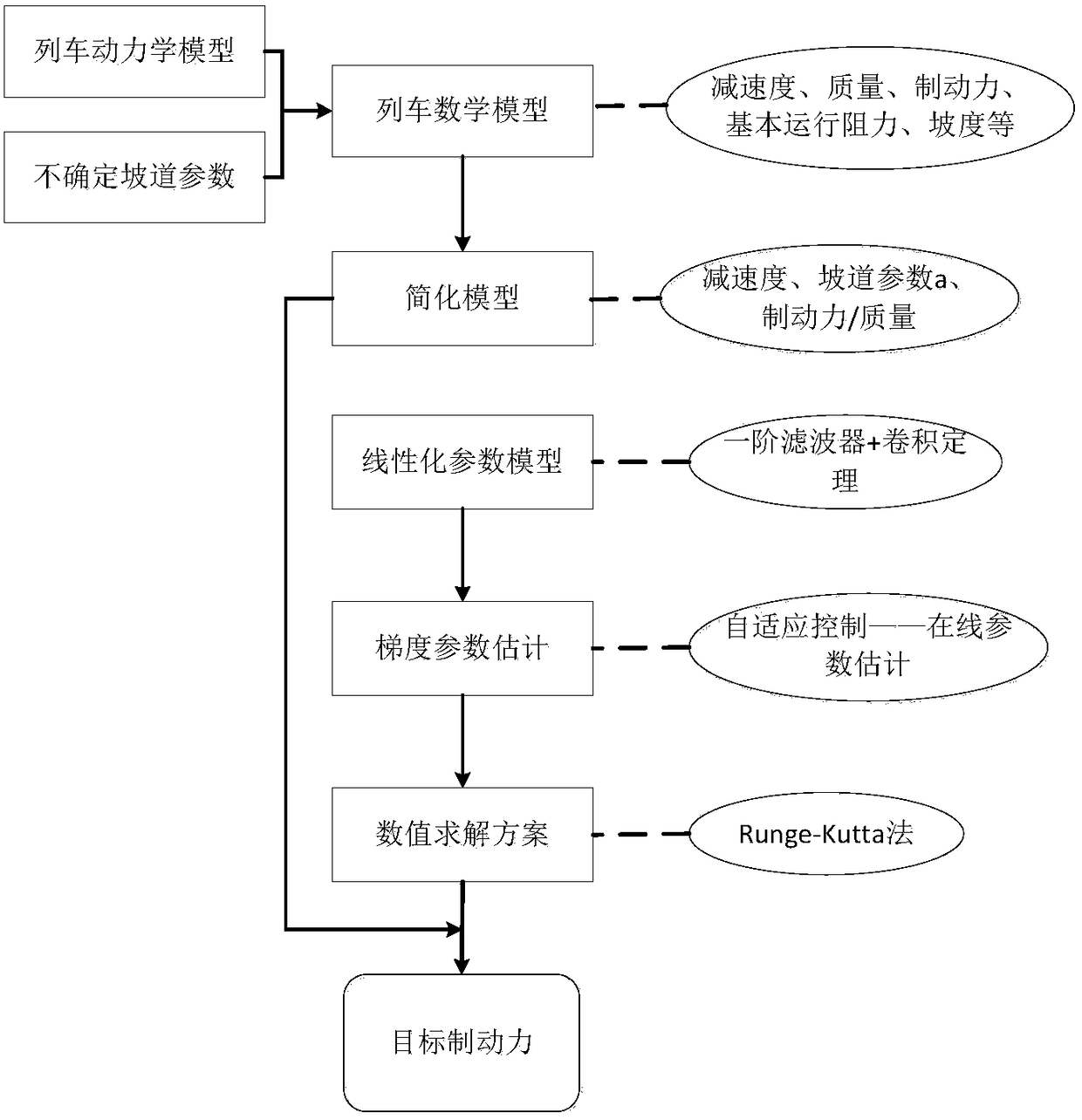

Rail vehicle adaptive gradient braking control method and system

ActiveCN106004830BImprove adaptabilityHigh braking precisionAutomatic initiationsEngineeringSelf adaptive

The invention provides a method and a system for controlling self-adaption gradient braking of a railway vehicle. The method comprises the following steps: estimating the ramp information at the next moment according to a current driving condition of the vehicle; calculating a target braking force according to the estimated ramp information; taking the target braking force as a control feedback volume and controlling the pressure of a braking cylinder. According to the method for controlling self-adaption gradient braking of the railway vehicle provided by theinvention, the braking force of the vehicle can be real-time adjusted according to the condition of line gradient, so that the adaptation of the vehicle to uncertain parameters under the ramp condition in the practical braking process can be increased.

