Torque detecting device of large-torque electric actuating mechanism

An electric actuator and torque detection technology, applied in the field of torque detection devices for high-torque electric actuators, to achieve the effects of high braking precision, stable braking and low braking noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

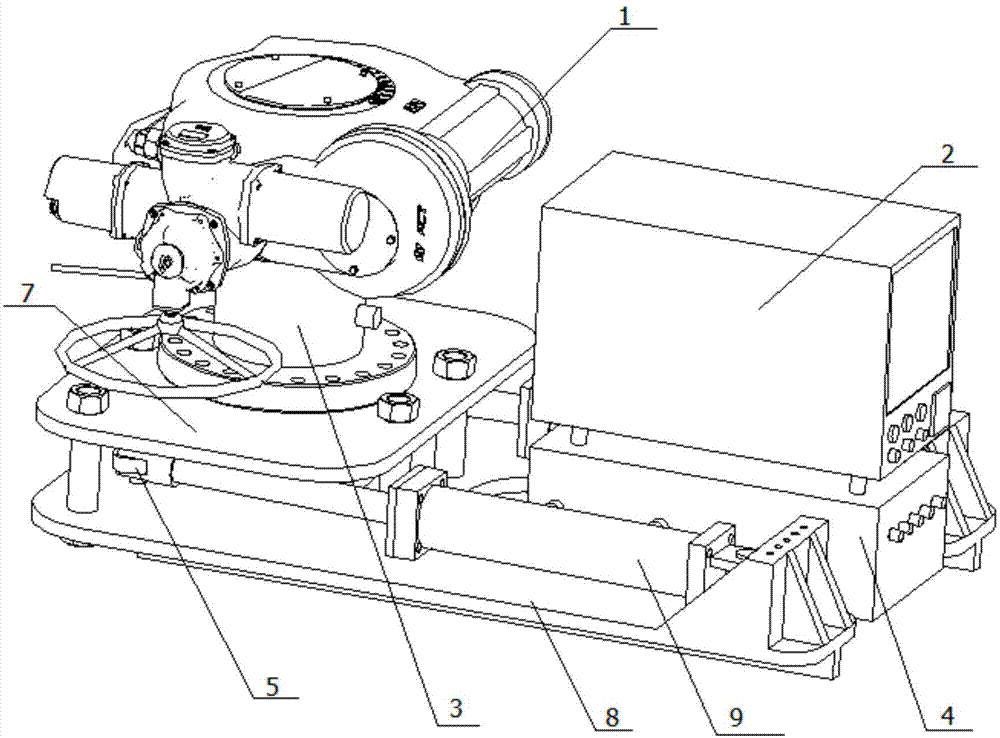

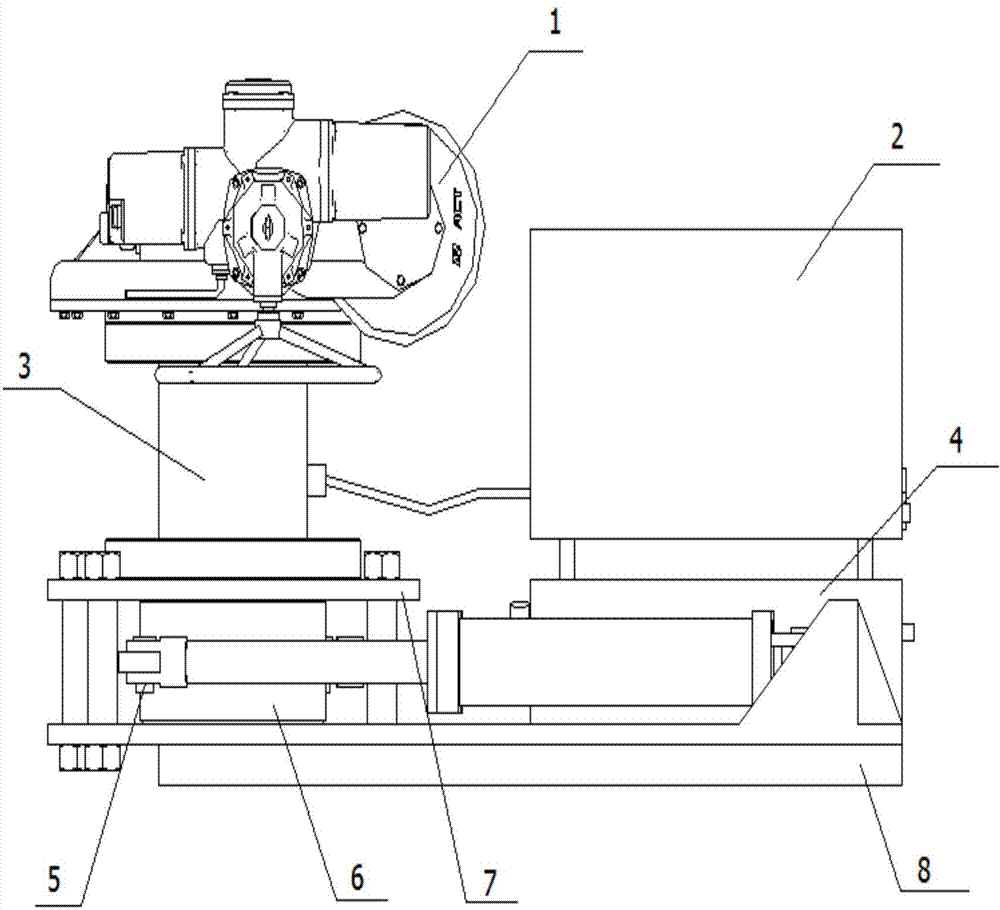

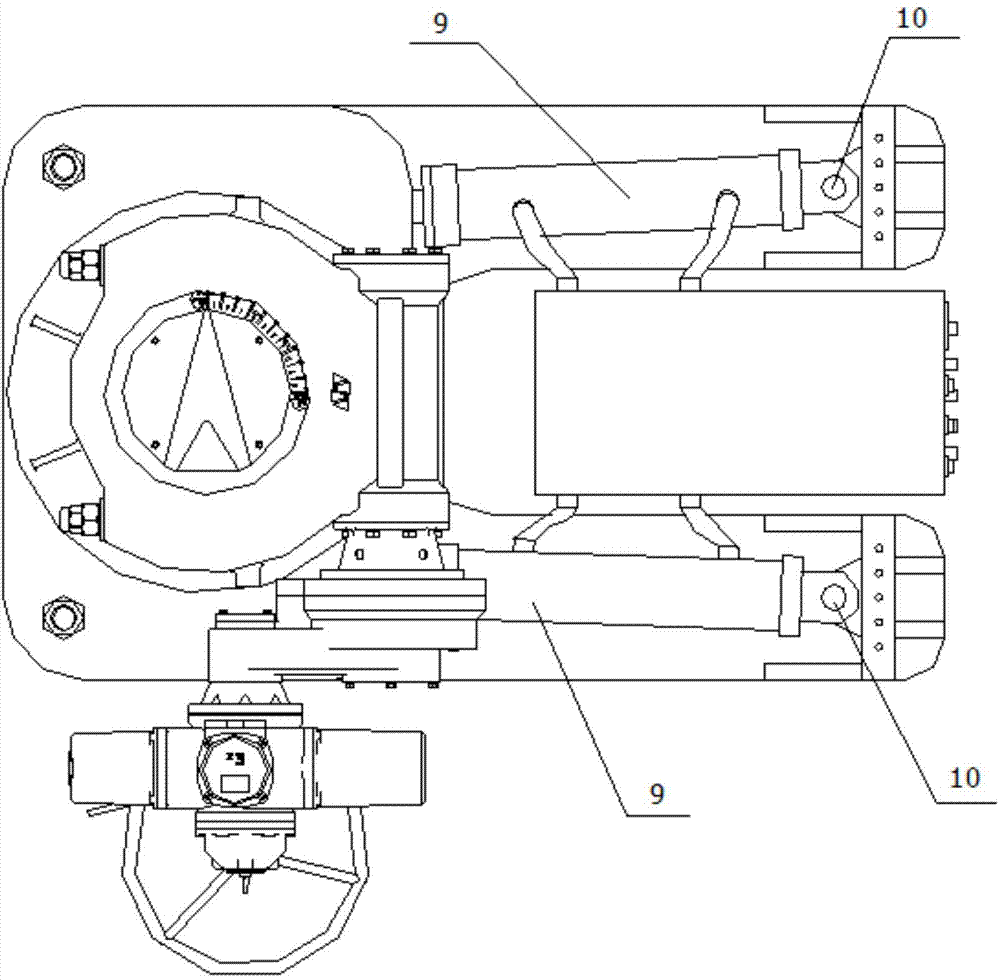

[0026] Such as figure 1 -shown in 4, a torque detection device of a high-torque electric actuator, which includes a high-torque electric actuator, a fixing mechanism, a torque detection mechanism, and a braking mechanism;

[0027] The high-torque electric actuator includes an electric actuator 1 and an output shaft connected to it, and the torque specification of the electric actuator is 100,000N.m to 300,000N.m;

[0028] The fixing mechanism includes a base 8 and a bottom plate 7 positioned above the base and fixed thereto;

[0029] The torque detection mechanism includes a reaction torque sensor 3 located under the electric actuator 1, one end of the reaction torque sensor is fixedly connected to the electric actuator, and the other end is fixed on the bottom plate 7;

[0030] The braking mechanism includes a transmission shaft and a brakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com