Method and device for deceleration and braking of electric vehicles and application of screw drive mechanism

A technology of electric vehicles and screw drive, which is applied to the operating mechanism of railway vehicle brakes, brake transmission devices, brakes, etc. Rod error and other problems, to avoid the brake caliper not in place, high-precision braking effect, and eliminate potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below.

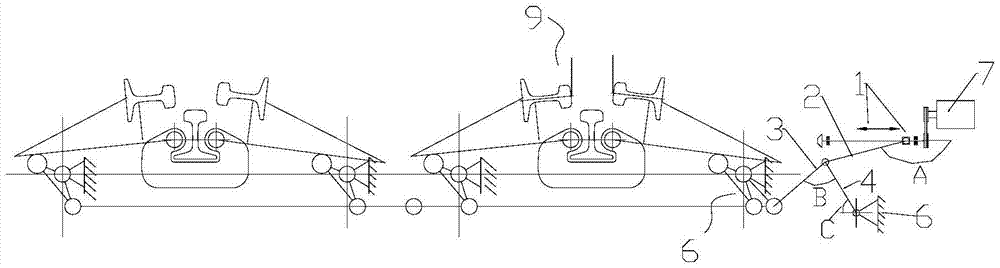

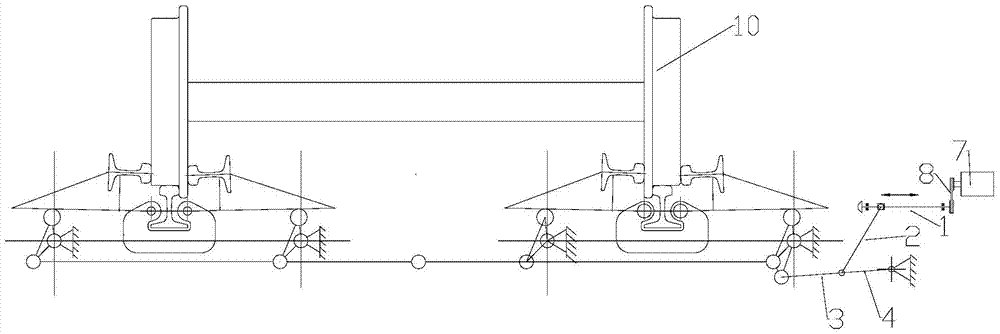

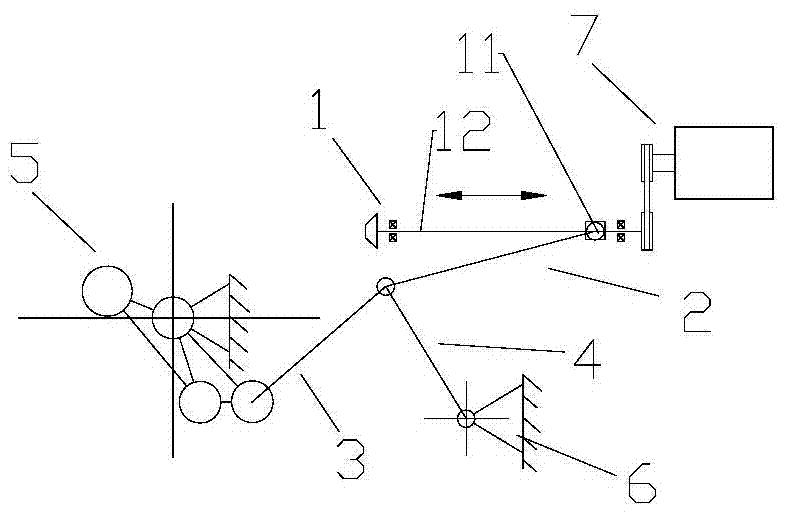

[0055] like Figure 1-Figure 8 , showing the ball screw mechanism 1, the initial connecting rod 2, the front connecting rod 3, the rear connecting rod 4, the crankshaft 5, the support seat 6, the motor 7, the belt transmission mechanism 8, the vehicle brake caliper group 9, the wheel 10, wherein the ball screw mechanism 1 has a slider 11 and a screw rod 12, the starting connecting rod 2 is a transmission connecting rod, the supporting base 6 includes a base, and the supporting base 6 also includes a mounting base for a translation mechanism. The structure of the bell crank 5 is like the structure of the bell crank 3 shown in Chinese patent ZL200420009399.1, which is a structure of the prior art.

[0056] The method for realizing deceleration and braking of rail electric vehicles in the present invention includes setting a base, an inner brake caliper and an outer brake caliper, and a motor. The connecting rod tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com