Owner:CRRC QINGDAO SIFANG CO LTD

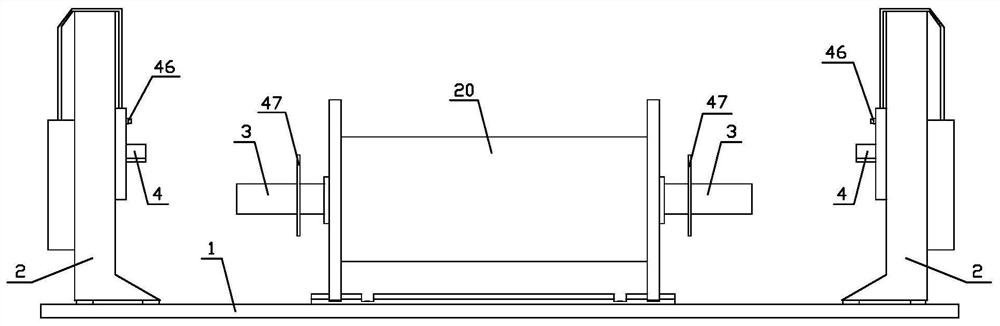

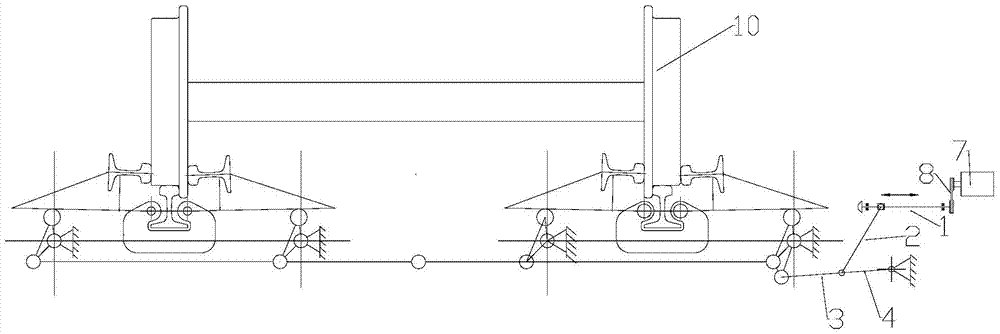

An automatic power cable unwinding device and its operating method

ActiveCN112193914BAvoid damageImprove versatilityFilament handlingElectronic waste recyclingPower cableEngineering

The invention discloses an automatic power cable unwinding device and an operation method thereof. Among them, the power cable automatic unwinding device includes an installation base plate, a door-shaped stand, a door-shaped stand walking mechanism, an intermediate transfer part, a lifting mechanism, a supporting part, a braking mechanism, a sensing part and a control part. The door-type stand is installed on the installation base plate, and is equipped with a door-type stand walking mechanism. Under the action of the door-shaped stand walking mechanism, the door-shaped stand can move left and right, the intermediate transfer part is used to connect with the cable reel to improve the versatility of the device of the present invention, and the lifting mechanism is used to drive the cable reel to lift When reaching a certain height, the braking mechanism cooperates with the sensing parts, etc., which is beneficial to realize unwinding the cable at a uniform speed. Since the present invention does not directly brake the cable reel, it avoids damage to the edge of the cable reel, and at the same time ensures the smoothness of braking. In addition, the braking precision of the device of the present invention is high.

