Quick positioning parts for steel bar binding

A technology of steel bar binding and positioning parts, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of low binding accuracy, difficult positioning, time-consuming and labor-intensive rework and rectification, etc., to improve quality and ensure accuracy high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

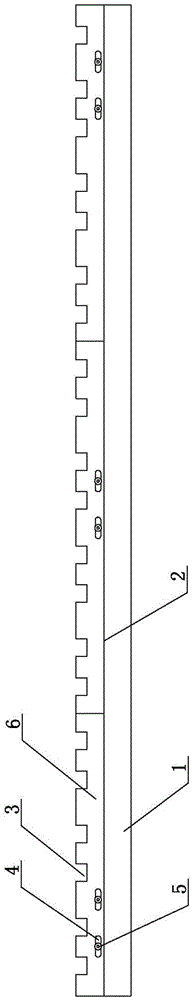

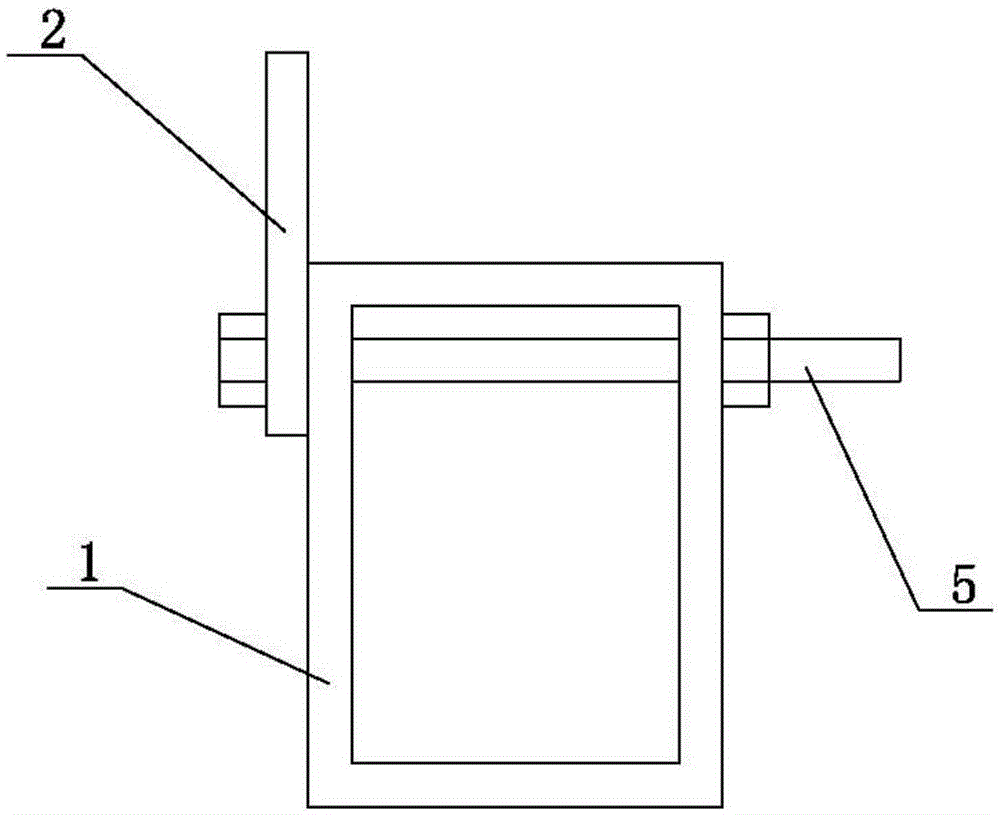

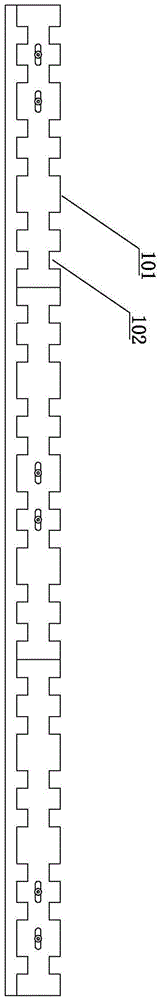

[0023] See figure 1 , figure 2 As shown, the fast positioning member for steel tying of the present invention has a mounting plate 2 for installing corresponding to the steel pipe 1 on the steel cage tying platform. On the upper side of the mounting plate is provided for multiple strips at one time. Multiple positioning slots 3 for binding and positioning the steel bars. The material of the mounting plate in this embodiment is thicker steel plate or other hard materials that are not easily deformed, and a positioning slot suitable for actual construction design needs is made on the mounting plate by a lathe. This kind of fast positioning member for steel bar binding is used to solve the technical problems of narrow space, no separate support system, different steel bar spacing, and quick installation and disassembly in the process of steel cage binding.

[0024] The present invention adopts the design of the positioning card slot. The installation card slot is set according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com