Patents

Literature

65results about How to "Reduce component weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

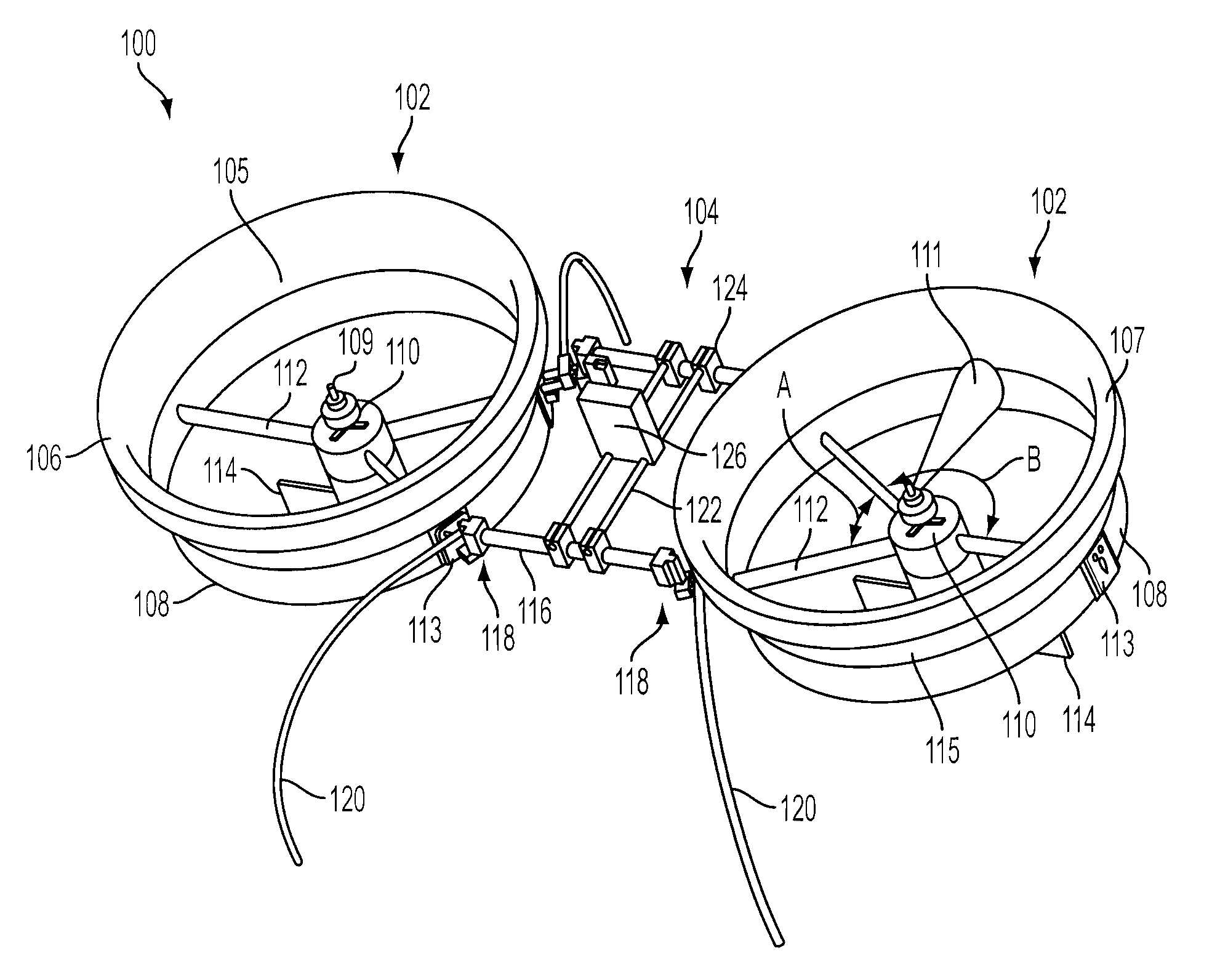

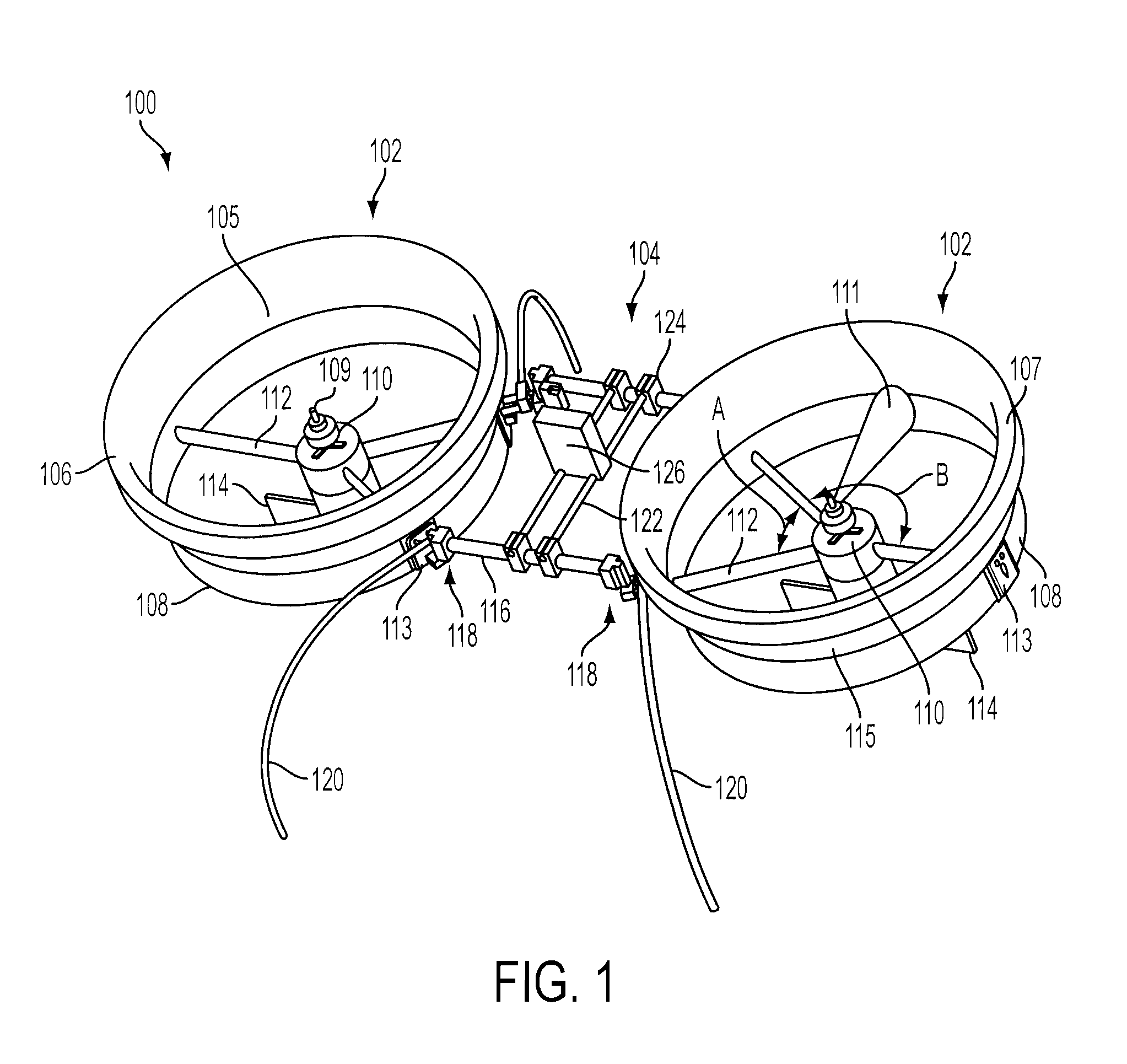

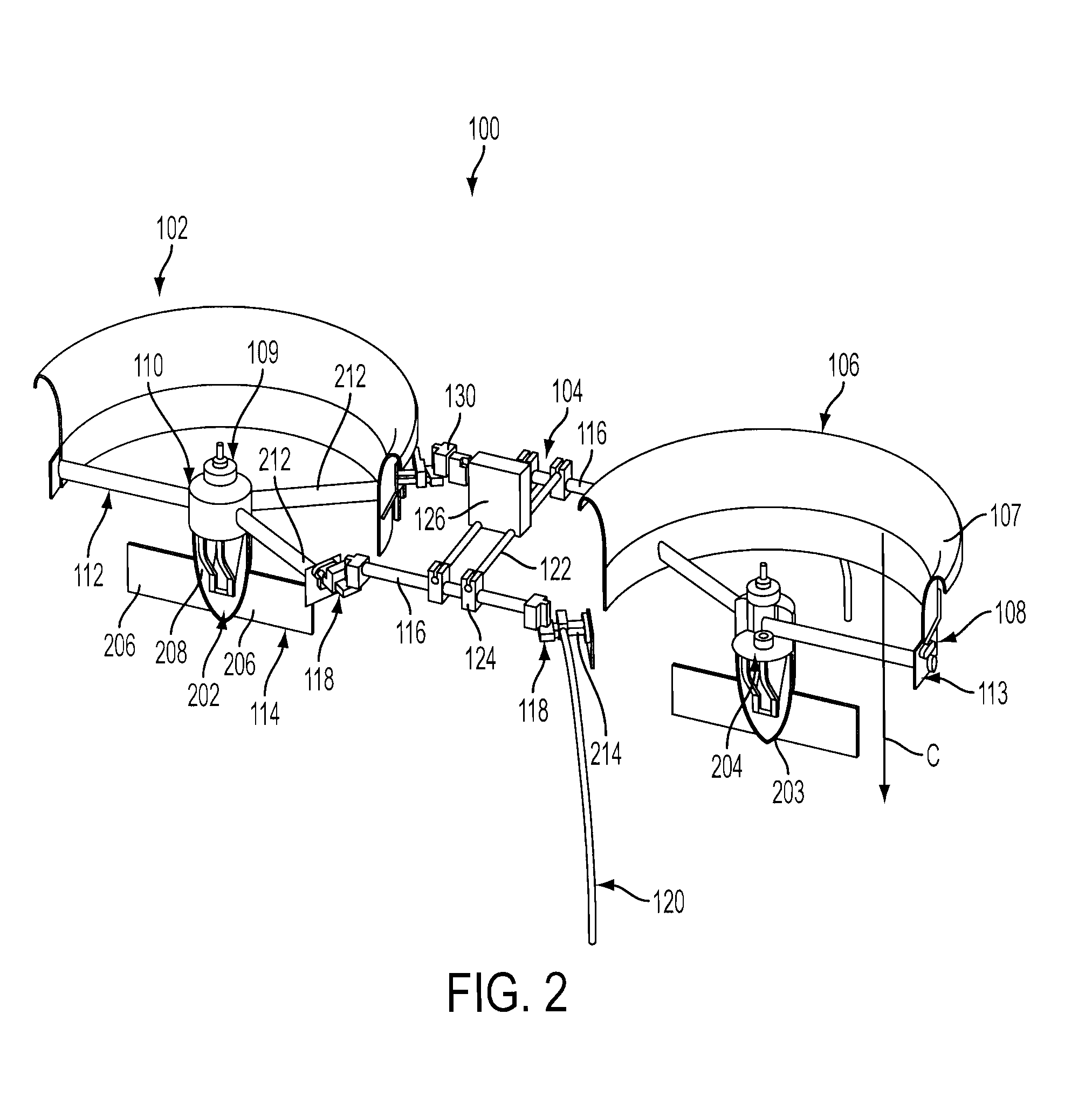

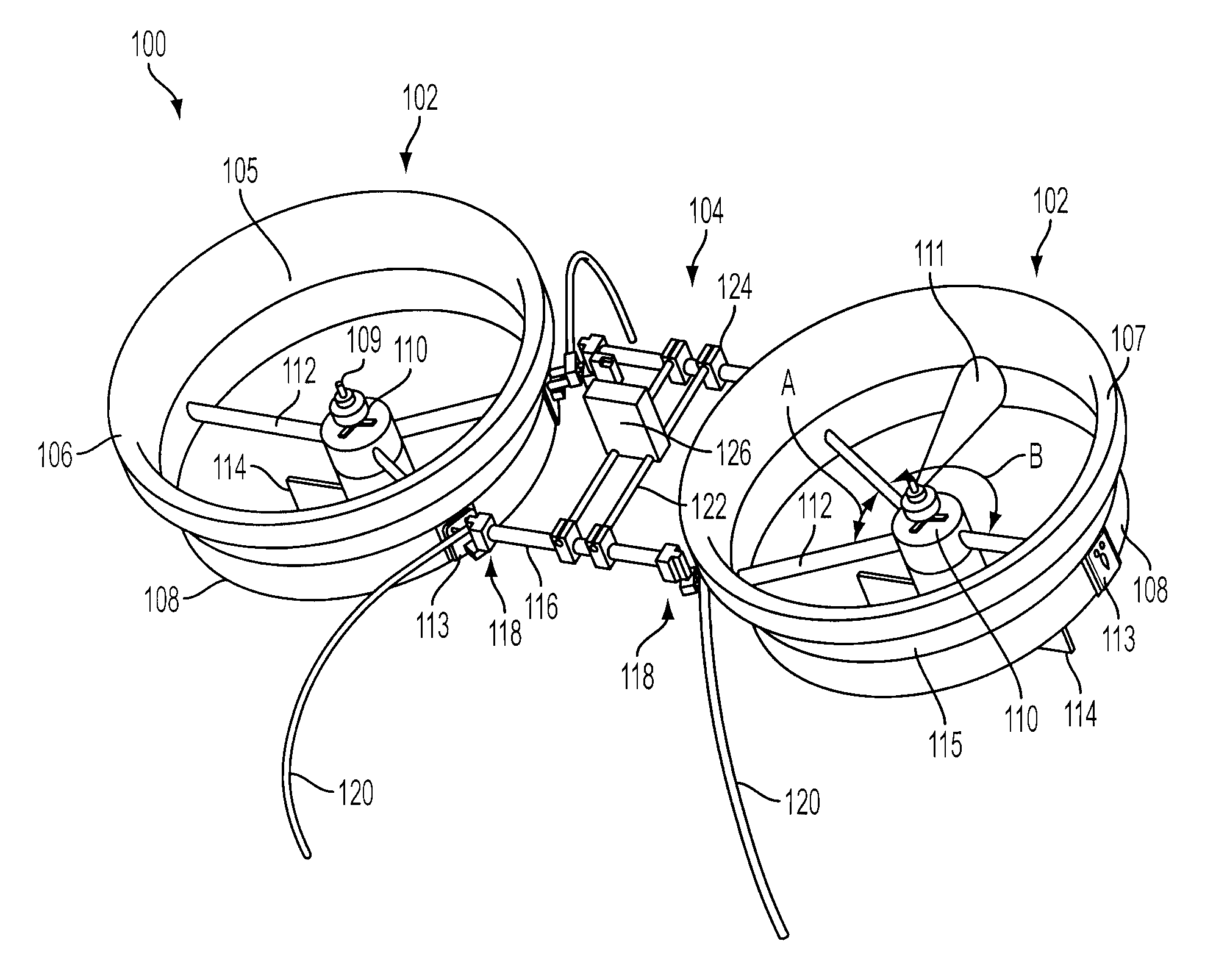

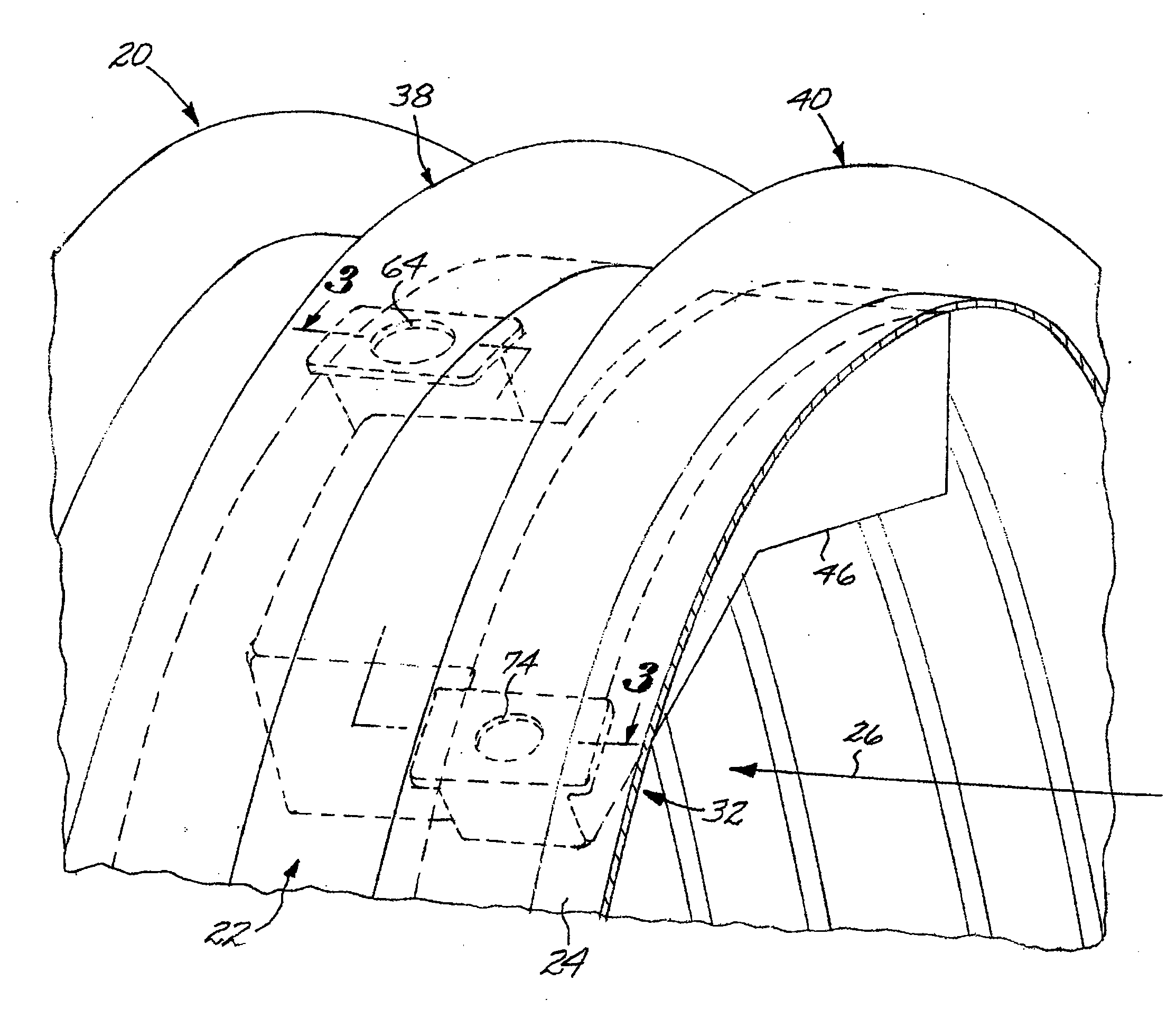

Vertical take off and landing unmanned aerial vehicle airframe structure

InactiveUS8328130B2Low costReduce weightAdditive manufacturing apparatusUnmanned aerial vehiclesEngineeringHigh intensity

An unmanned aerial vehicle selectively formed of high strength composite structural part portions and lightweight aerodynamic foam portions to provide a low-cost and lightweight UAV that comports with export, civil airspace, and safety regulations. To further to reduce an overall weight of the UAV, mechanical elements are designed to provide multiple functionalities. Structural elements may be manufactured in same or similar non-specialized processes, and non-structural elements manufactured in same or similar non-specialized processes, reducing overall manufacturing costs. Materials and bonding elements are selected to provide frangibility and yet maintain normal flight structural integrity.

Owner:HONEYWELL INT INC

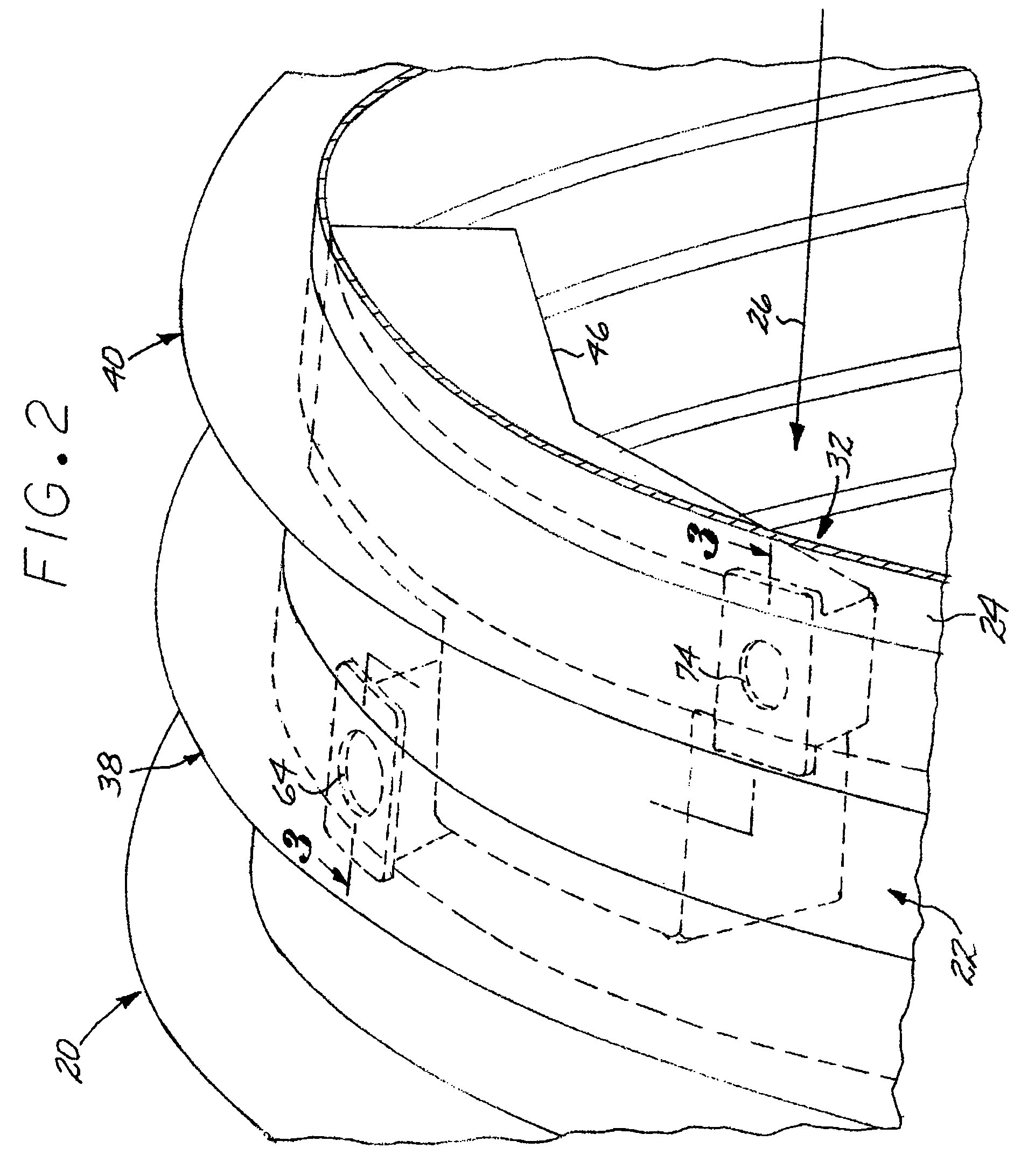

Vertical take off and landing unmanned aerial vehicle airframe structure

InactiveUS20100140415A1Reduce weightLow costAdditive manufacturing apparatusUnmanned aerial vehiclesHigh intensityAirframe

An unmanned aerial vehicle selectively formed of high strength composite structural part portions and lightweight aerodynamic foam portions to provide a low-cost and lightweight UAV that comports with export, civil airspace, and safety regulations. To further to reduce an overall weight of the UAV, mechanical elements are designed to provide multiple functionalities. Structural elements may be manufactured in same or similar non-specialized processes, and non-structural elements manufactured in same or similar non-specialized processes, reducing overall manufacturing costs. Materials and bonding elements are selected to provide frangibility and yet maintain normal flight structural integrity.