Owner:贵州电网有限责任公司都匀福泉供电局

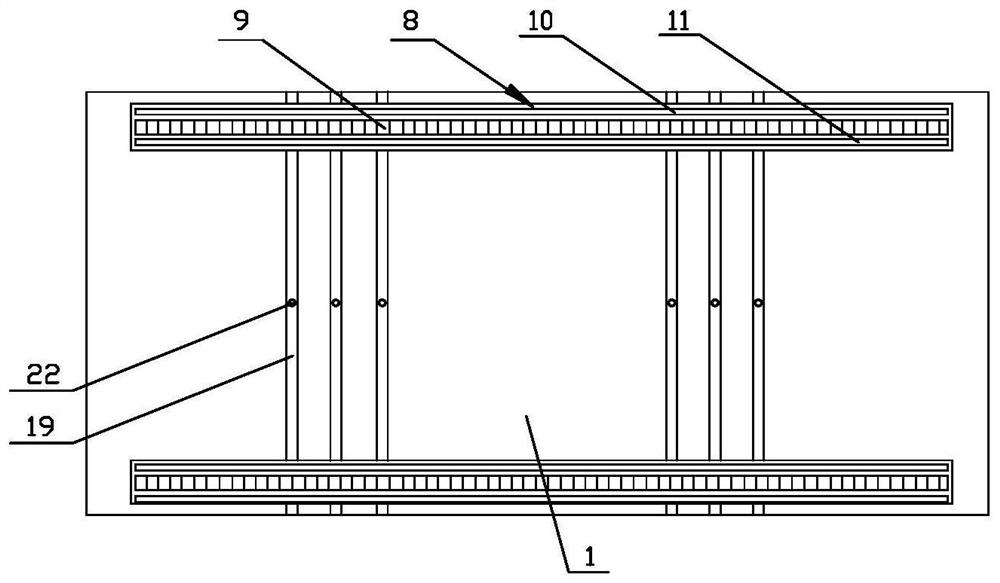

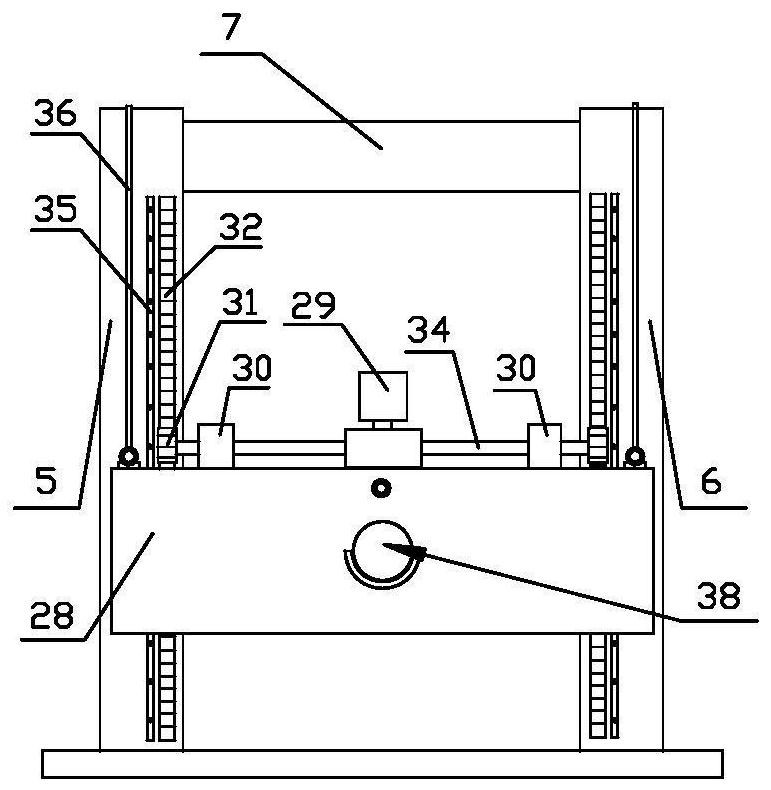

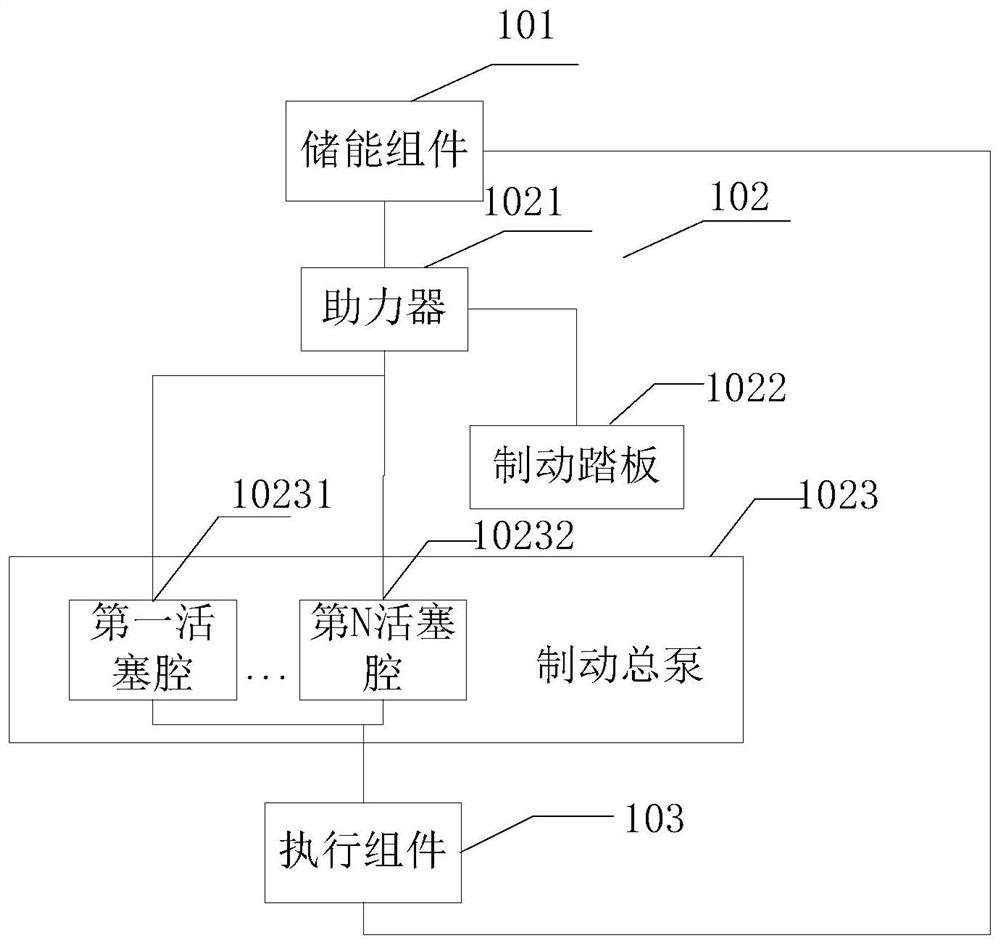

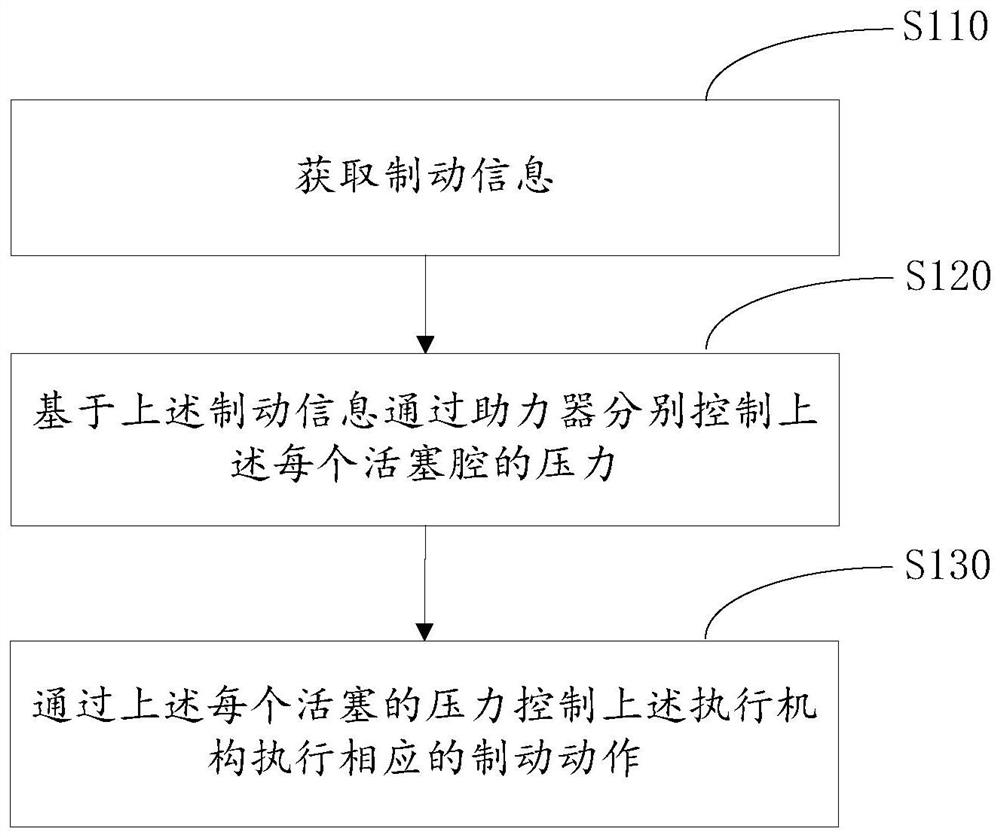

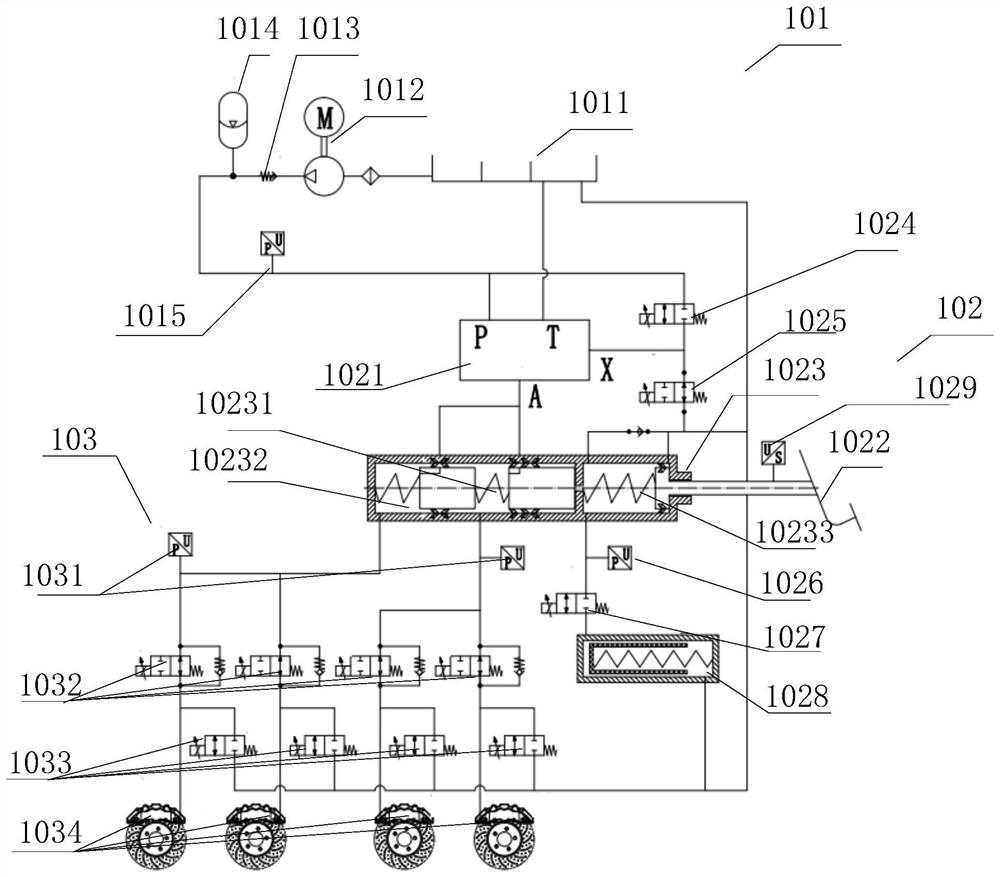

Hydraulic braking system, hydraulic braking control method and related equipment

ActiveCN114162102AHigh braking precisionFast braking responseBraking action transmissionMaster cylinderDisplacement control

The invention discloses a hydraulic brake control system, a hydraulic control method and related equipment. The system comprises an energy storage assembly, a control assembly and an execution assembly. The control assembly comprises boosters, a brake master cylinder and a brake pedal, the brake master cylinder comprises at least two piston cavities, the boosters are connected to the piston cavities respectively, and the boosters are used for controlling the pressure of the piston cavities according to the displacement of the brake pedal so as to send out a brake instruction; the execution assembly is used for executing the braking action corresponding to the control instruction sent by the control assembly. The booster is connected with each piston cavity of the brake master cylinder, the pressure of each piston cavity can be directly controlled through the displacement of the brake pedal, the execution assembly completes the braking action based on the pressure, the braking action is faster, the pistons do not move in the cavities, and complete decoupling of multi-piston movement is achieved.

