An automatic power cable unwinding device and its operating method

A power cable and automatic technology, applied in the field of electric power, can solve the problems of inaccurate braking force control, bending resistance, large motion inertia, damage, etc. of the cable disc, so as to avoid the problem of braking stability and high braking precision , the effect of improving the versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0185] Embodiment 2 describes an operation method of an automatic power cable unwinding device. Wherein, the automatic power cable unwinding device adopts the power cable automatic unwinding device in the first embodiment above.

[0186] Utilize this operation method, can realize the automatic unwinding operation of cable reel 20, concrete operation process is as follows:

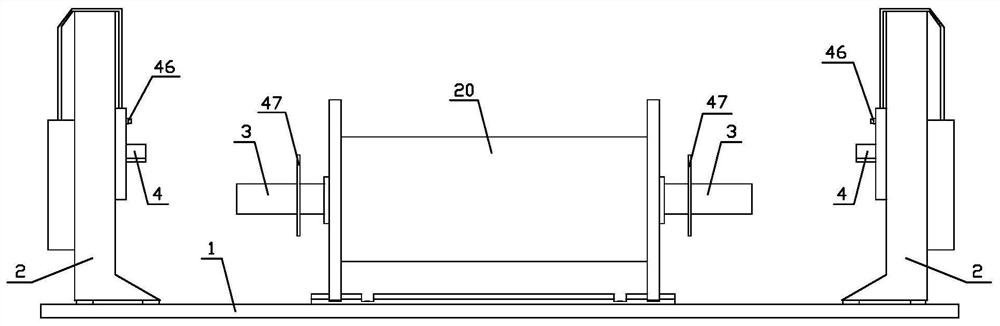

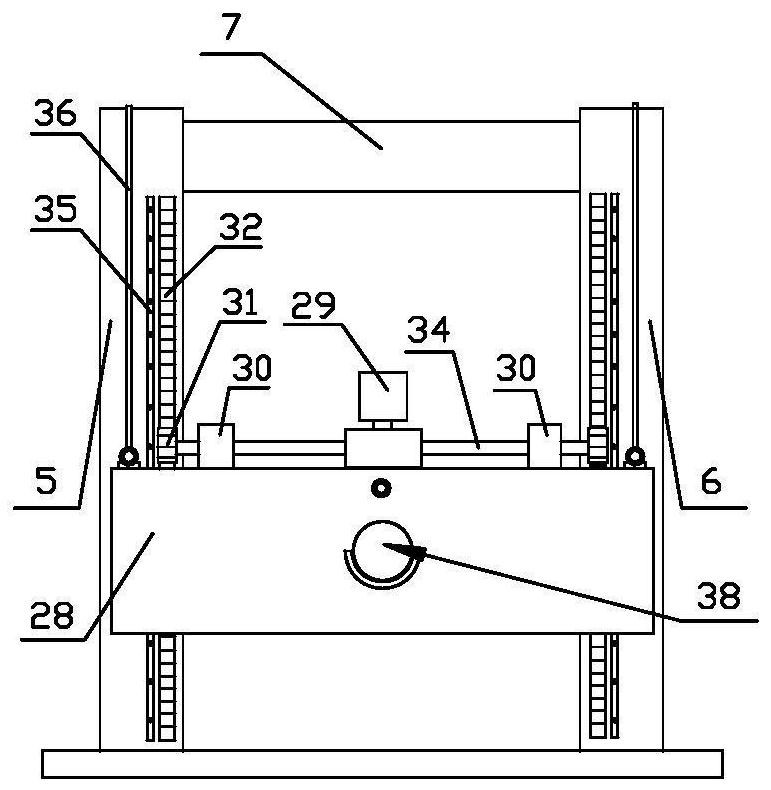

[0187] a. Align the flanges of the two intermediate transfer parts 3 with the middle holes of the cable reel 20, and fasten them with bolts. After the fastening is completed, the intermediate transfer parts 3 are connected to the cable reel 20 as one, as Figure 14 shown.

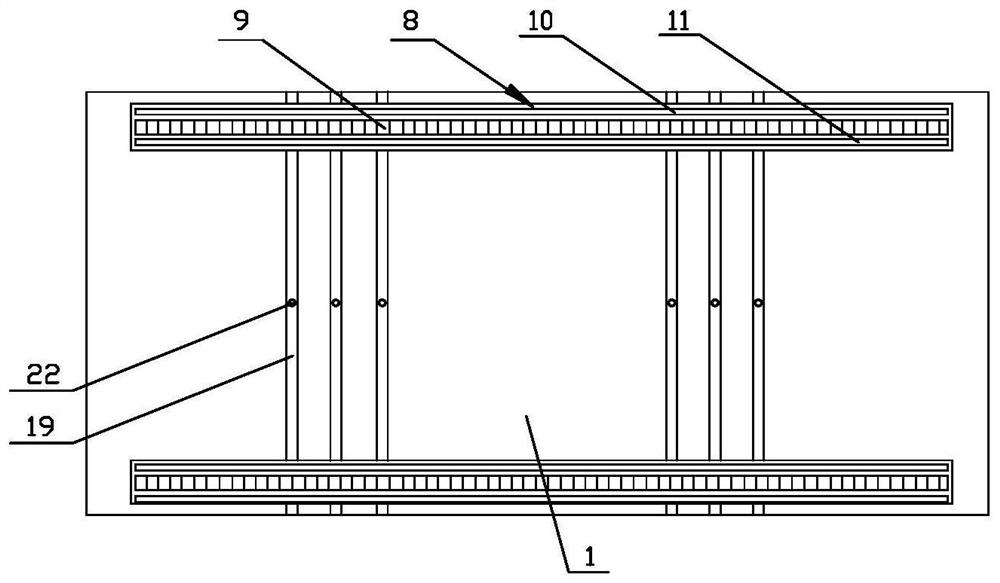

[0188] b. From the front side or rear side of the installation base plate 1, push the cable reel 20 with the intermediate transfer part 3 into a certain group of cable reel guide grooves 19, the group of cable reel guide grooves 19 and the cable The discs 20 are equal in width.

[0189] Wherein, the width of the cable reel 20 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com