Dispensing device for semiconductor chip packaging

A chip packaging and glue dispensing device technology, which is applied to the surface coating liquid device, cleaning method and utensils, cleaning methods using tools, etc., can solve problems that easily affect the dispensing effect, and improve the dispensing quality. Good support, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

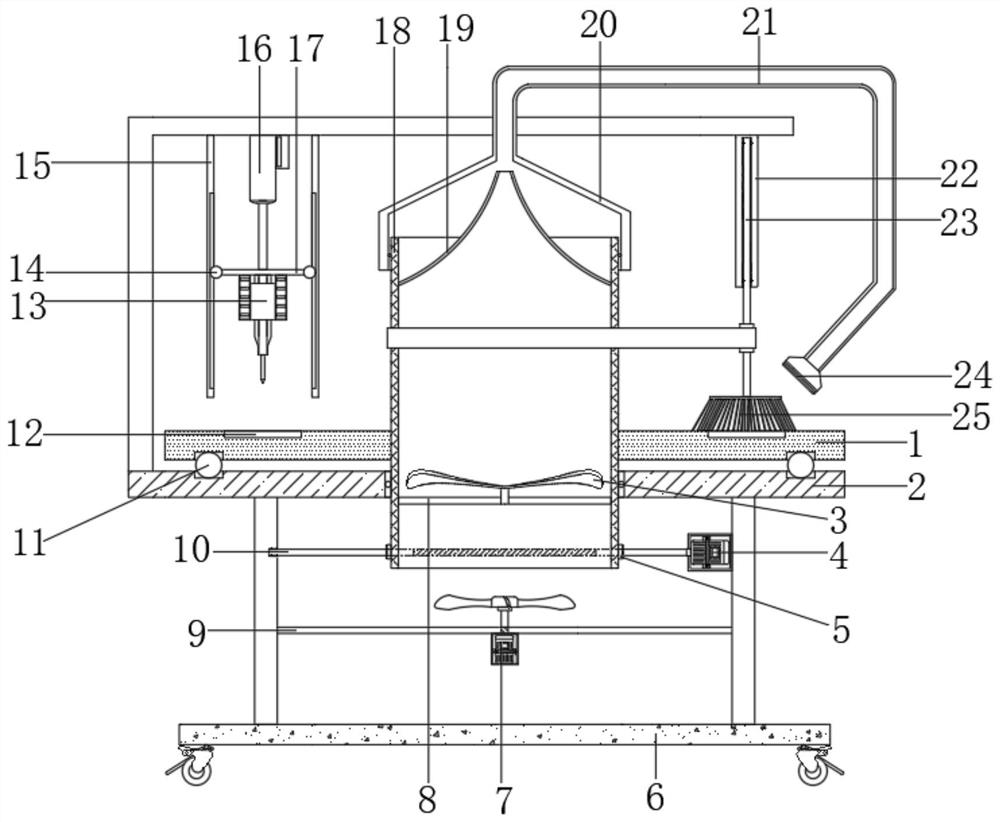

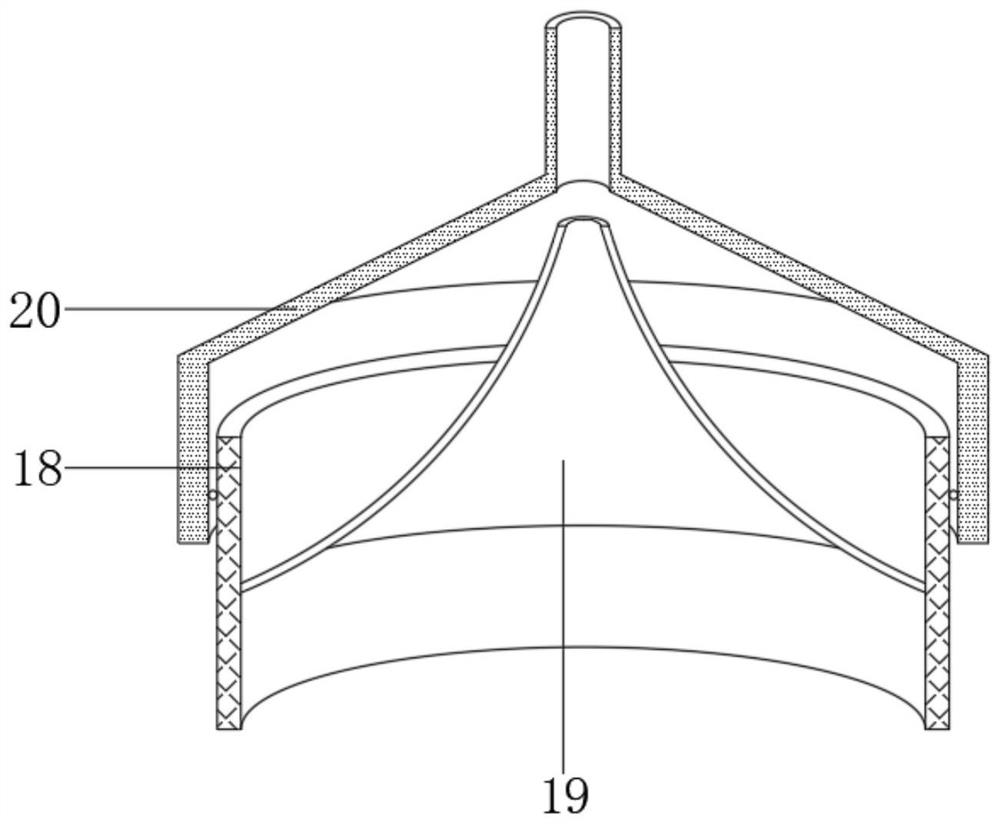

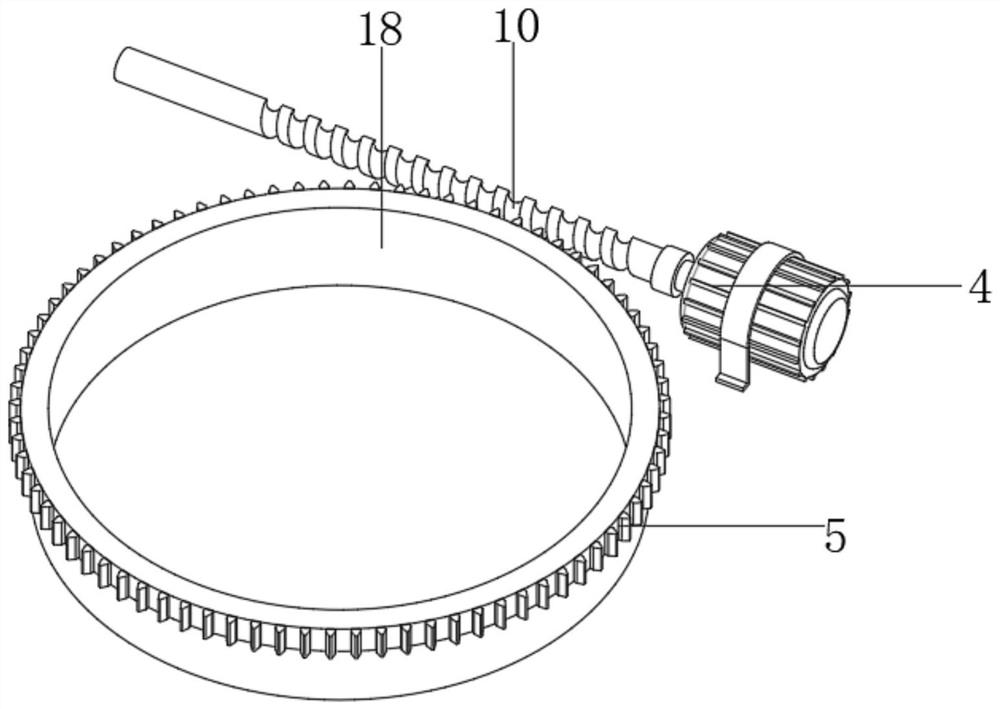

[0030] refer to Figure 1-4 , a dispensing device for semiconductor chip packaging, comprising a dispensing station 1 and a fixed support platform 2, the centers of the dispensing platform 1 and the fixed support platform 2 are respectively provided with a mounting groove and an adapter, and the inner wall of the mounting groove is welded with a The transmission tube 18 connected by the transfer interface through the bearing rotation, and both sides of the bottom outer wall of the fixed support platform 2 are vertically welded with side support plates, and a drive mechanism is installed on the opposite side of the transmission tube 18 and the side support plates, and the side support plates The opposite side is fixed with a bracket 9 by bolts, the bracket 9 is equipped with a blower 7, the top side of the fixed support platform 2 is welded with an L-shaped top plate, and the bottom end side of the end of the top plate is fixed with a fixed tube 22 by bolts. The inner wall of c...

Embodiment 2

[0039] refer to figure 1 and Figure 5 , a dispensing device for semiconductor chip packaging. Compared with Embodiment 1, this embodiment also includes a strengthening mechanism installed on the side of the L-shaped top plate close to the push rod motor 16.

[0040] Wherein, the reinforcement mechanism includes two fixed vertical rods 15 vertically welded to the L-shaped top plate.

[0041] Wherein, the opposite sides of the two fixed poles 15 are provided with arc-shaped inner grooves 26 , and both sides of the mounting plate 17 are welded with sliding ball heads 14 slidably connected with the arc-shaped inner grooves 26 .

[0042] When the present invention is in use: use the setting of the strengthening mechanism, utilize the mutual cooperation between the sliding ball head 14 and the arc-shaped inner groove 26, play a good role in supporting and limiting the mounting plate 17, and then improve the movement of the dispenser 13 up and down. Stability, to ensure the smooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com