High-precision brake mechanism

A brake mechanism, high-precision technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of relatively high heat dissipation requirements, large braking torque, stator and rotor contact, etc., to reduce installation requirements, reduced braking torque, and the effect of reduced component weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

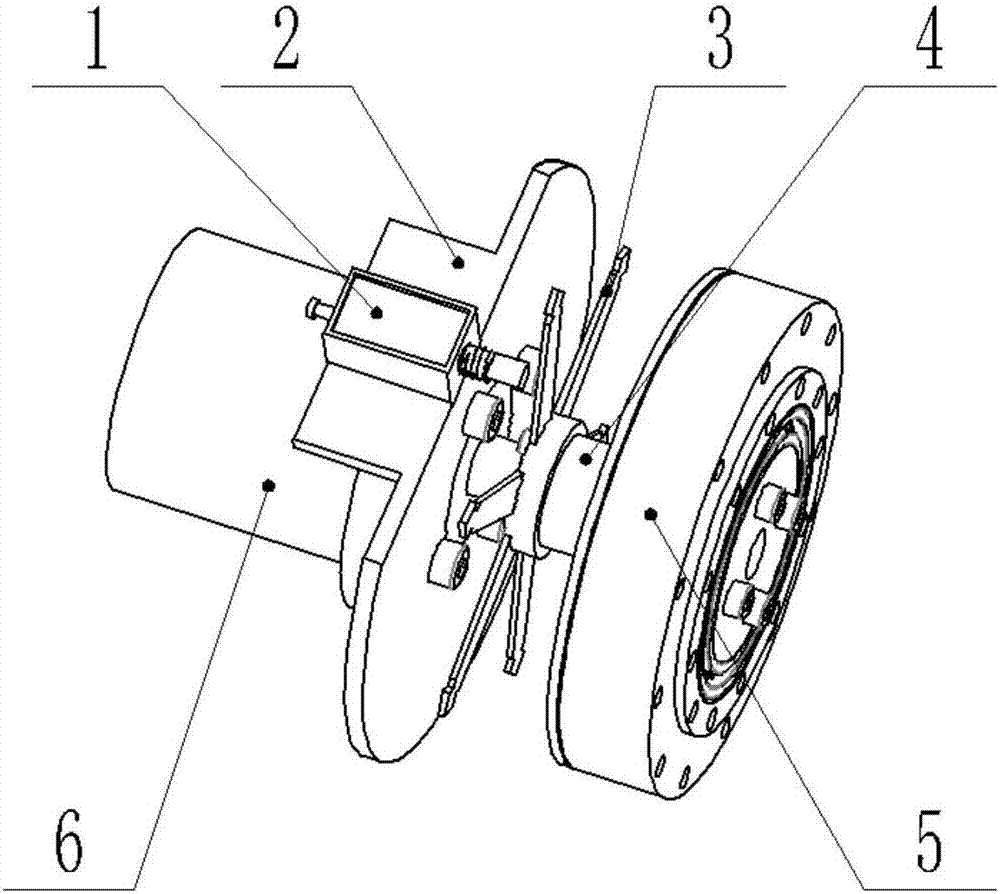

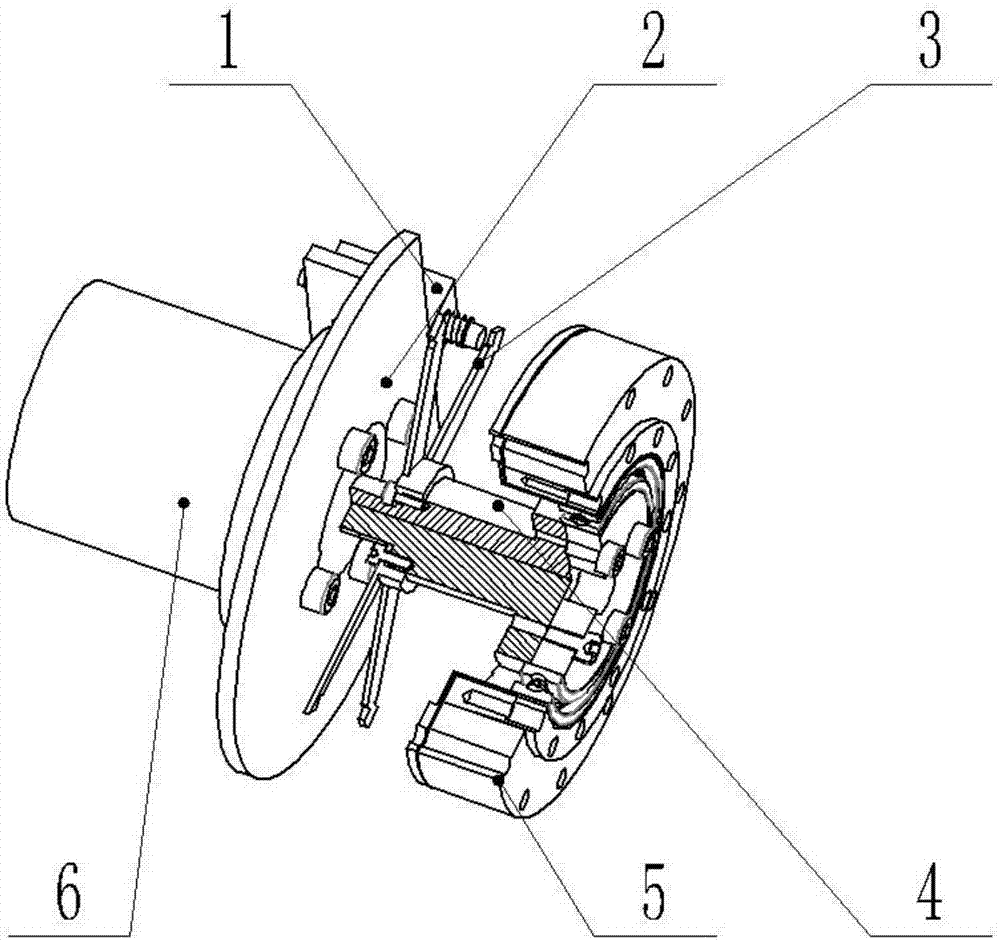

[0033] The high-precision braking mechanism of this embodiment includes a brake switch 1, a brake disc 3, a switch connecting frame 3, a rotating shaft 4 and a driving device 6; Rotational movement; the driving device is connected to the input end of the rotating shaft, and drives the rotating shaft to perform