Owner:HONEYWELL INT INC

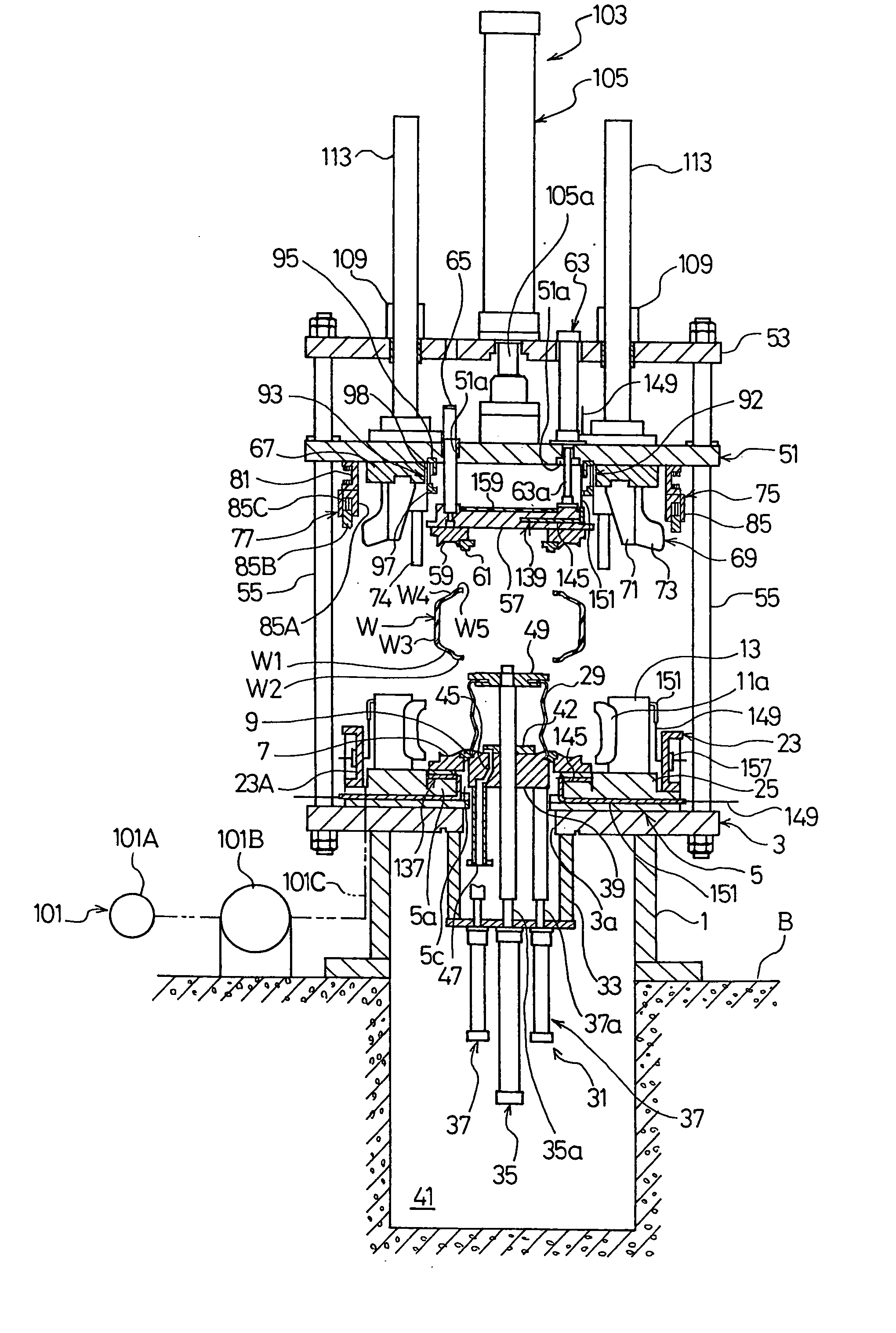

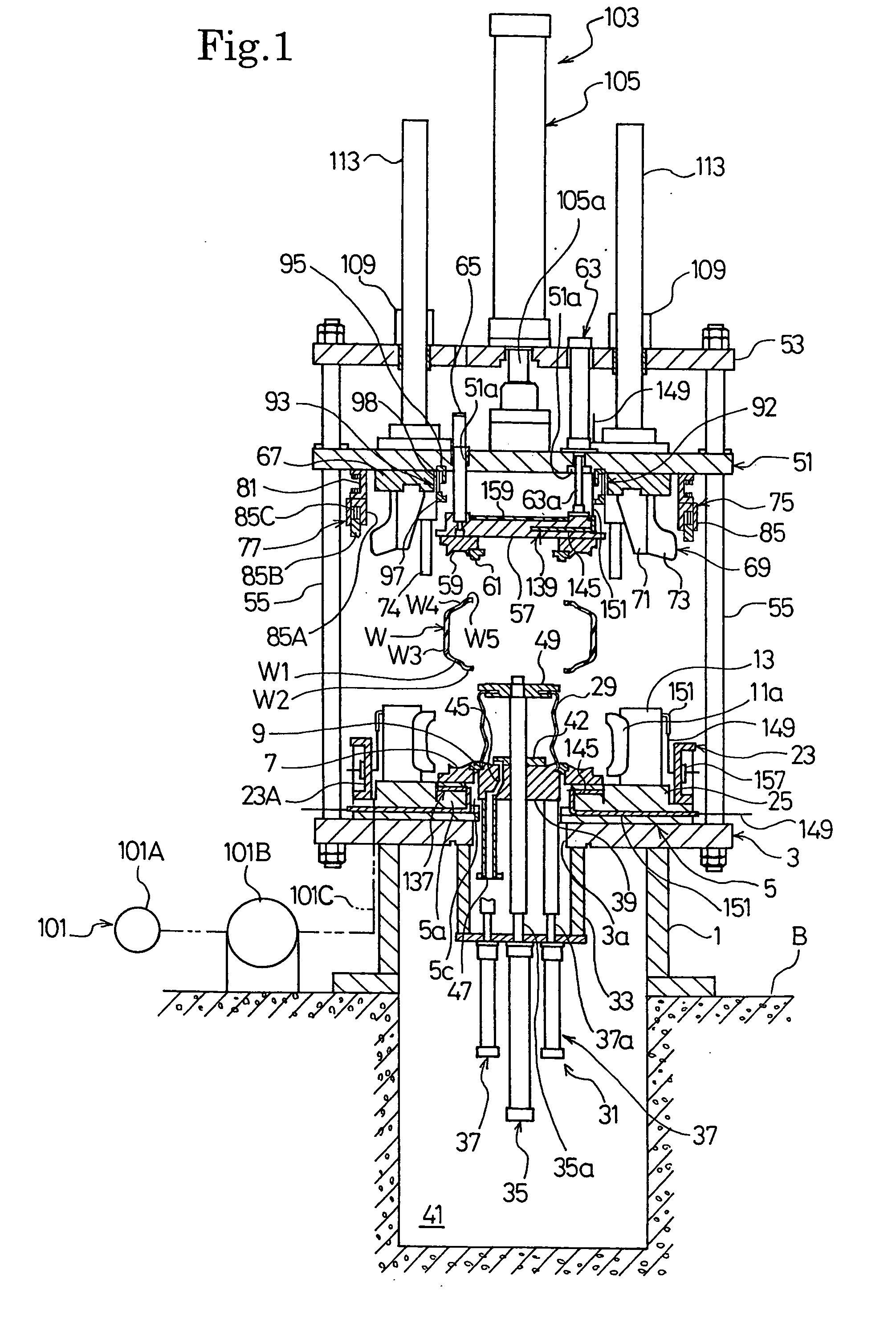

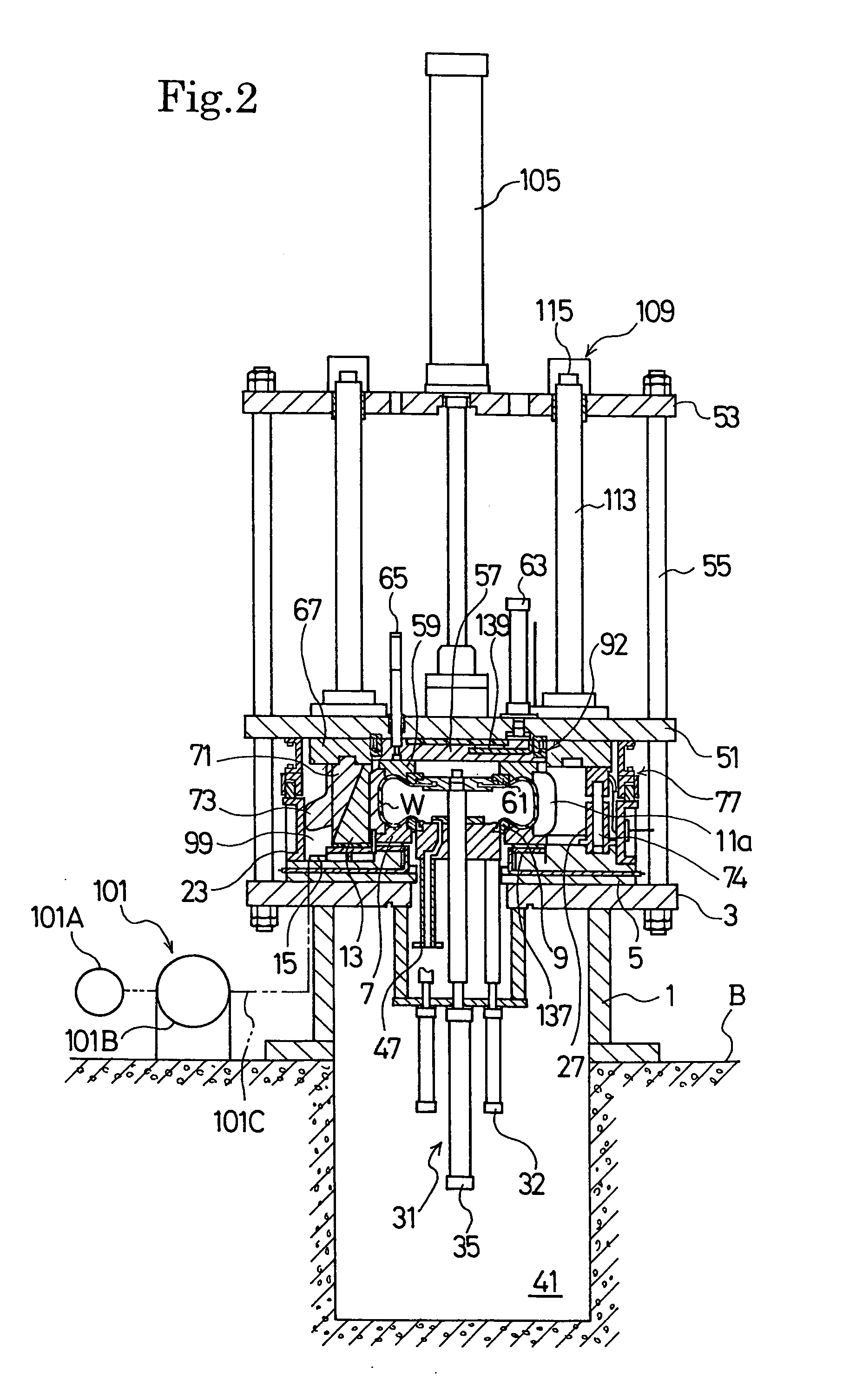

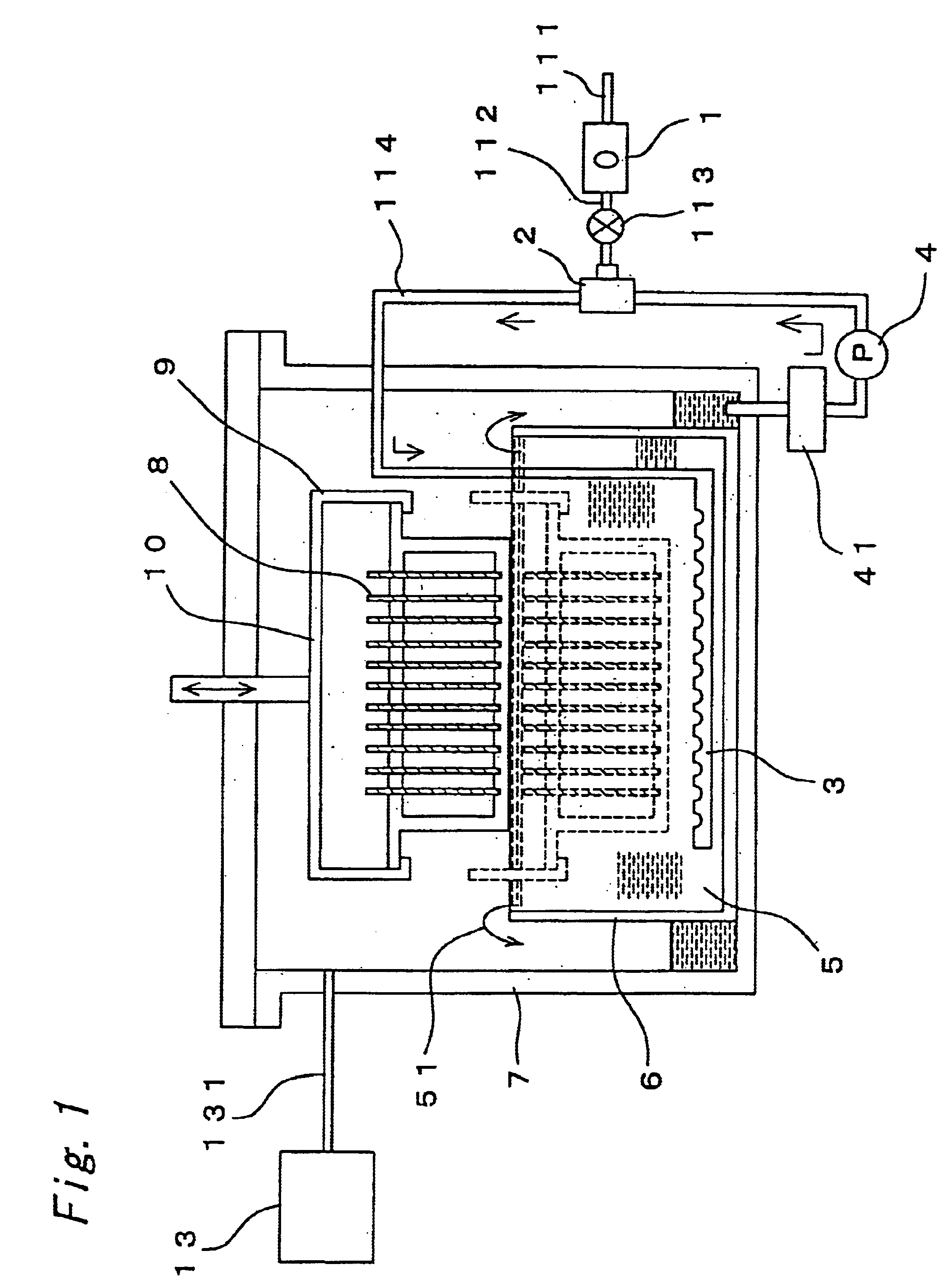

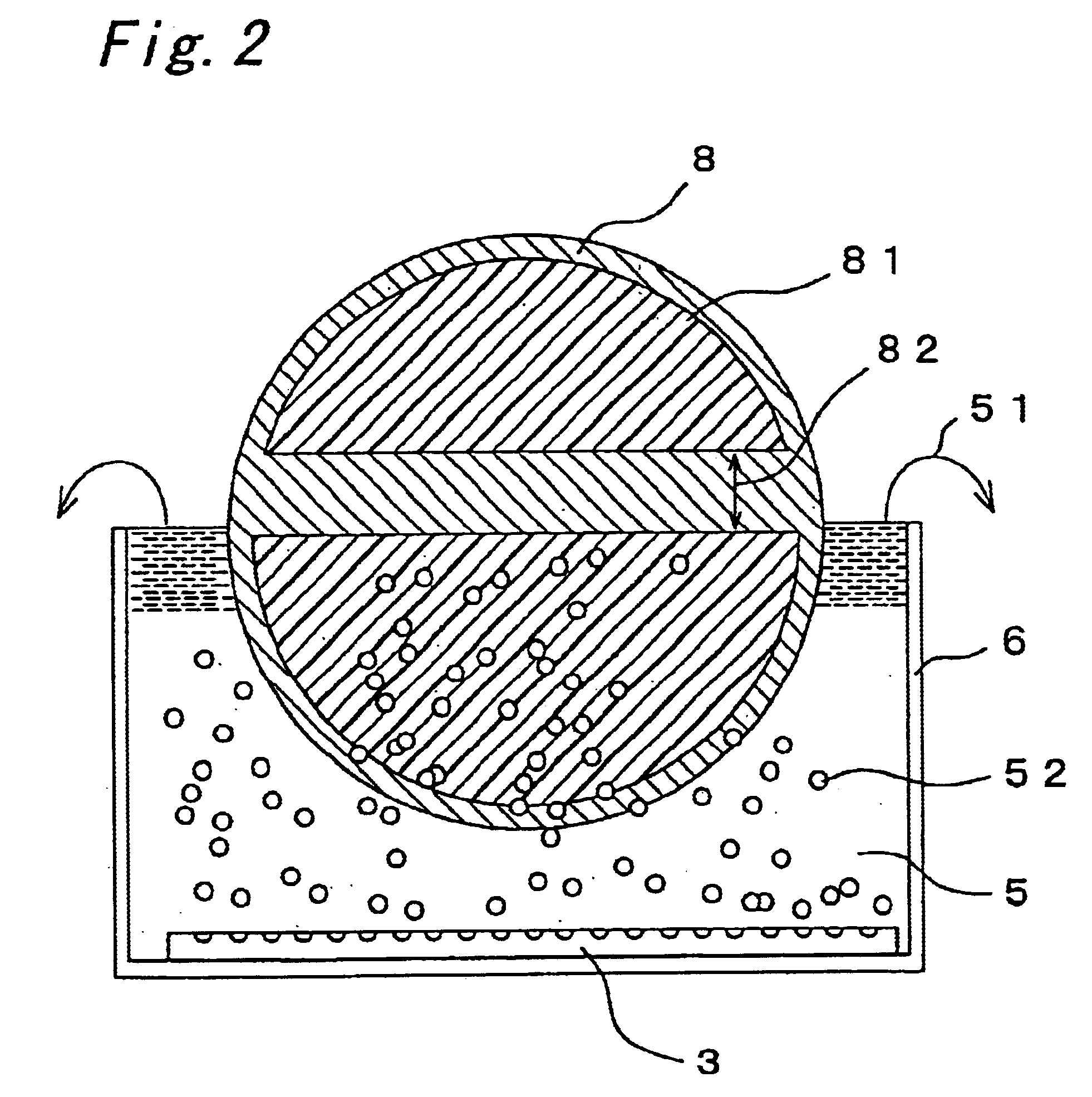

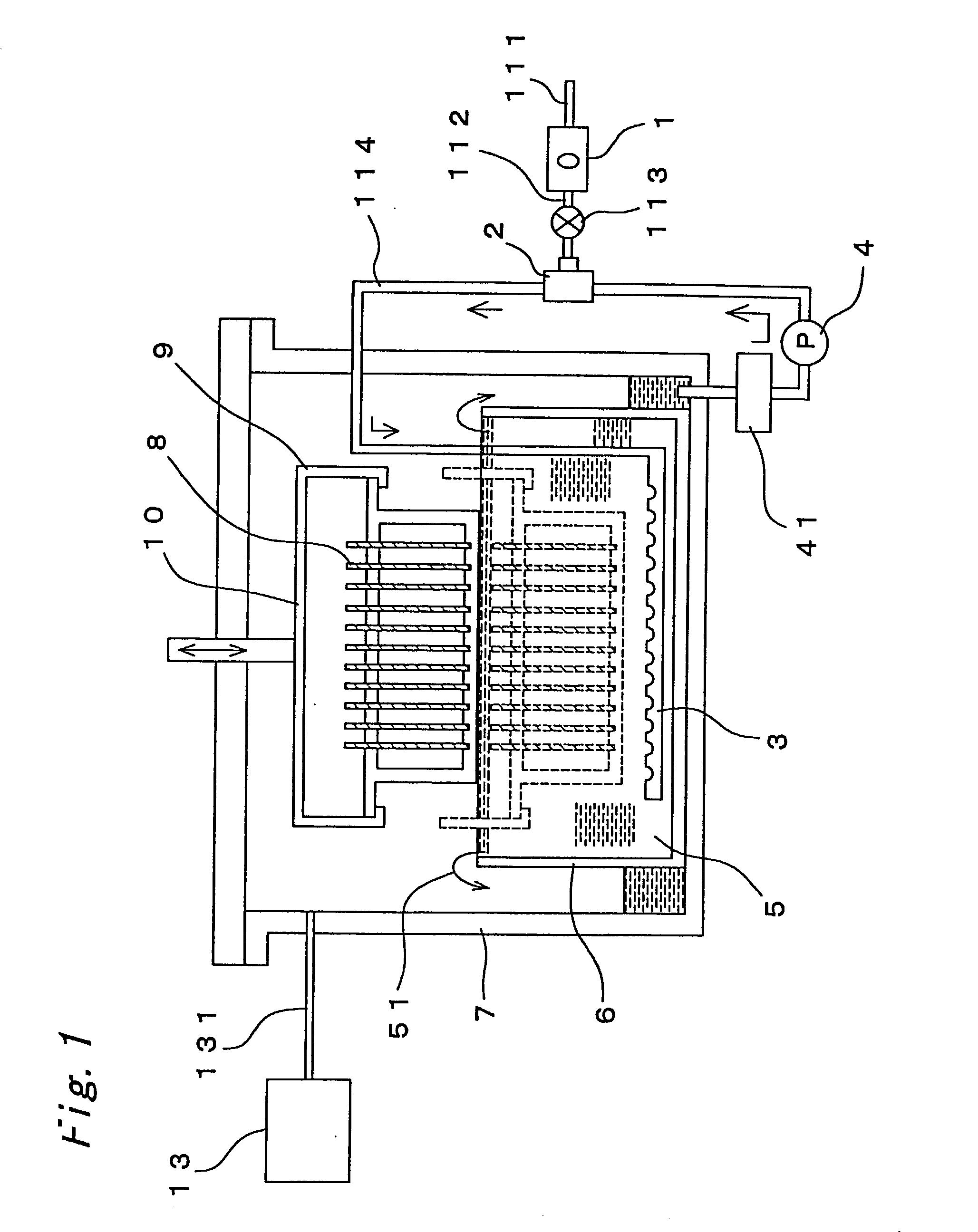

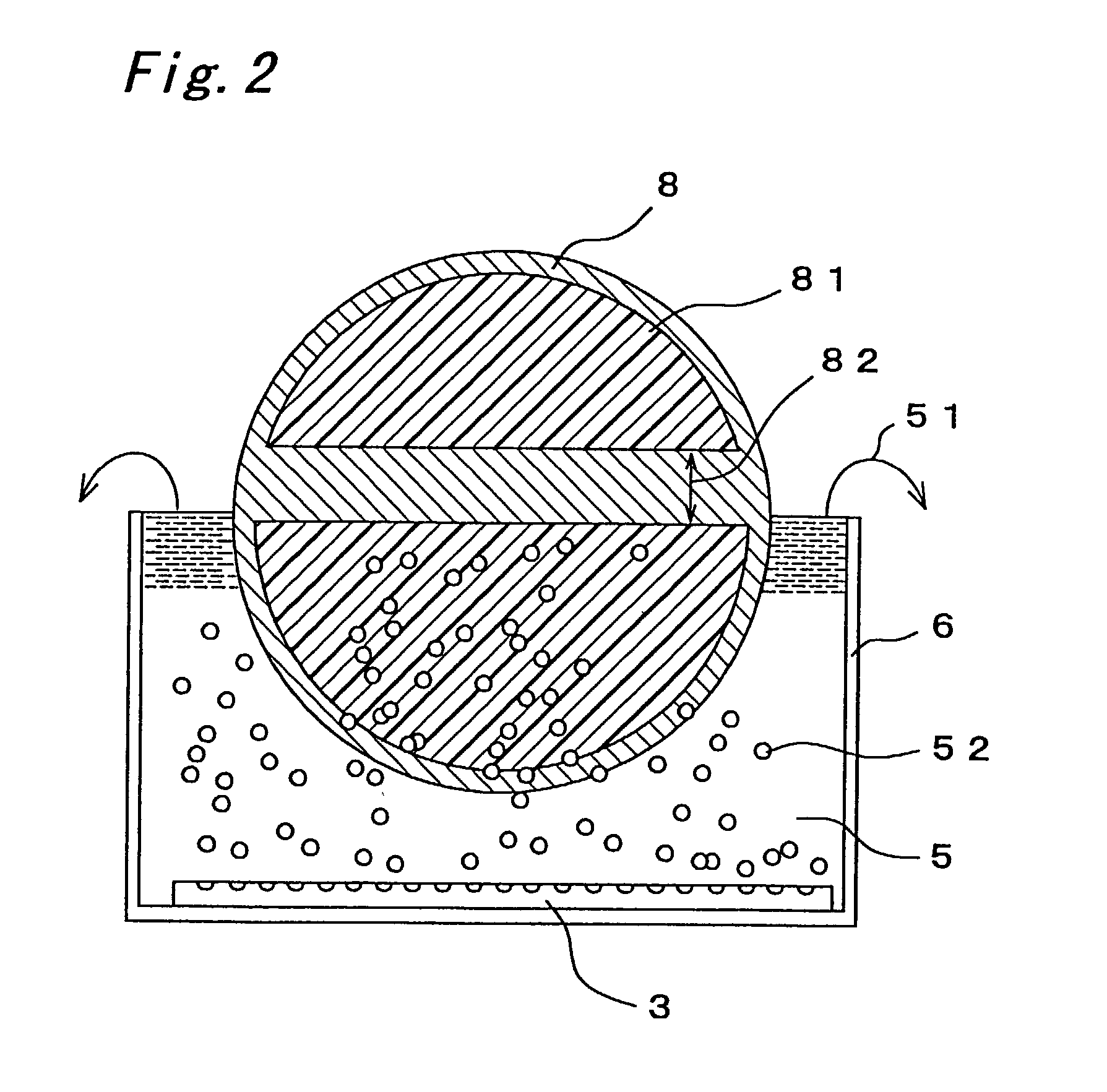

Method and device for vulcanizing tire

A tire press includes a sectional type mold which has an annular lower mold section secured to an upper surface of a lower plate, an annular upper mold section disposed under an upper plate which is vertically moveably placed above the lower plate so that the upper mold section moves vertically along with the upper plate, and a side mold section having a plurality of sectors divided along a circumferential direction thereof and located radially outwardly of the lower mold section in an openable and closable manner. Holding segments which hold the sectors are provided on outer peripheral sides of the sectors. The holding segments are placed on the lower plate so as to move forward and away from the center of the annular lower mold section. Guide segments which are engagable with and disengagable from outer peripheral sides of the holding segments are suspended from the upper plate radially outwardly of the upper mold section. First heating means are provided under the lower mold section, second heating means are provided over the upper mold section, and third heating means are provided on the outer peripheral side of the sectors. The engagement of the guide segments with the holding segments causes the holding segments to move forward to close the sectors, thereby setting a green tire in the mold. After applying a pressure into the set green tire to inflate it, the green tire is heated by the heating means to cure it.

Owner:THE YOKOHAMA RUBBER CO LTD

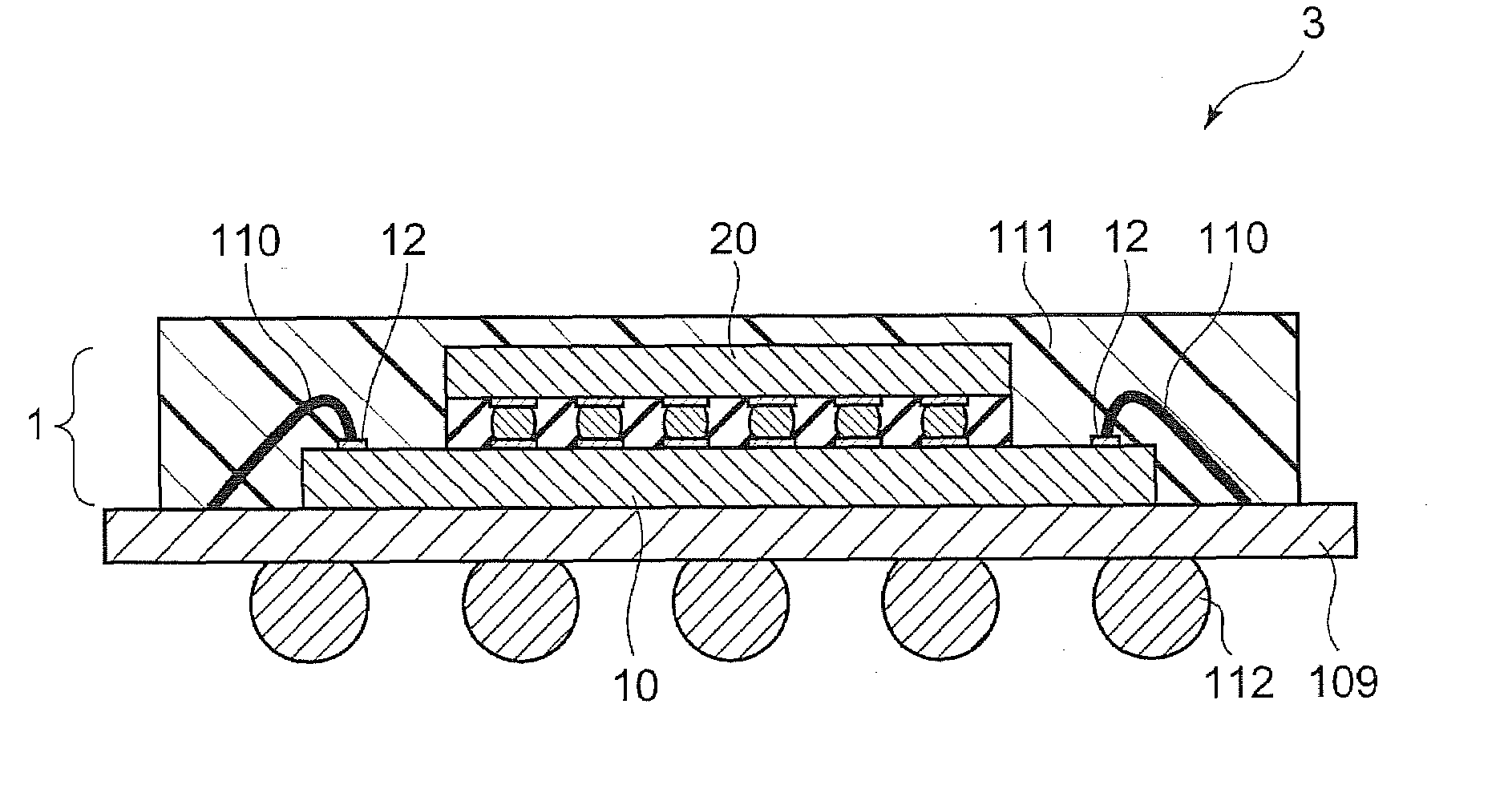

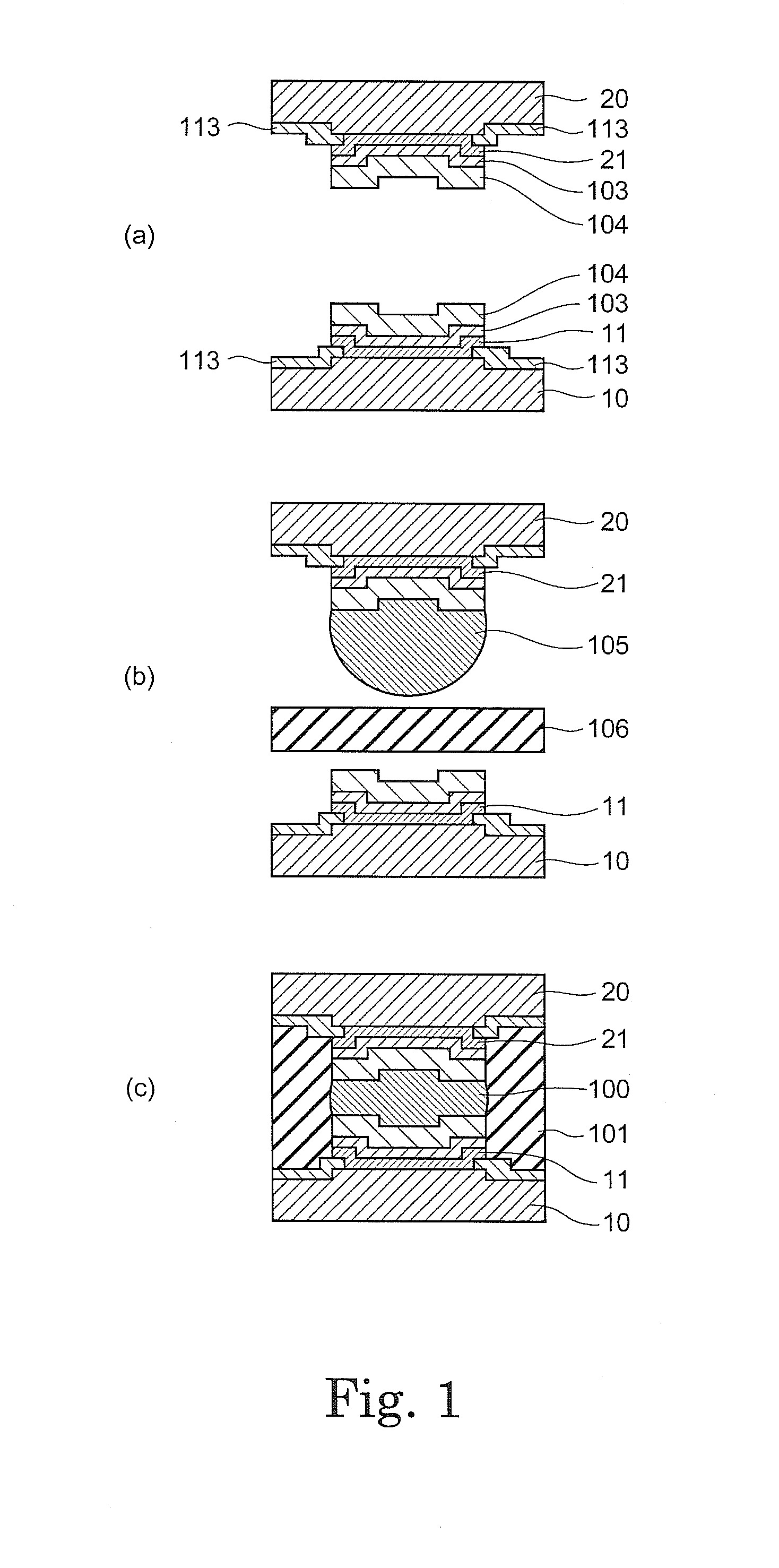

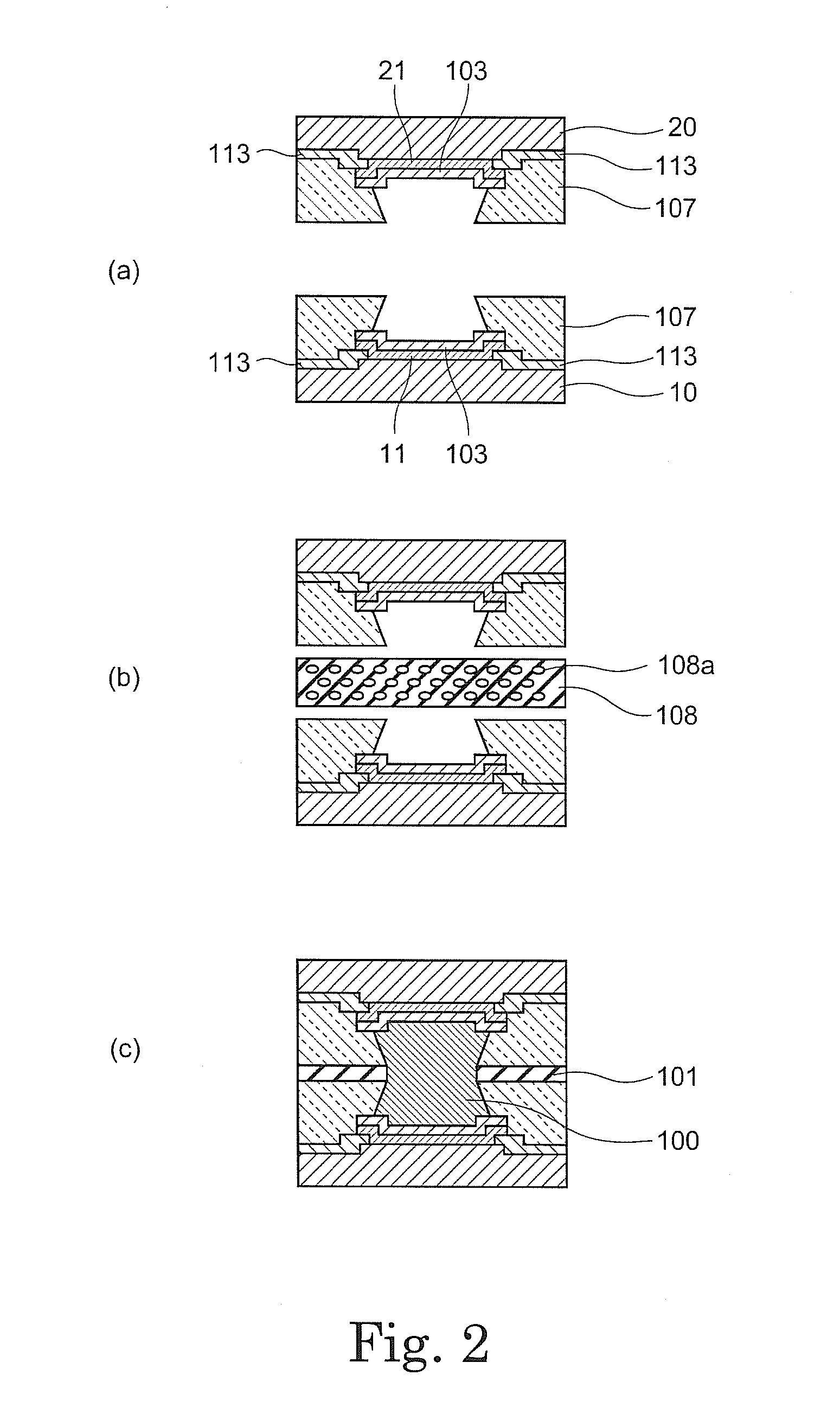

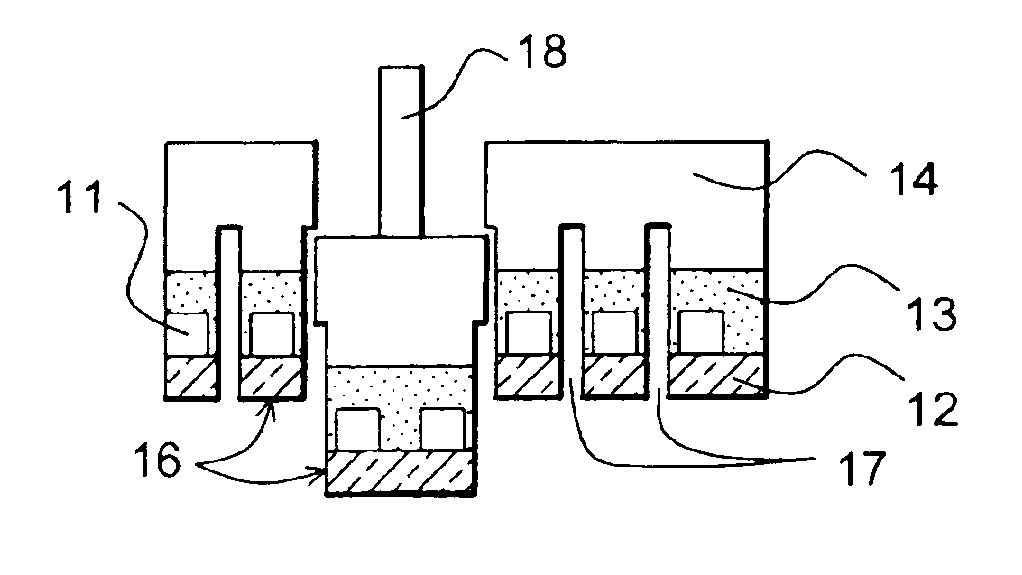

Adhesive tape and semiconductor device using the same

InactiveUS20100078830A1Good ion migration resistanceGood solder wettabilitySemiconductor/solid-state device detailsSynthetic resin layered productsChIP-on-chipSemiconductor chip

The present invention relates to an adhesive tape for electrically connecting semiconductor chips in a chip-on-chip type semiconductor device. The adhesive tape comprising: (A) 10 to 50 wt % of film forming resin; (B) 30 to 80 wt % of curable resin; and (C) 1 to 20 wt % of curing agent having flux activity.

Owner:SUMITOMO BAKELITE CO LTD

Thin chip resistant powder topcoats for steel

ActiveUS20090110934A1Thinner and economicalImprove steering and ride controlSynthetic resin layered productsPretreated surfacesEpoxyWax

The present invention provides chip-resistant powder topcoats for corrosion resistant powder coated steel substrates, such as, for example, automotive suspension coil springs, comprising powder coatings formed from one or more wax and a resin component of one or more toughened epoxy resin. The present invention provides dual coatings of toughened epoxy powder basecoats and topcoats, which may be foamed and / or fiber reinforced. The powder used to form the chip resistant topcoat can further comprise up to 200 phr or, preferably, up to 75 phr of one or more extender, or 0.5 or more phr of one or more extender, such as barium sulfate, while fully retaining its chip resistant properties. In addition, the powder used to form the chip resistant topcoat can be a low temperature curing powder comprising one or more low temperature curing agent. The invention provides methods for making the dual coatings comprising applying to the substrate a toughened, zinc-loaded, epoxy coating powder, applying to the powder coated substrate a wax containing toughened epoxy topcoat and heating to fuse or cure the coating powders.

Owner:AKZO NOBEL COATINGS INT BV

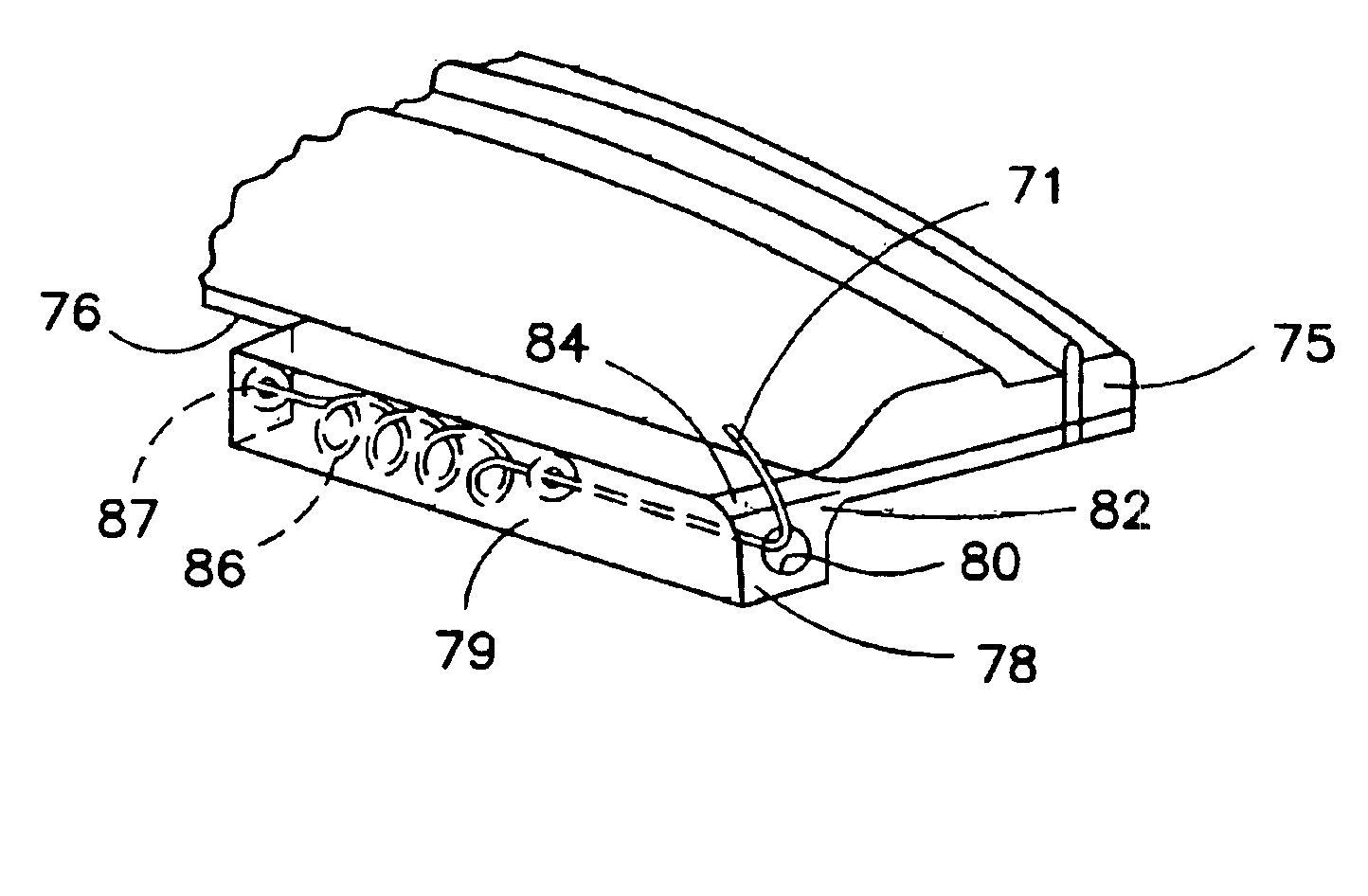

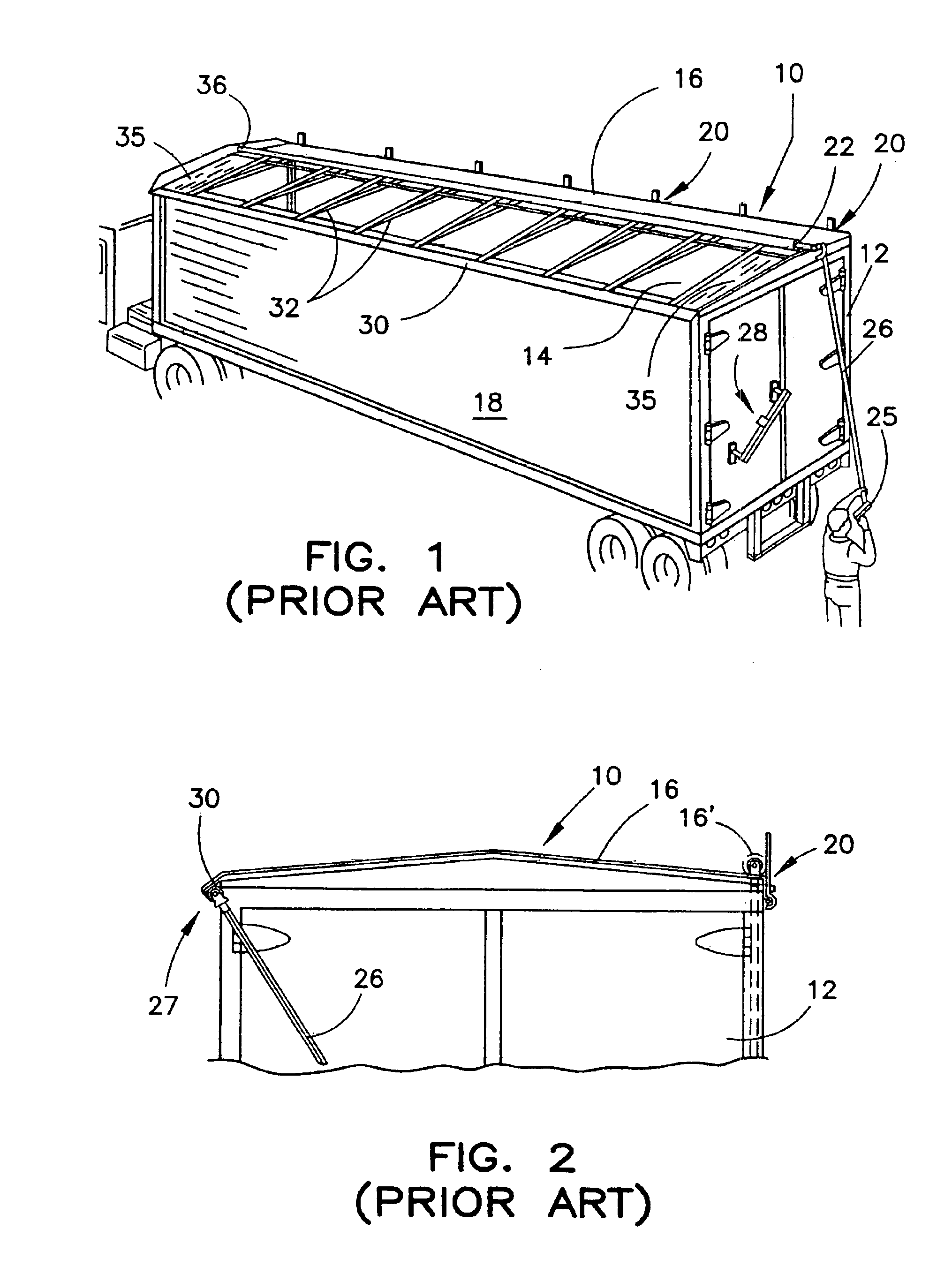

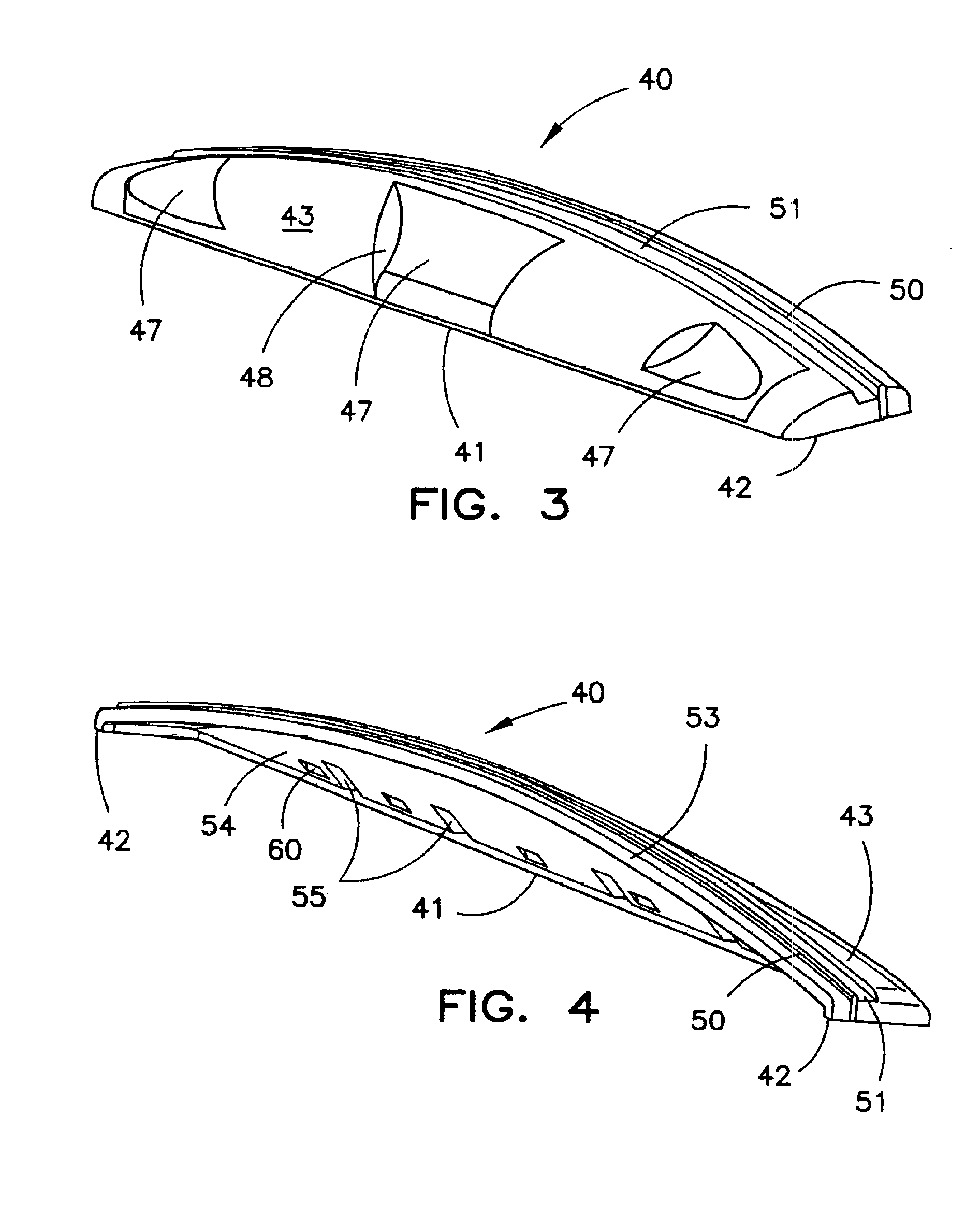

End cap for roll tarp system

InactiveUS6886879B2Reduce component weightReduce material requirementsRemovable external protective coveringsLoad coveringEngineeringFront edge

A one-piece molded end cap is provided for use with a container tarping system. The end cap is in the form of an aerodynamically shaped shell and includes a trough and ridge configuration at the rear edge to provide a sealing surface for the side edge of the flexible cover of the tarping system. A deflection barrier is formed at the underside of the end cap shell and is configured to deflect material loaded into the container away from the end cap. In a further embodiment, the end cap can include a tensioning mechanism integral with a front edge of the end cap. The tensioning mechanism includes an elongated body having a bore within which a tensioning element is disposed. The tensioning element applies tension to a drive mechanism of the tarping system through a cable.

