Jacking bracket system for segmented mounting of bridge tower and construction process thereof

A lifting support and construction technology technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large amount of auxiliary materials and large construction safety risks, and achieve the effect of saving auxiliary materials and reducing safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

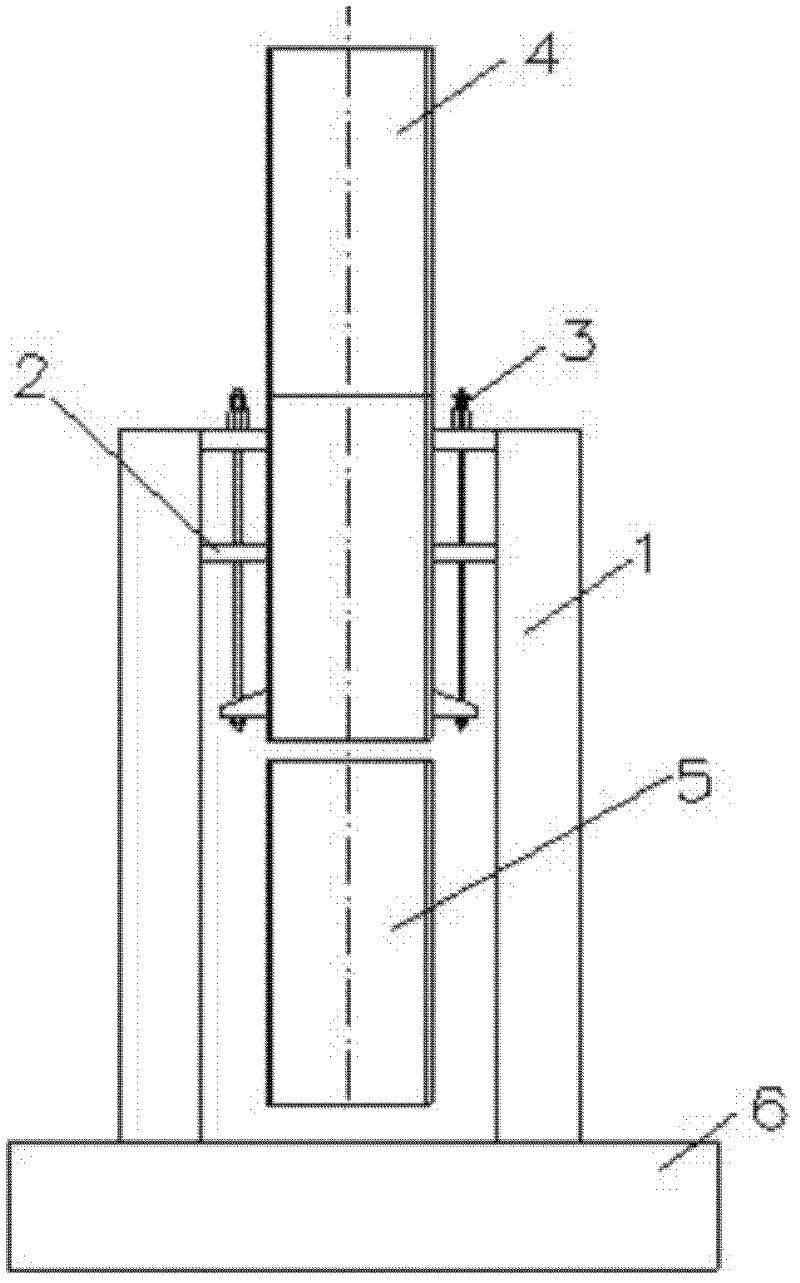

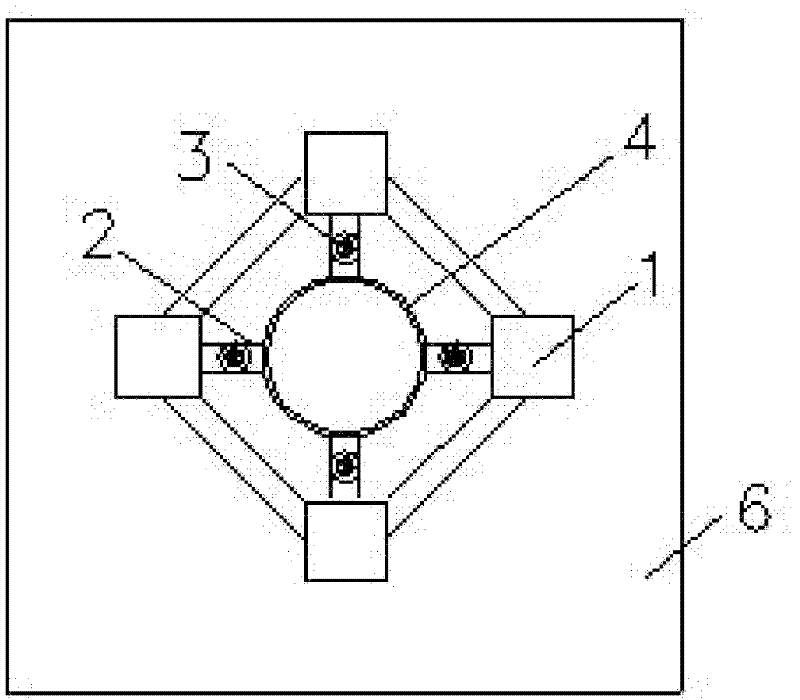

[0026] like Figure 1~2 As shown, a jacking bracket system for segmental installation of bridge towers according to the present invention is composed of a fixed bracket 1, a limit device 2 and a jacking device 3, and the fixed bracket 1 is fixed on the foundation 6 around the bridge tower. , the inside of the fixed support 1 is symmetrically provided with a limiting device 2 for limiting the bridge tower in the center, and the fixed support 1 or the limiting device 2 is provided with a jacking device 3, and the bottom