Track vacuum pump with optimized bearing arrangement

A vacuum pump and rail technology, which is applied to the parts of the pumping device for elastic fluid, the parts of the rotary piston type/swing piston type pump, the pump, etc., to achieve the effect of long time and less wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

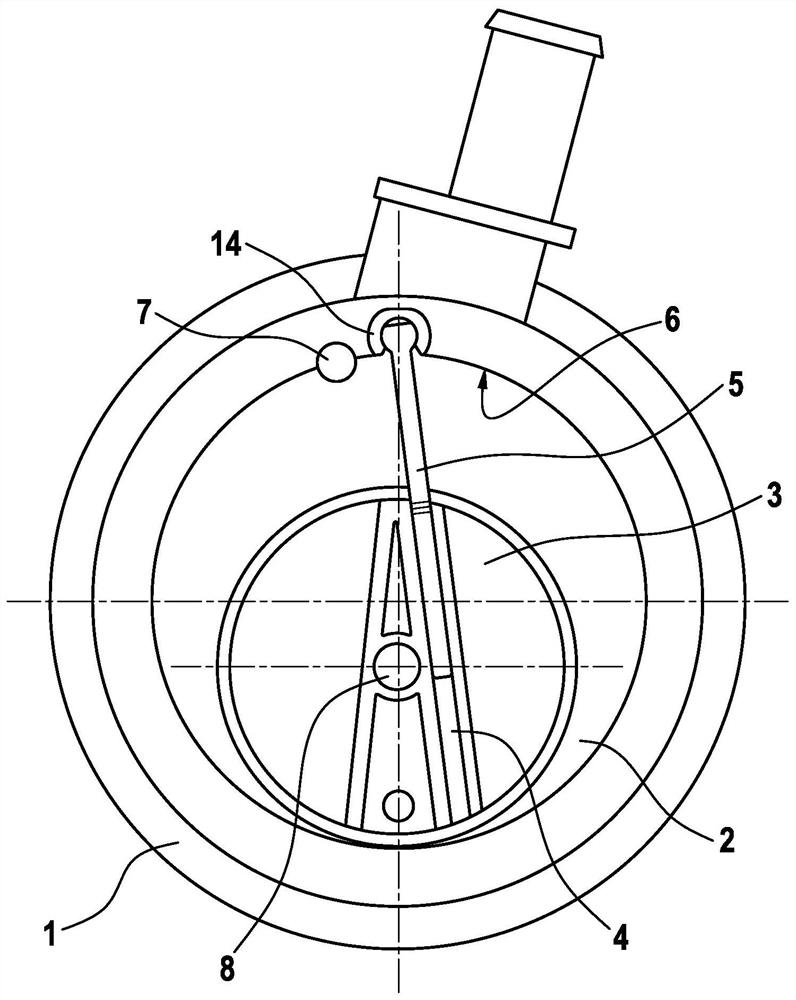

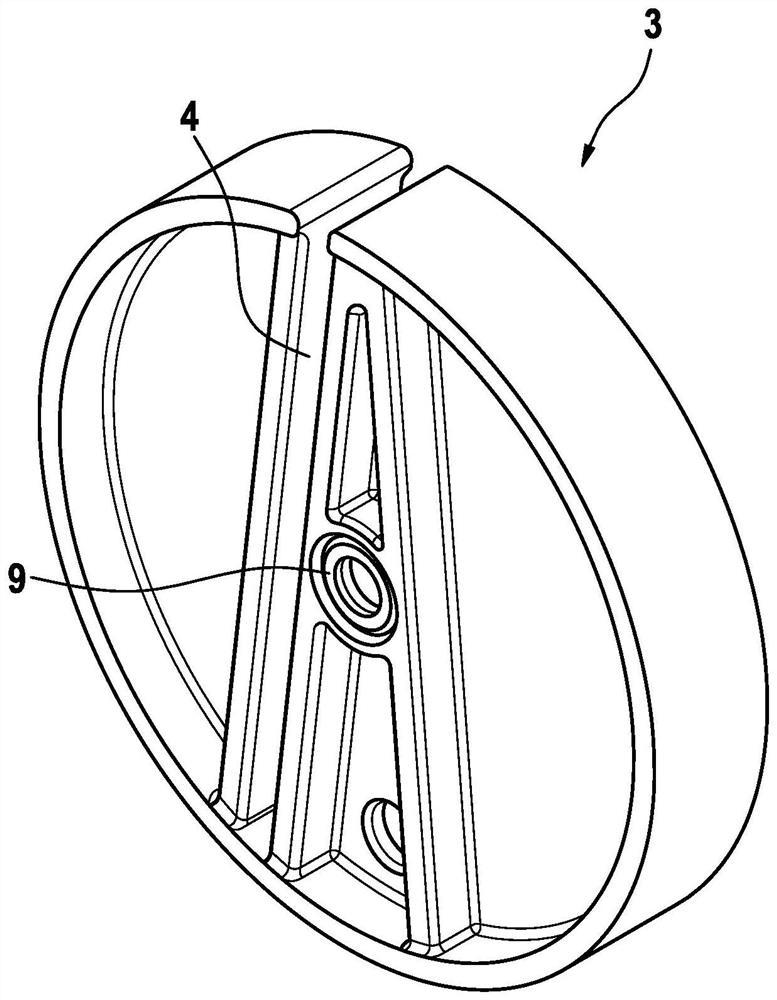

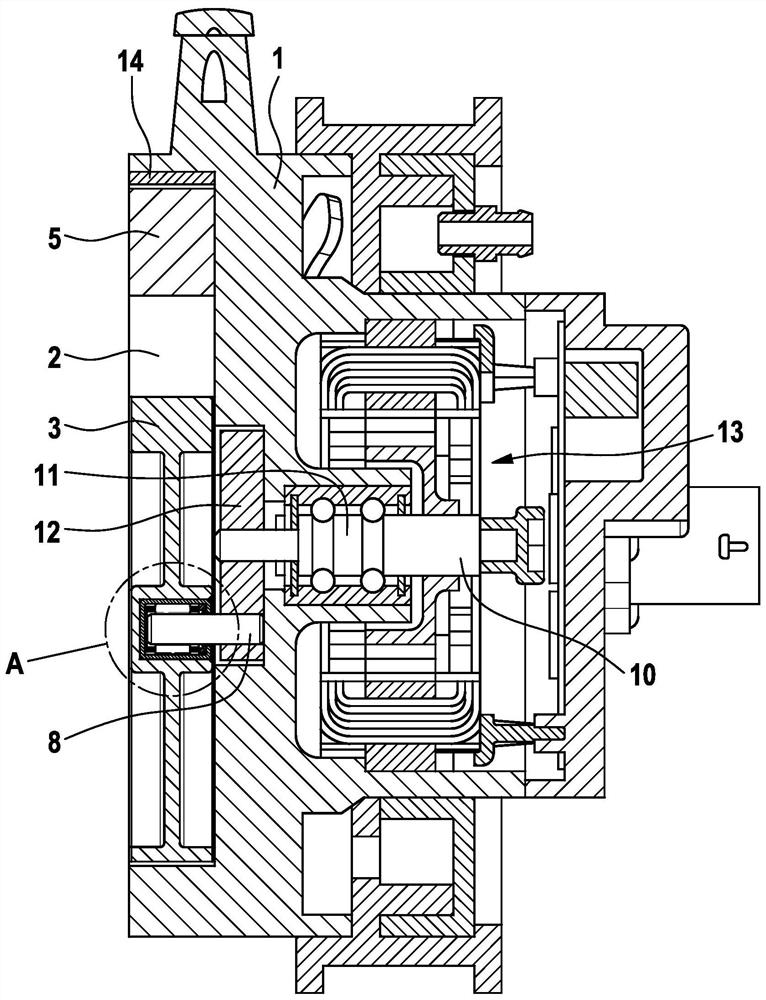

[0036] Such as Figure 1 to Figure 3As shown, an orbital vacuum pump according to one embodiment of the invention is formed by a pump housing 1 comprising a pump chamber 2 with cylindrical chamber walls. In the pump housing 1 , a shaft 10 is arranged to be rotatably mounted by means of a bearing 11 . An eccentric disk 12 with an eccentrically arranged crank pin 8 is fixed on the shaft 10 . The crankpin 8 engages in the center of a cylindrical orbital eccentric piston 3 designed as a piston sleeve.

[0037] The eccentric disc 12 influences the circular movement of the orbital eccentric piston 3 through the pump chamber 2 via the crank pin 8 , wherein the circumferential sliding contact of the orbital eccentric piston 3 with the cylindrical chamber wall is maintained. A guide groove 4 is provided in the track eccentric piston 3 , and the guide groove 4 slidably receives the anti-slip member 5 . The anti-slip member 5 is pivotally mounted at the free end in the pump chamber wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com