Owner:AERO INDS

Method for selectively transferring at least an element from an initial support onto a final support

InactiveUS6959863B2Resistive lossReduce congestionLaser detailsSemiconductor laser structural detailsSurface layerEngineering

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

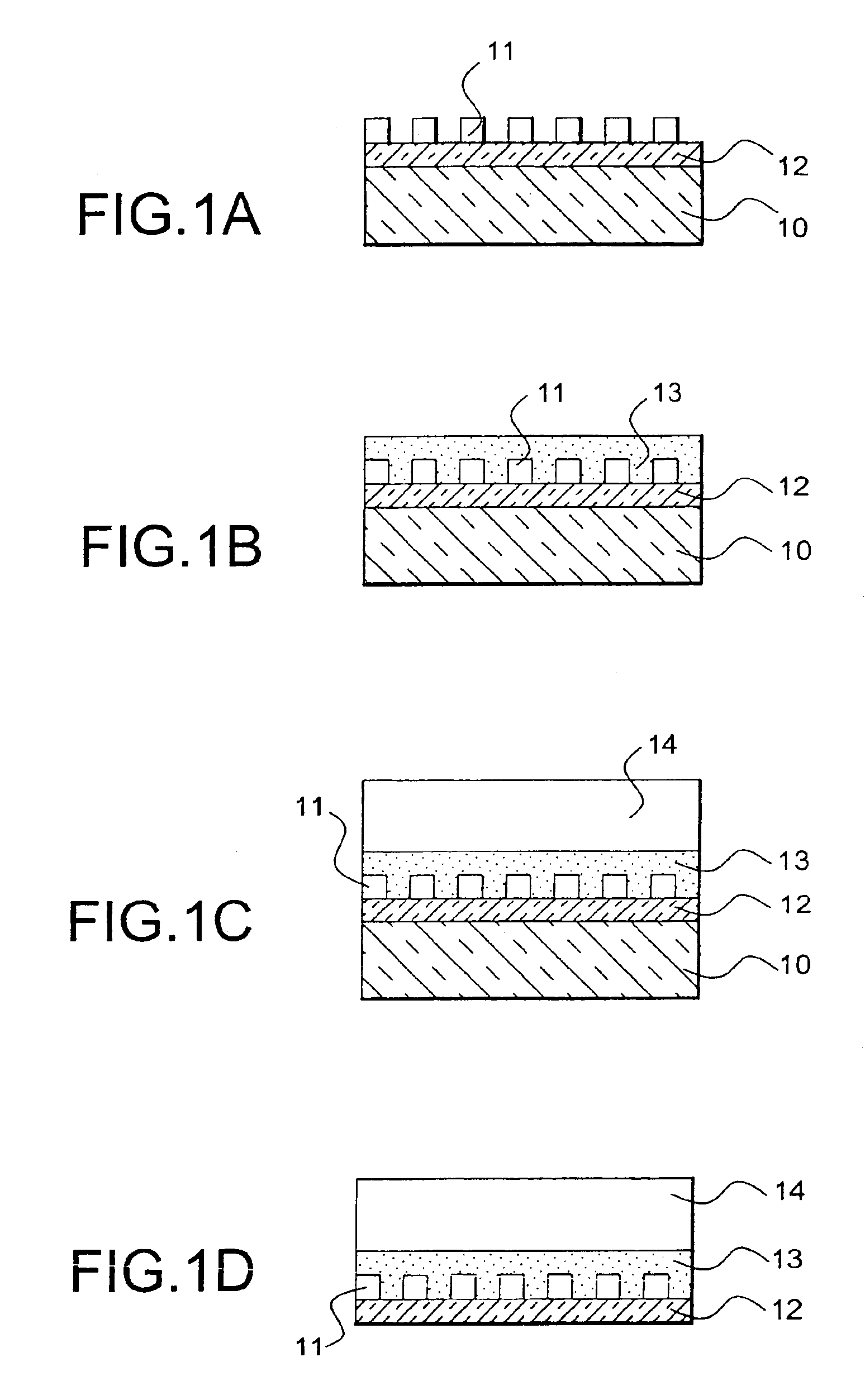

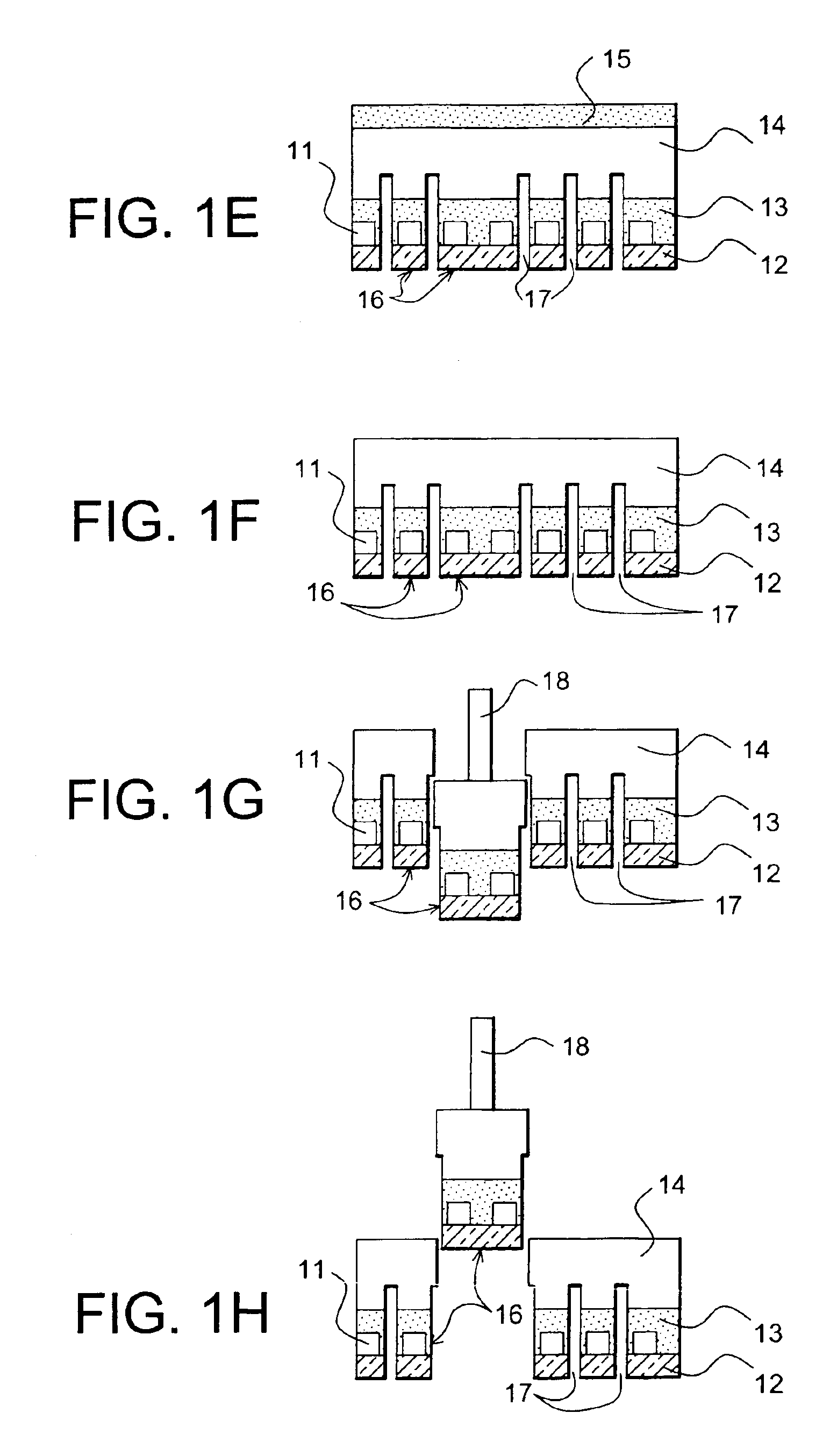

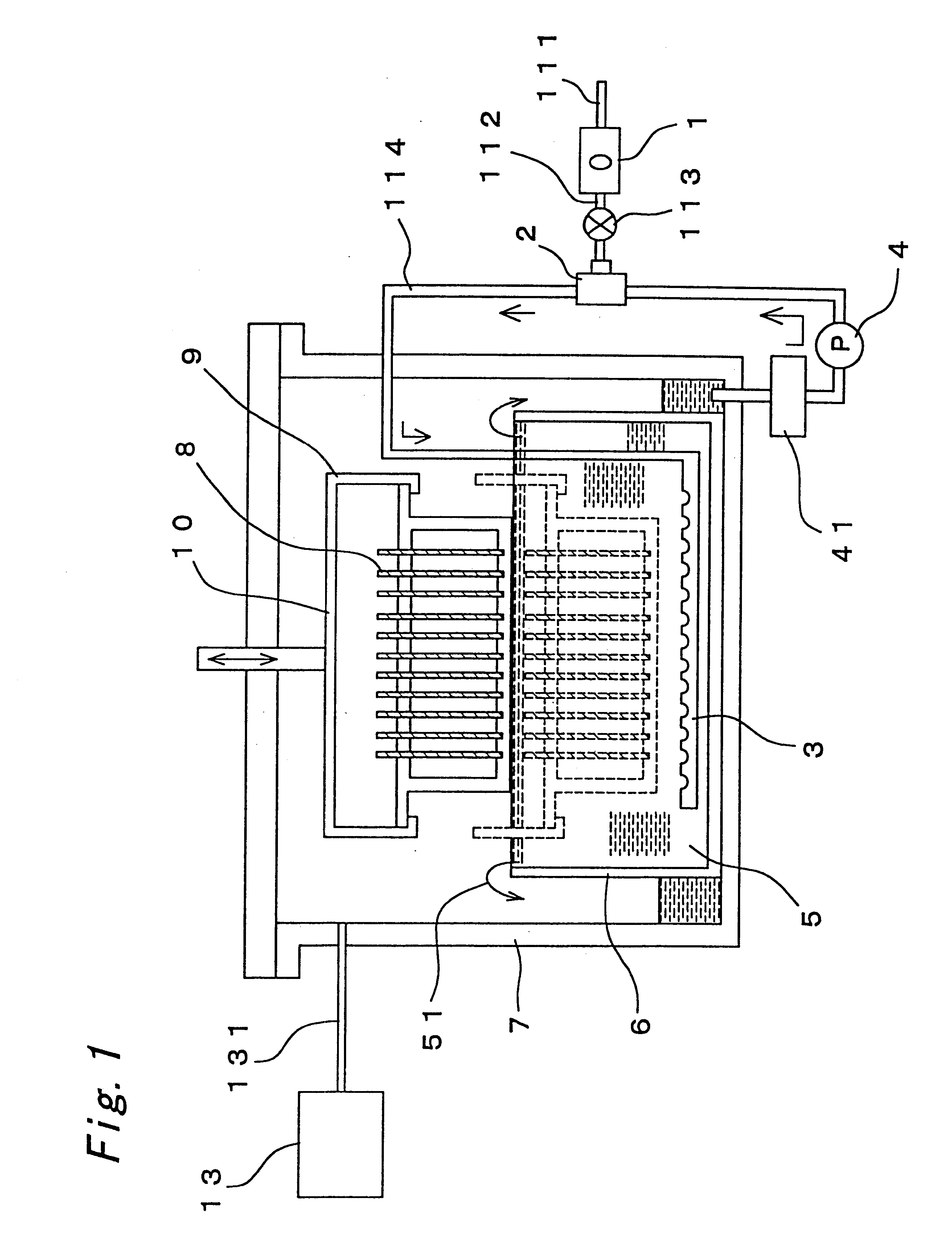

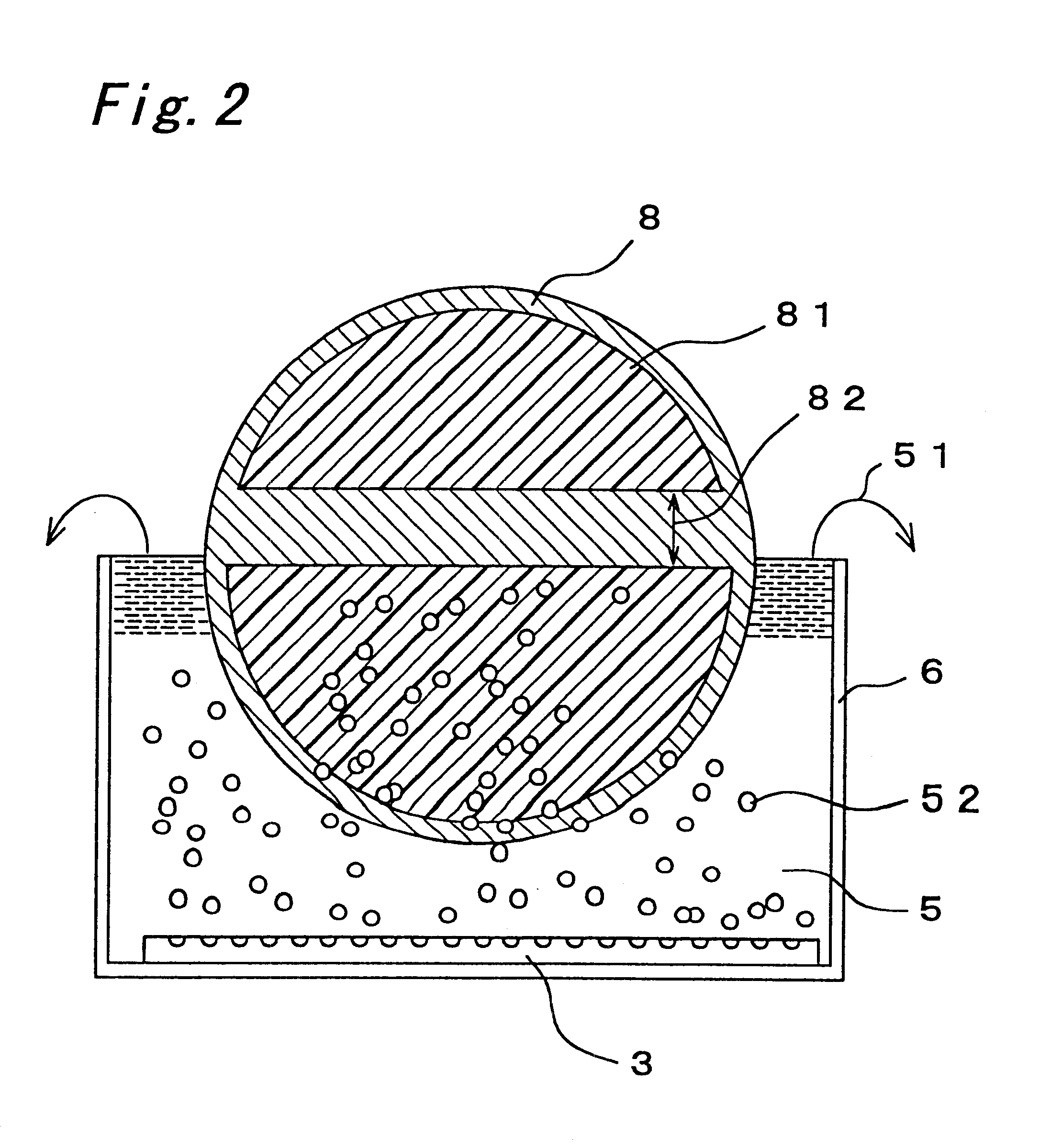

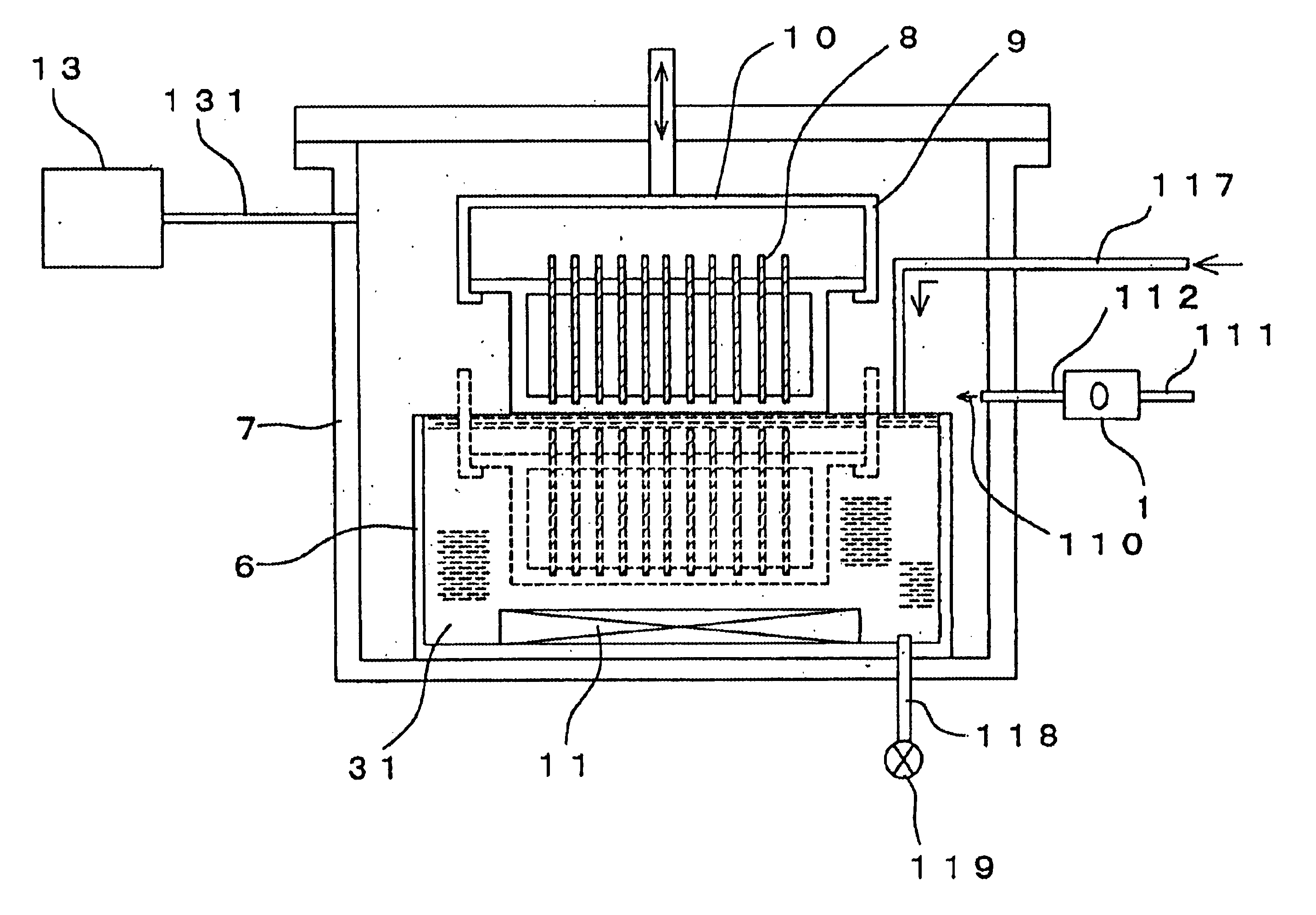

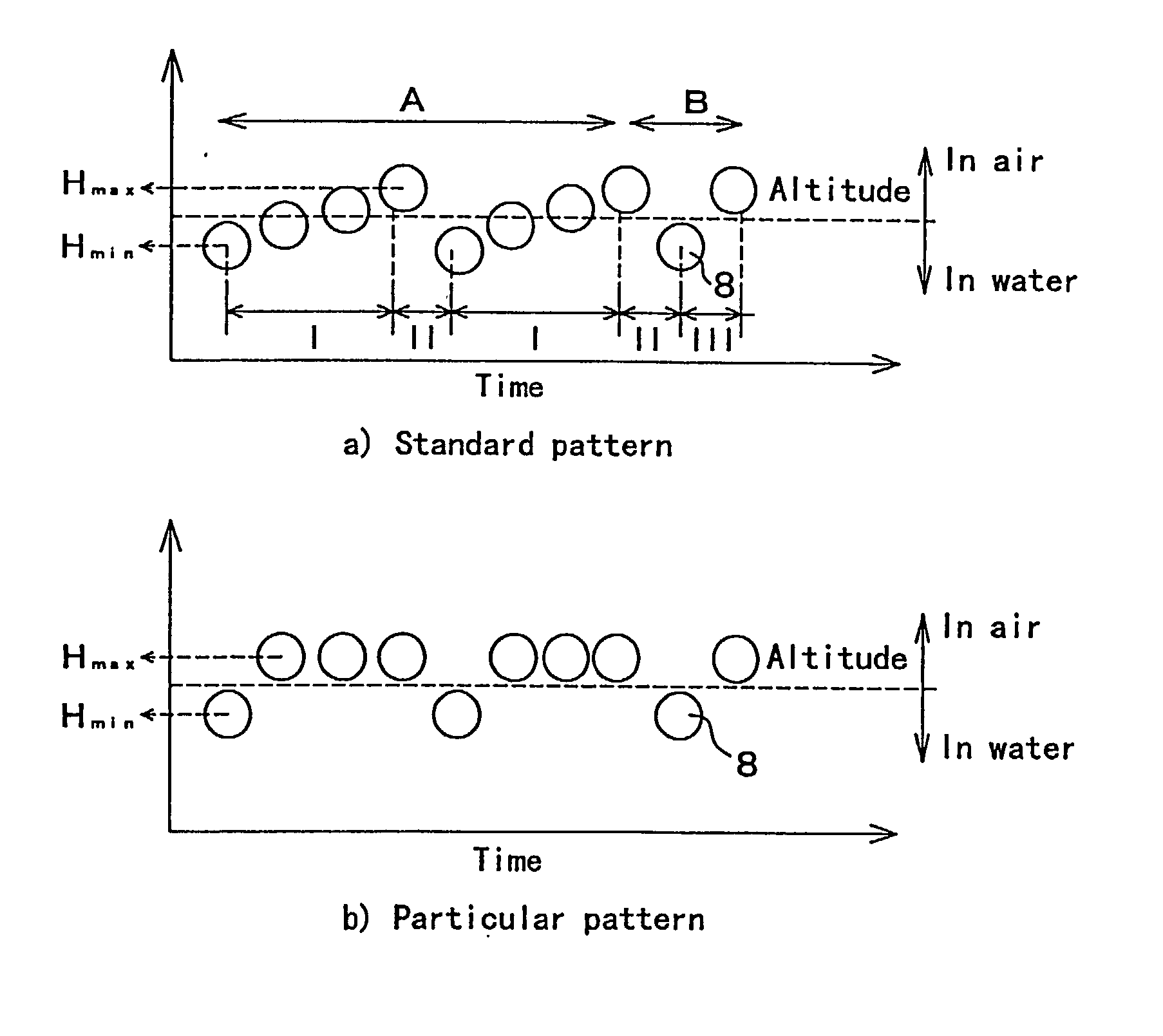

Method of removing photoresist film

InactiveUS6517999B1Increase contact frequencyIncrease ratingsElectrostatic cleaningSemiconductor/solid-state device manufacturingResistGas phase

A method of removing photoresist film with high efficiency of removal and friendliness with the environment while reducing the material consumption and the cost for the ventilation facility, and an apparatus used for the method are provided. Particularly the present invention provides a method of removing a photoresist film provided on a surface of a substrate, comprising steps of in a sealed system, disposing the substrate surface having the photoresist film to contact with a photoresist film removing solution, making ozone exist in gas phase and / or solution phase in the vicinity of the liquid surface of the photoresist film removing solution, and changing a relative position between the surface of the substrate and the liquid surface of the solution to decompose or remove the photoresist film from the substarate, characterized in that the relative position is changed continuously or intermittently within a range between a position where a bottom edge of the substrate is present above the liquid surface of the solution, and another position where a top edge of the substrate is present below the liquid surface of the solution. The present invention also provides an apparatus used for the method.

Owner:MITSUBISHI ELECTRIC CORP +1

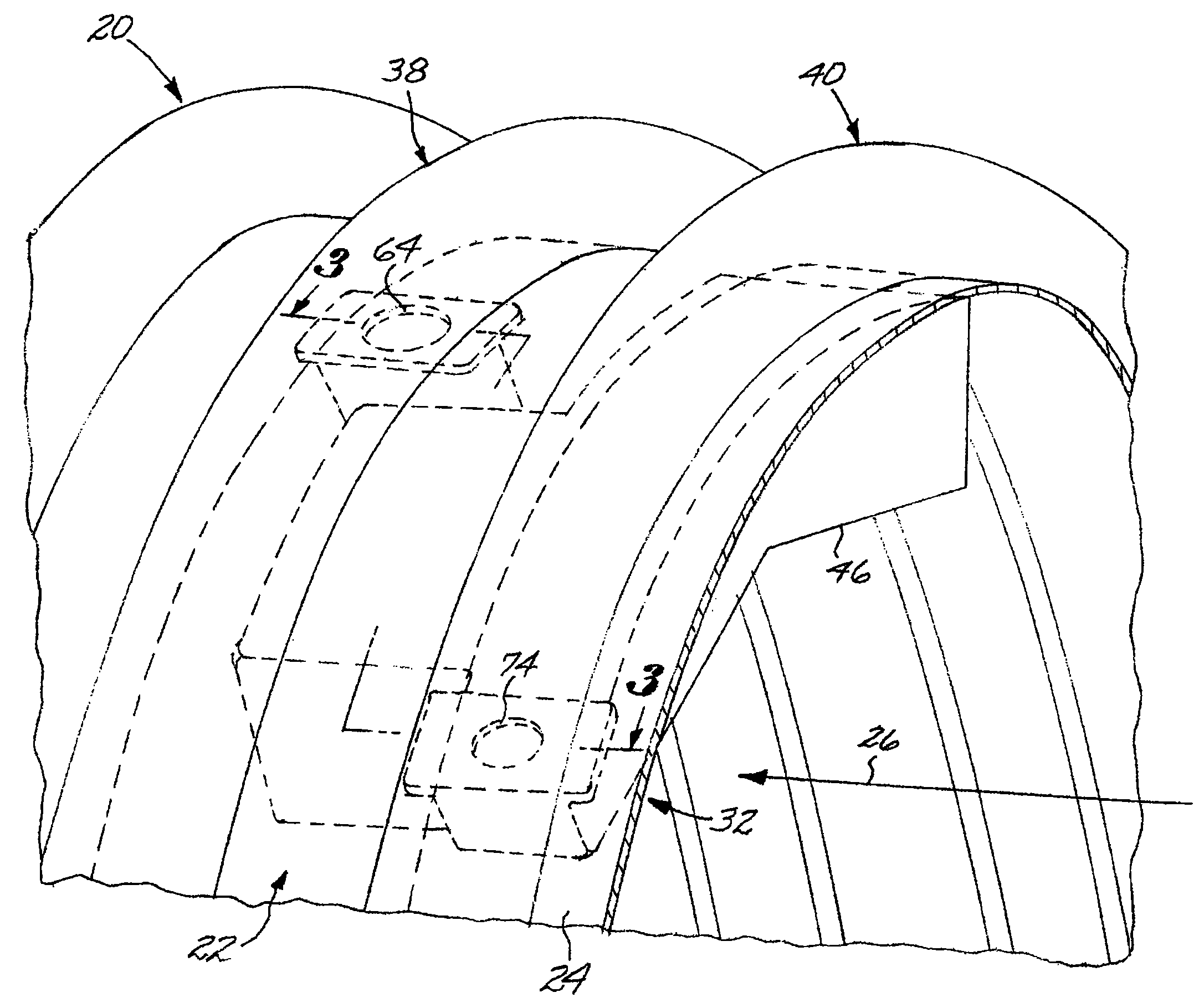

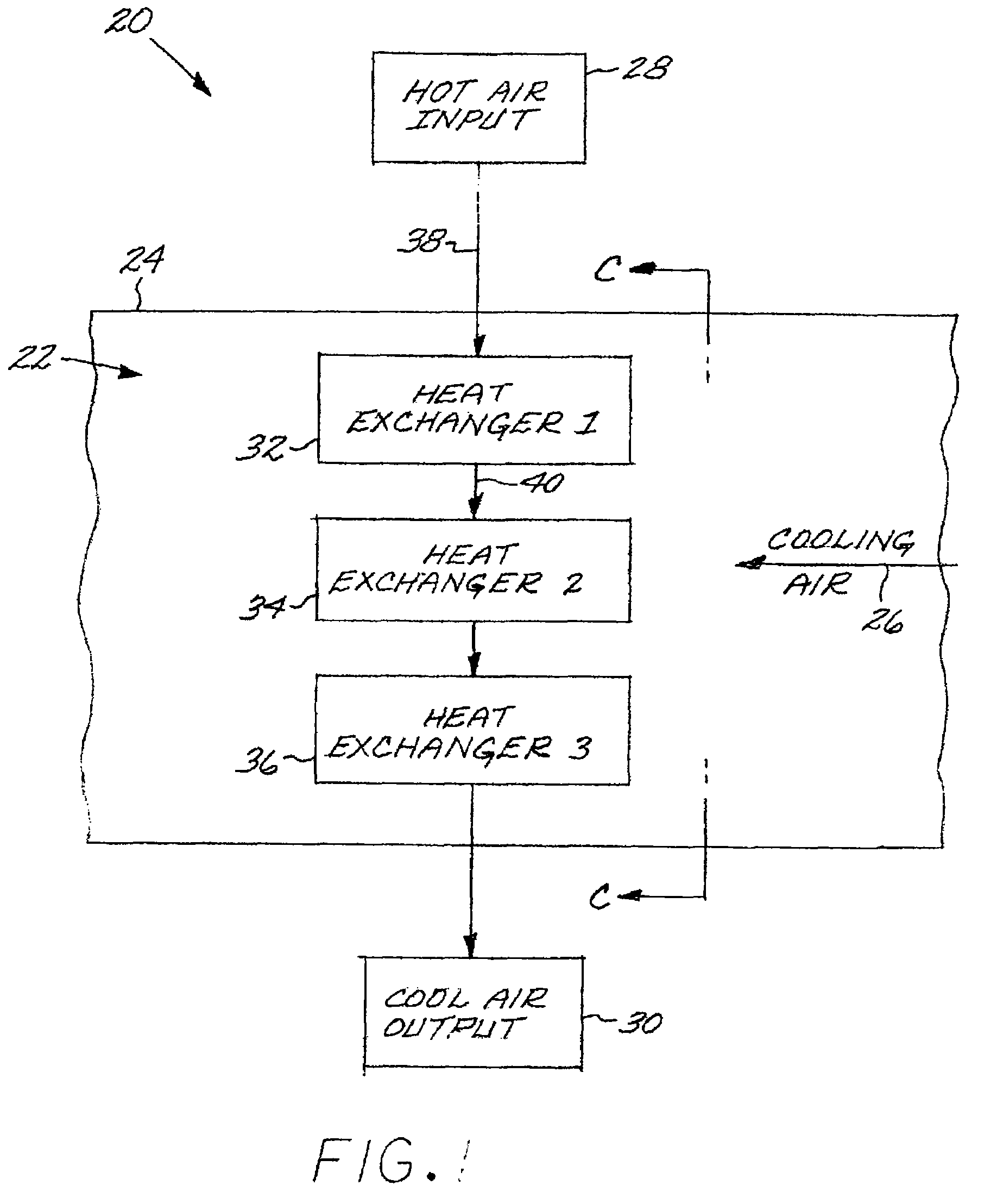

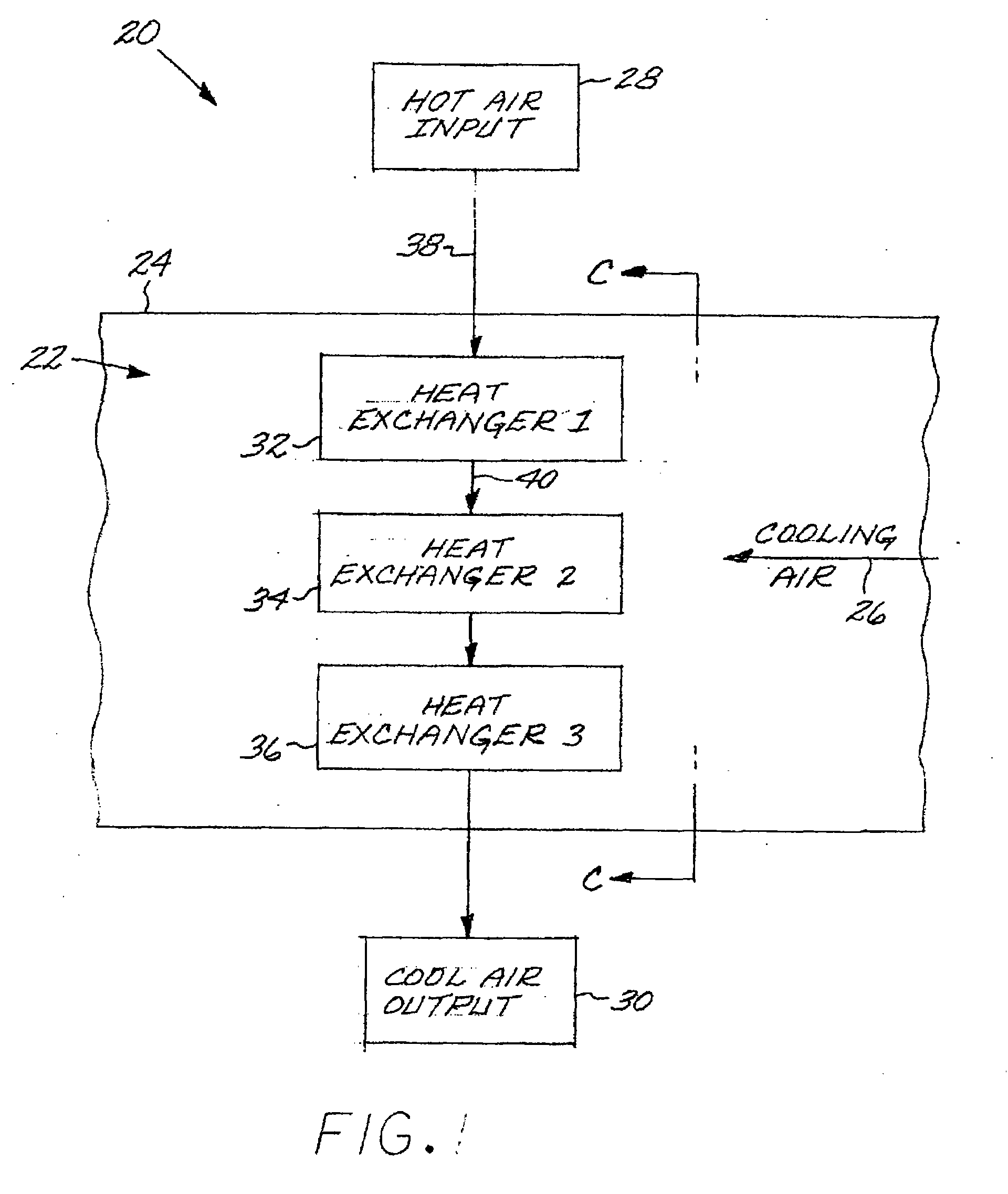

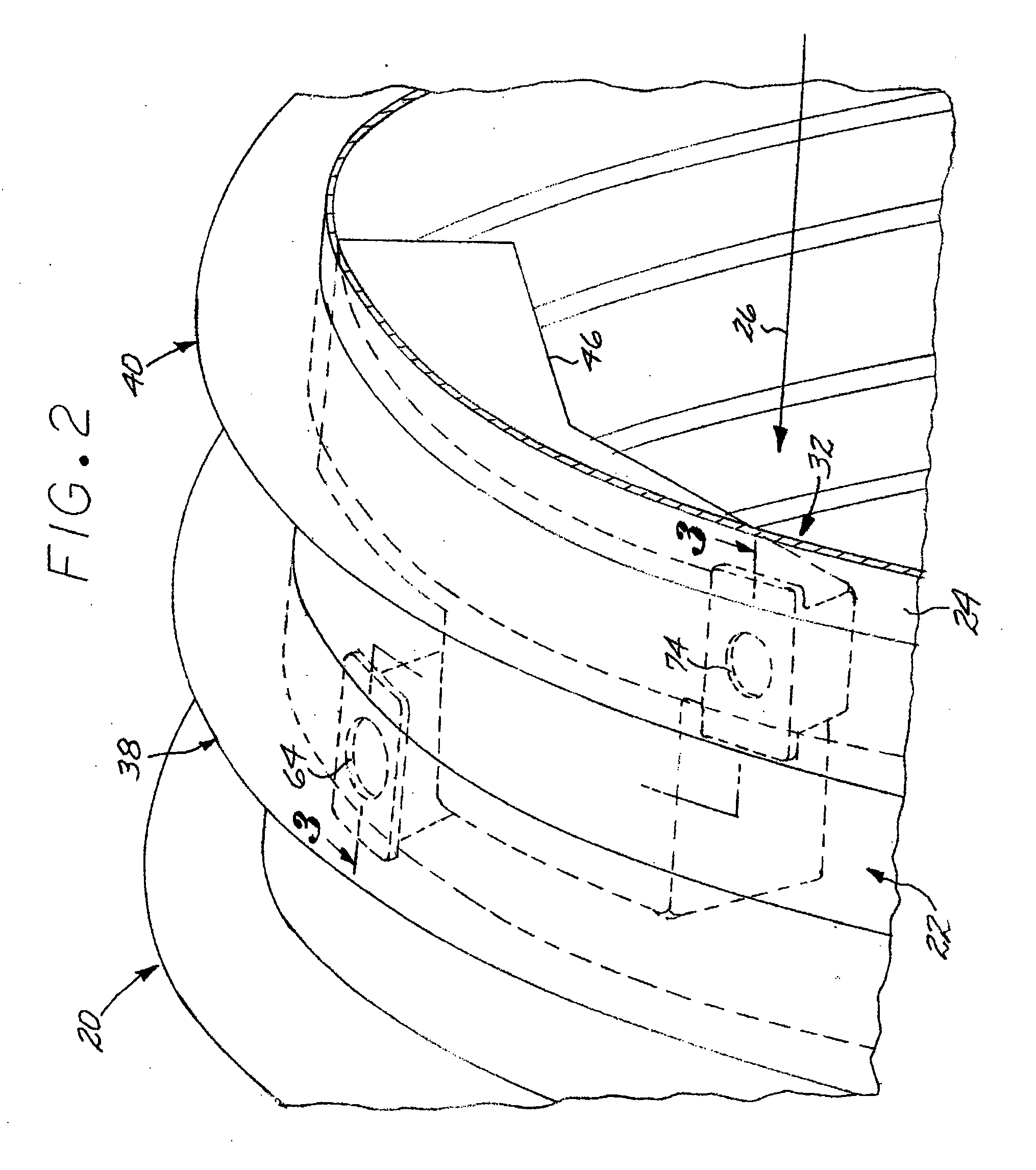

Heat exchanger system having manifolds structurally integrated with a duct

ActiveUS7784528B2Saving substantial amountLower overall pressure dropRecuperative heat exchangersHeat exchanger casingsEngineeringInlet manifold

A heat exchanger system includes a duct having a duct wall with a duct wall outer surface and a duct wall inner surface; and a heat exchanger partial shell hermetically joined to the duct wall inner surface. The heat exchanger partial shell and a shell portion of the duct wall inner surface constitute a heat exchanger. A heat exchanger inlet manifold is defined by a nonplanar inlet sheet of material hermetically joined to the duct wall outer surface. A heat exchanger outlet manifold is defined by a nonplanar outlet sheet of material hermetically joined to the duct wall outer surface. A heat exchanger inlet opening extends through the duct wall between the inlet manifold and the heat exchanger, and a heat exchanger outlet opening extends through the duct wall between the outlet manifold and the heat exchanger.

