Automatic rake-lifting concentrator

A concentrator and automatic technology, applied in the sedimentation tank and other directions, can solve the problems of unsatisfactory bottom material concentration, low degree of automation, hindering application, etc., and achieve the effect of high automation, good effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

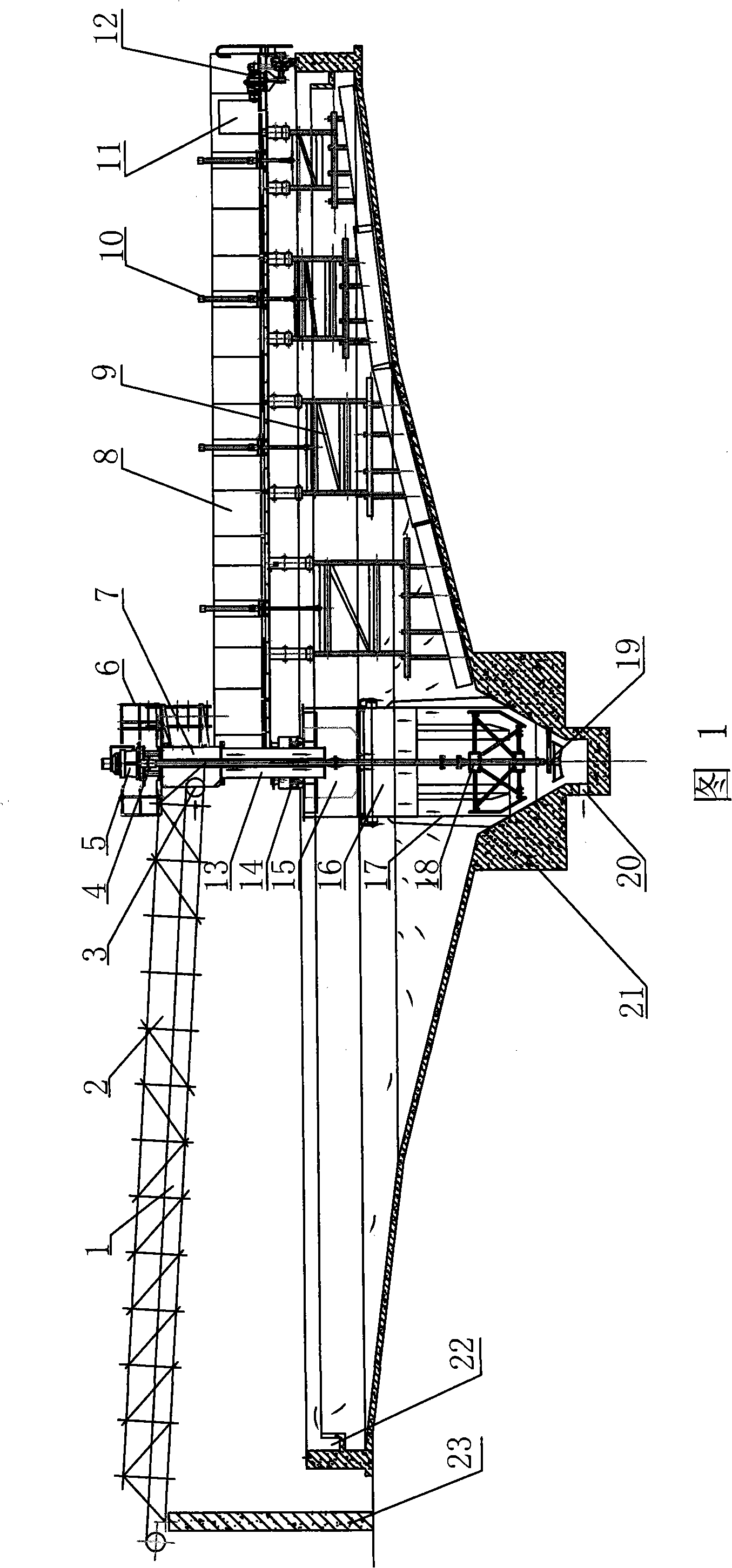

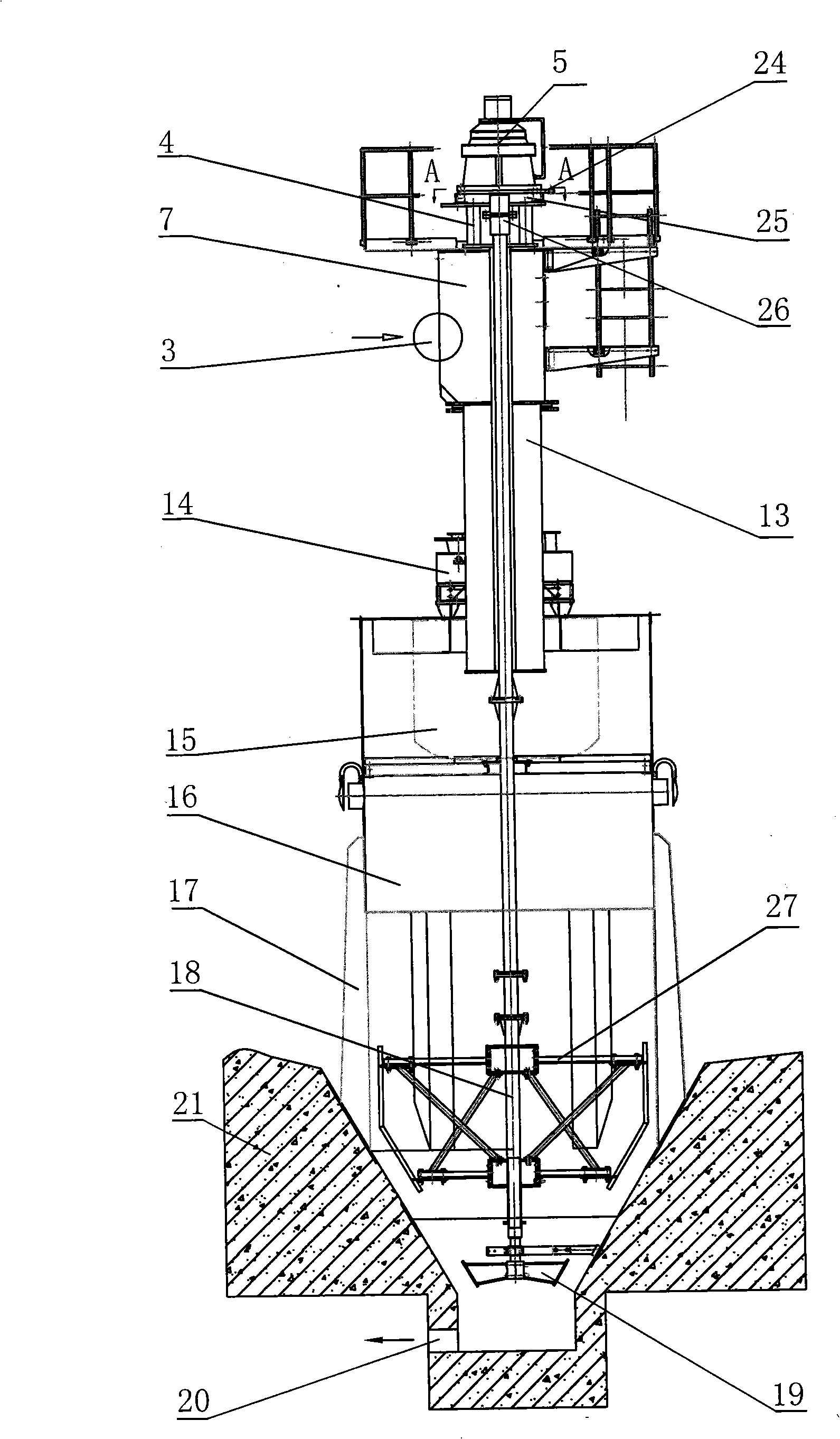

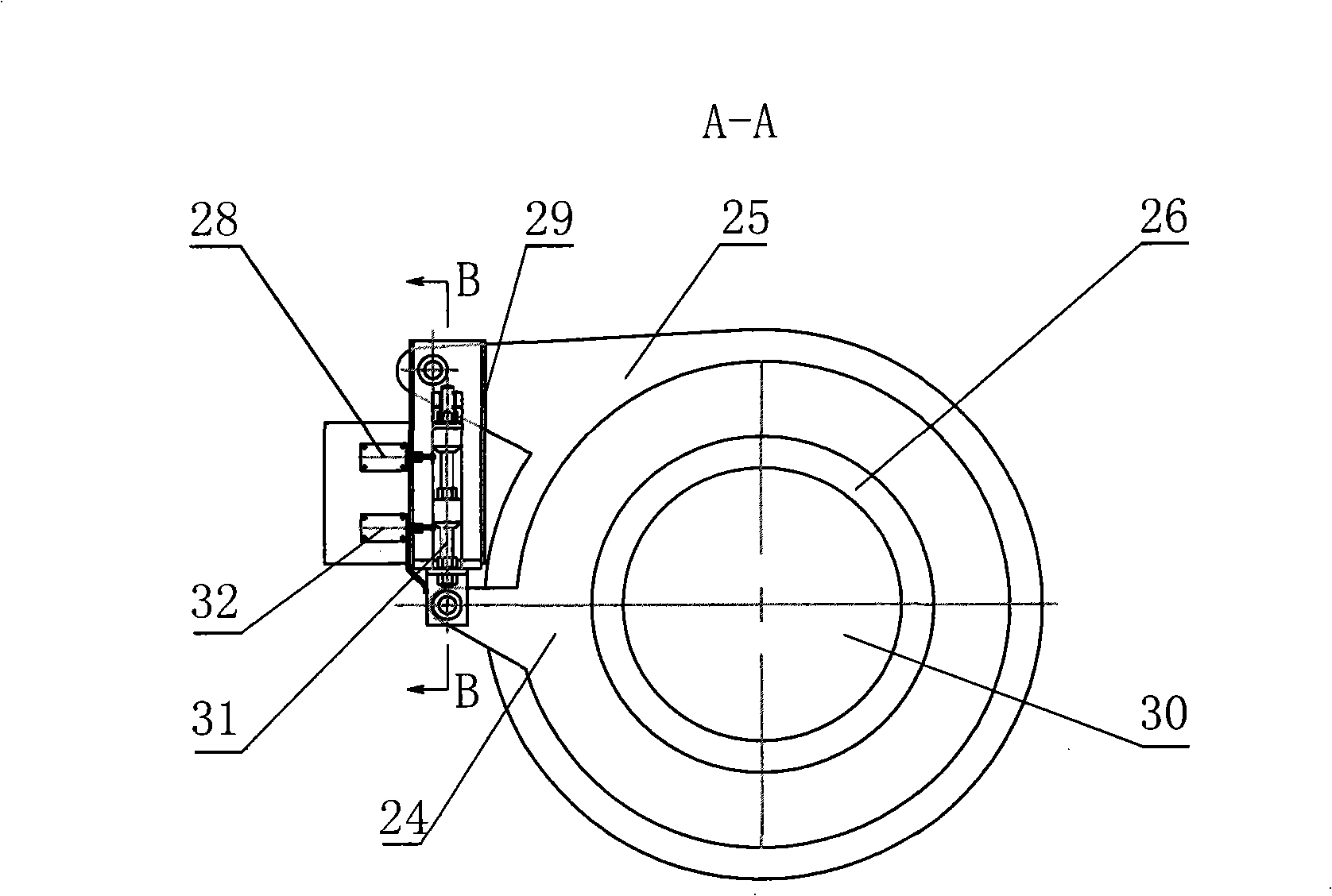

[0018] As shown in Figures 1 to 6, it includes a main shaft 18, which is a segmented shaft connected coaxially by connectors. The shaft sleeve 26 is coaxially connected with the output shaft 30 of the main shaft driving device 5. The main shaft driving device 5 is supported by the turntable 4 arranged on the bracket 6. 24, the ring-shaped lug connecting piece 24 is connected with a rotary baffle 29 by bolts, the upper side of the rotary baffle 29 is horizontally provided with a rotary shaft 34, and one end of the rotary shaft 34 in the rotary baffle is set with a spring 35, The other end of the rotary shaft is connected with another ring-shaped lug connector 25 fixed horizontally on the upper part of the turntable 4 through bolts, and a pull rod 31 is arranged on the upper part of the rotary shaft parallel to the rotary shaft. The sliding contact head 33 is also provided with an alarm travel switch 32 and an overload shutdown travel switch 28 activated by colliding with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com