Owner:武汉元丰汽车电控系统股份有限公司 +1

Method and device for deceleration and braking of electric vehicles and application of screw drive mechanism

InactiveCN104802824BLarge thrustThere will be no problem of large shock and vibrationBraking action transmissionRail brake actuationLinear motionReduction drive

The invention discloses a method for realizing decelerating brake of a rail electric vehicle. The method comprises a step of arranging a pedestal, vehicle inner and outer brake calipers, a motor, a big crankshaft and a link transmission mechanism, and also comprises the following steps: (1) flexibly connecting the motor with a translation mechanism to convert the rotation of the motor into linear motion, pushing the link transmission mechanism through the translation mechanism via a transmission link to relieve and brake wheels of the rail electric vehicle; (2) meanwhile moving the transmission link under pushing of the translation mechanism to realize an effect of increasing thrust to naturally slow down a brake end point, and acting most of impact force stressed on the transmission link on the translation mechanism and a mounting seat thereof when the transmission link is close to or at the brake end point. The invention also discloses an electric vehicle decelerator device and application of the lead screw transmission mechanism. The brake process is stable, inadequate brake caused by kinematic accumulative error can be effectively avoided, the impact and the vibration to the motor are effectively reduced, a motor shaft is protected, and the brake precision is improved.

Owner:FOSHAN ANJIELUN TECH CO LTD

An intelligent control compound braking device and its braking method

ActiveCN111994060BAct as a brakeReduce wearBraking element arrangementsBraking action transmissionMaster cylinderControl theory

The invention relates to the technical field of automobile braking, and discloses an intelligent control composite braking device and a braking method thereof, comprising a brake pedal, a push rod is arranged on one side of the brake pedal, and a master cylinder piston is arranged on one side of the push rod One side of the push rod is fixedly connected to the brake master cylinder, one side of the brake master cylinder is fixedly connected to the oil pipe one, and the oil pipe one end is provided with a caliper. , the inside of the caliper is fixedly welded with a mounting plate, one end of the oil pipe is fixedly connected to the oil pipe two, and the two ends of the oil pipe two are respectively provided with a brake auxiliary cylinder, the inner part of the brake auxiliary cylinder is fixedly installed with an auxiliary cylinder piston, and the outer circumference of the auxiliary cylinder piston is fixedly installed with piston groove. The intelligent control composite braking device and its braking method, using electro-hydraulic hybrid braking, have fast braking speed, high braking precision, simple structure and low manufacturing cost, which improves the degree of intelligent control and the braking safety of vehicles. performance.

Owner:东莞市金久鼎电子科技有限公司

A rail vehicle air brake parking control method and system

The invention discloses a rail vehicle air brake parking control method, the steps include acquiring a first preset relationship between speed and friction coefficient under different braking forces; acquiring the current braking force and current speed of the rail vehicle to obtain the current friction coefficient; Correct the current friction coefficient according to the obtained current deceleration to obtain the corrected friction coefficient; compare whether the current deviation between the current deceleration and the preset deceleration is within the preset deviation range, and if so, obtain the current braking force corresponding to the current friction coefficient ; If not, obtain the corrected braking force corresponding to the corrected friction coefficient. Accurately obtain the current friction coefficient based on the current speed and current braking force, and correct the current friction coefficient to obtain the corrected friction coefficient, and select the correct friction coefficient between the current friction coefficient and the corrected friction coefficient according to the current deceleration to make the braking force more accurate value, the braking accuracy is higher. The invention also discloses a rail vehicle air brake parking control system.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

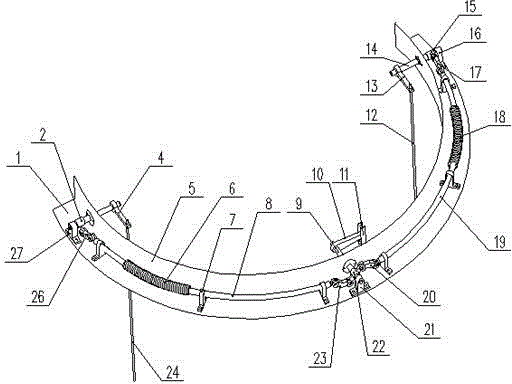

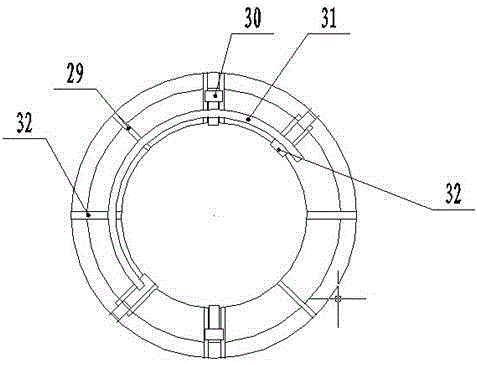

Ring type safe plier connecting rod pulling mechanism

InactiveCN102815638BSolve safe operationLifting is effectiveHoisting equipmentsEngineeringPulling action