Owner:GENERAL ELECTRIC CO

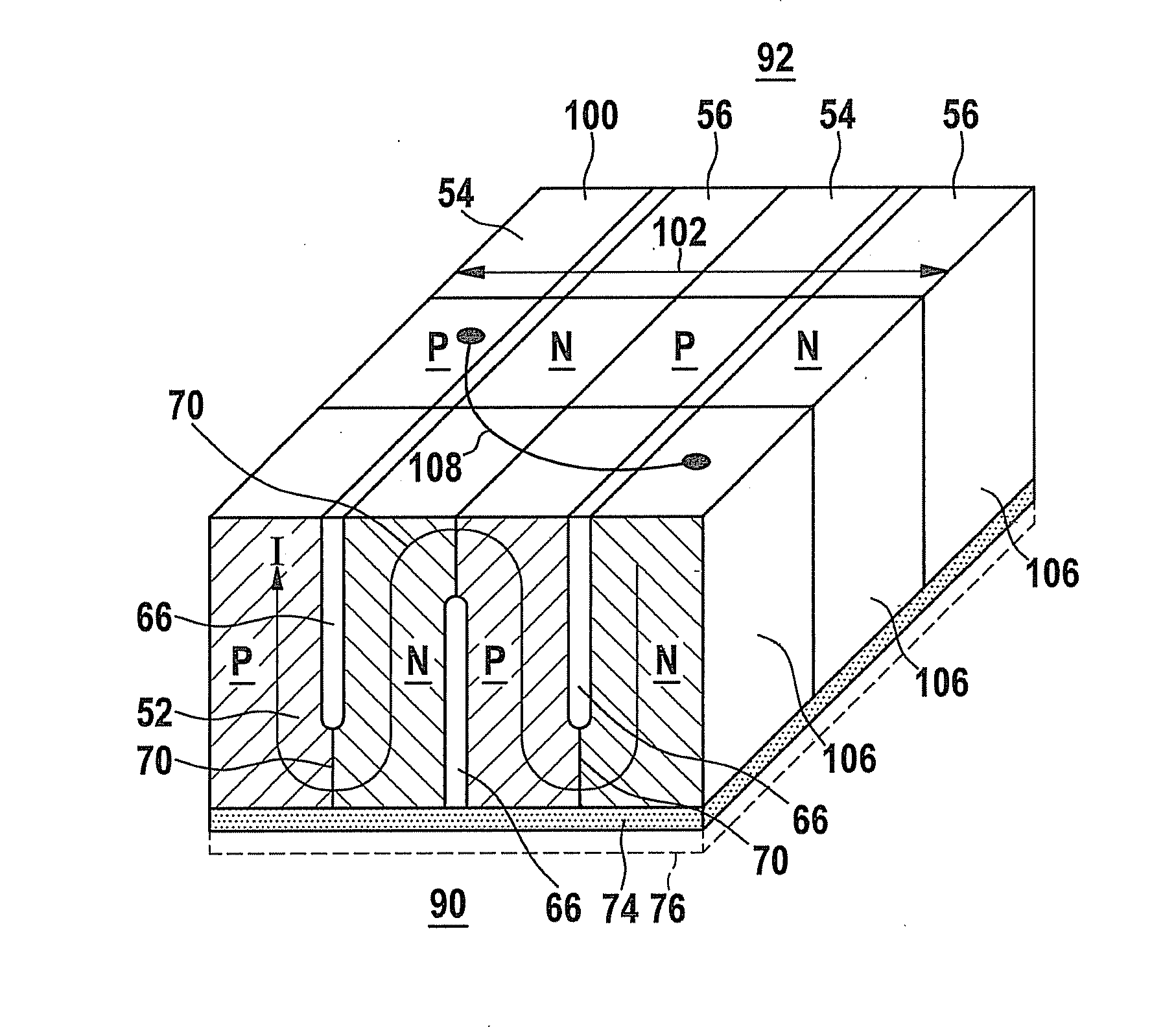

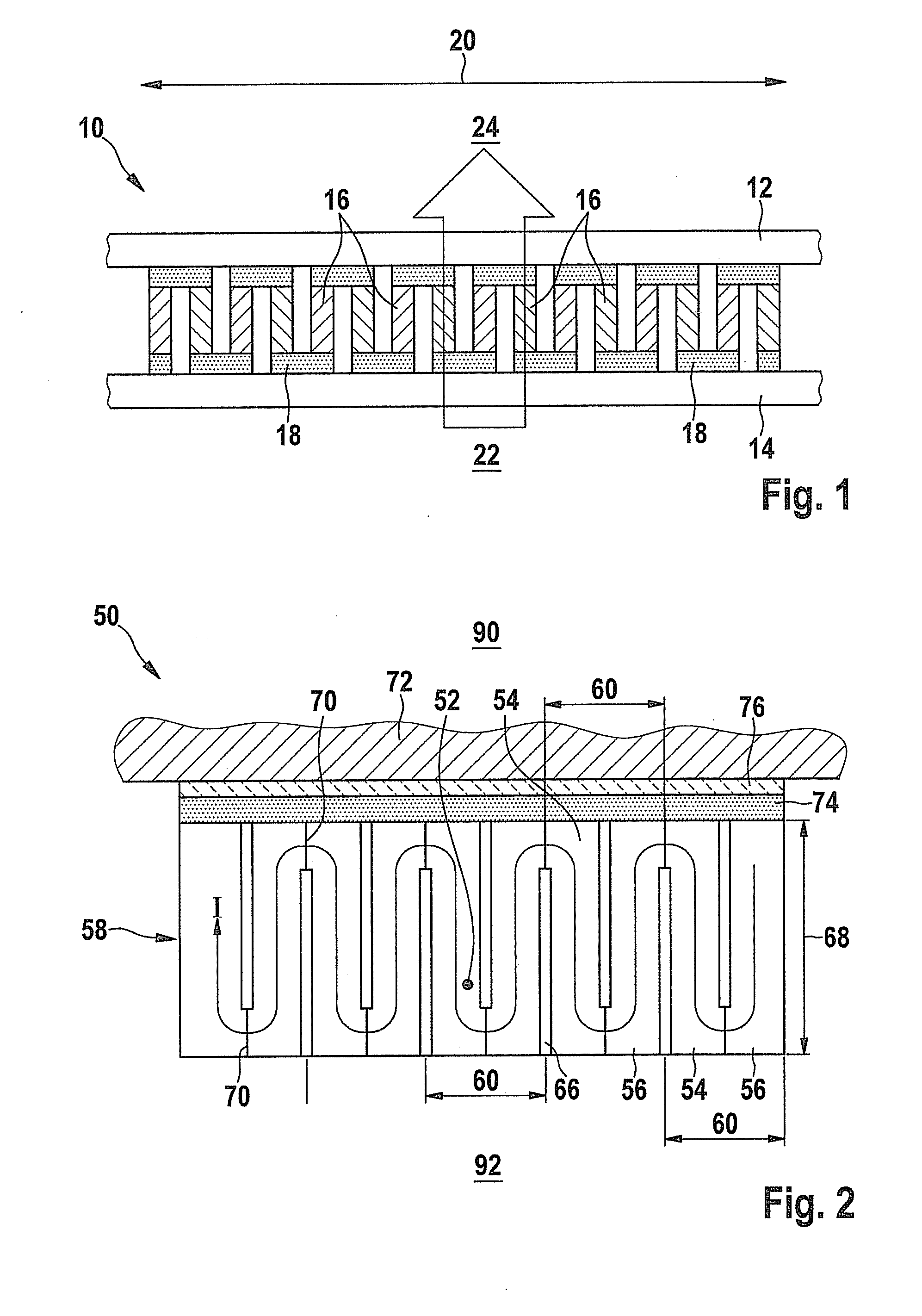

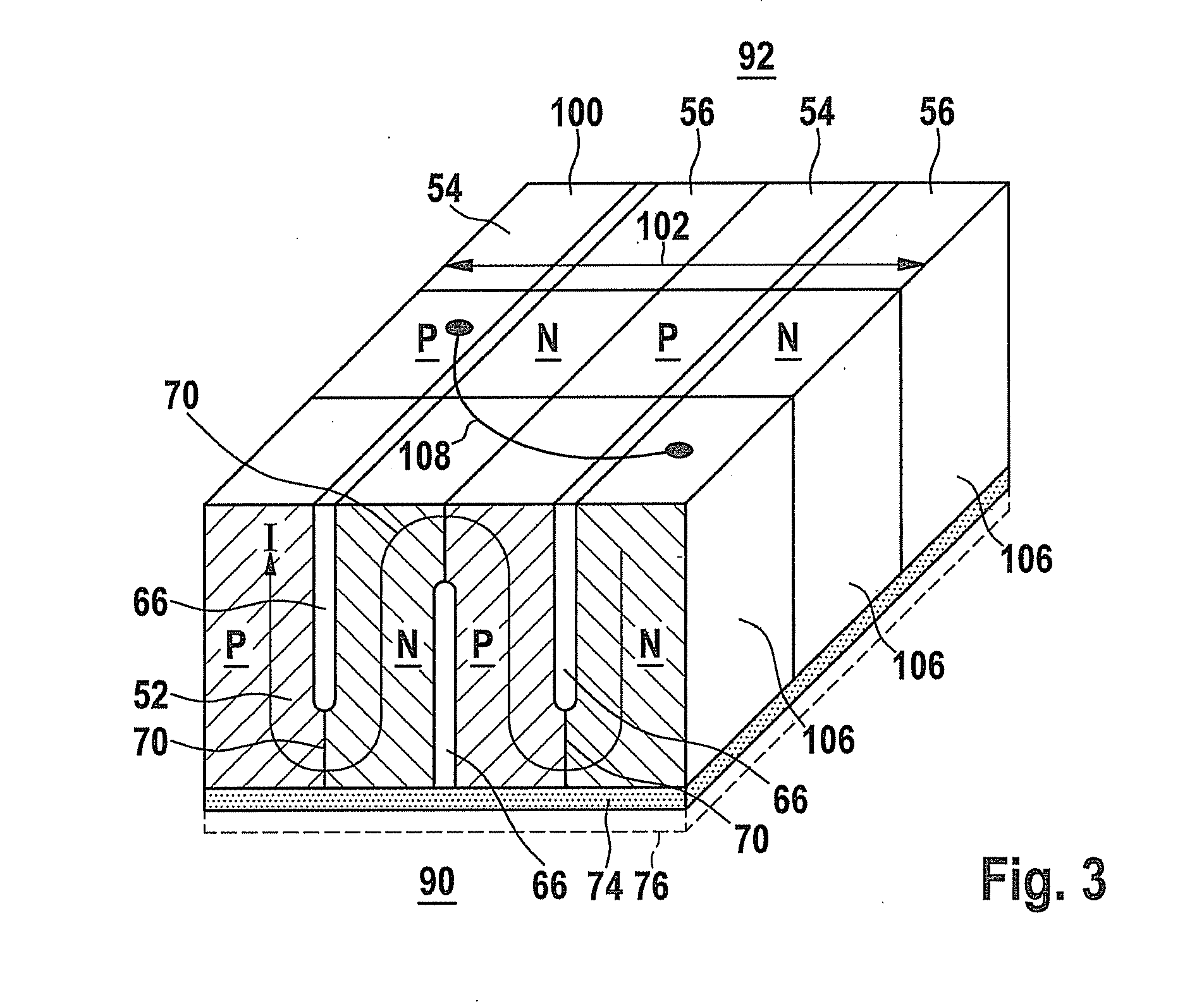

Thermoelectric generator including a thermoelectric module having a meandering p-n system

InactiveUS20120103379A1Improve efficiencyReduce in quantityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentConductive materialsElectric current

A thermoelectric module having a plurality of p-n-couples, every two adjacent p-n-legs forming one p-n-couple. The p-n-legs are each manufactured from conductive materials. The p-n-legs of the plurality of p-n-couples are separated in an alternating sequence by an electrically insulating gap which creates a meandering current flow.

Owner:ROBERT BOSCH GMBH

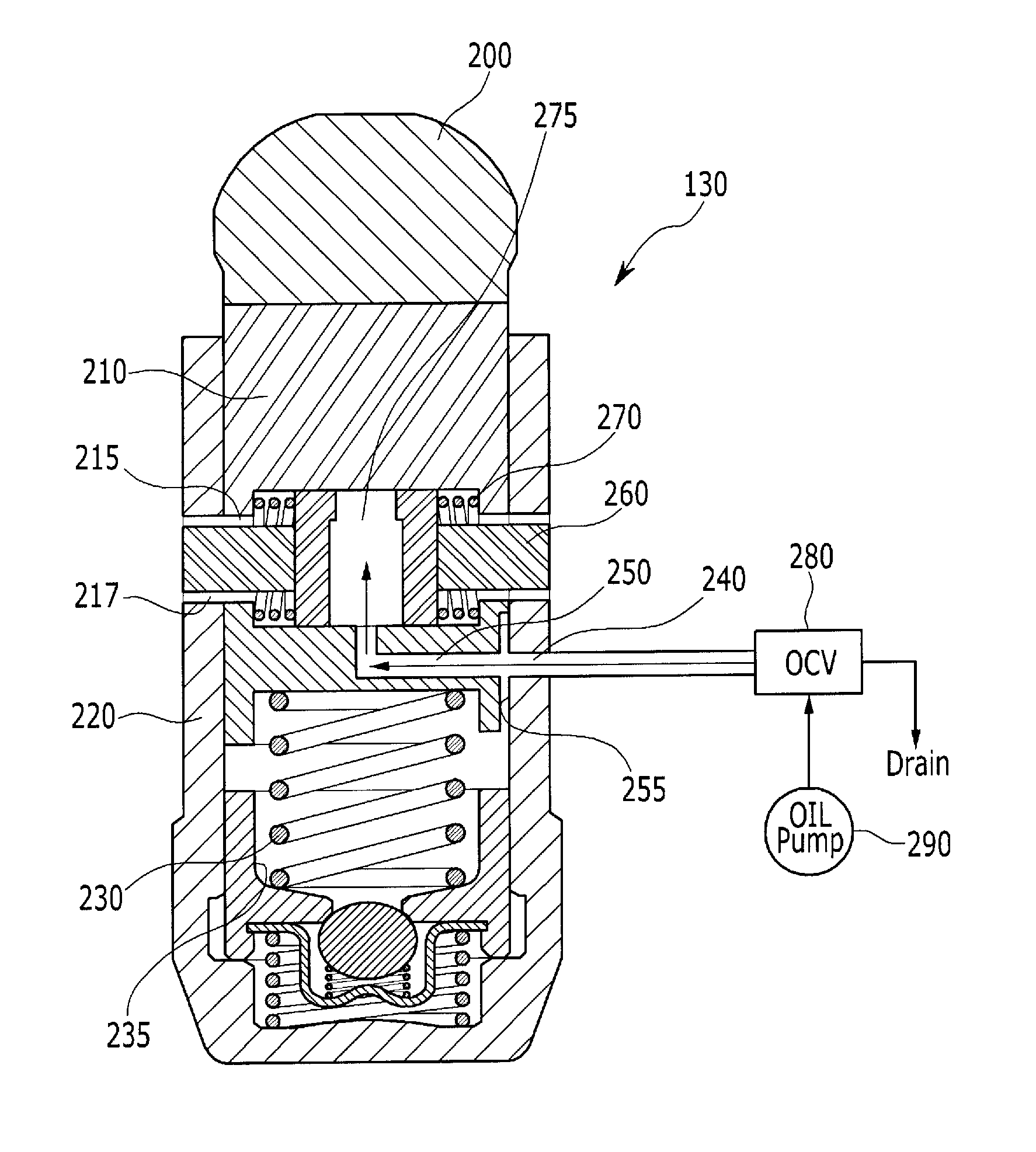

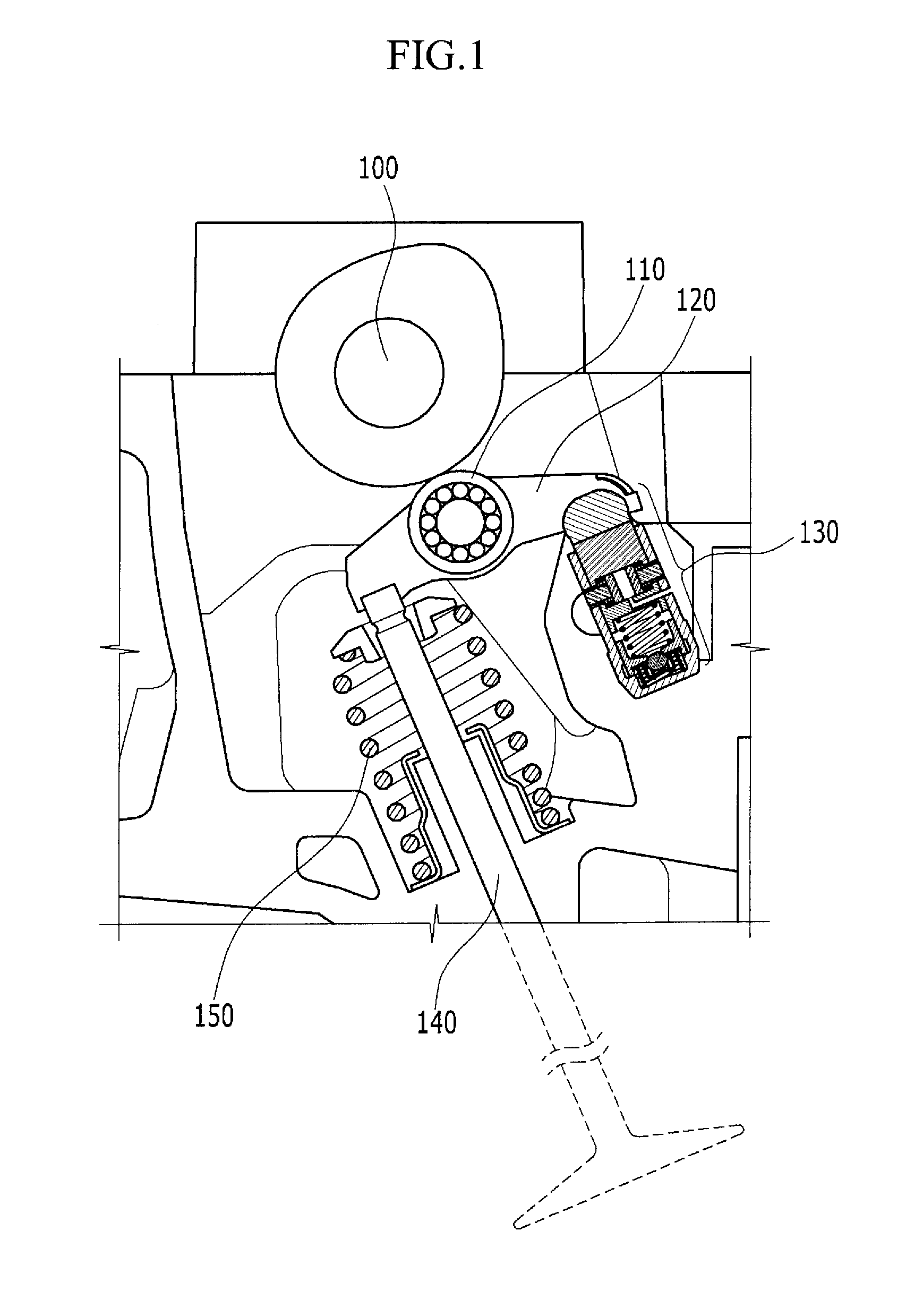

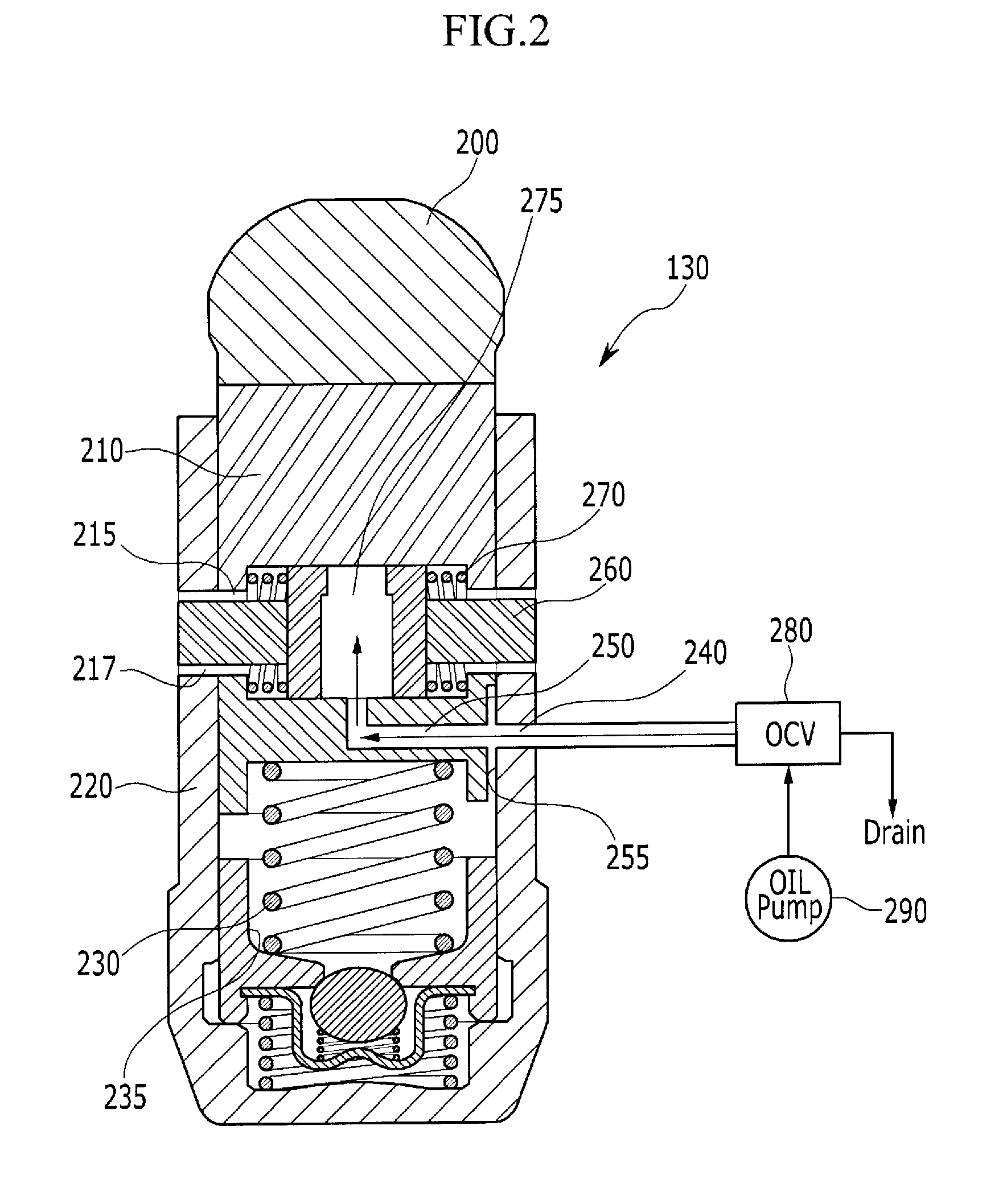

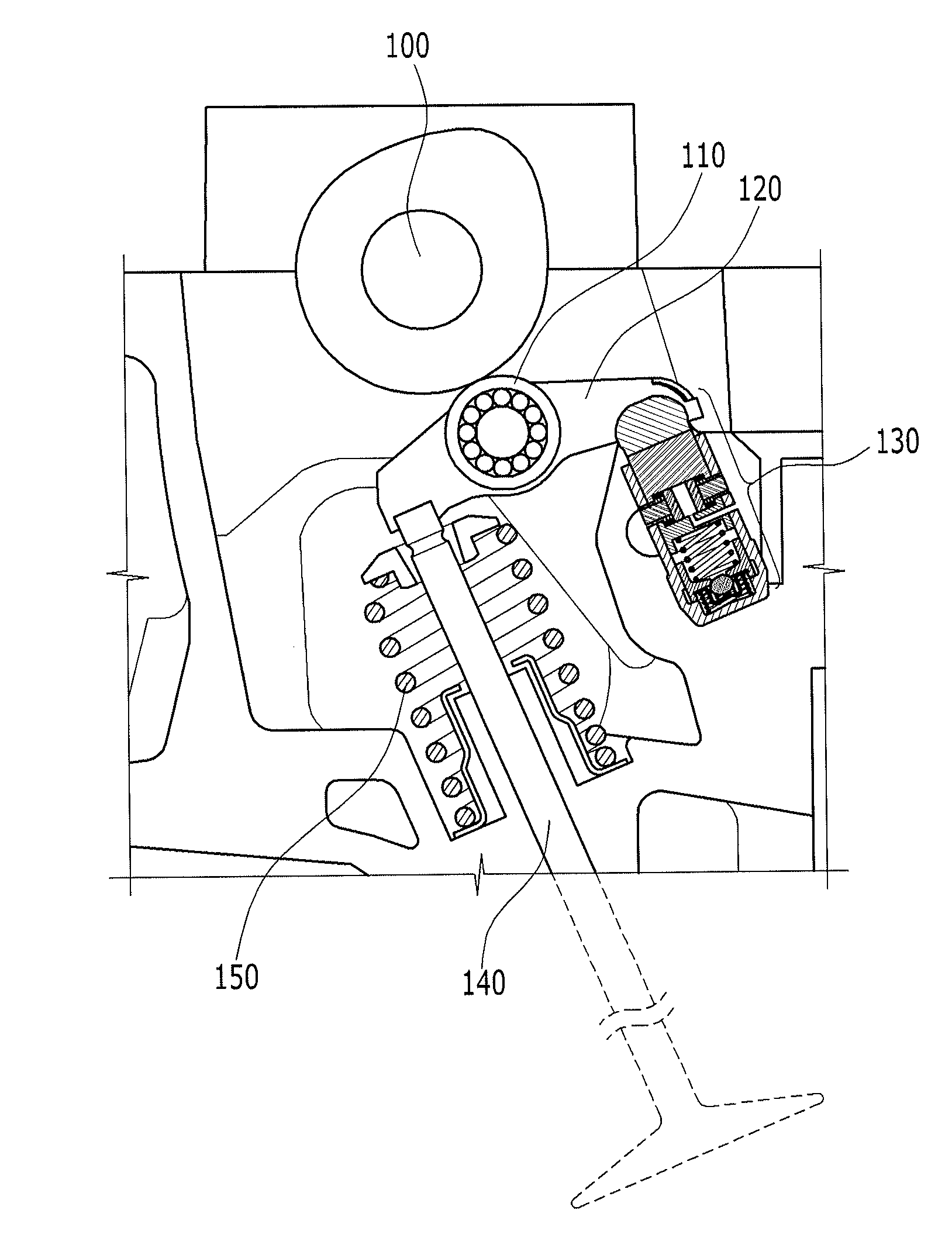

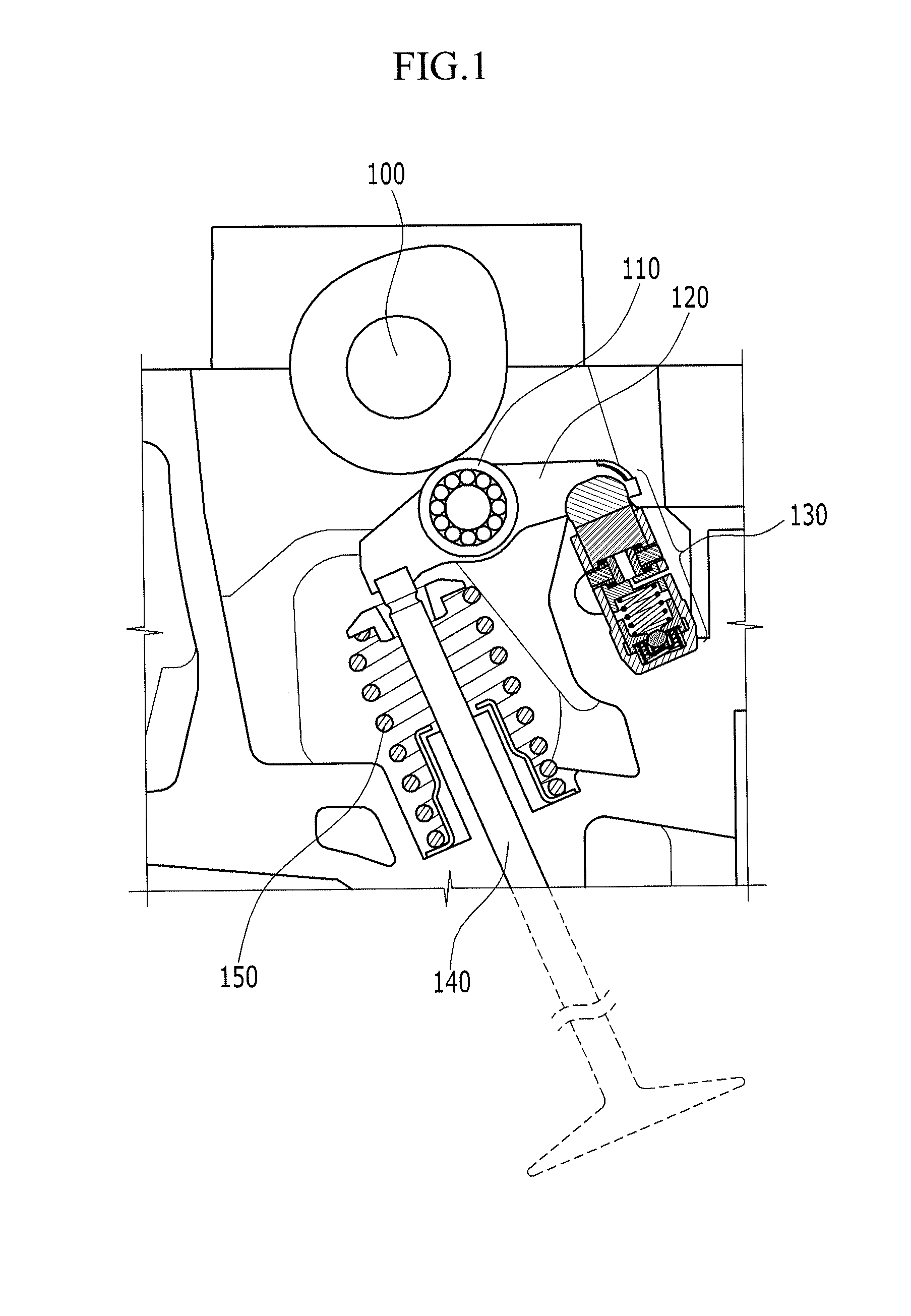

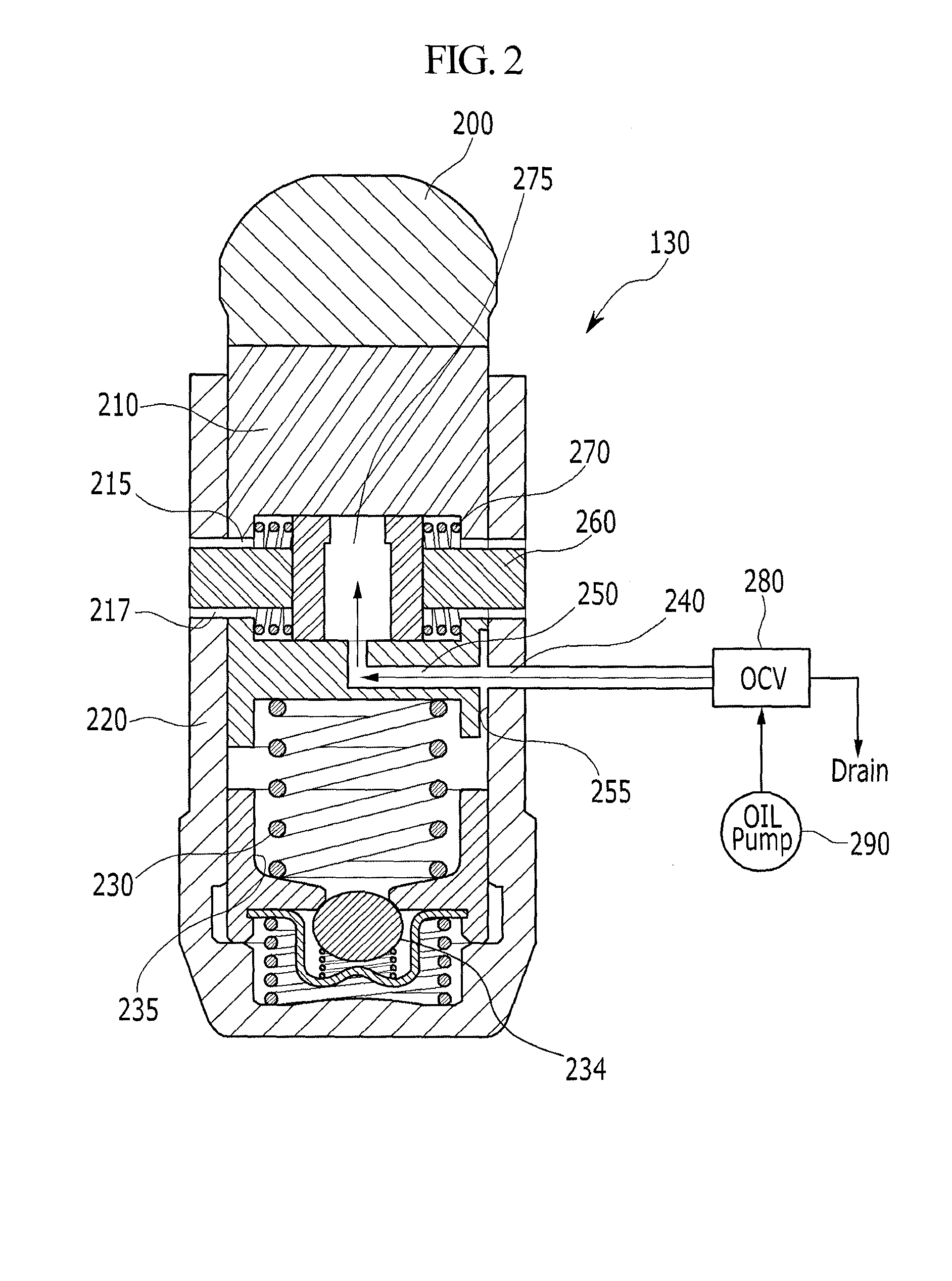

Engine that is Equipped with Variable Valve Device

InactiveUS20120067312A1Small structureReduce component weightValve arrangementsMachines/enginesEngineeringMechanical engineering

An engine includes a hydraulic pressure lash adjuster (HLA) pivotally supporting an end of a swing arm and having a valve supporting the other end of the swing arm, wherein the hydraulic pressure lash adjuster includes a housing, a plunger of which one end portion thereof may be slidably inserted into the inside of the housing, the other end portion of which extends outwards and supports the end of the swing arm by selectively moving upwards or downwards in a length direction of the housing, a stopper pin slidably mounted in a chamber of the plunger so as to selectively lock the plunger to the housing such that the plunger cannot move in the housing, and a hydraulic pressure supply portion that selectively supplies one side of the stopper pin with a hydraulic pressure in the chamber of the plunger to move the stopper pin toward the housing.

