Integrated adjustable bridge structure for high-voltage cable construction

A high-voltage cable and bridge structure technology, applied in electrical components and other directions, can solve the problems of inability to change the width of the bridge, high construction cost, complicated construction, etc., and achieves good fixing effect, convenient storage and transportation, and improves the effect of construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

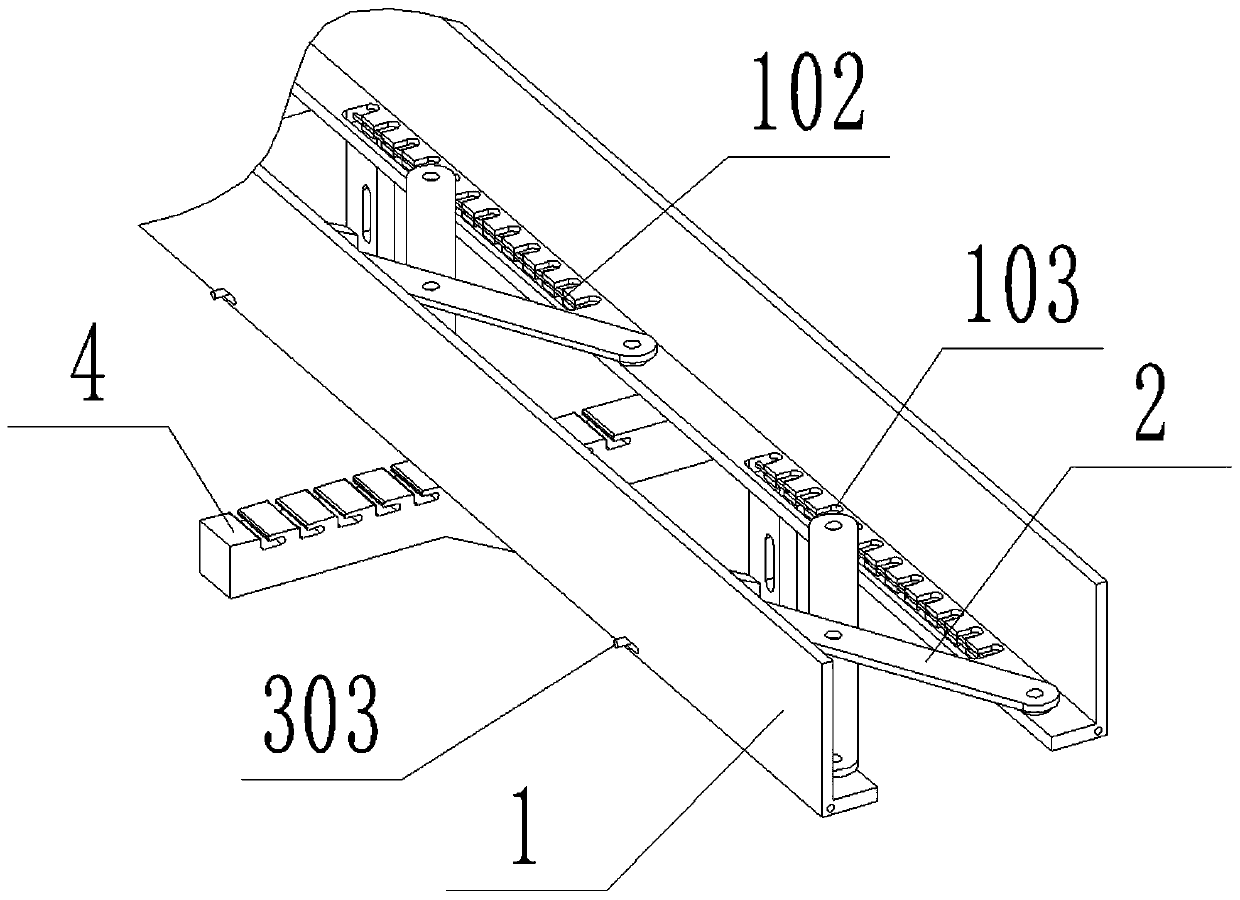

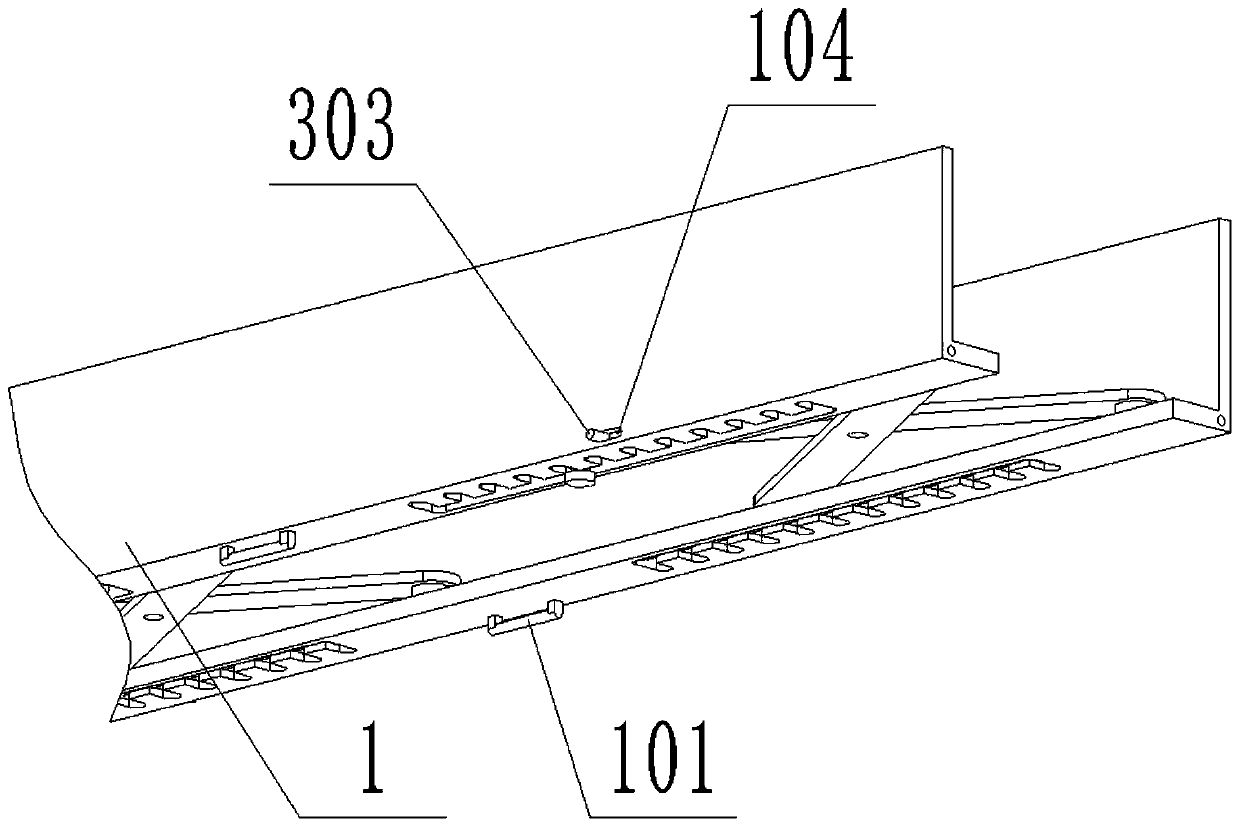

[0032] As attached figure 1 Attached Figure 8 Shown:

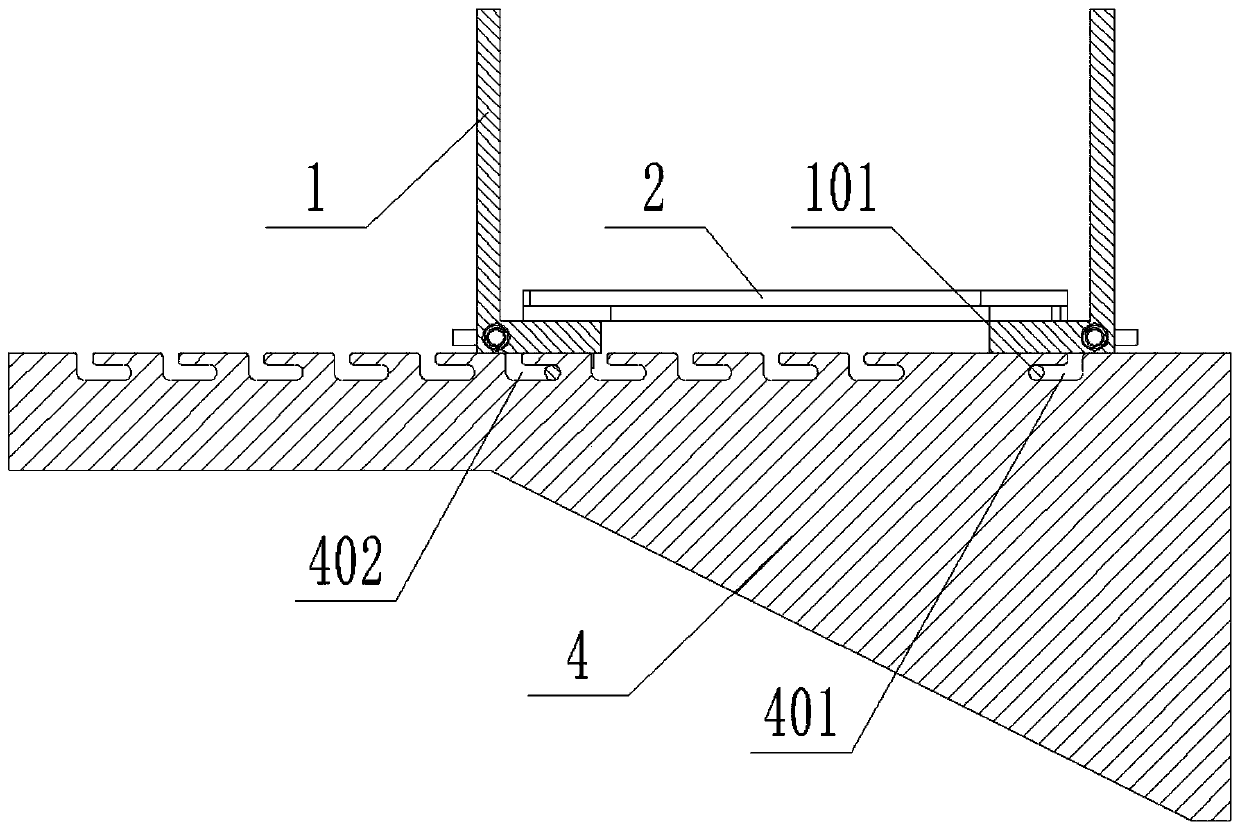

[0033] The present invention provides an integrated adjustable bridge structure for high-voltage cable construction, including: side plate 1, fixed clamping shaft 101, sliding groove 102, clamping groove 103, lock groove 104, bottom connecting rod 2, roller 201, lock pin 3. Spring 301, tooth 302, hand dial 303, bridge support arm 4, fixed end slot 401 and movable end slot 402; the bottoms of the two sets of side plates 1 are connected by multiple sets of bottom connecting rods 2; each set of side plates 1 A set of lock pins 3 are slidably connected to the inner side of the bottom; multiple sets of bridge support arms 4 are inserted together at the bottom of the two sets of side plates 1.

[0034] Among them, the bottom surface of the side plate 1 is provided with multiple sets of sliding grooves 102, and one end of the bottom surface of the bottom connecting rod 2 is axially connected to a set of rollers 201, and the rollers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com