The invention discloses a ring type safe plier connecting rod pulling mechanism which is suitable for ring type elevators. The ring type safe plier connecting rod pulling mechanism comprises a speed limiter rope dragging mechanism, a left safe plier pulling mechanism, a right safe plier pulling mechanism, a left linkage mechanism and a right linkage mechanism, the speed limiter rope dragging mechanism, the left safe plier pulling mechanism and the right safe plier pulling mechanism are installed on an arc-shaped bottom plate and an arc-shaped side plate which are mutually connected and arranged on the inner side of a lift car, the left safe plier pulling mechanism and the right safe plier pulling mechanism are distributed on the left and right sides of the speed limiter rope dragging mechanism respectively, the speed limiter rope dragging mechanism is respectively connected with the left safe plier pulling mechanism and the right safe plier pulling mechanism by the aid of the left linkage mechanism and the right linkage mechanism, namely, when the speed limiter is operated, by the aid of the left linkage mechanism and the right linkage mechanism, the speed limiter rope dragging mechanism synchronously drives the left safe plier pulling mechanism and the right safe plier pulling mechanism to perform pulling actions for corresponding safe pliers. The ring type safe plier connecting rod pulling mechanism has the advantages of being simple in structure, high in braking accuracy and good in reliability.

Owner:CHINA UNIV OF MINING & TECH