Owner:HYUNDAI MOTOR CO LTD

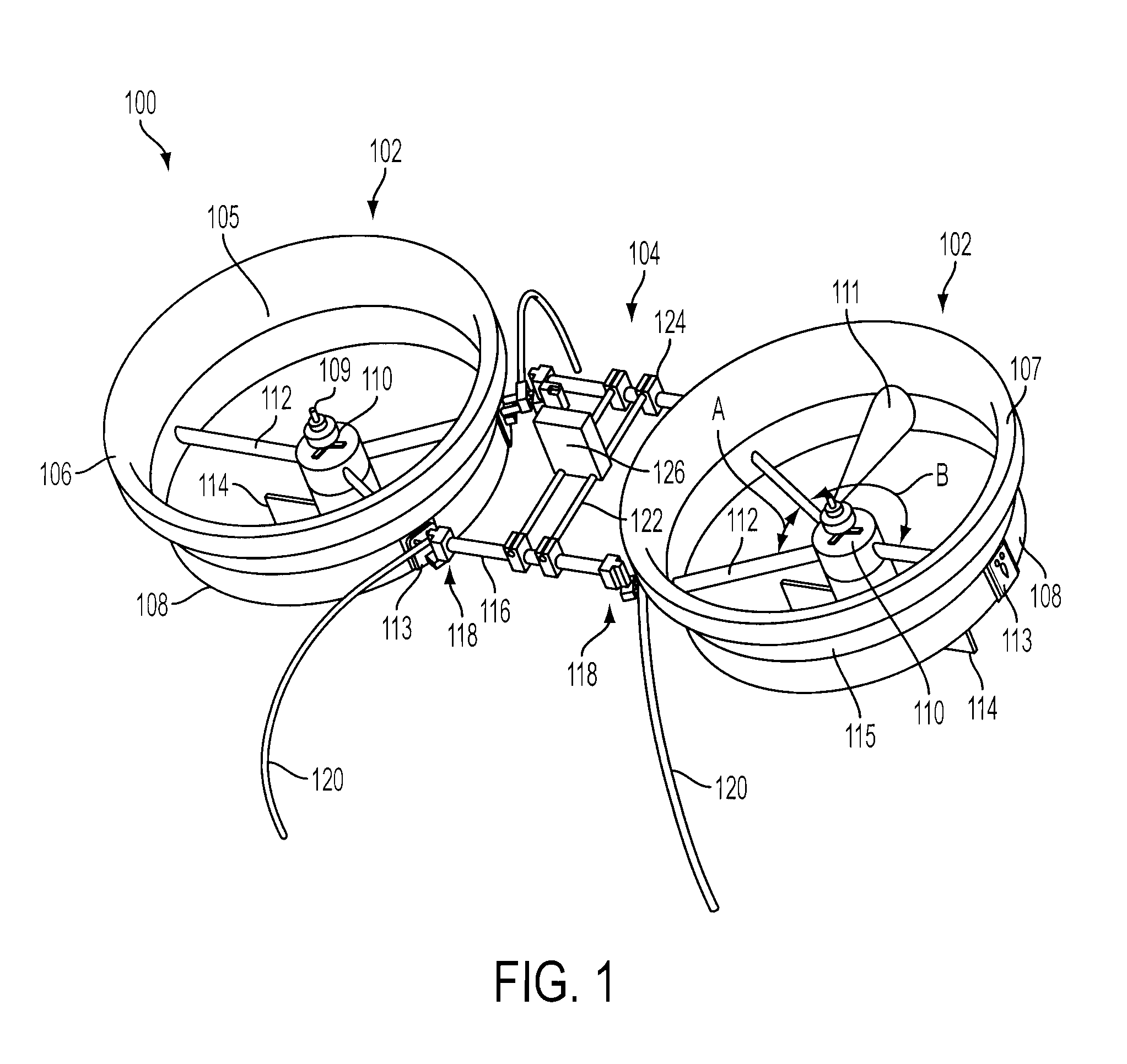

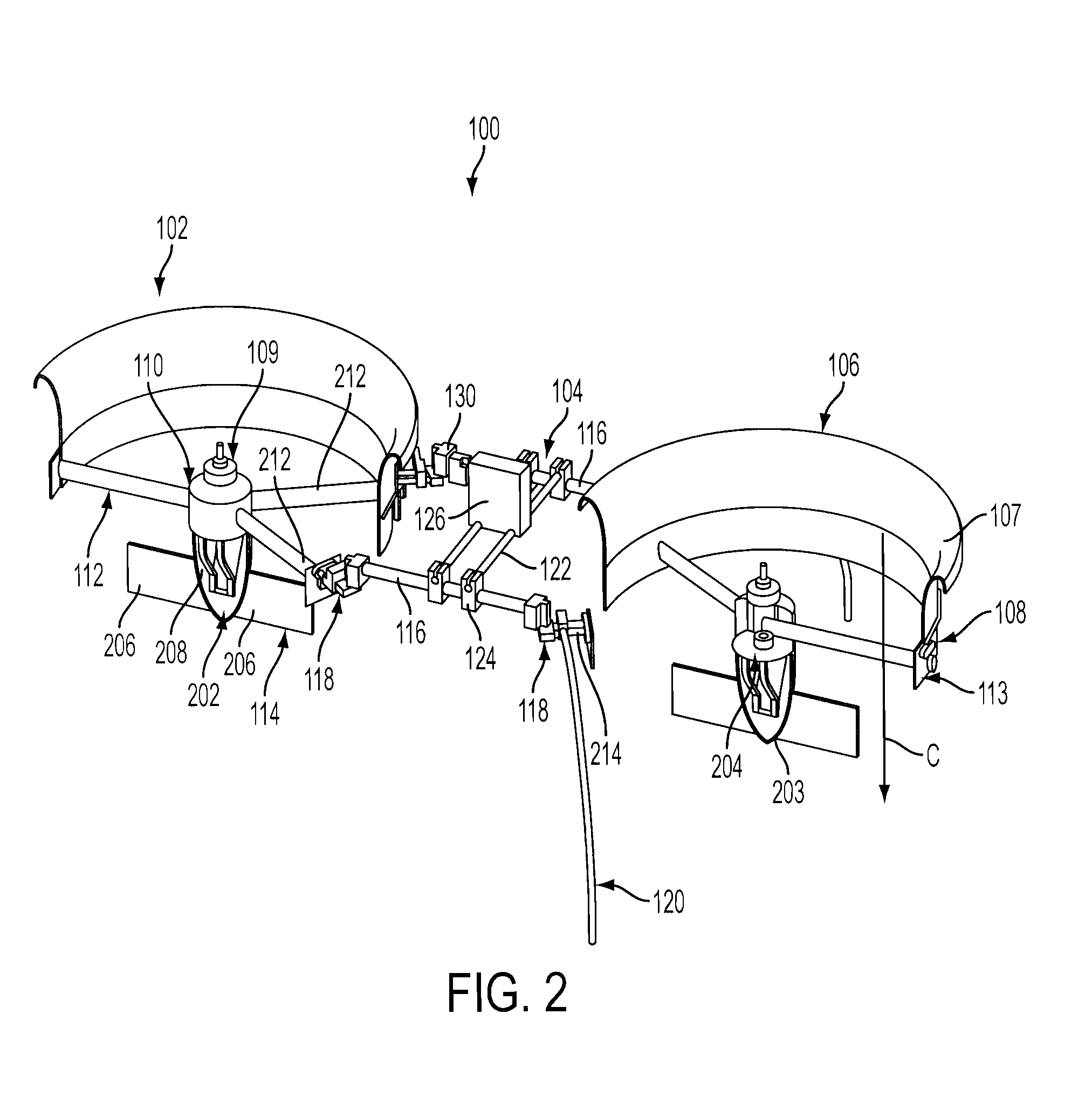

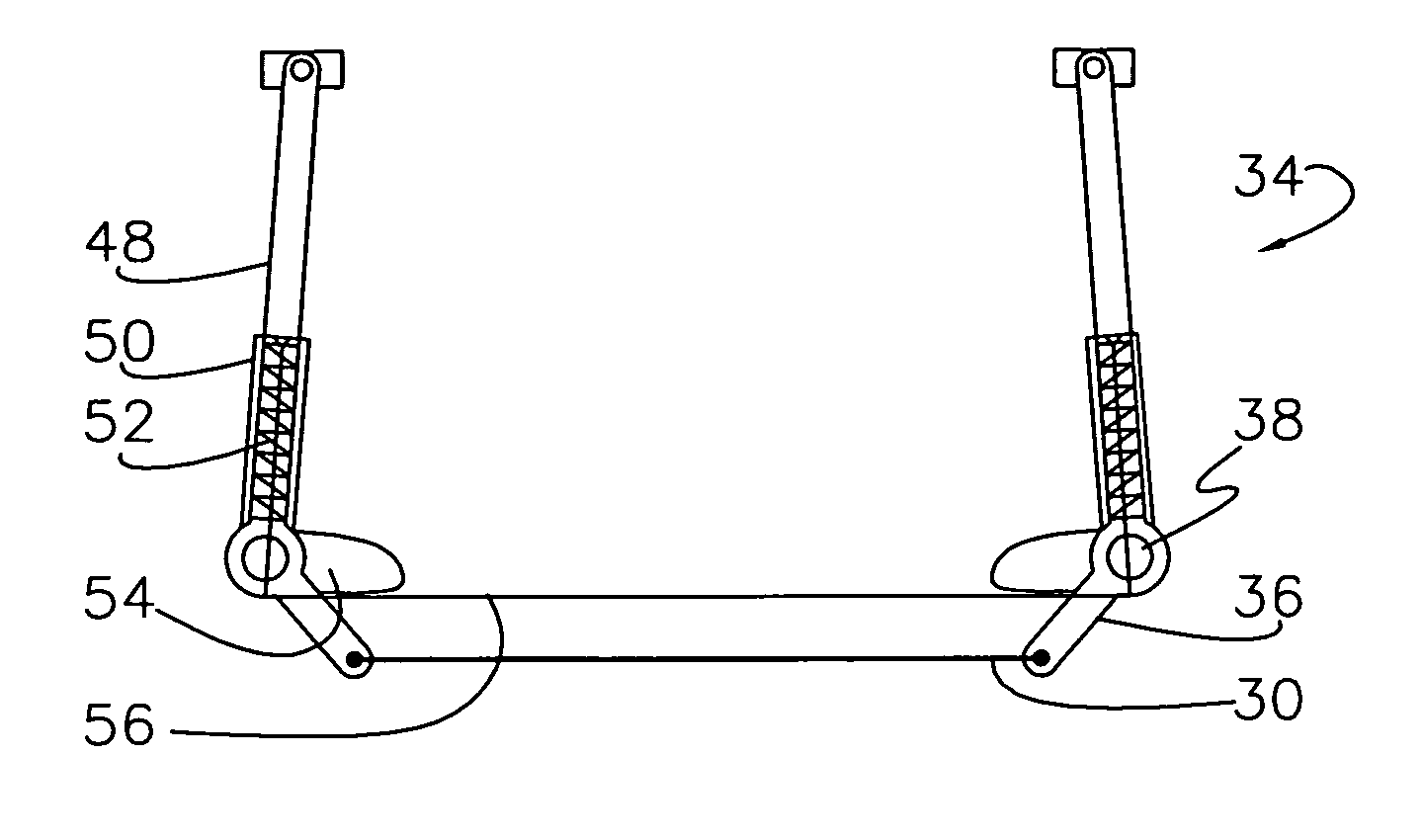

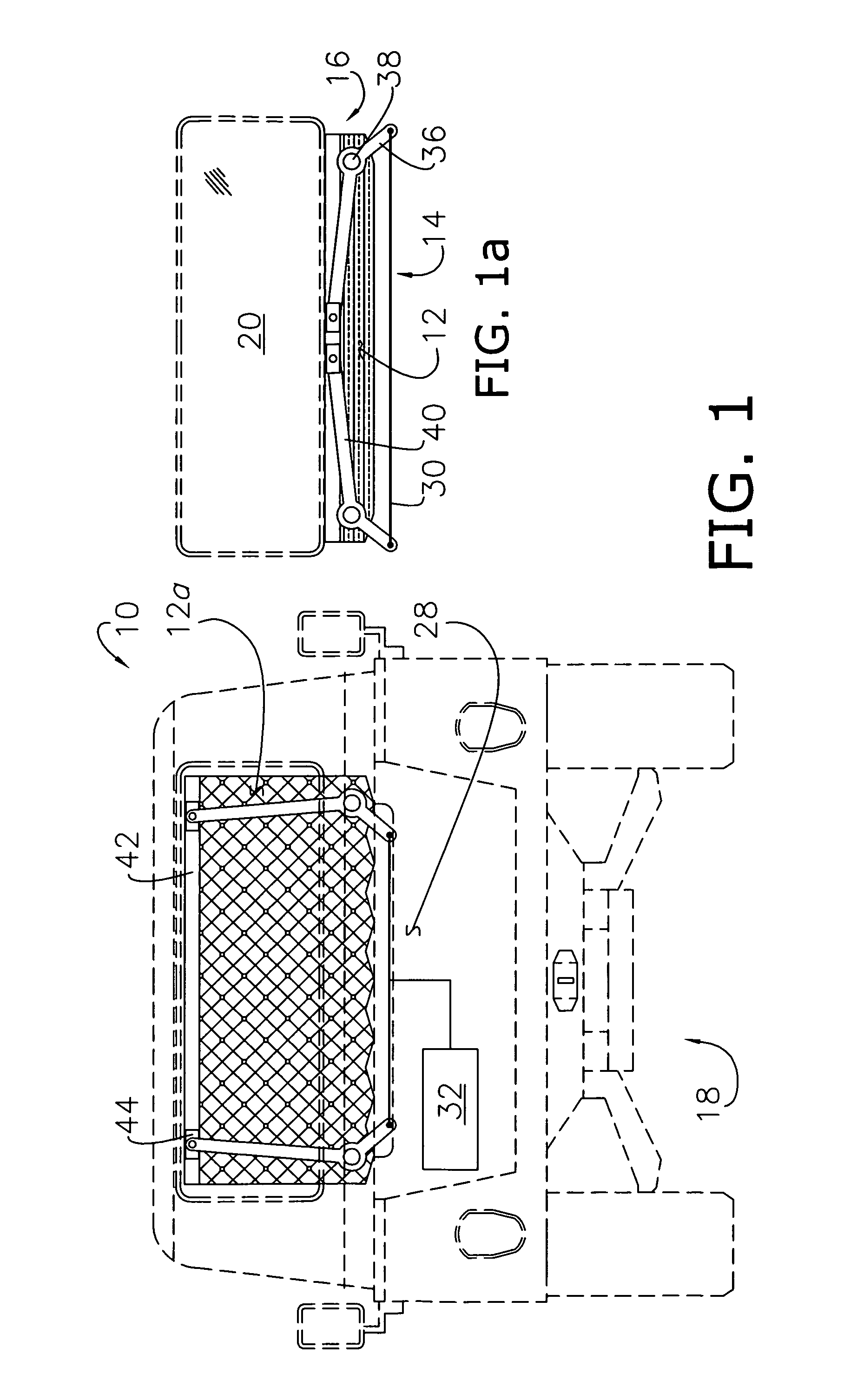

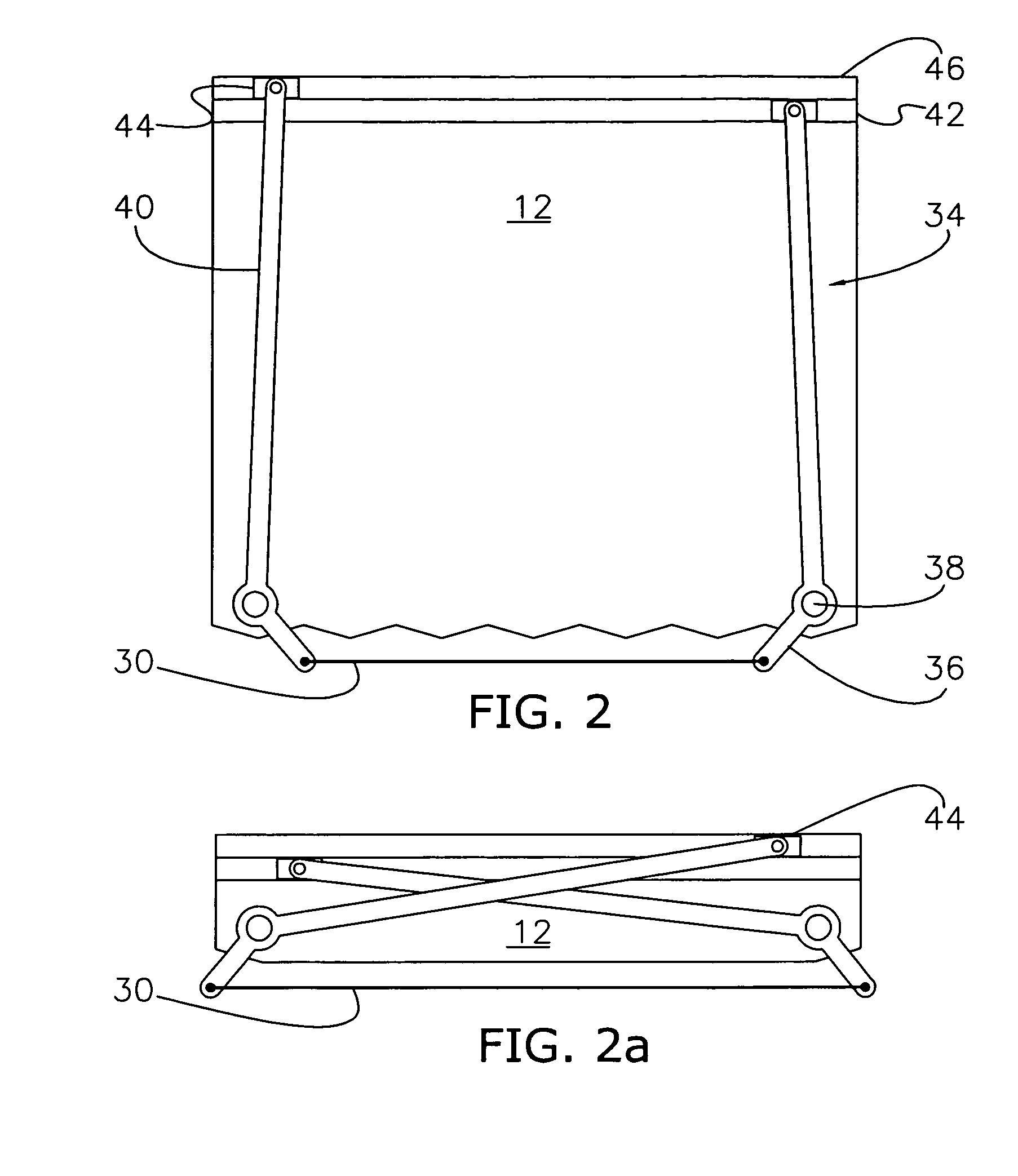

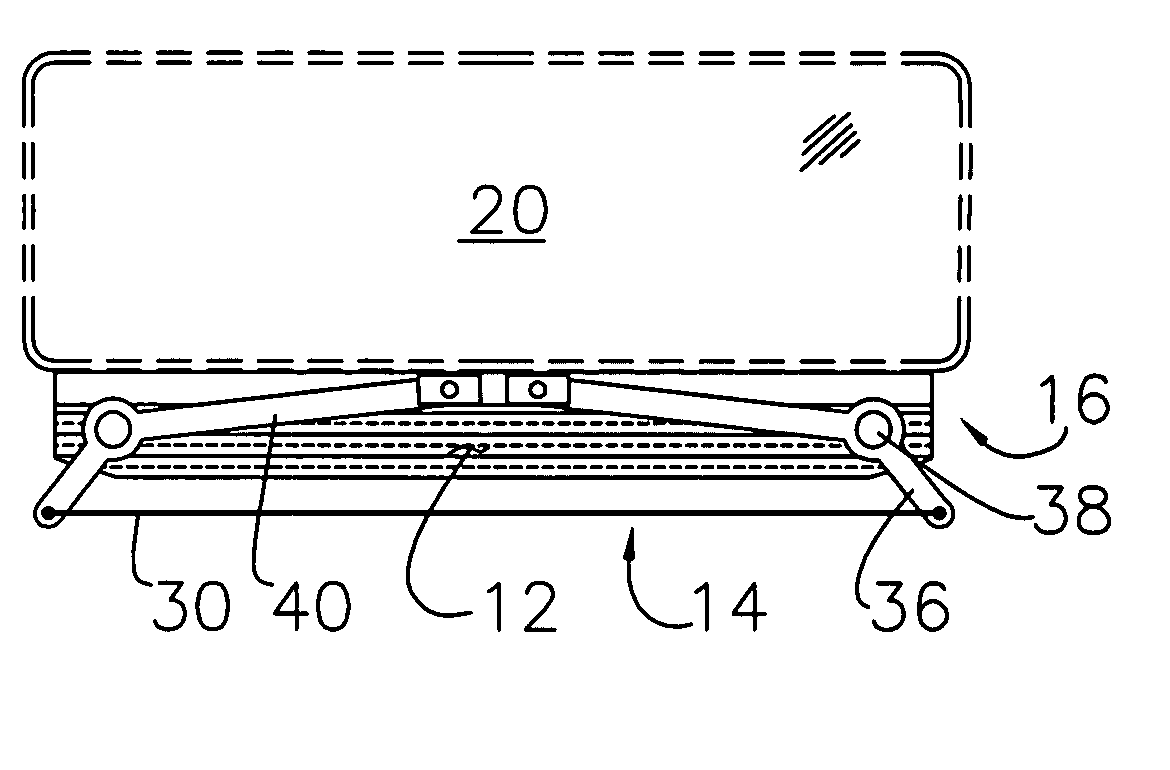

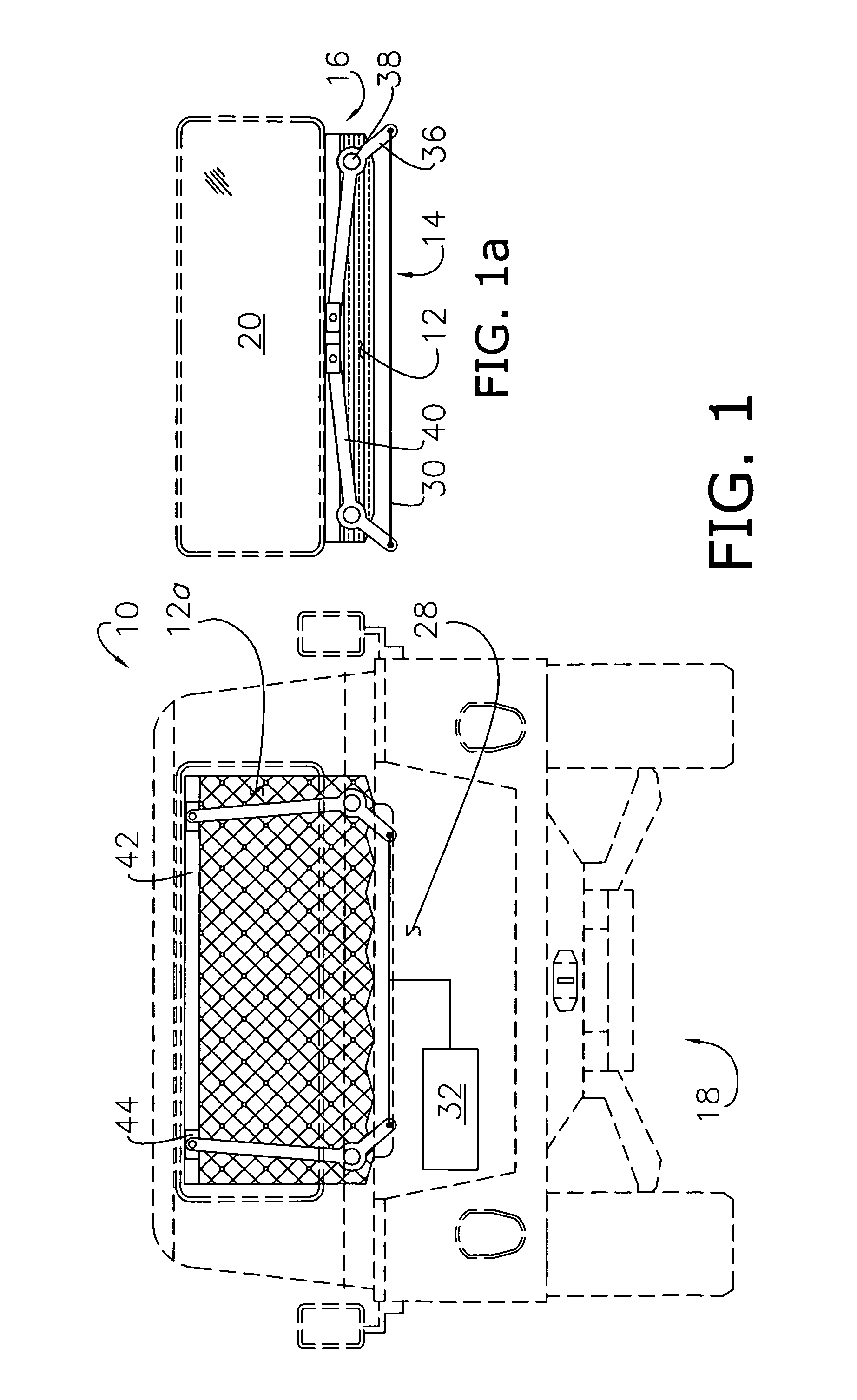

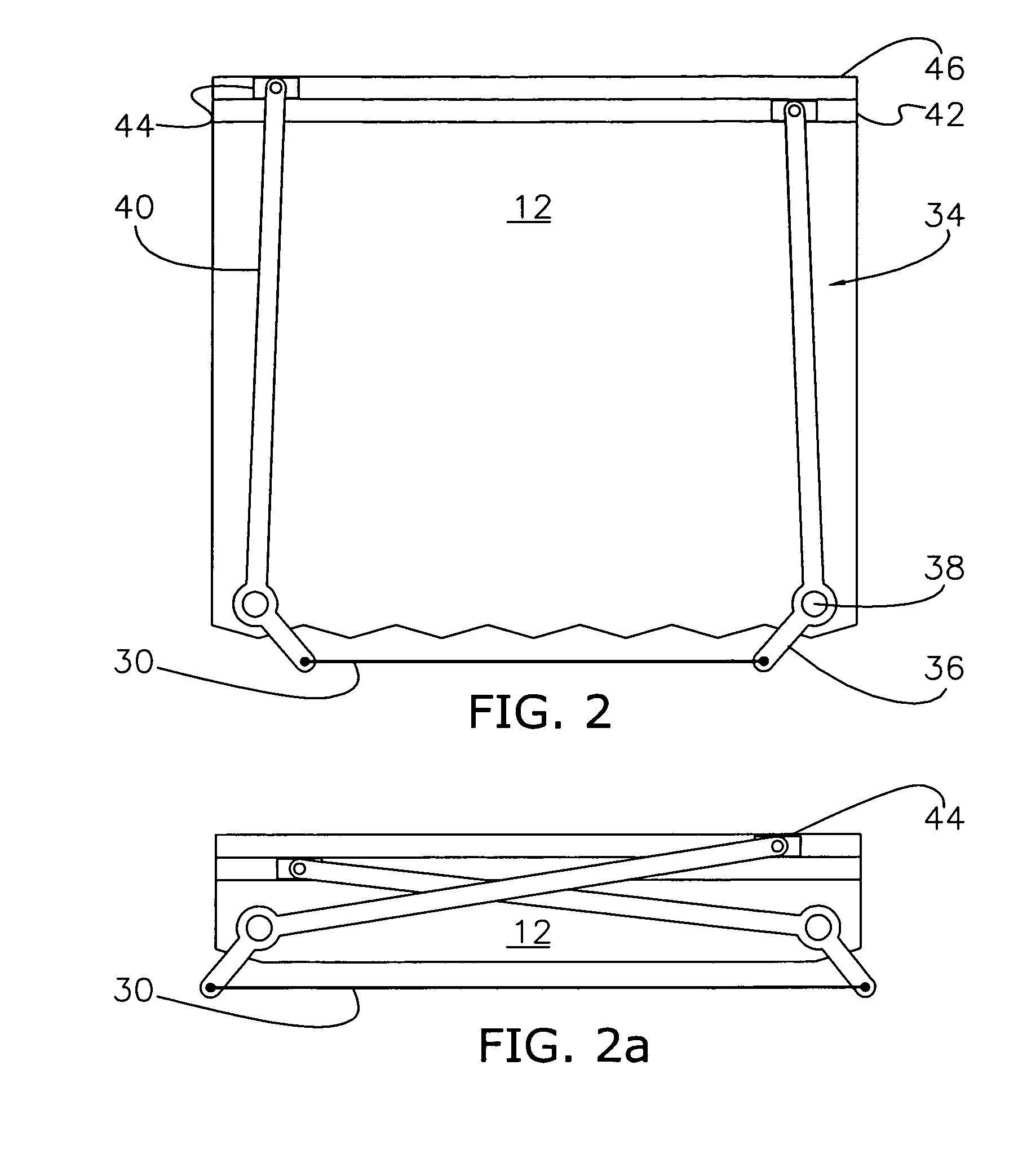

Cover deploying system utilizing active material actuation

A system for deploying and stowing a cover, including a mechanical assembly coupled to the cover, preferably comprising a plurality of deploy arms and synchronization means, and reconfigurable between deployed and stowed conditions, and further including an actuator presenting an active material element operable to undergo a change, when activated, and operable to cause the assembly to reconfigure as a result of the change.

Owner:GM GLOBAL TECH OPERATIONS LLC

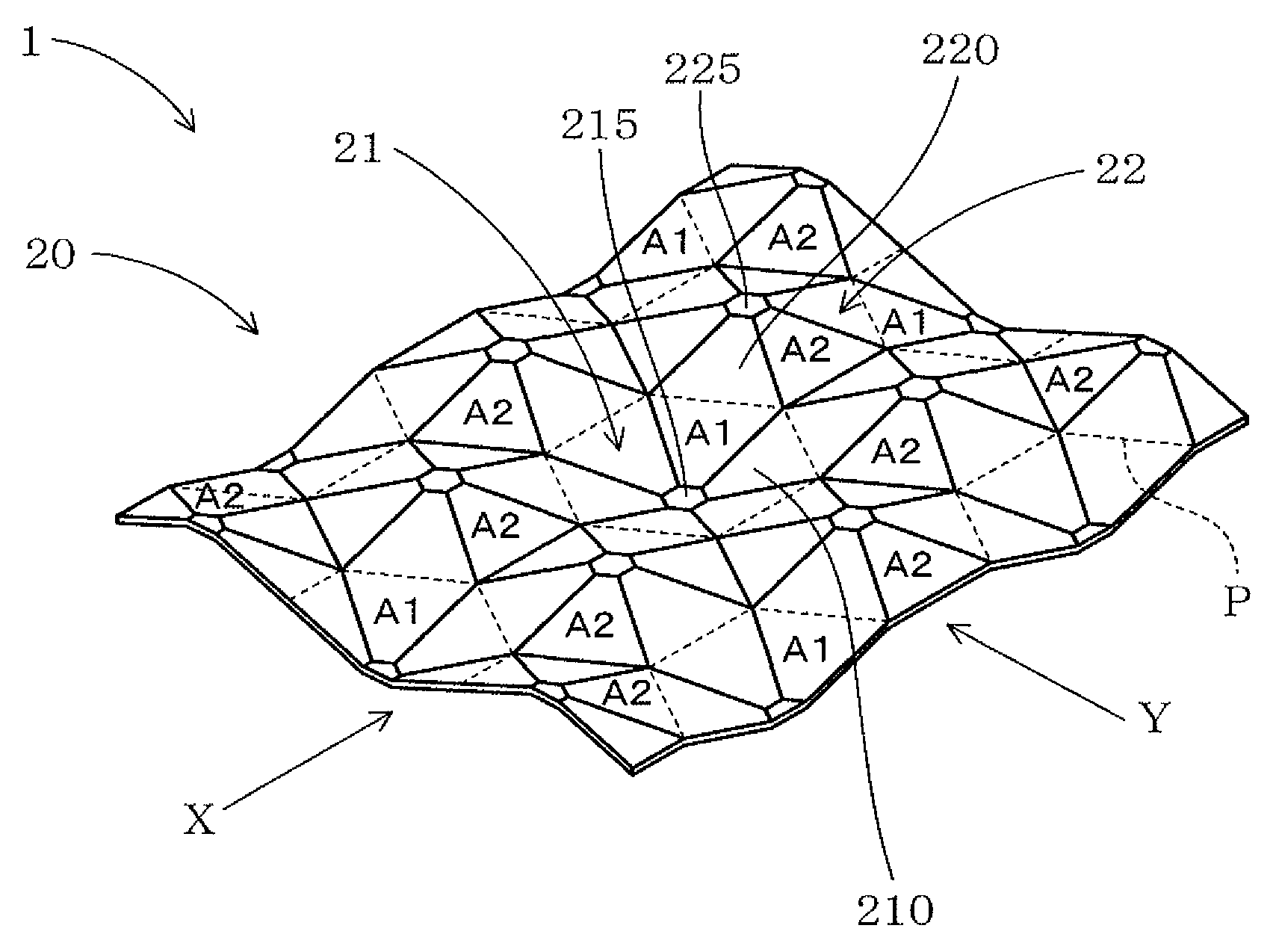

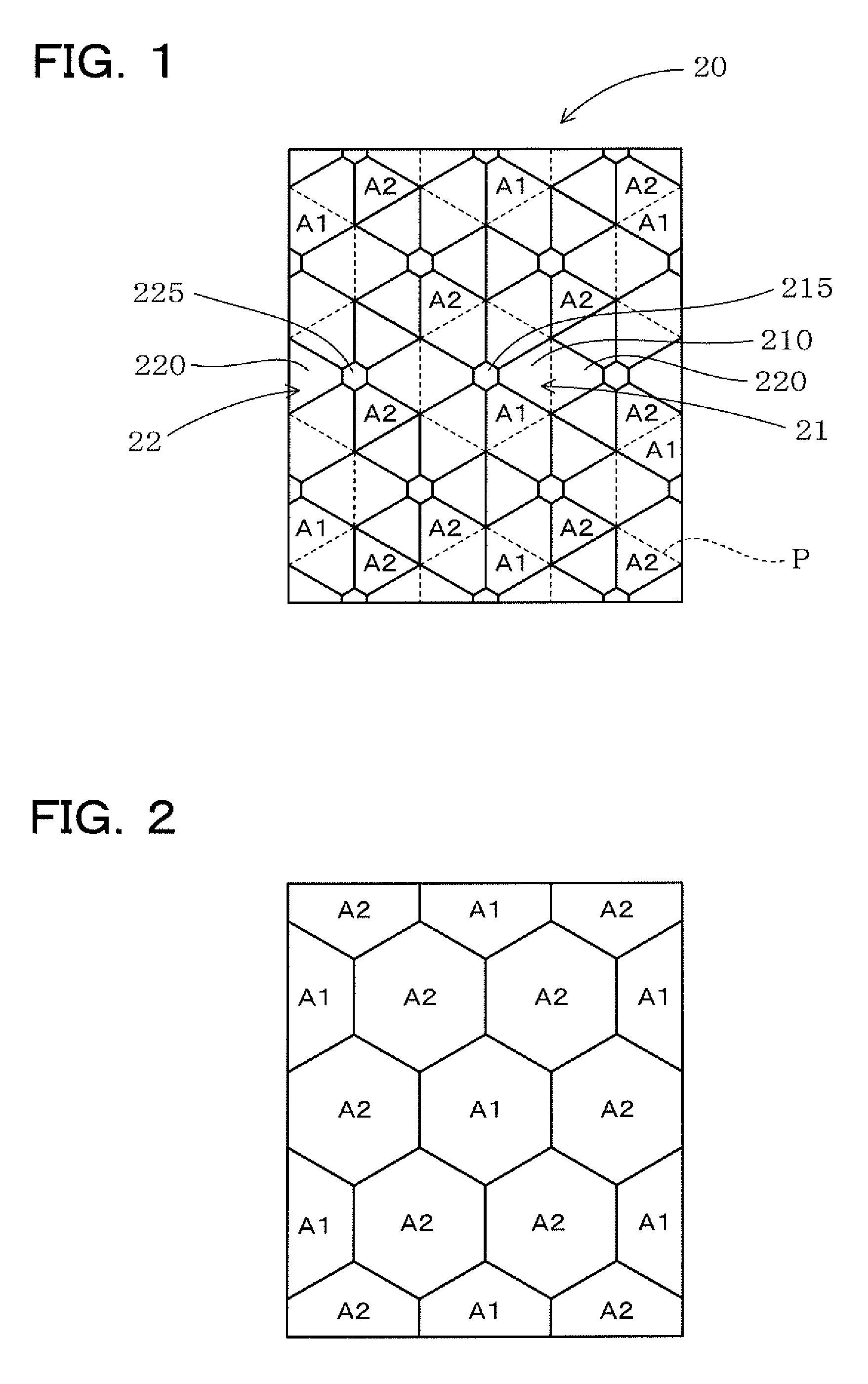

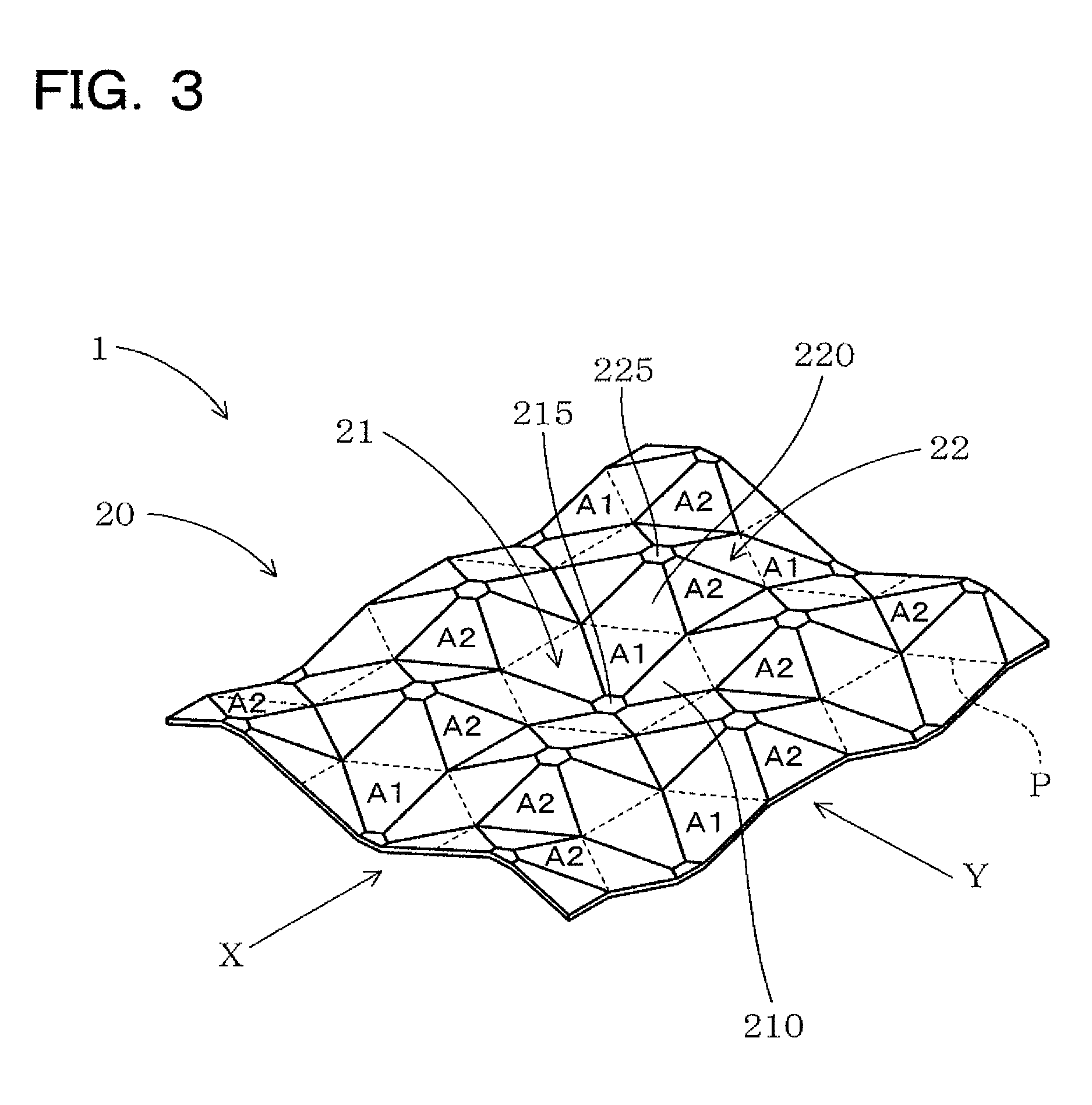

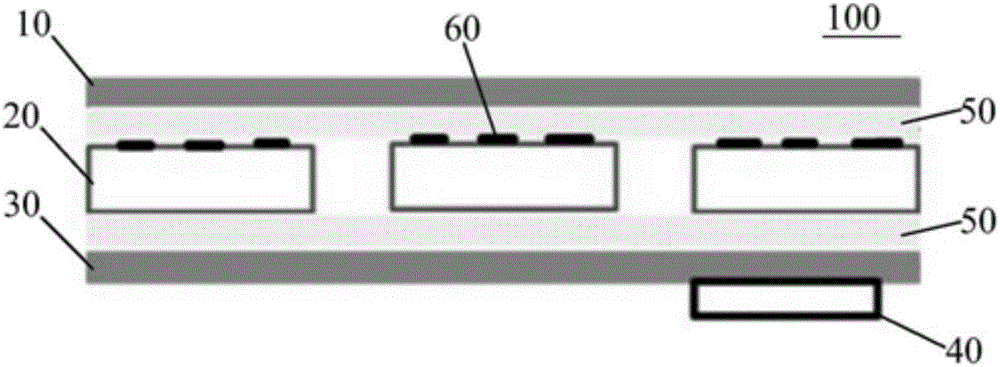

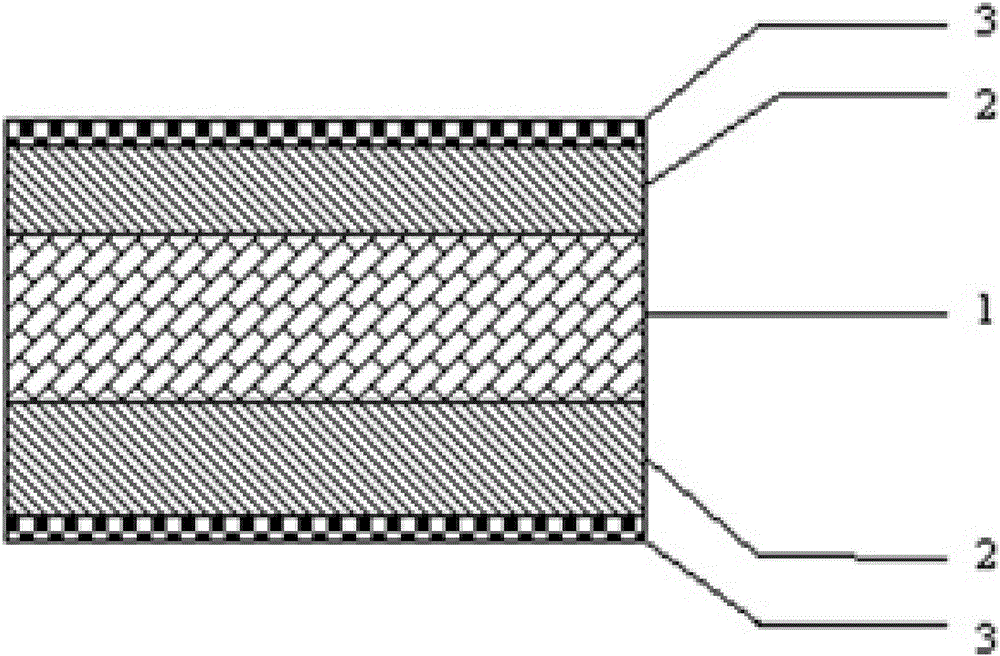

Sheet material having concave-convex section, and laminated structure and vehicle panel using the same

ActiveUS9108239B2Reduce component weightReduce material costsEnvelopes/bags making machineryLayered productsEngineeringPyramid

Within an area of substantially regular hexagons arranged at regular intervals on an imaginary reference plane, a sheet material includes a concave-convex section (20) having a basic pattern in which one first region (A1) is surrounded by six second regions (A2). This basic pattern repeats in regular intervals in lateral and longitudinal directions of the sheet material. The concave-convex section includes first protruding portions (21) and second protruding portion (22), which protrude in opposite directions from each other in the thickness direction in the first regions and the second regions, respectively. The first and second protruding portions may have a hexagonal pyramidal shape or a truncated hexagonal pyramidal shape.

