Lifting tooling for hydraulic immersed pump and lifting method

A hoisting method and submersible pump technology, which are applied in the directions of transportation and packaging, load hoisting components, ship parts, etc. Shake and other problems, to achieve the effect of reducing the lifting length, reducing the bending, and ensuring the installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

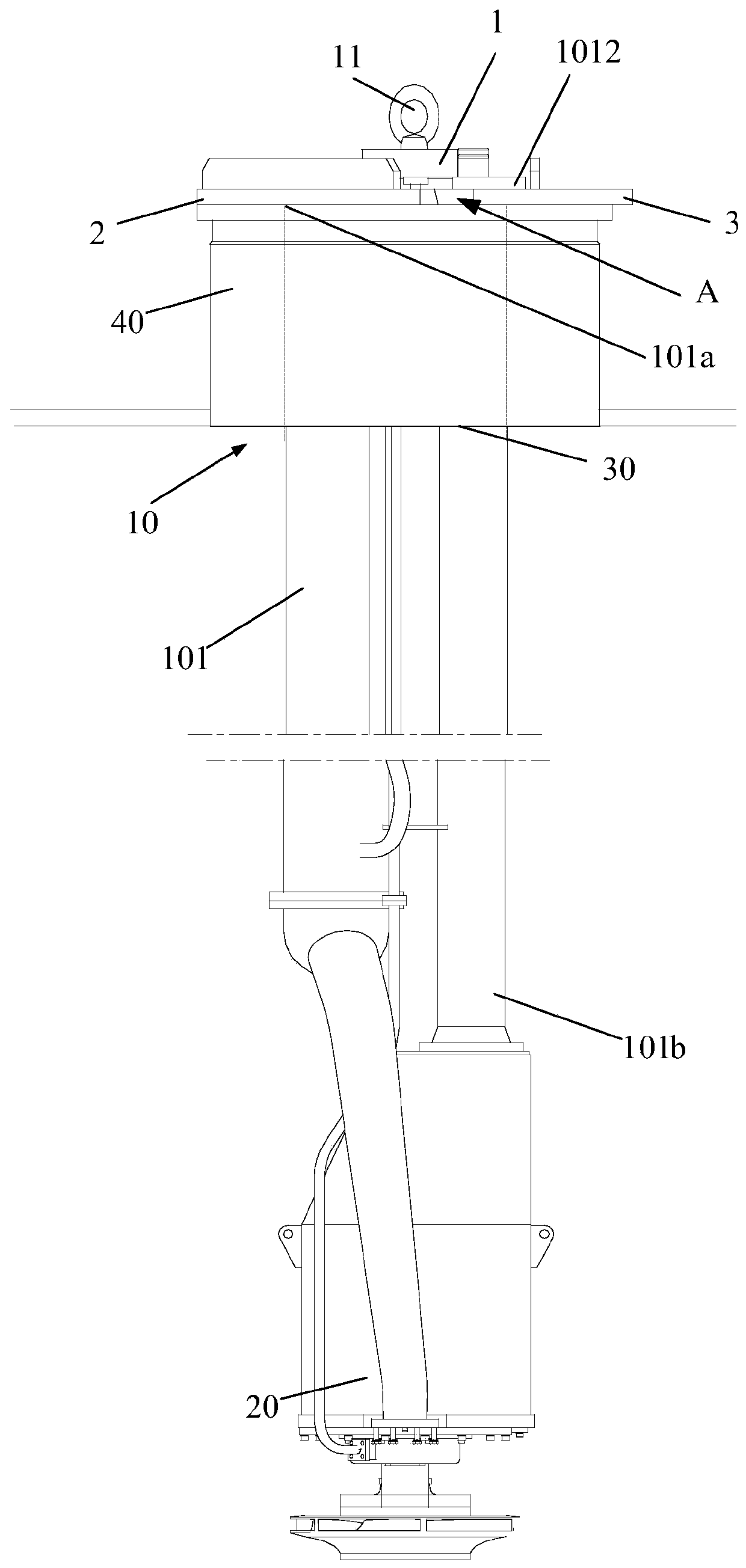

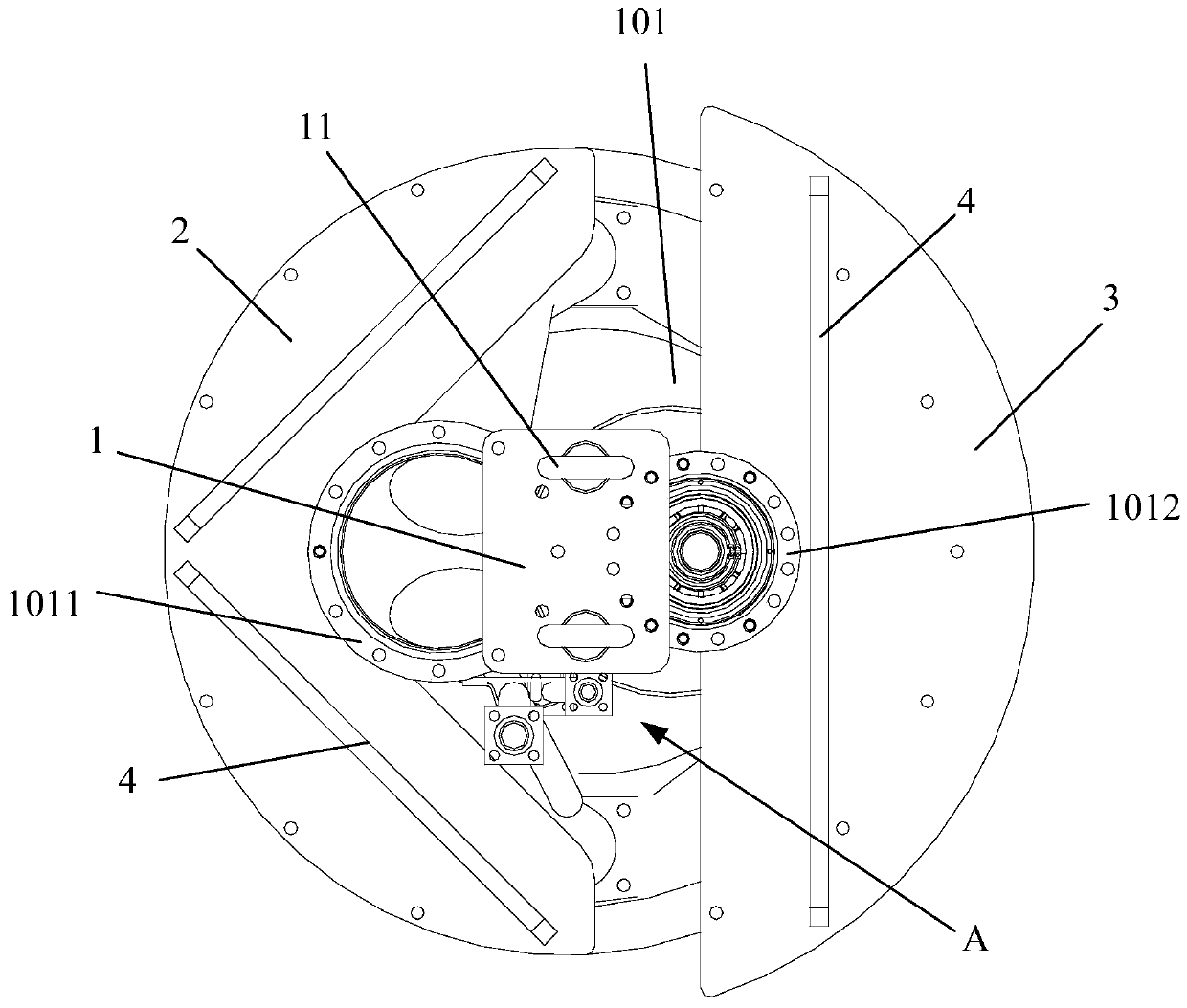

[0039] figure 1 It is a schematic diagram of the usage state of the hoisting tool provided by the embodiment of the present invention, figure 2 It is a top view of the hoisting tool provided by the embodiment of the present invention, combined with figure 1 and figure 2 , the hoisting tool is suitable for hoisting the first transmission pipe 101 and the second transmission pipe 102 of the power transmission pipe 10 of the hydraulic submersible pump ( figure 1 not shown), the hoisting tool includes a hoisting board 1 , a first supporting board 2 and a second supporting board 3 .