rotational movement, so that the rotating shaft 4 rotates relative to the switch connection frame 2; the brake switch is installed on the switch connection frame;

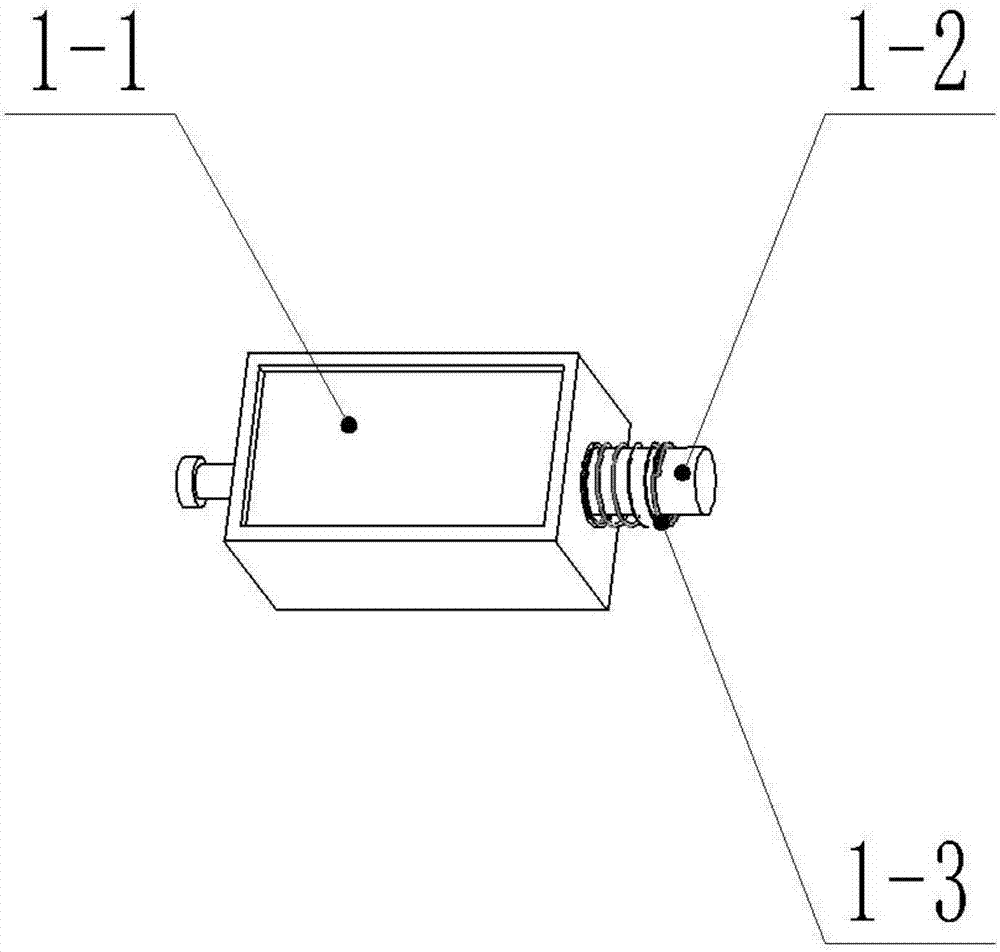

[0034] The brake switch 1 includes an electromagnetic switch 1-1, an iron core 1-2 and a return spring 1-3, the electromagnetic switch 1-1 is fixed on the switch connecting frame 2, and the iron core 1-2 is inserted into the electromagnetic In the cylindrical through hole in the center of the switch 1-1, the connection between the electromagnetic switch 1-1 and the iron core 1-2 is completed by the return spring 1-3; the electromagnetic switch 1-1 is fixed by M2 screws On the switch connecting plate 2, the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com