Owner:SUMITOMO LIGHT METAL INDS LTD

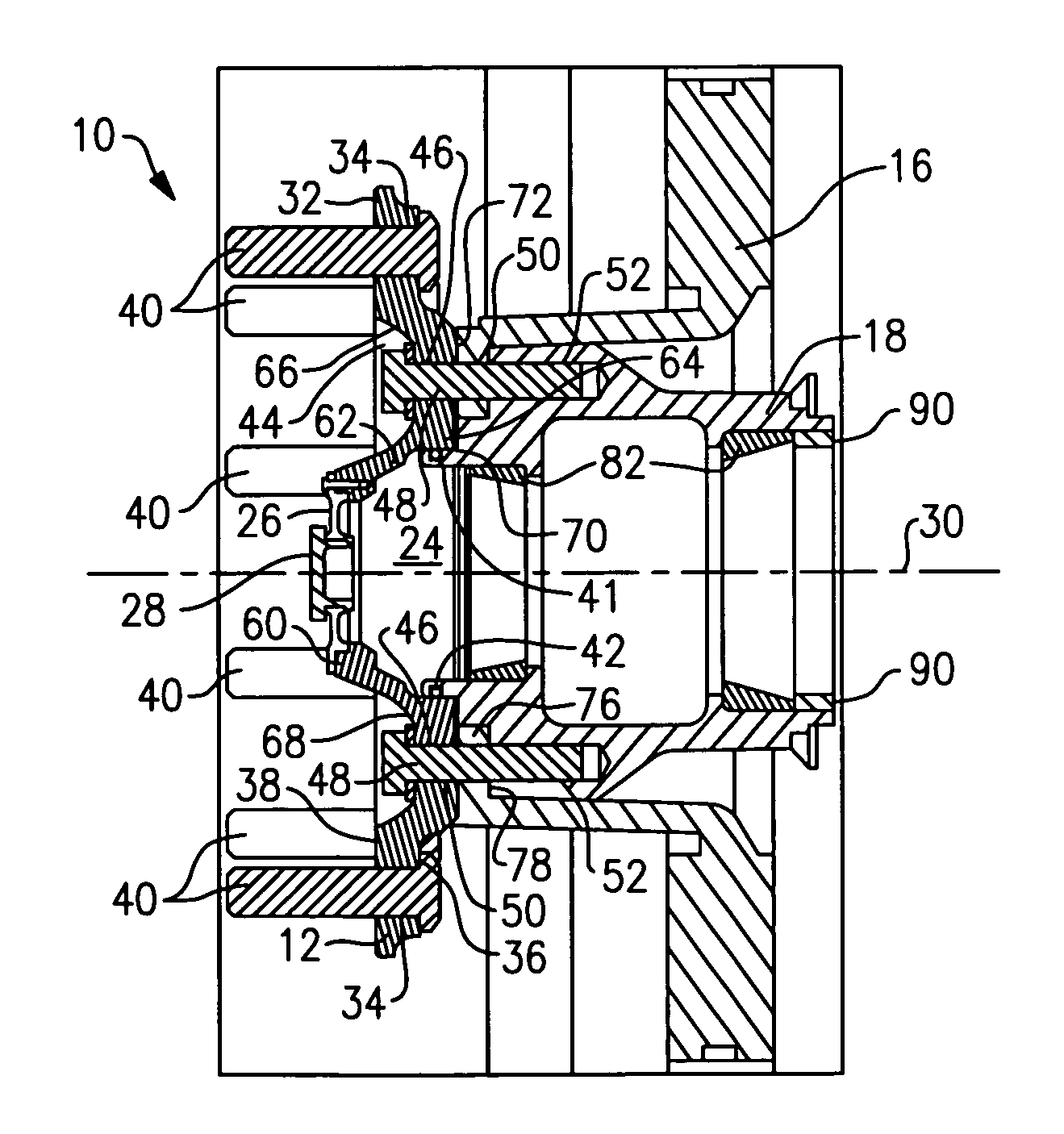

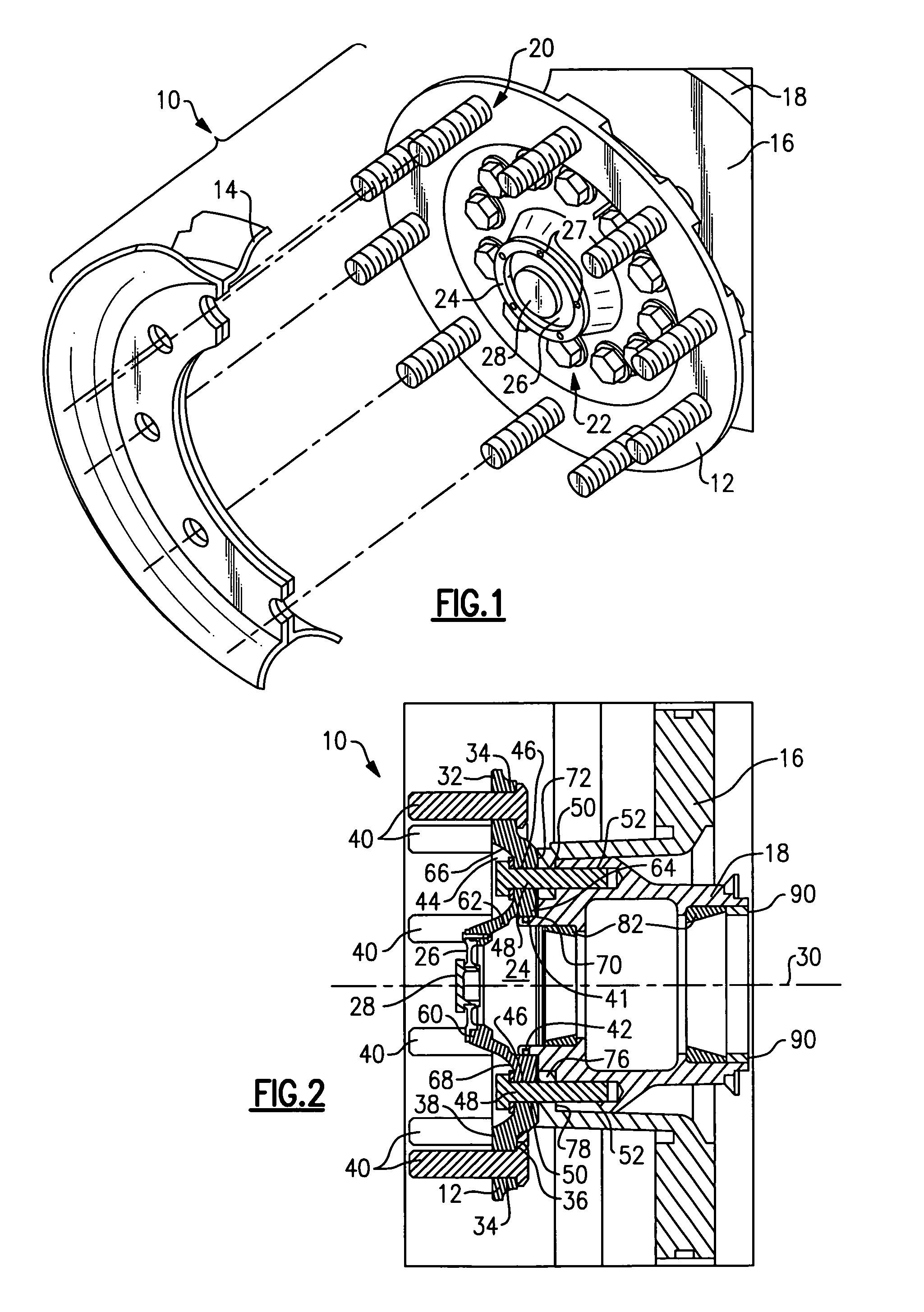

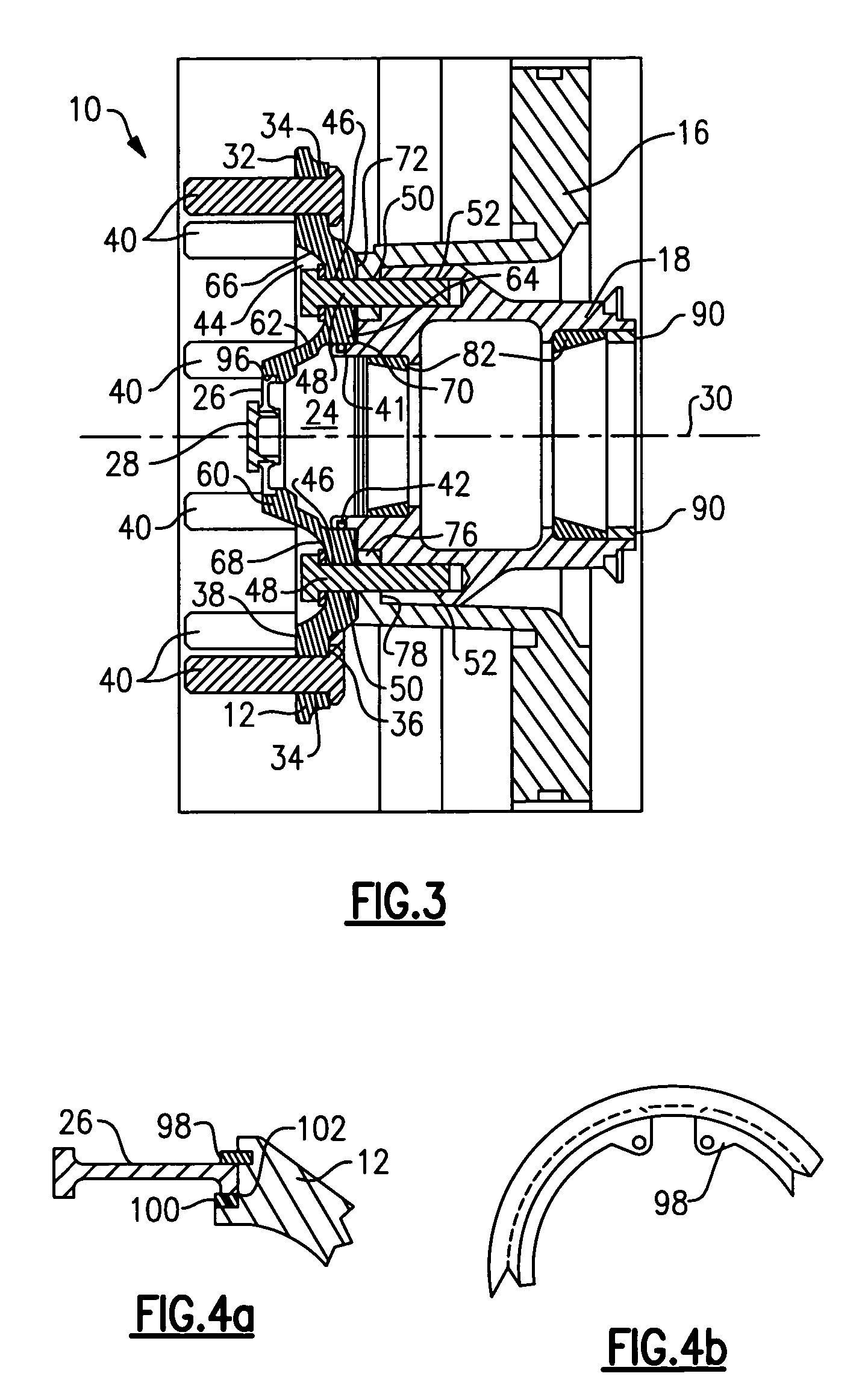

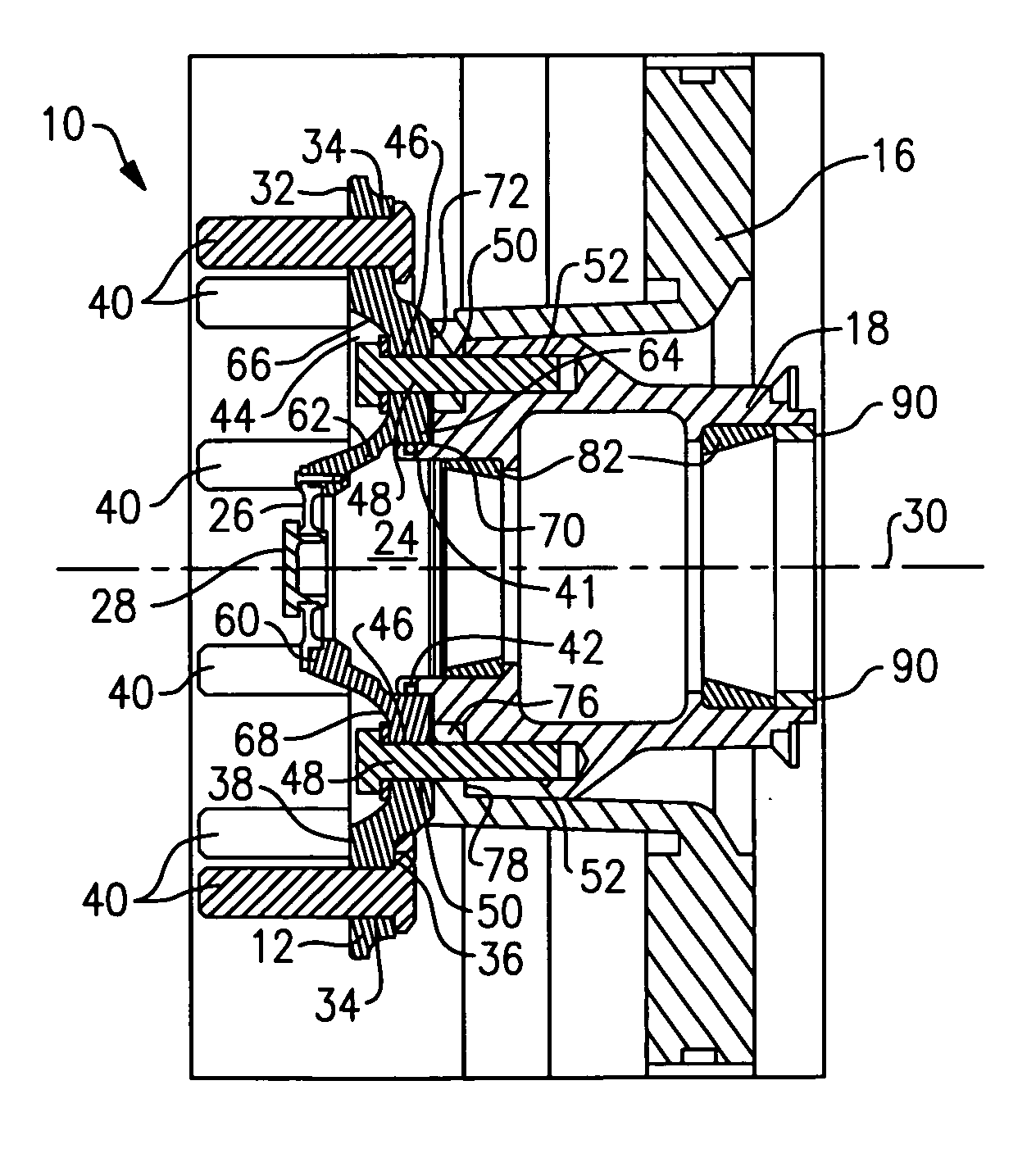

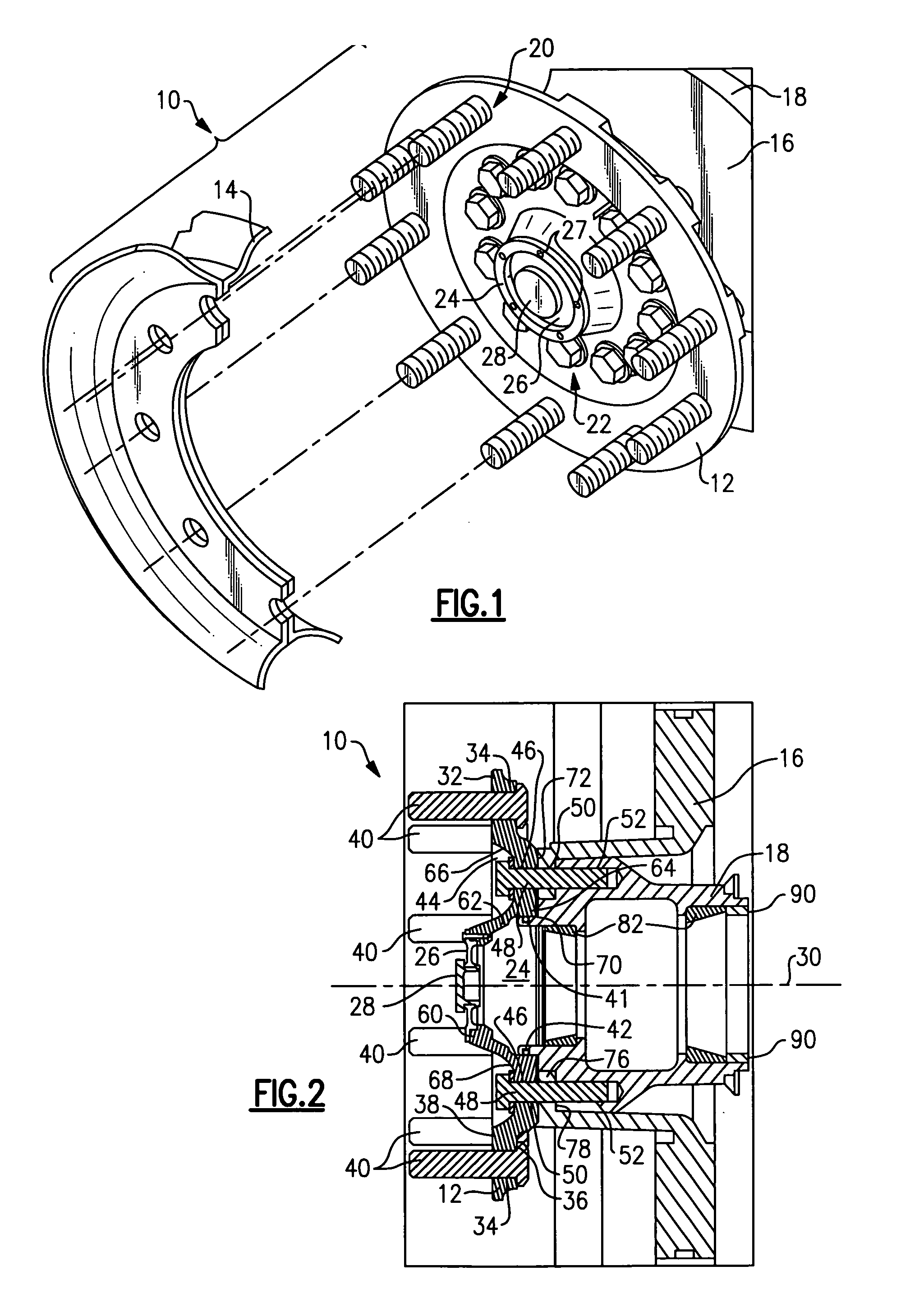

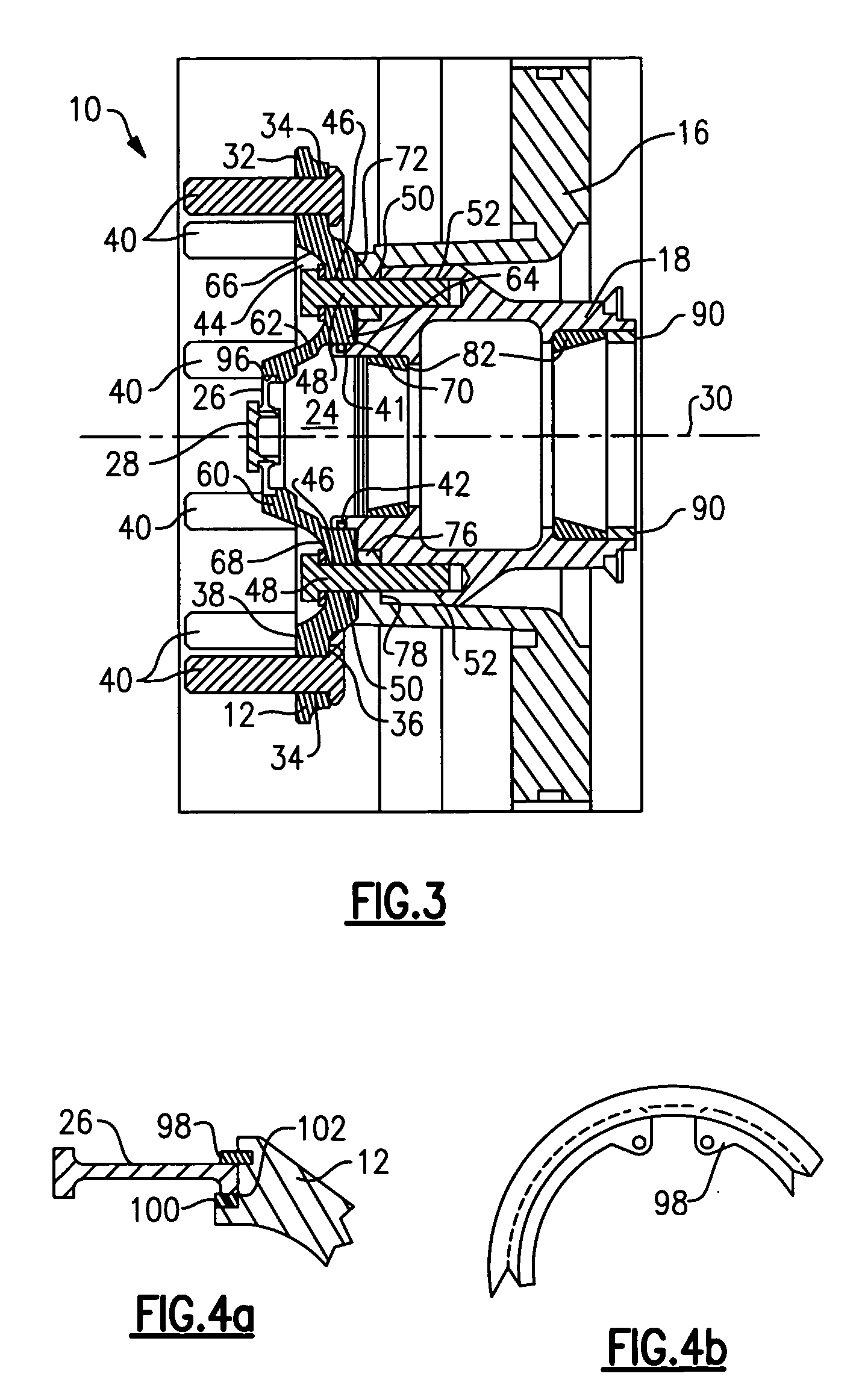

Wheel hub adaptor

A vehicle wheel assembly includes a hub adaptor that eliminates the need for a separate hub cap and gasket by providing wheel rim, wheel hub, and brake component attachment interfaces, as well as a lubrication chamber that can be visually inspected to monitor lubrication levels. The hub adaptor comprises a single piece body having an outwardly extending mounting flange with a first plurality of apertures that define a wheel rim attachment interface. The hub adaptor also includes an inner recessed area with a second plurality of apertures that define both the wheel hub and brake component attachment interfaces. The hub adaptor also includes an inner circumferential surface that provides a piloting and sealing interface between the hub adaptor and the wheel hub.

Owner:ARVINMERITOR TECH

Cover deploying system utilizing active material actuation

InactiveUS20090277595A1Extend battery lifeLow costWindowsAntiglare equipmentMarine engineeringActuator

A system for deploying and stowing a cover, including a mechanical assembly coupled to the cover, preferably comprising a plurality of deploy arms and synchronization means, and reconfigurable between deployed and stowed conditions, and further including an actuator presenting an active material element operable to undergo a change, when activated, and operable to cause the assembly to reconfigure as a result of the change.

Owner:GM GLOBAL TECH OPERATIONS LLC

Wheel hub adaptor

A vehicle wheel assembly includes a hub adaptor that eliminates the need for a separate hub cap and gasket by providing wheel rim, wheel hub, and brake component attachment interfaces, as well as a lubrication chamber that can be visually inspected to monitor lubrication levels. The hub adaptor comprises a single piece body having an outwardly extending mounting flange with a first plurality of apertures that define a wheel rim attachment interface. The hub adaptor also includes an inner recessed area with a second plurality of apertures that define both the wheel hub and brake component attachment interfaces. The hub adaptor also includes an inner circumferential surface that provides a piloting and sealing interface between the hub adaptor and the wheel hub.

Owner:ARVINMERITOR TECH

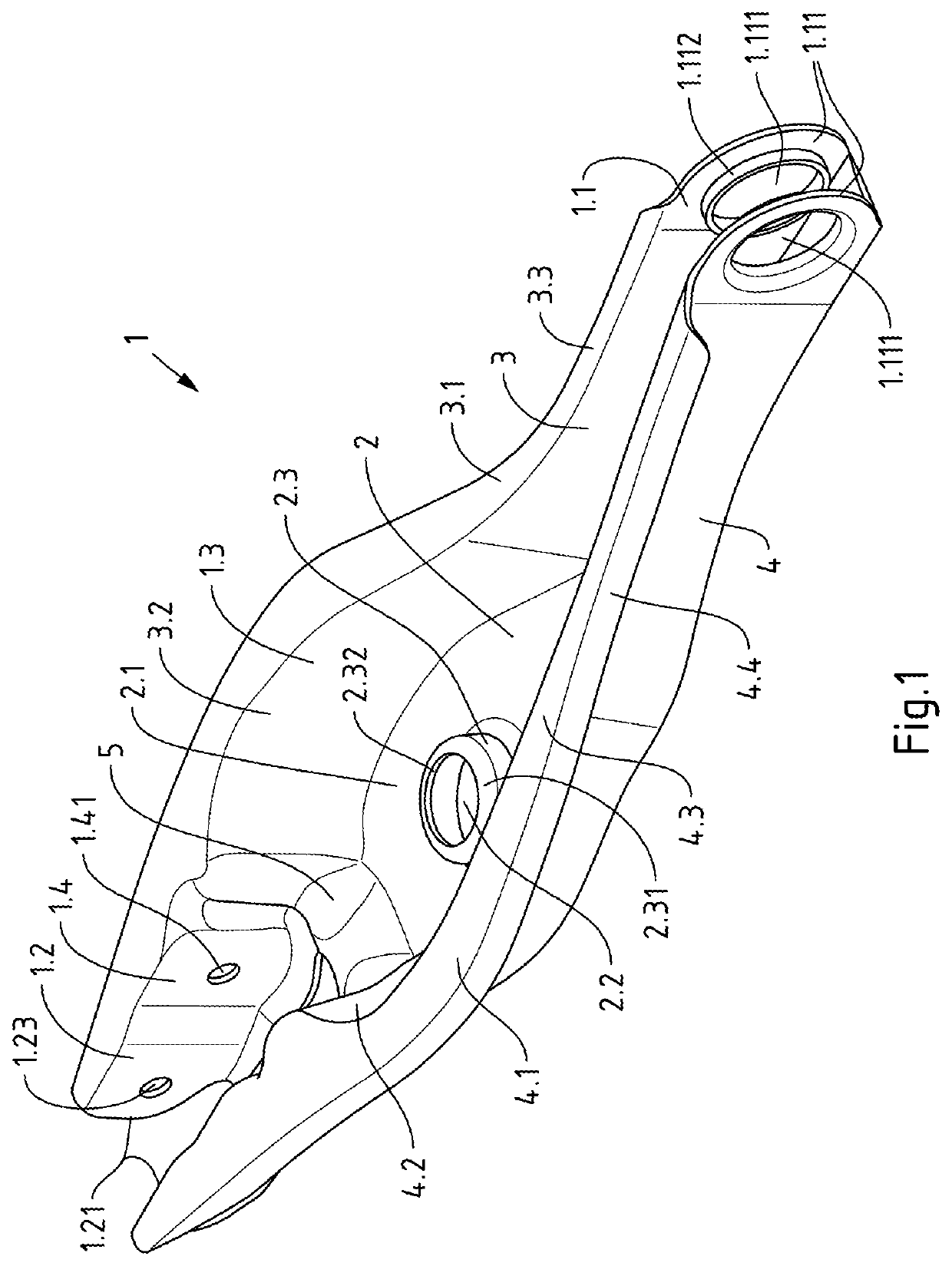

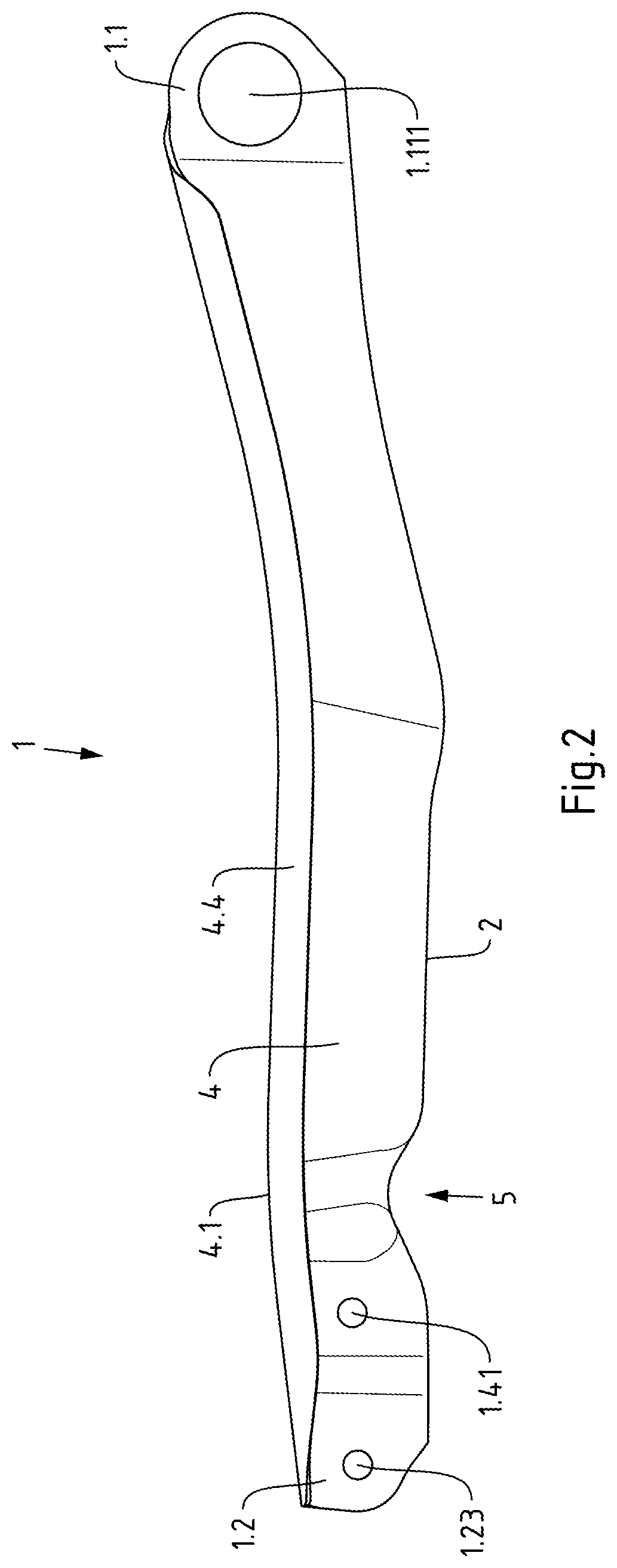

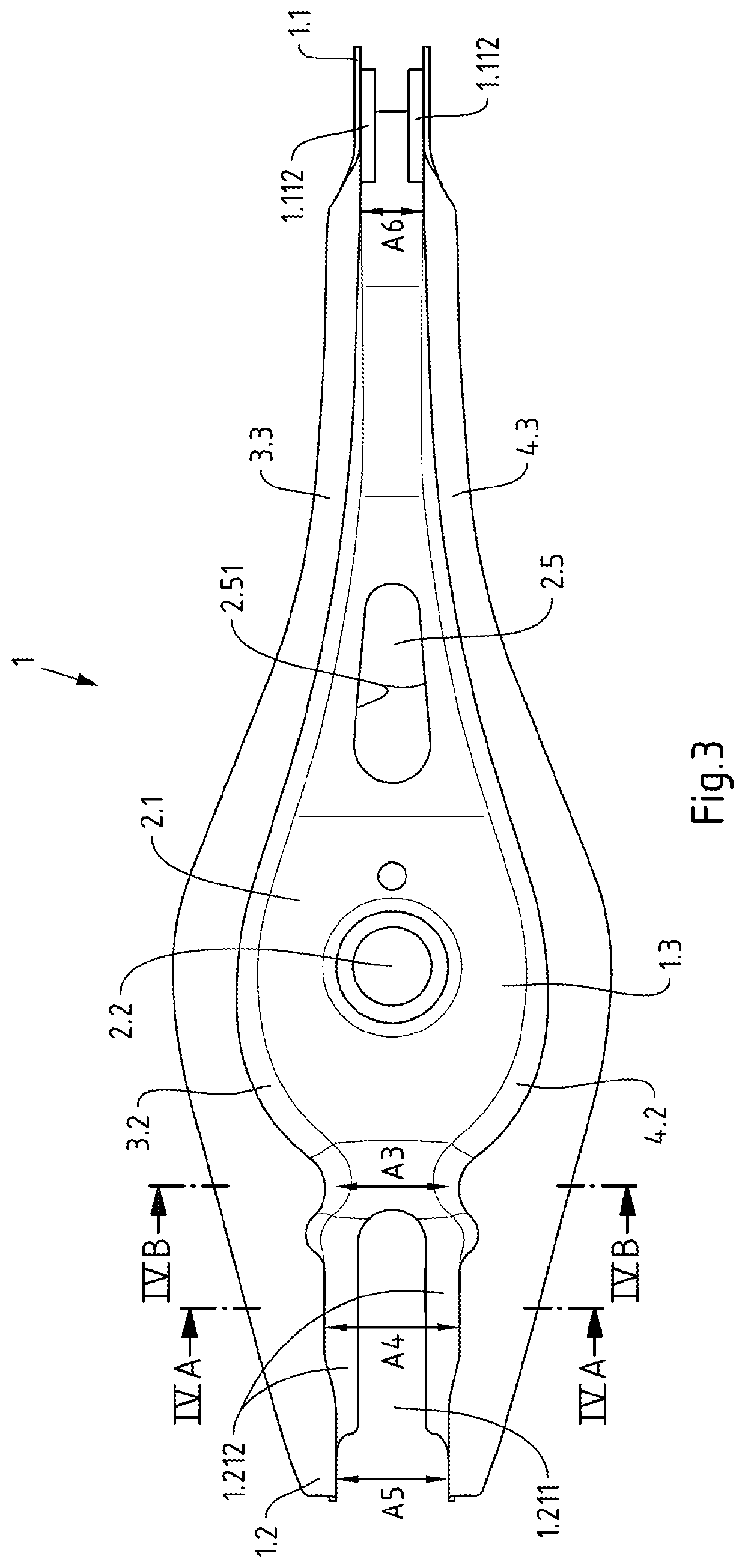

Single-Shell Spring Control Arm

ActiveUS20200324599A1Reduce weightIncrease stiffnessResilient suspensionsPivoted suspension armsClassical mechanicsControl arm

The invention relates to a single-shell spring control arm formed of sheet metal for a wheel suspension of a motor vehicle, with upwardly directed side limbs connected to one another by a base, with a first end section for connection to a chassis girder, with a second end section for wheel-side connection, with a spring receiving section, which is located between the two end sections and has a spring support surface formed on the base, and with a damper receiving section formed between the spring receiving section and the second end section for connecting a shock absorber. In order to achieve at relatively low component weight and favorable manufacturing costs improved stiffness with respect to high axle loads, the invention provides that a U-shaped constriction is formed between the spring support surface and the damper receiving section, which constriction extends in the base and in the side limbs.