of the jacking device 3 is fixedly connected with the bridge tower ; Wherein, there are 4 jacking devices 3, which are arranged symmetrically along the periphery of the bridge tower. Wherein, the limit device 2 inside the fixed support 1 has adjustability, the fixed support 1 and its limit device 2 can adjust the position of the bridge tower, so that the bridge tower is upright; the fixed support 1 is fixed on a firm foundation, and the fixed support 1 The stren...

Embodiment 2

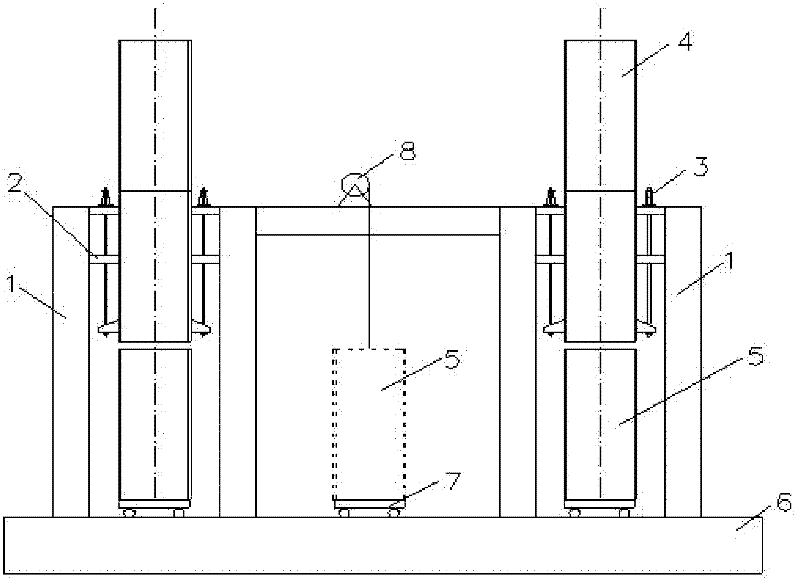

[0035] In the above step 4, use the fixed bracket 1 as a support, use the lifting device 8 to lift the bridge tower section 5 to be installed, place it vertically on the translation trolley 7, and move the translation trolley 7, so that the bridge tower section 5 to be installed enters the Install below the pylon section 4. Other structures and construction techniques of the jacking support system are the same as in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com