Automatic locating structure for textile machine

An automatic positioning and textile machinery technology, applied in textiles and papermaking, needle punching machines, non-woven fabrics, etc., can solve the problems of complex braking mechanism, short braking delay time, large parking error, etc., and achieve the goal of braking mechanism Simple, high braking precision, small rotational inertia effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

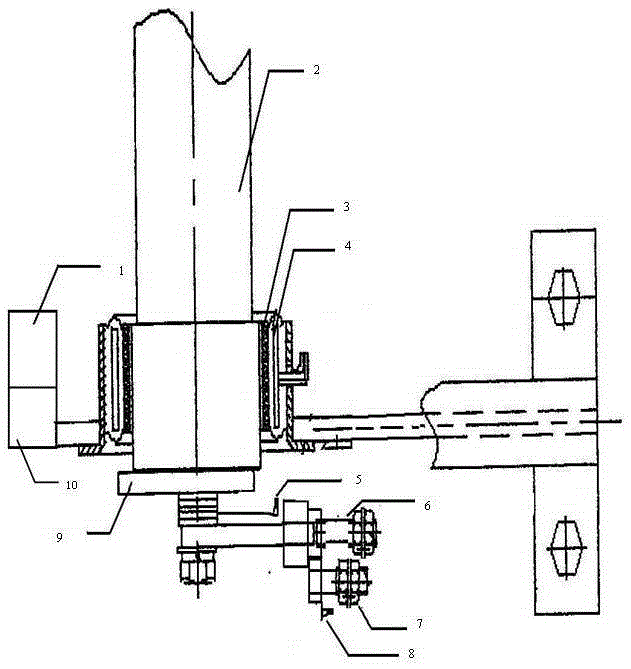

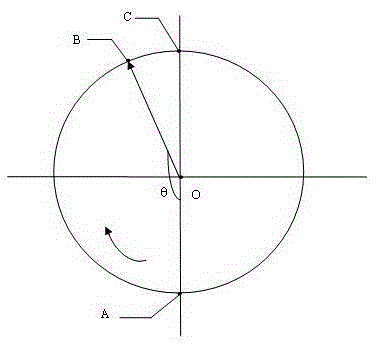

[0019] refer to figure 1 As shown, when the main motor drives the main shaft (2) to slowly decelerate under the control of the frequency converter (10), the controller (1) starts the sensing detection task, and the bottom dead center sensor (5) starts to detect the connecting rod crank (9 ) to the bottom dead center, when it is detected that the number of times the connecting rod crank (9) reaches the bottom dead center is less than 30 times per minute, the controller (1) sends a clutch clutch signal to the gear difference transmission (6), and this , the positioning gear (7) and the tooth difference transmission device (6) mesh, and the positioning gear starts to work; in the design of the tooth difference transmission device (6), the positioning gear (7) rotates 12 times every time the main shaft (2) rotates once ;When the positioning gear (7) starts and the bottom dead center sensor (5) detects that the connecting rod crank (9) reaches the bottom dead center, the counting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com