Owner:AUTOTECH ENG DEUT

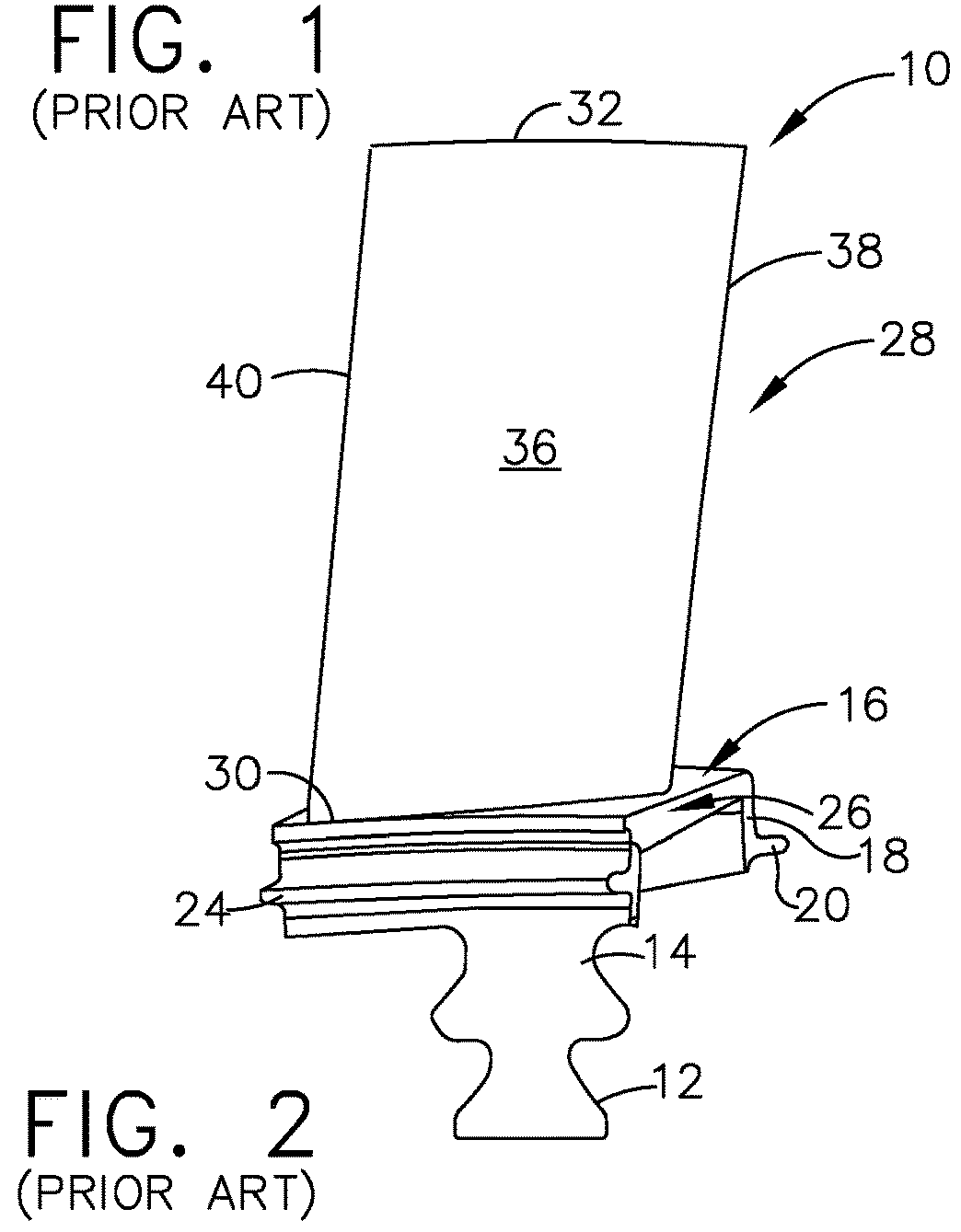

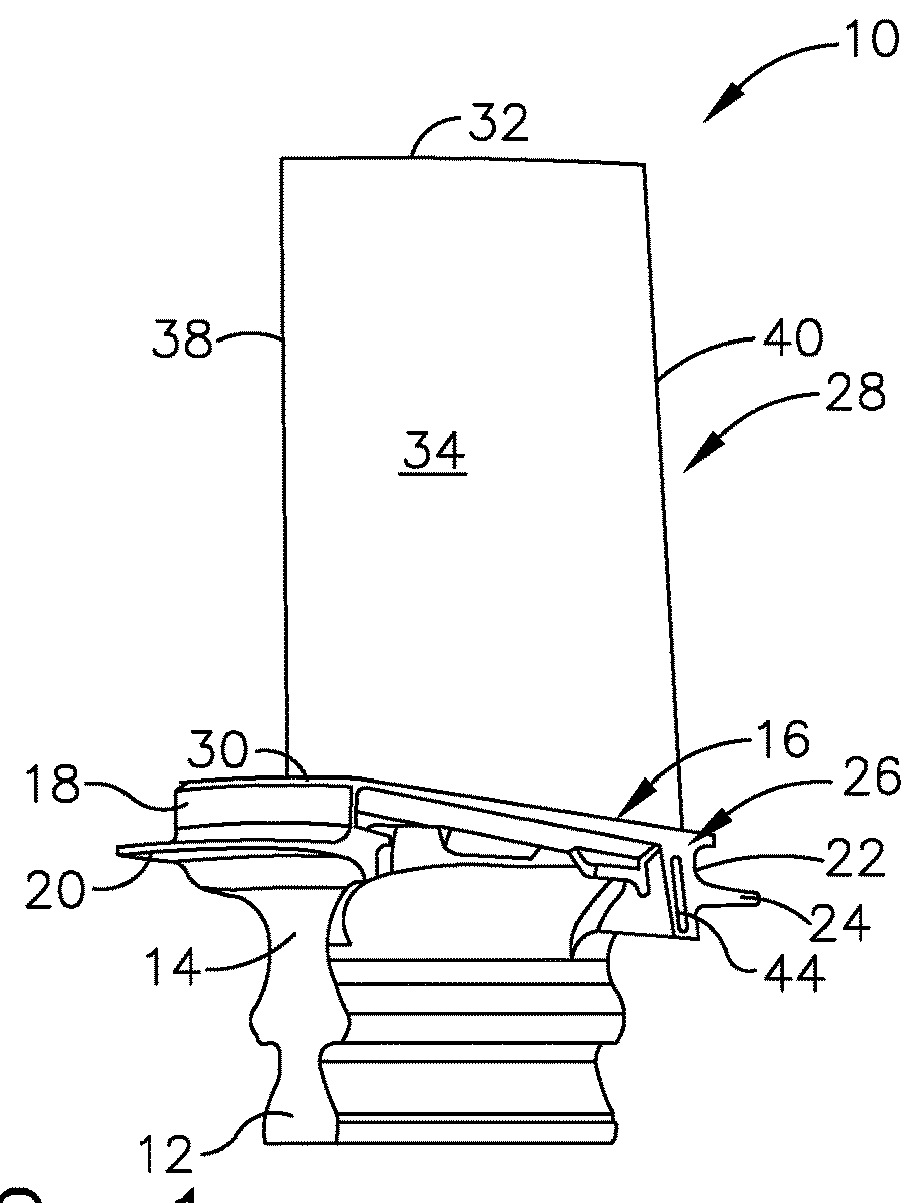

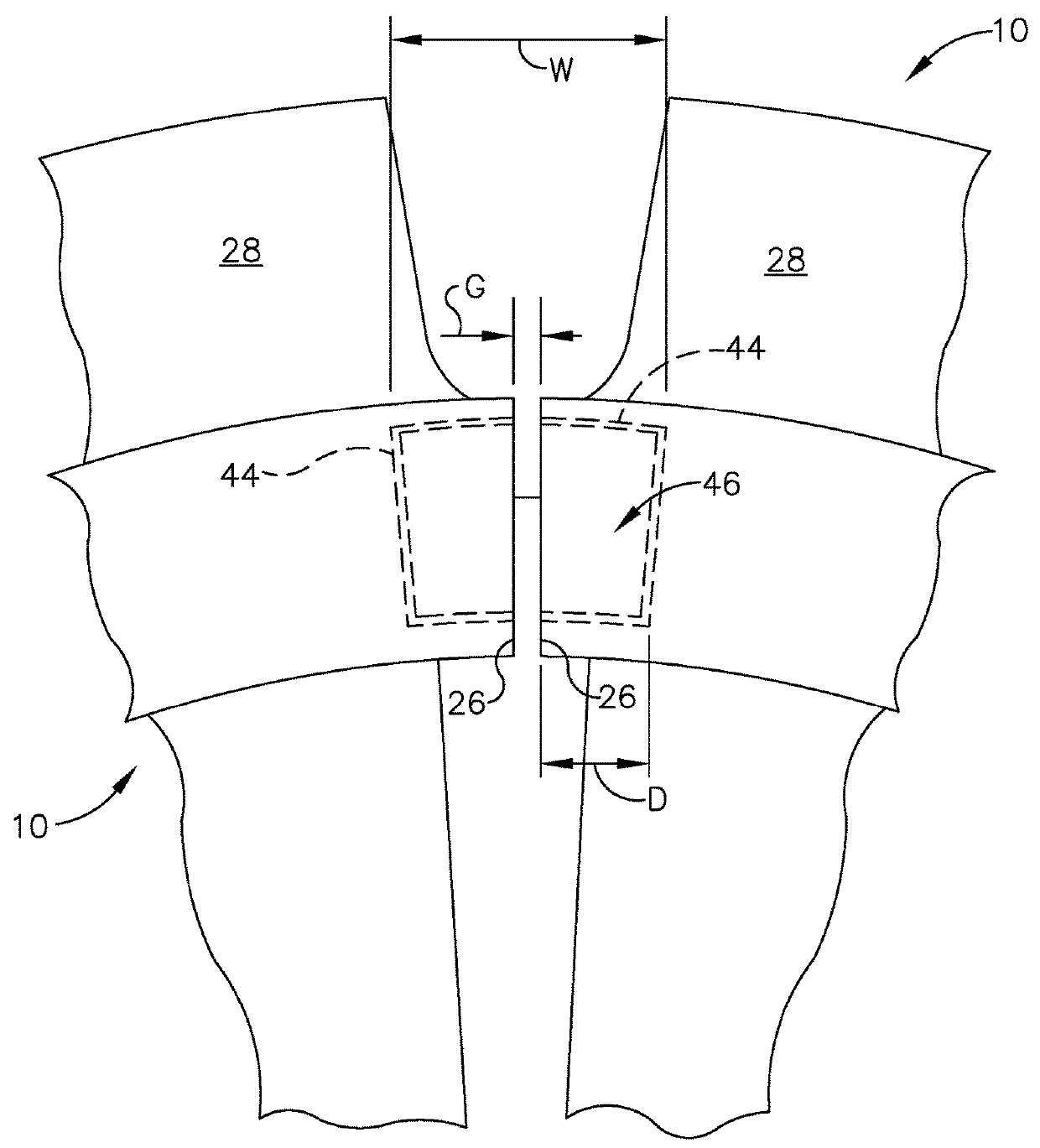

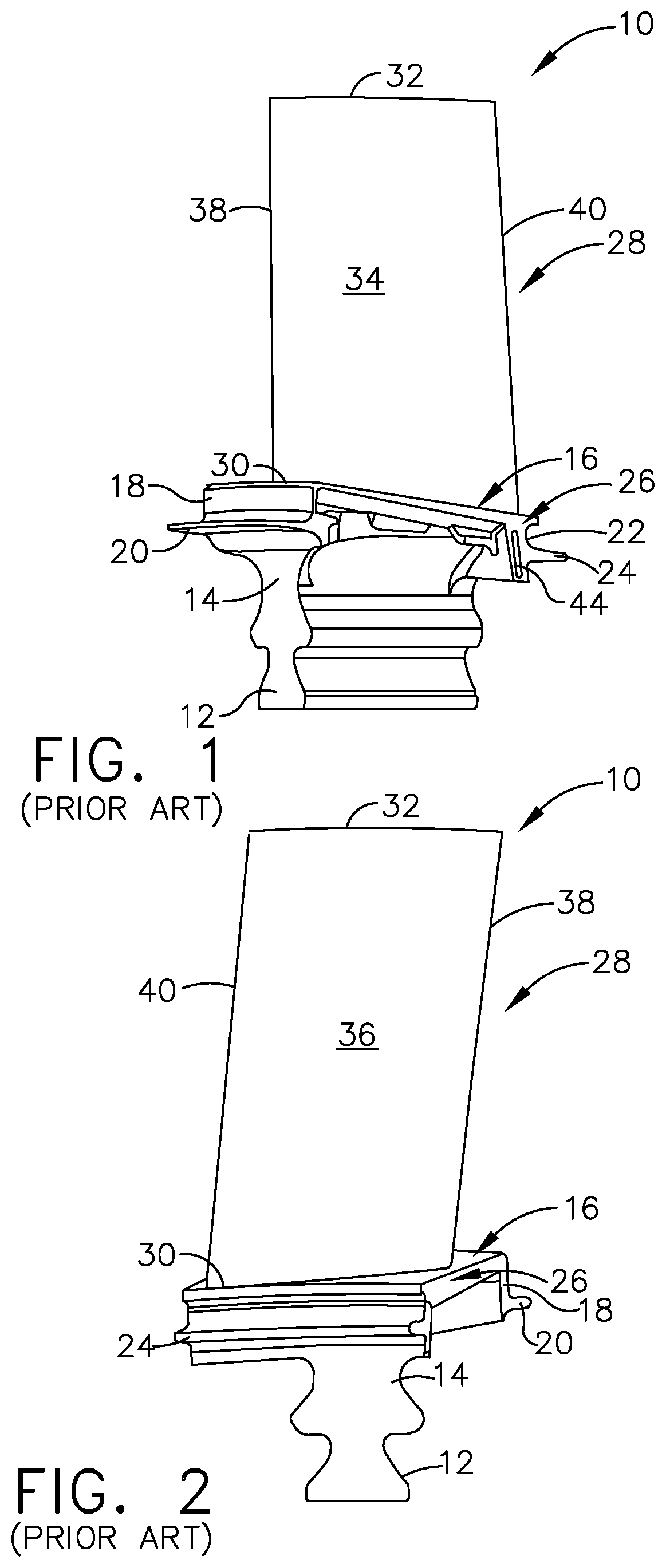

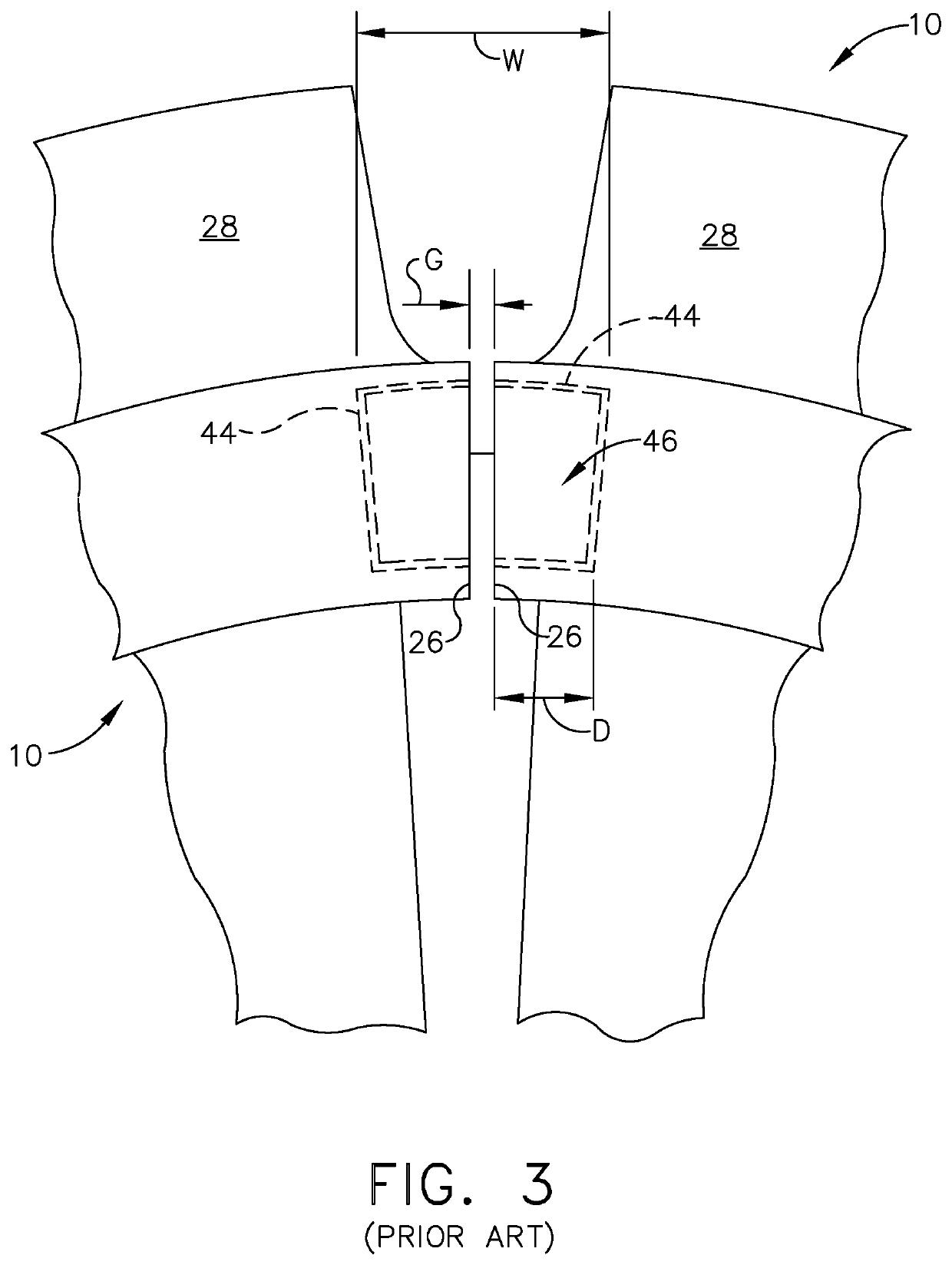

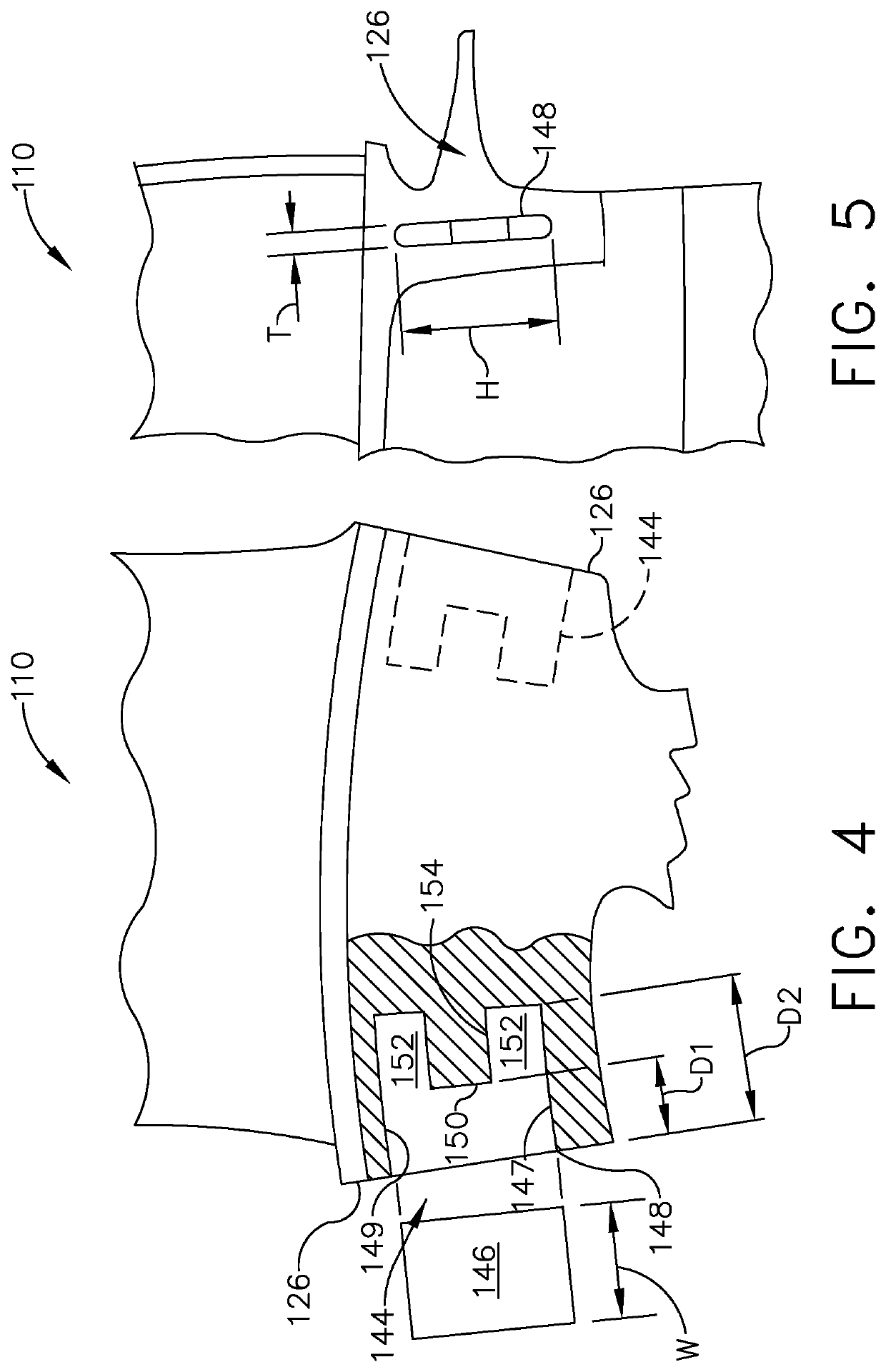

Gas turbine engine component incorporating a seal slot

A turbine engine component includes: a body bounded by an end face; and a seal slot having an opening communicating with the end face, the seal slot including a receptacle defining a boundary configured to receive and position a spline seal, and an open chamber communicating with the seal slot and extending beyond the boundary.

Owner:GENERAL ELECTRIC CO

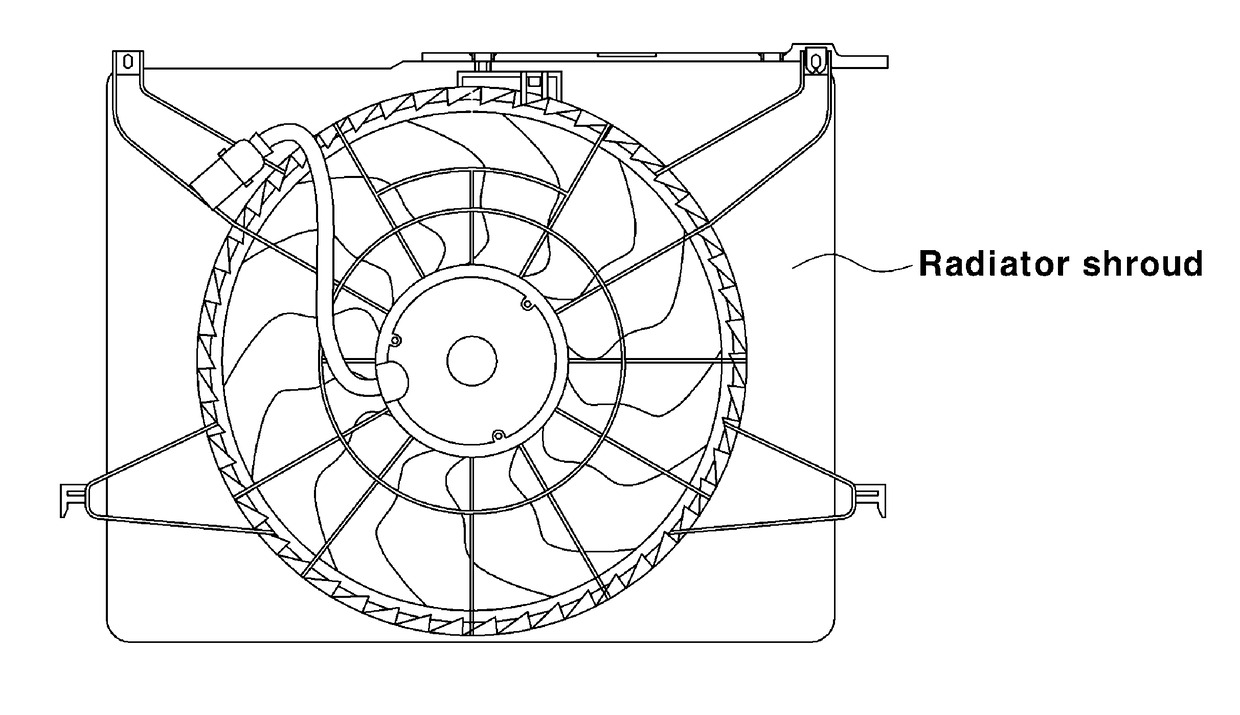

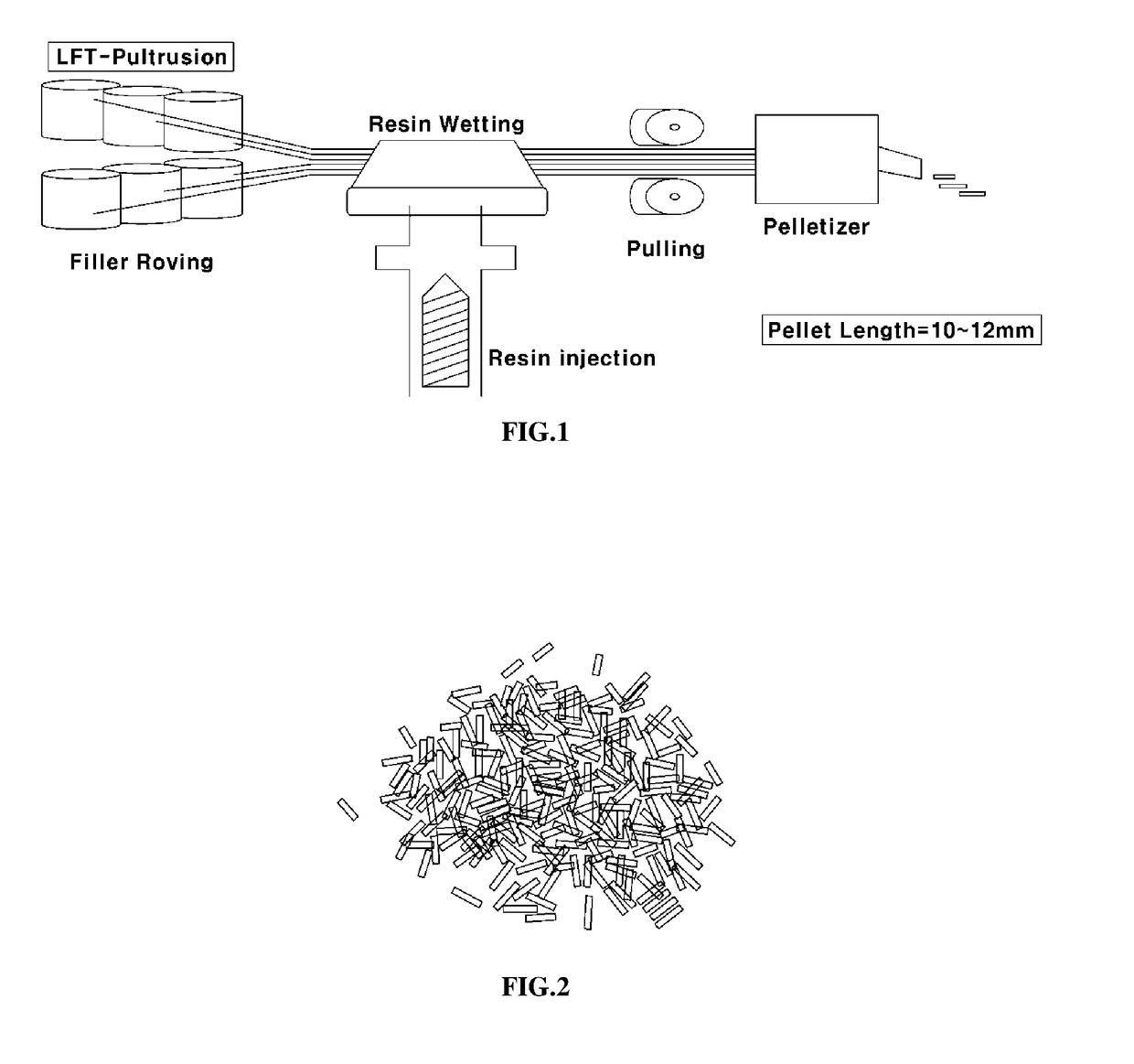

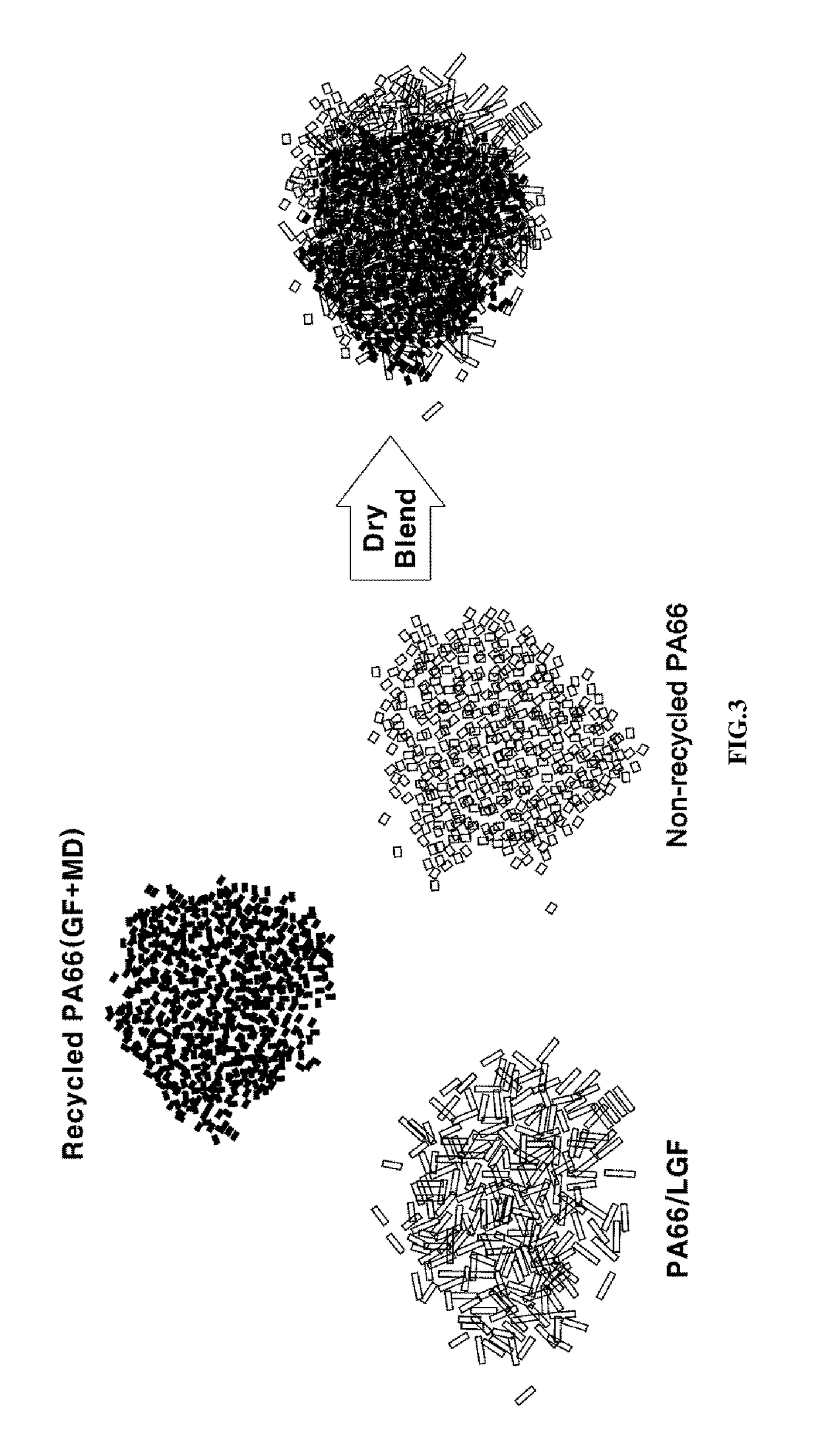

Polyamide resin composition comprising fiber reinforced polyamide pellet and molded article thereof

InactiveUS20170275458A1Reduce component weightSatisfactory mechanical propertyPlastic recyclingMachines/enginesPolymer scienceShell molding

Disclosed are a polyamide resin composition comprising a fiber reinforced polyamide pellet, a molded article comprising the polyamide resin composition and a method of manufacturing the molded article. The polyamide resin composition includes the fiber reinforced polyamide pellet, which can be produced by pultrusion, such that moldability and mechanical properties of molded articles may be sufficient using the recycled polyamide 66 resin. In addition, although the polyamide resin composition contains a less amount of inorganic substance, mechanical properties of the molded article are sufficient, weight of molded articles can be reduced and production costs can be reduced.

Owner:HYUNDAI MOTOR CO LTD +1

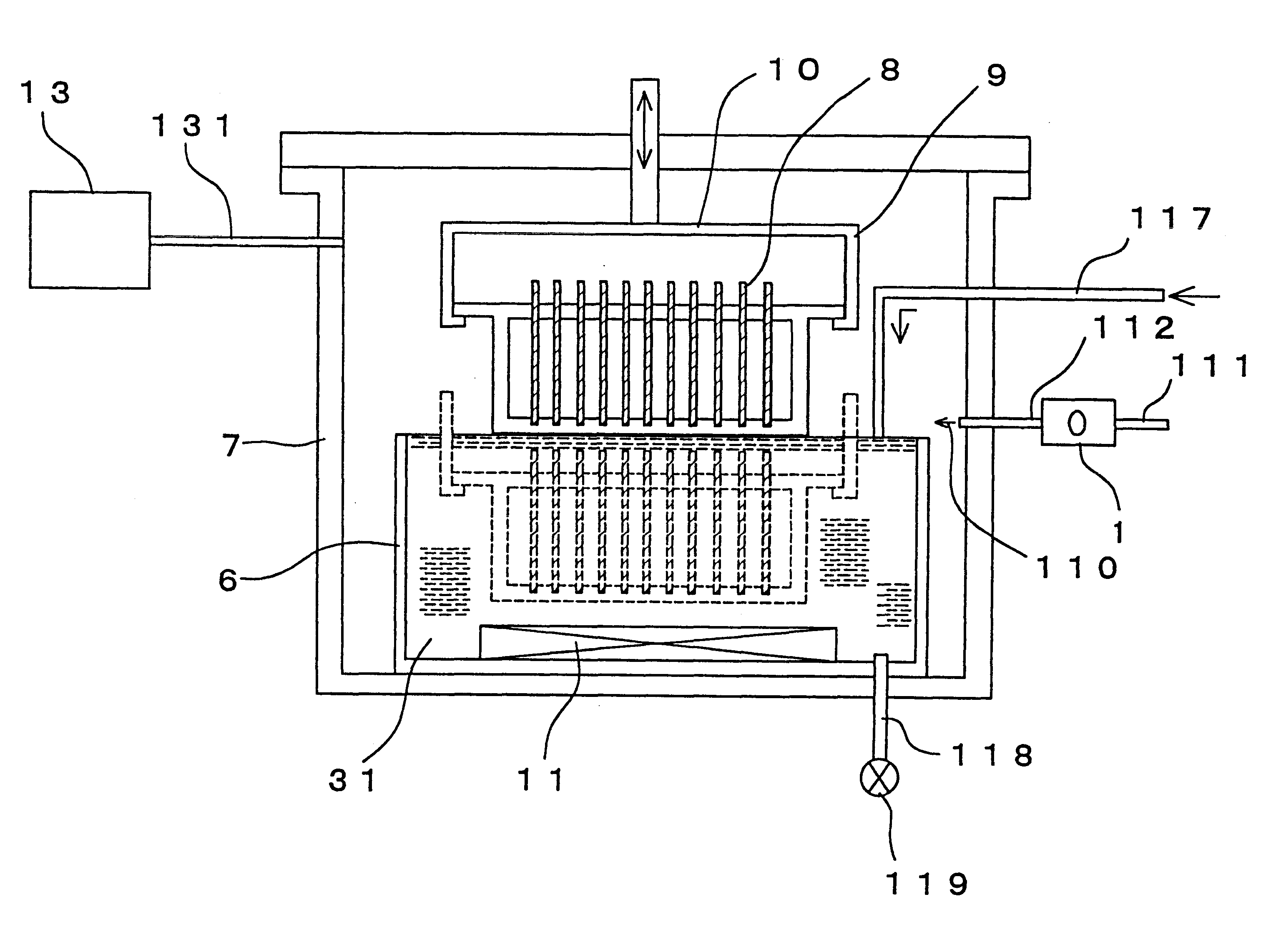

Apparatus for removing photoresist film

InactiveUS6715944B2Increase contact frequencyIncrease ratingsSemiconductor/solid-state device manufacturingElectrostatic cleaningResistLiquid state

An apparatus for removing a photoresist film includes a substrate cassette for fixing a substrate having a surface covered with a photoresist film, an ozone feed tube for supplying ozone, a liquid feed tube for supplying a liquid photoresist film removing solution, and a processing tank for recovering and processing at least one of ozone and the liquid photoresist film removing solution, wherein the liquid photoresist film removing solution is supplied through the liquid feed tube as a liquid or mist, at least one of ozone and the photoresist film removing solution being continuously supplied.

Owner:AGILENT TECH INC

Apparatus for removing photoresist film

InactiveUS20020115024A1Increase contact frequencyIncrease ratingsSemiconductor/solid-state device manufacturingElectrostatic cleaningResistGas phase

A method of removing photoresist film with high efficiency of removal and friendliness with the environment while reducing the material consumption and the cost for the ventilation facility, and an apparatus used for the method are provided. Particularly the present invention provides a method of removing a photoresist film provided on a surface of a substrate, comprising steps of in a sealed system, disposing the substrate surface having the photoresist film to contact with a photoresist film removing solution, making ozone exist in gas phase and / or solution phase in the vicinity of the liquid surface of the photoresist film removing solution, and changing a relative position between the surface of the substrate and the liquid surface of the solution to decompose or remove the photoresist film from the substarate, characterized in that the relative position is changed continuously or intermittently within a range between a position where a bottom edge of the substrate is present above the liquid surface of the solution, and another position where a top edge of the substrate is present below the liquid surface of the solution. The present invention also provides an apparatus used for the method.

