Multi-directional coordinated rotating fixed bridge support

A bridge bearing and coordinated technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of aggravated friction pair damage speed, complex stress state, and support damage, so as to reduce the maintenance and repair work in the later period, The effect of low manufacturing cost and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

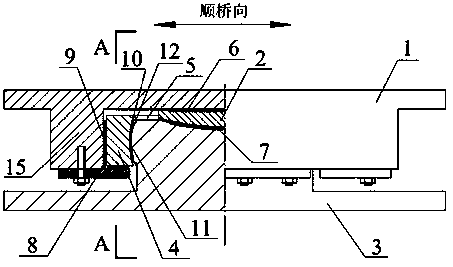

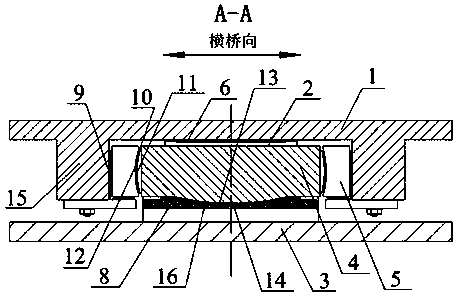

[0017] Such as figure 1 and figure 2 As shown, among them, figure 1 For the present invention, place the figure along the direction of the bridge, figure 2 It is a layout diagram of the present invention along the direction of the cross bridge, a multi-directional coordinated rotating and fixed bridge bearing, including: an upper bearing plate 1, a spherical crown lining plate 2 and a lower bearing plate 3, and the upper bearing plate 1 It includes an upper support plate stopper 15 and a boss located on the top of the upper support plate stopper 15, the boss is fixed with the beam body through anchor bolts or welding, and the lower end of the upper support plate stopper 15 is provided with Notch, the upper end of the lower bearing plate 3 is located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com