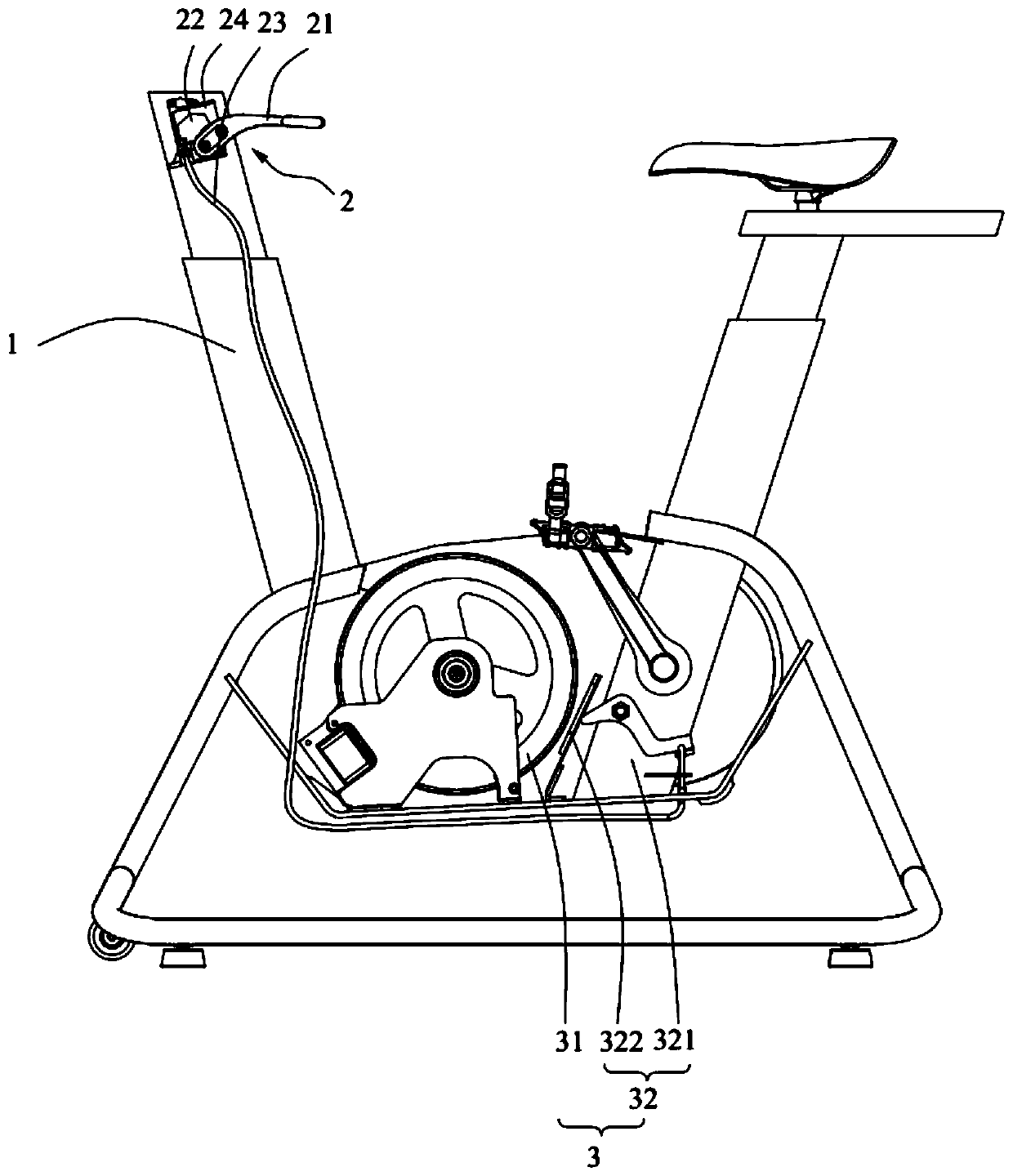

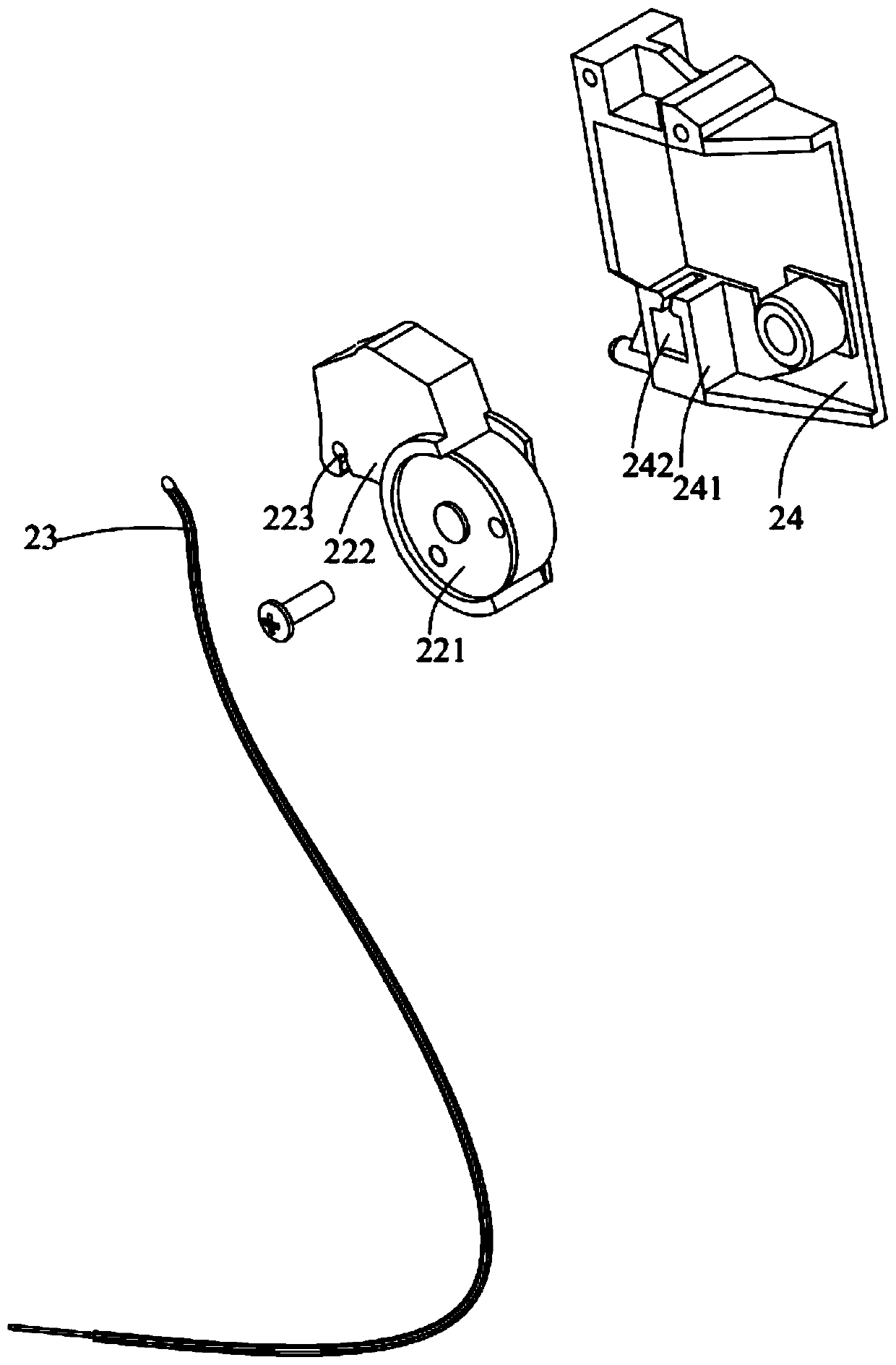

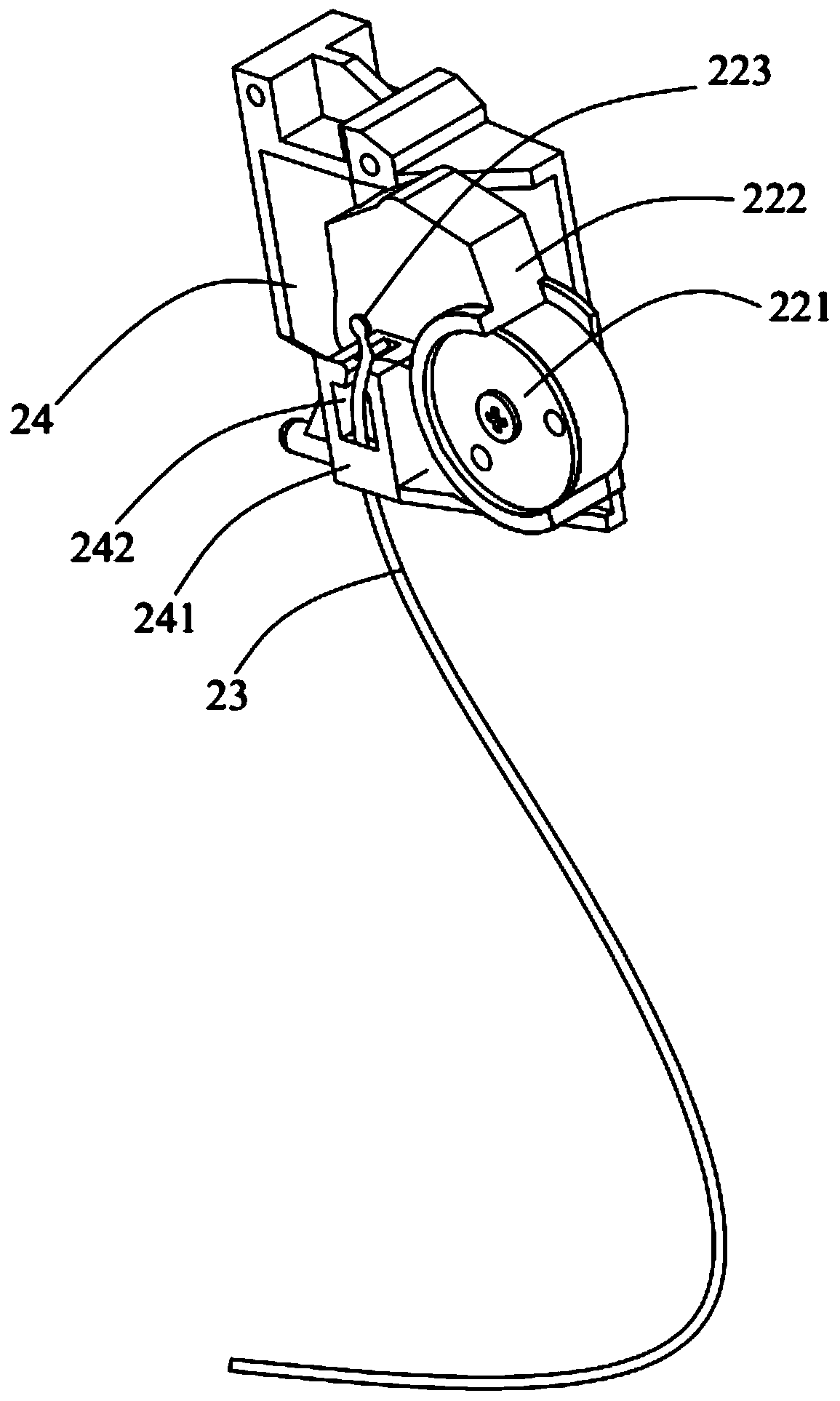

Brake device and fitness bicycle

PendingCN110585659AAchieve emergency mechanical braking effectRealize the role of normal ridingMovement coordination devicesCardiovascular exercising devicesFreewheelEngineering

The invention belongs to the technical field of fitness equipment, and discloses a brake device and a fitness bicycle. The brake device comprises a frame, wherein a driving mechanism and a brake mechanism are arranged on the frame; the driving mechanism comprises a handle, a rotary base and a rope; the rotary base is connected to one end of each of the handle and the rope respectively; the brake mechanism comprises a flywheel and a brake assembly; both the flywheel and the brake assembly are rotationally arranged on the frame; the brake assembly is connected to the other end of the rope; the handle is configured to drive the rotary base to rotate relative to the frame; and the brake assembly is driven to rotate relative to the frame through the movement of the rope, so that the brake assembly can be pressed against the flywheel. According to the brake device, the driving mechanism and the brake mechanism cooperate with each other, the handle is linked with the rotary base and the ropein the braking or pressure relief process, and the brake assembly is driven to contact the flywheel selectively through the movement of the rope, so that high brake accuracy and high reliability are achieved, thereby improving the user experience.