Owner:AGILENT TECH INC

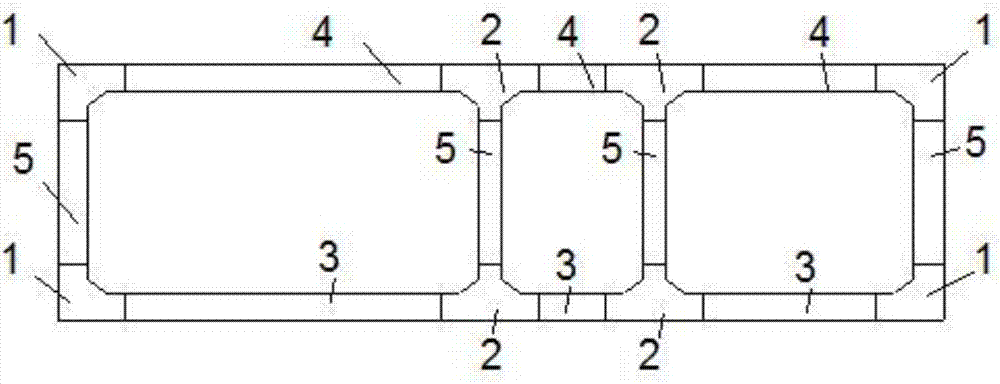

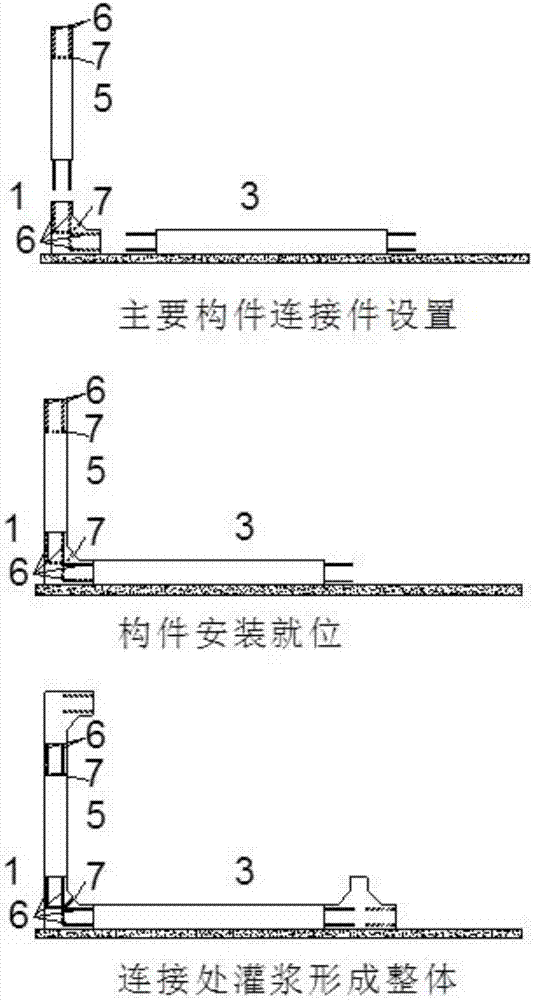

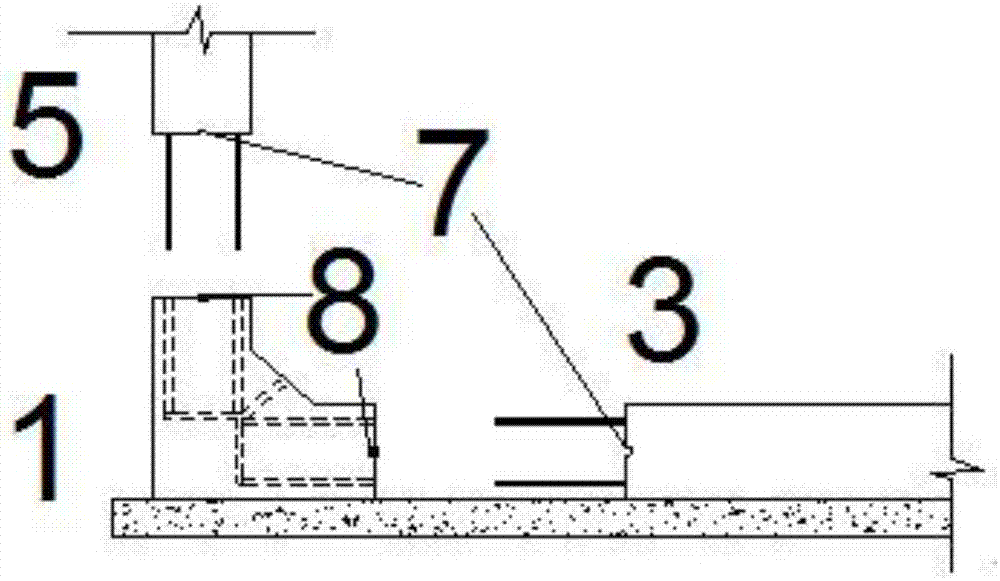

Pipe rack prefabrication and assembly construction method

InactiveCN106930322ALess number of deformation seamsReduce component weightArtificial islandsUnderwater structuresSupporting systemPre stress

The invention discloses a pipe rack prefabrication and assembly construction method. The construction method comprises the following steps: a pipe rack is decomposed to different components; the components are manufactured and cured in a prefabrication factory; after a foundation pit in a construction site is excavated, a groove is inspected, and a cushion layer is arranged; a slide layer is arranged on the top surface of the cushion layer; beam plate components on a baseplate are lifted, and are placed in place from the middle to two sides of the baseplate; a prestressed steel strand is inserted through the baseplate for primary tightening; wallboard components are mounted to build a top plate support system; beam plate components on a top plate are mounted; a prestressed steel strand is inserted through the top plate for primary tightening; prestressed reinforcements of the baseplate and the top plate are tensioned to adjust the overall size of the pipe rack; and component connecting places and prestress reserved holes are closed through pressure grouting to finish assembly and construction of the section of pipe rack. A new large-section pipe rack construction scheme can provide a preassembly scheme to an ultralarge-section multi-cabin pipe rack. Compared with a traditional assembly scheme, the component weight is reduced, and the requirements on large machinery by the assembly construction are reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

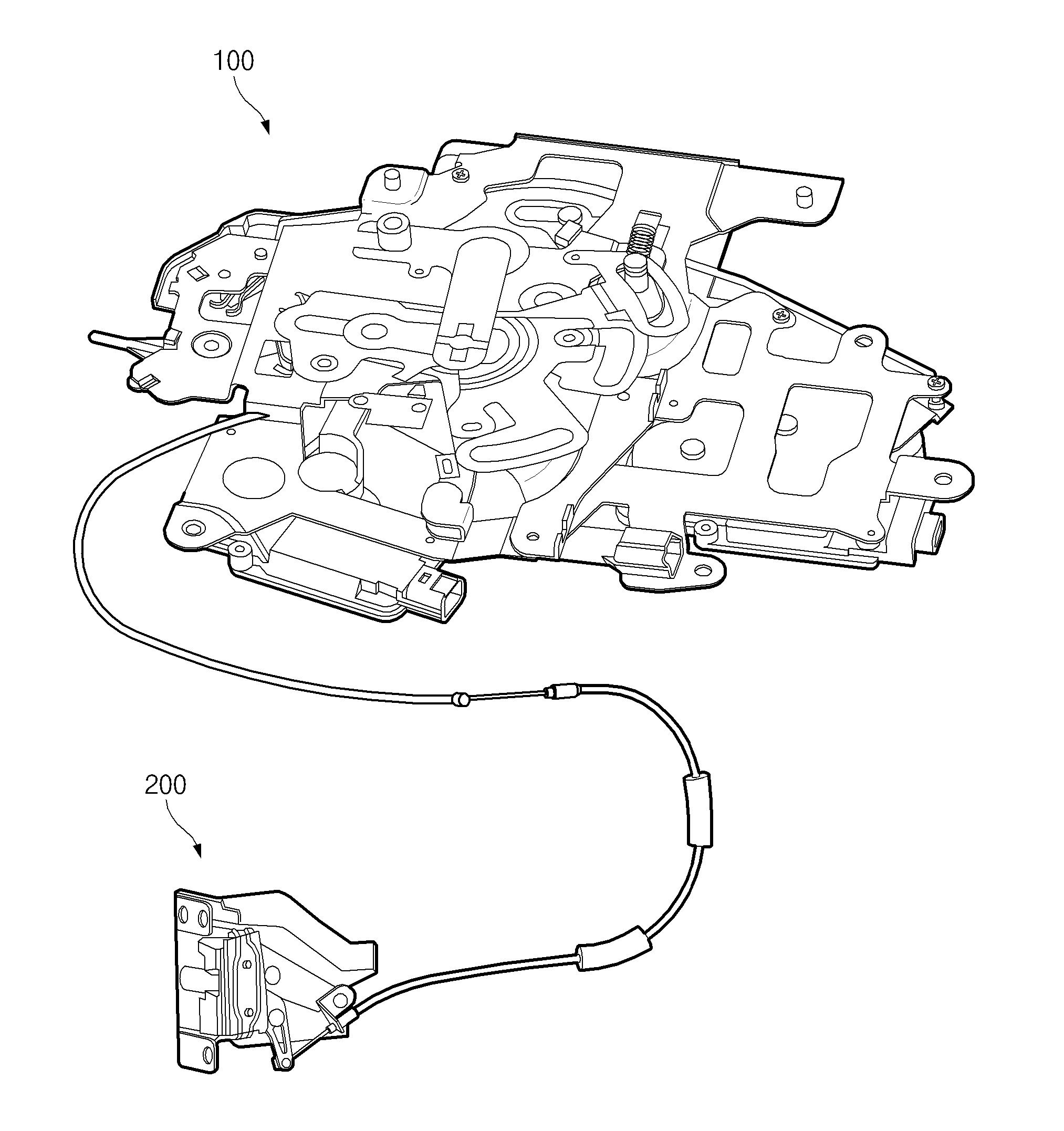

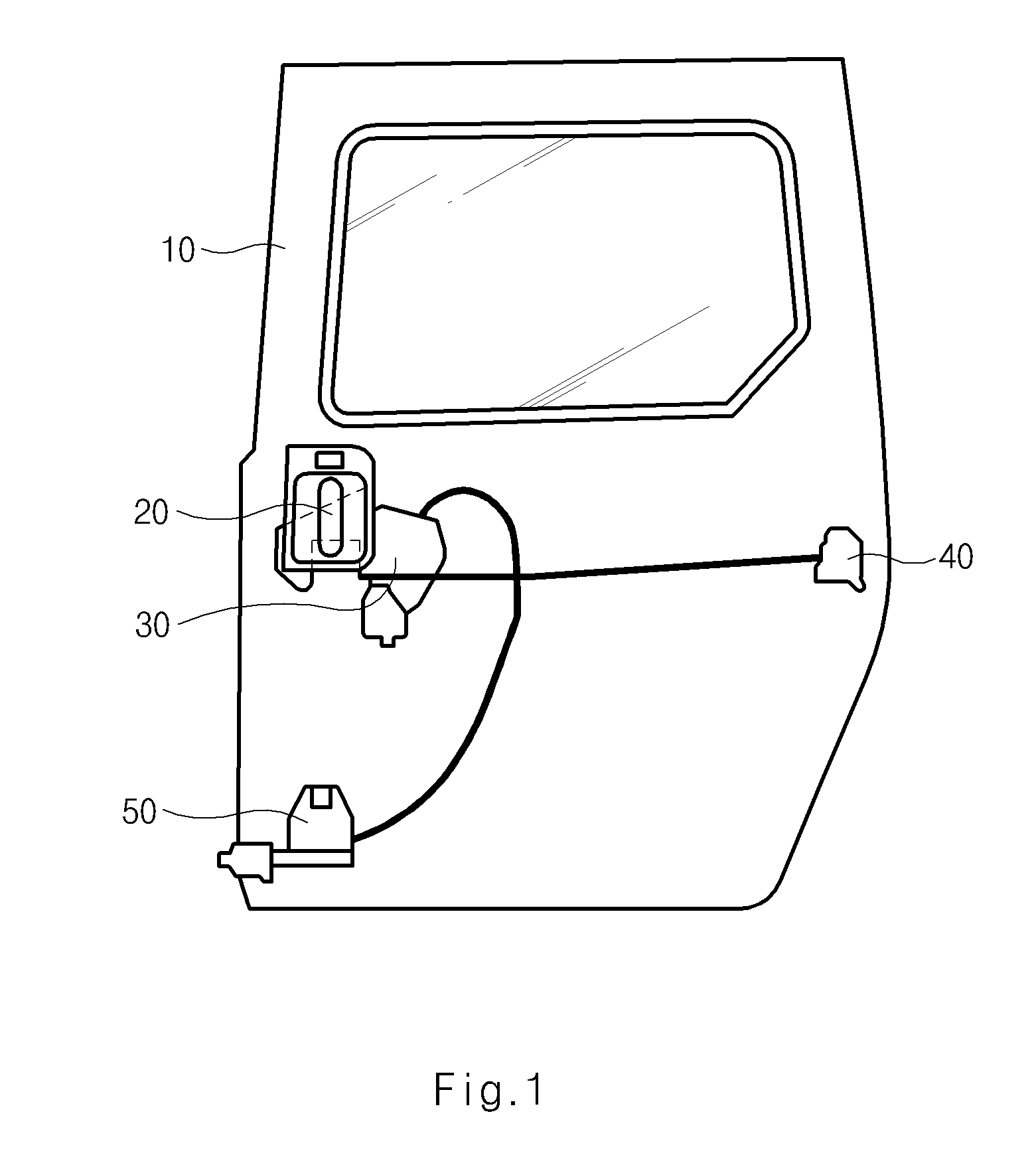

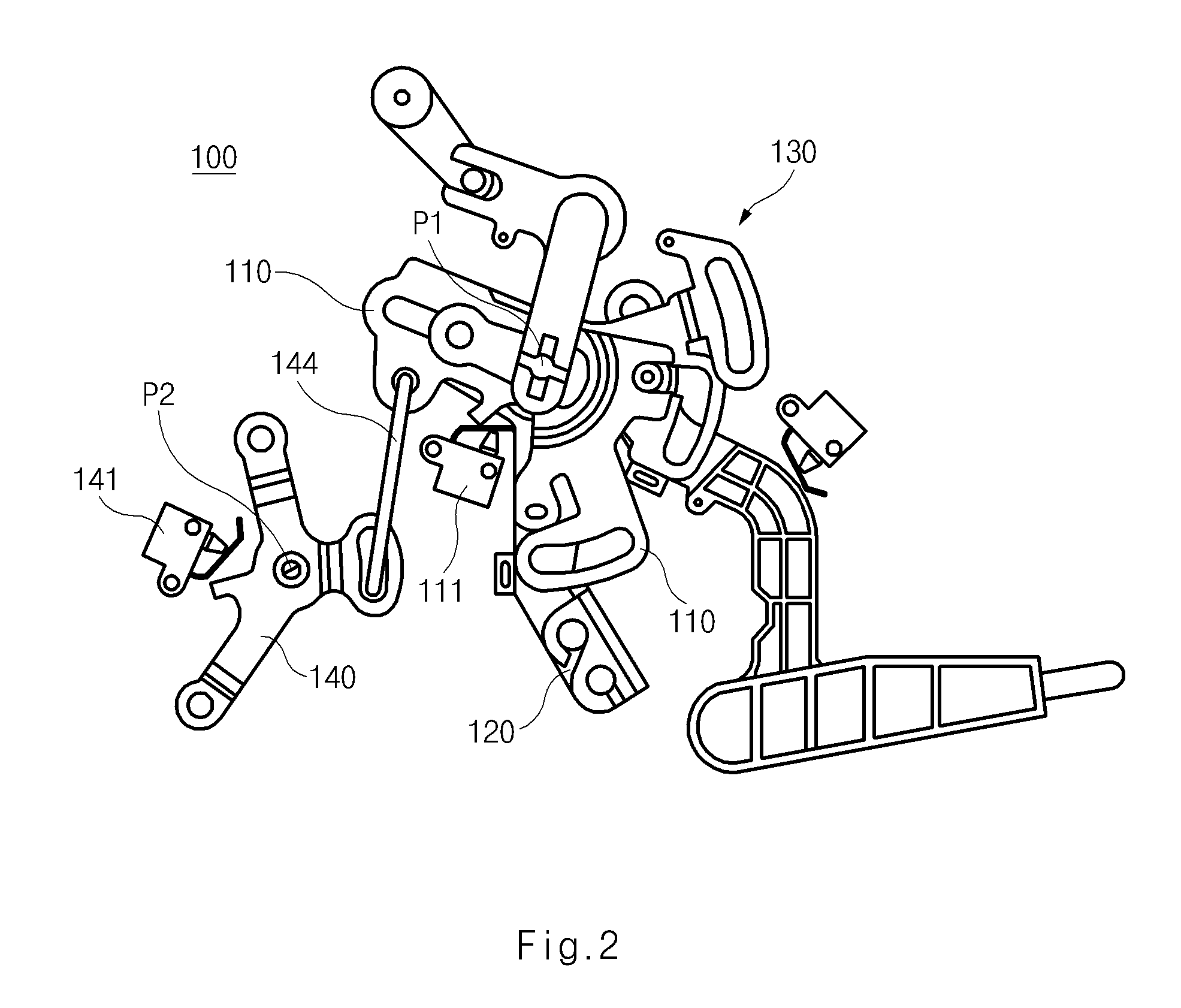

Locking controller structure of sliding door

InactiveUS20110314744A1Lower component costsReduce manufacturing costMan-operated mechanismPower-operated mechanismElectrical controlClosure operation

A locking controller mechanism that is capable of opening or closing a sliding door mounted on a vehicle and controlling opening or closing operation of the sliding door through an electrical control unit (ECU), may include an outside lever rotatably mounted about a first pivot shaft and connected to an outside handle that enables the door to be opened or closed on the outside of a vehicle body, a latch release lever rotatably mounted to the first pivot shaft and connected to the outside lever to control latch cables, an inside lever rotatably mounted to the first pivot shaft and connected to the outside lever and an inside handle that enables the door to be opened or closed on the inside of the vehicle body, and a hold open lever rotatably mounted to a second pivot shaft and pivotally connected to the outside lever to be rotatable when the door is closed.

Owner:HYUNDAI MOTOR CO LTD

Heat treatable steel, product formed thereof having ultra high strength and excellent durability, and method for manufacturing same

ActiveUS20180002775A1High strengthIncreased durabilityFurnace typesHeat treatment furnacesIn vehicleUltimate tensile strength

The present invention relates to a formed product used in vehicle components and the like, and to a method for manufacturing the same. The present invention provides heat treatable steel, a formed product using the same having ultra-high strength and excellent durability, and a method for manufacturing the same, wherein the heat treatable steel contains, in wt %, C (0.22-0.42%), Si (0.05-0.3%), Mn (1.0-1.5%), Al (0.01-0.1%), P (0.01% or less (including 0), S (0.005% or less), Mo (0.05-0.3%), Ti (0.01-0.1%), Cr (0.05-0.5%), B (0.0005-0.005%), N (0.01% or less), the balance Fe, and other inevitable impurities, Mn and Si satisfying Relationship formula (1), below, Mo / p satisfying Relationship formula (2), below: [Relationship formula 1] Mn / Si≧5 [Relationship formula 2] Mo / P≧15.

Owner:POHANG IRON & STEEL CO LTD

Heat exchanger system having manifolds structurally integrated with a duct

ActiveUS20080156473A1Reduce component weightReduce complexityRecuperative heat exchangersHeat exchanger casingsEngineeringInlet manifold

A heat exchanger system includes a duct having a duct wall with a duct wall outer surface and a duct wall inner surface; and a heat exchanger partial shell hermetically joined to the duct wall inner surface. The heat exchanger partial shell and a shell portion of the duct wall inner surface constitute a heat exchanger. A heat exchanger inlet manifold is defined by a nonplanar inlet sheet of material hermetically joined to the duct wall outer surface. A heat exchanger outlet manifold is defined by a nonplanar outlet sheet of material hermetically joined to the duct wall outer surface. A heat exchanger inlet opening extends through the duct wall between the inlet manifold and the heat exchanger, and a heat exchanger outlet opening extends through the duct wall between the outlet manifold and the heat exchanger.

Owner:GENERAL ELECTRIC CO

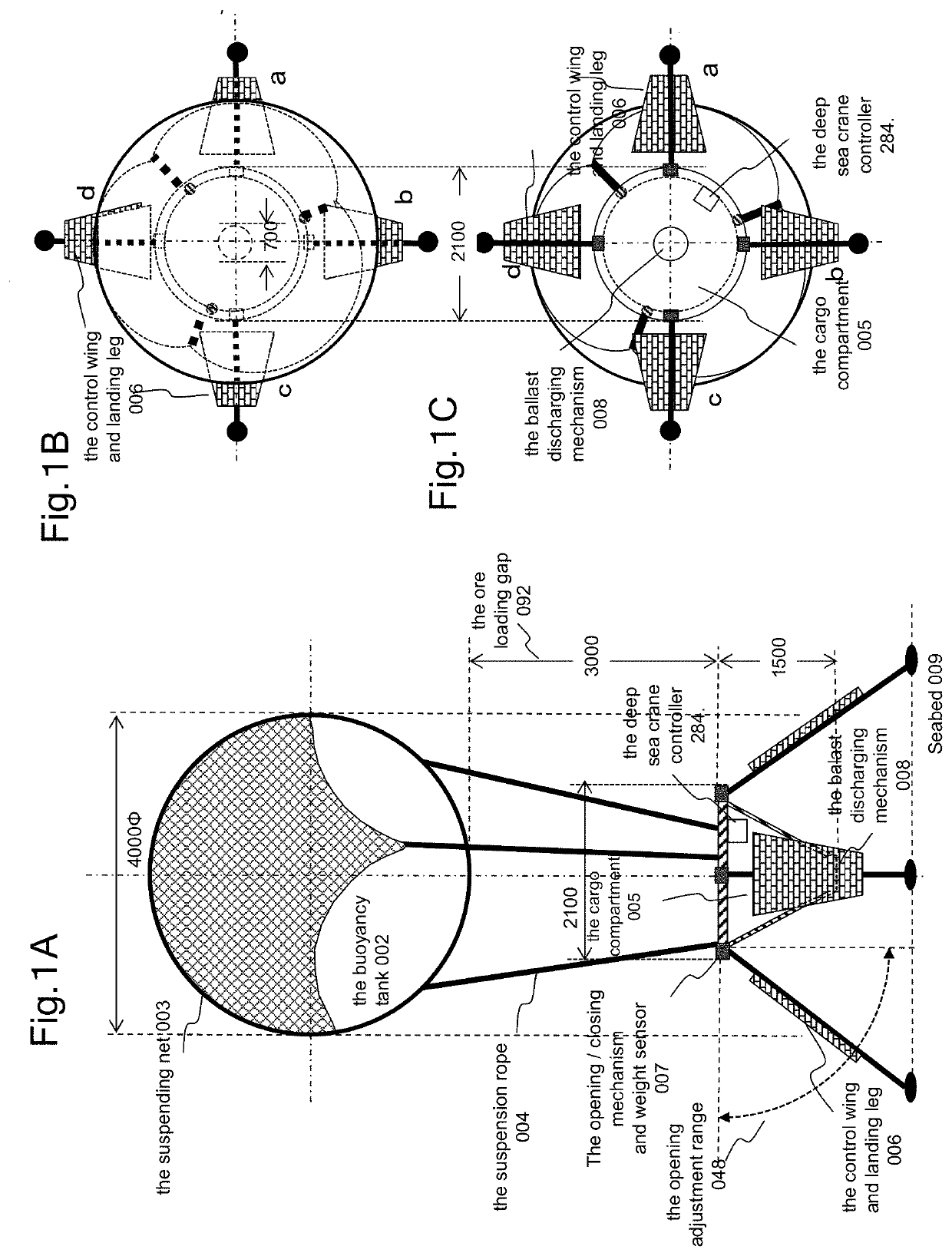

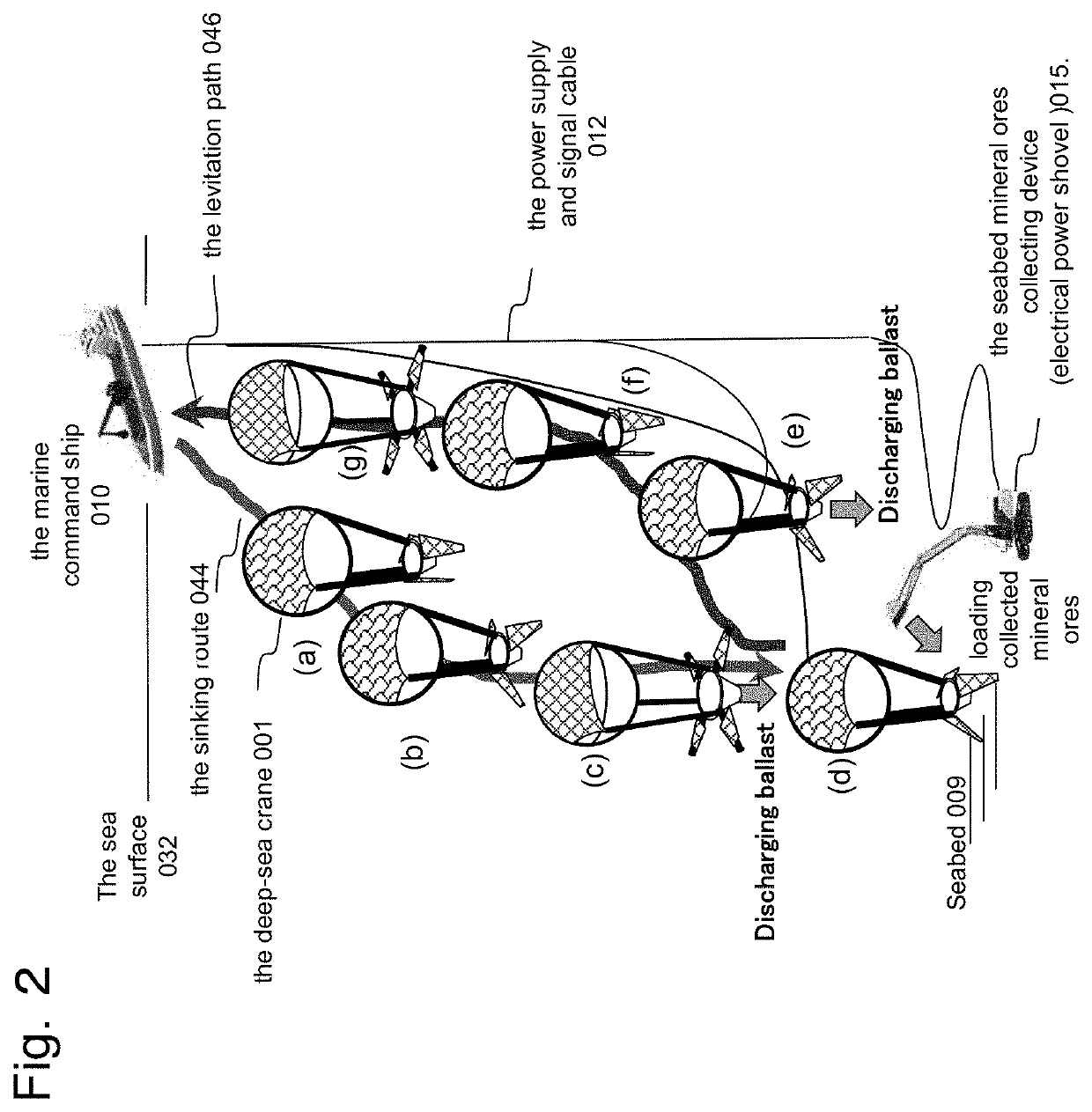

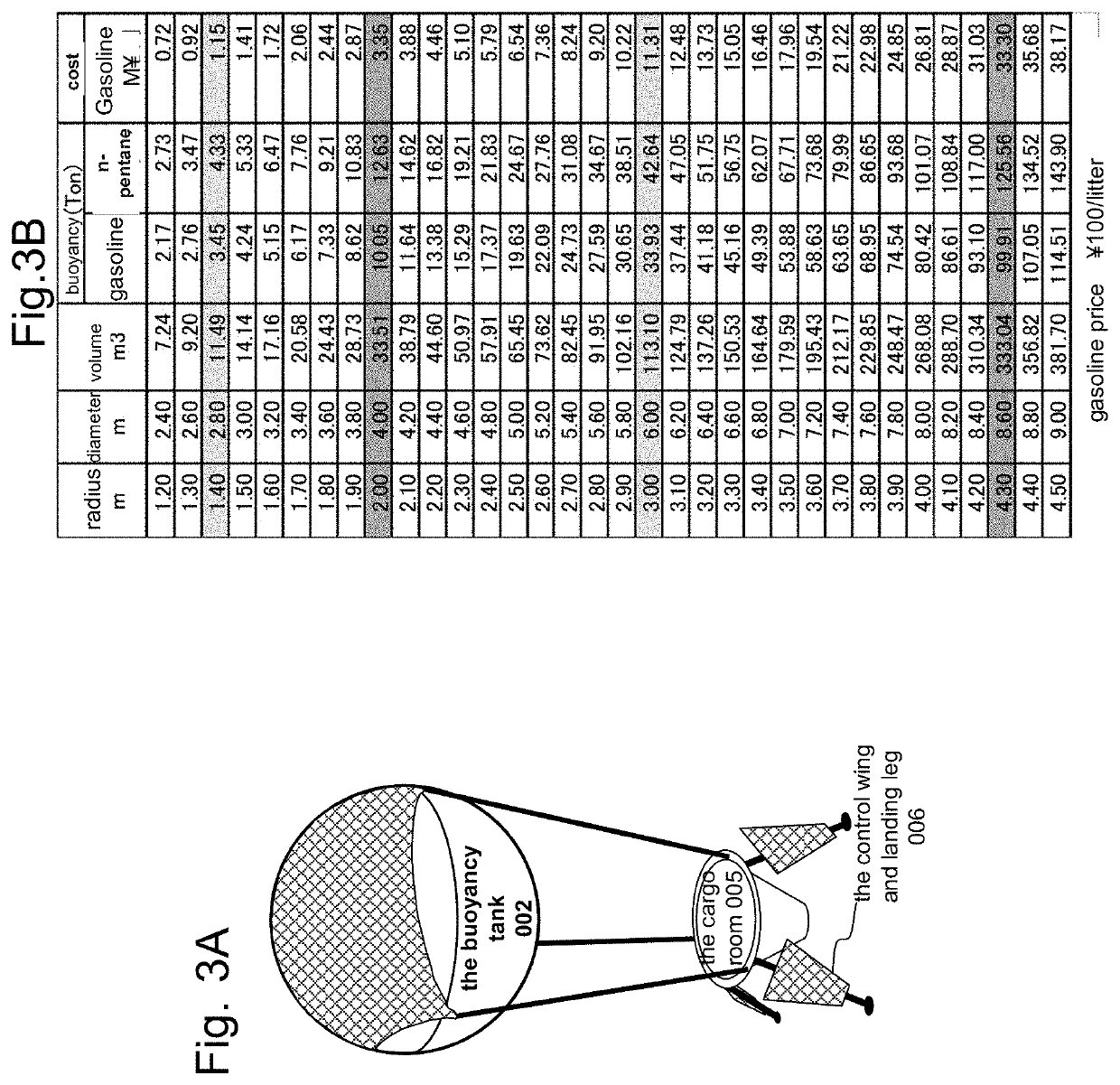

Seabed resource lifting apparatus

PendingUS20210214916A1Avoiding pressure resistance requirementLighter specific gravityMechanical machines/dredgersVessel salvagingBuoyant flowGeotechnical engineering

The present invention relates to a system and its equipments to collect mineral ores on the seabed and to float them up to the sea surface by utilizing the buoyancy of a liquid having a specific gravity less than that of water at room temperature. It is an underwater navigator capable of autonomous navigation that descends at a specific gravity of around 1.0 with a ballast that cancels buoyancy when descending from the sea surface, and ascends at a specific gravity of around 1.0 by exchanging mineral ores with the ballast on the seabed. On the seafloor, it is accompanied by a device that collects seabed mineral ores for the underwater vehicle.

Owner:LAKSHMI CO LTD

Engine that is equipped with variable valve device

InactiveUS8640664B2Small structureReduce component weightValve arrangementsMachines/enginesEngineeringMechanical engineering

An engine includes a hydraulic pressure lash adjuster (HLA) pivotally supporting an end of a swing arm and having a valve supporting the other end of the swing arm, wherein the hydraulic pressure lash adjuster includes a housing, a plunger of which one end portion thereof may be slidably inserted into the inside of the housing, the other end portion of which extends outwards and supports the end of the swing arm by selectively moving upwards or downwards in a length direction of the housing, a stopper pin slidably mounted in a chamber of the plunger so as to selectively lock the plunger to the housing such that the plunger cannot move in the housing, and a hydraulic pressure supply portion that selectively supplies one side of the stopper pin with a hydraulic pressure in the chamber of the plunger to move the stopper pin toward the housing.

Owner:HYUNDAI MOTOR CO LTD

Frameless crystalline silicon cell completely-PID-resistant light assembly and cell panel

InactiveCN105845763AReduce component weightReduce component thicknessPhotovoltaic energy generationSemiconductor devicesAluminiumCells panel

The invention discloses a frameless crystalline silicon battery completely anti-PID lightweight assembly, including: a front glass, a cell, a back plate and a junction box, the battery is located between the front glass and the back plate; the front The plate glass is photovoltaic ultra-clear patterned glass with a thickness of 4.0-5.0 mm, and the surface of the front glass is coated with nano-titanium dioxide film. There are packaging material layers between them, the packaging material layer is polyolefin, the junction box is electrically connected to the battery sheet, and a wavelength conversion agent is mixed in the packaging material layer, and the wavelength conversion agent can convert invalid or low The effective wavelength of sunlight is shifted to the effective wavelength. The frameless crystalline silicon battery of the present invention is completely anti-PID, and the light-weight component abandons the aluminum frame, and the component can meet the load requirement of 5400pa without framing; and the component is completely resistant to PID, and reduces the weight of the component, reduces the thickness of the component, and reduces the manufacturing cost .

Owner:董友强

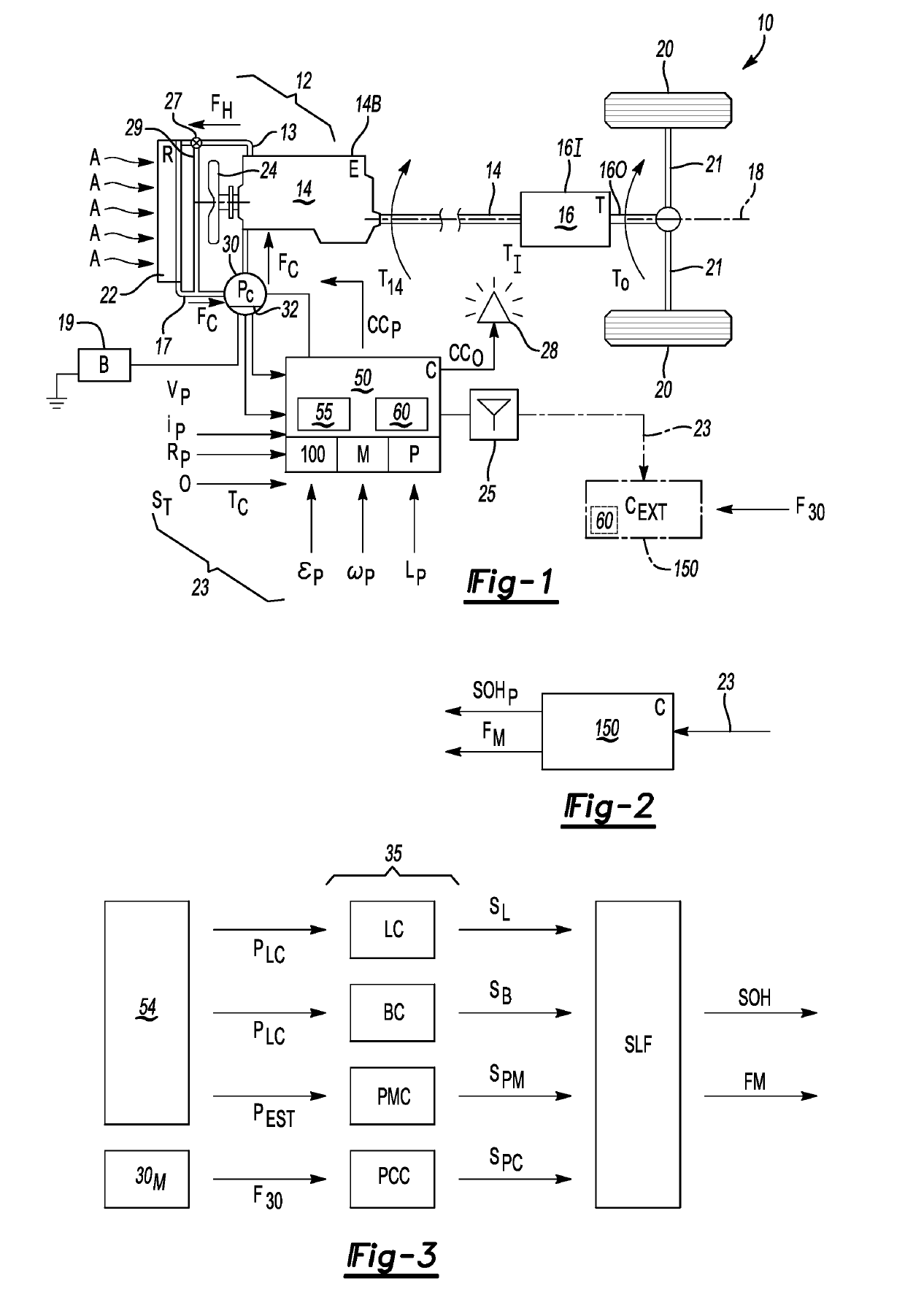

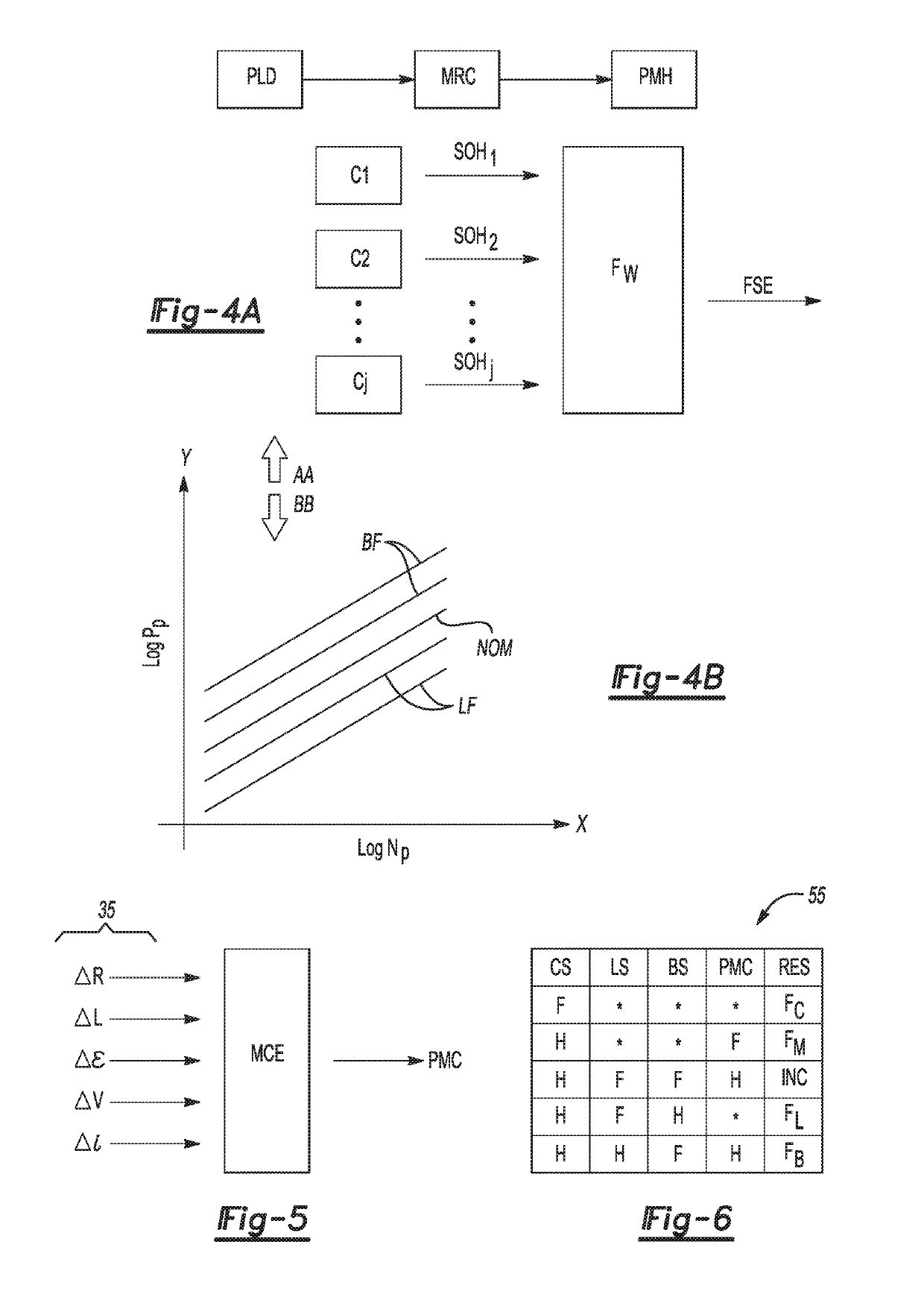

Prognostic system and method for an electric coolant pump

ActiveUS10273867B2Eliminate parasitic power lossImprove fuel economyPump testingCoolant flow controlElectric machineState of health

A thermal management system includes an electric coolant pump, power source, and controller. The pump is in fluid communication with a heat source and a radiator, and has pump sensors for determining a pump voltage, speed, and current. The battery energizes the sensors. The controller receives the voltage, speed, and current from the sensors, determines a performance of the pump across multiple operating regions, calculates a numeric state of health (SOH) quantifying degradation severity for each of a plurality of pump characteristics across the regions, and executes a control action when the calculated numeric SOH for any region is less than a calibrated SOH threshold. The pump characteristics include pump circuit, leaking / clogging, bearing, and motor statuses. A vehicle includes an engine or other heat source, a radiator; and the thermal management system. The controller may execute a prognostic method for the electric coolant pump in the vehicle.

Owner:GM GLOBAL TECH OPERATIONS LLC

Gas turbine engine component incorporating a seal slot

ActiveUS10941671B2Reduce component weightEngine manufactureBlade accessoriesControl engineeringControl theory

A turbine engine component includes: a body bounded by an end face; and a seal slot having an opening communicating with the end face, the seal slot including a receptacle defining a boundary configured to receive and position a spline seal, and an open chamber communicating with the seal slot and extending beyond the boundary.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com