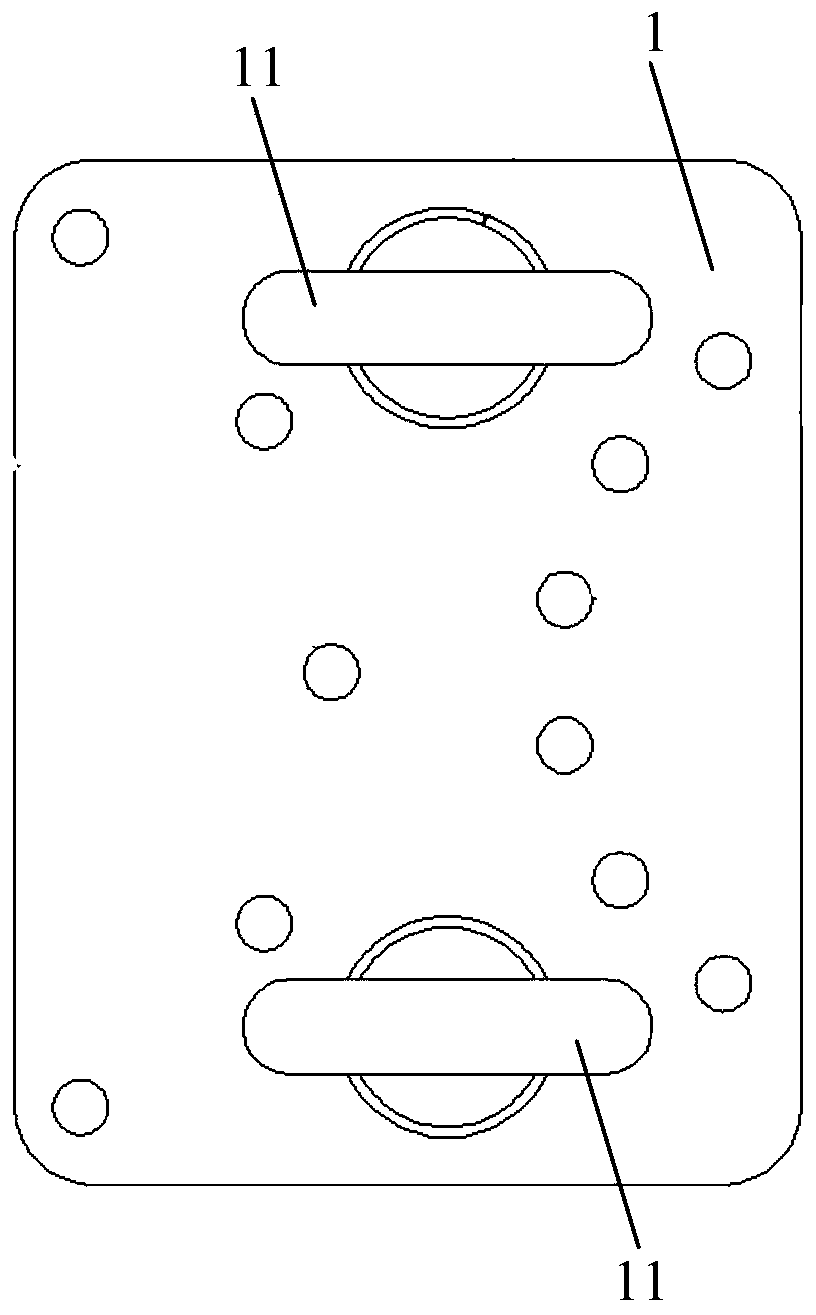

[0040] The lifting plate 1 is used to connect with one side of the first flange 1011 and the second flange 1012 on the flange end 101 a of the first transmission p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com