Owner:深圳卡路里体育技术有限公司

An electronically controlled vector magnetic field device and its installation method

Owner:PEKING UNIV

Brake apparatus

The invention discloses a brake apparatus which comprises a rotary drum, a spline shaft, a cam with an internal spline, a cam with an internal circular hole, a coupling, a brake pad and a conical brake disc. The spline shaft is inserted into the rotary drum, the conical brake disc is matched with the brake pad, the rotary drum is connected with a motor by a support, the brake pad is fixedly arranged on the support, a conical surface is arranged at the peripheral edge of the brake pad, the conical brake disc comprises a conical disc and a sleeve, the conical disc runs in with the conical surface, the sleeve is integrally connected with the conical disc, one end of the sleeve is positioned in the rotary drum and is fixedly connected with the cam with the internal circular hole, a tower torsion spring is arranged at the tail end of the spline shaft, and two ends of the tower torsion spring are respectively connected with the spline shaft and the sleeve. The brake apparatus has the advantages that the rotary drum is small in size and low in cost; the brake apparatus is high in brake precision, and the brake stability can be improved; the problem that an existing rotary drum generates heat in no-load states can be effectively solved, and accordingly the mechanical performance of the brake apparatus can be improved.

Owner:NINGBO ZHONGHUANG MACHINE & ELECTRICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com