Inclined plate selective culture method and device for aerobic granular sludge

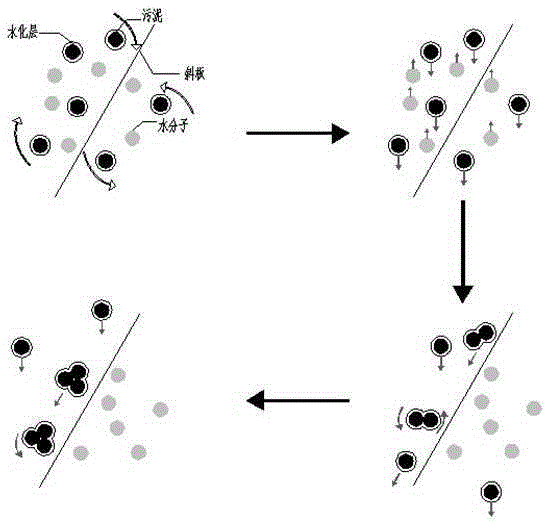

An aerobic granular sludge, selective cultivation technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problem of increasing the initial investment cost of the aerobic granular sludge process in the start-up time, and hindering the application of aerobic granular sludge in the start-up time , Long start-up time of aerobic granular sludge and other problems, to achieve the effect of shortening start-up time, shortening cultivation time, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

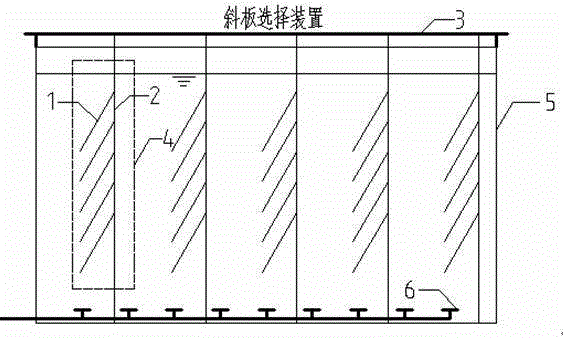

[0013] Embodiment 1: as figure 2 and image 3 As shown, the inclined plate 1 in the inclined plate selective cultivation device for aerobic granular sludge involved in the present invention can be distributed in parallel along the vertical direction of the aerobic reactor 5 to form a plurality of longitudinal inclined plate groups 4, and fixed In reactor 5, the formation of aerobic sludge particles is promoted. The present invention proposes that the area of the inclined plate 1 in the unit volume of the reactor 5 is controlled at 5 ~ 30m 2 Inclined board / 1m 3 Within the range of the pool capacity, and the ratio of the sum of the projected areas of each set of inclined plates 1 on the bottom of the reactor 5 to the area of the bottom of the reactor 5 should be controlled within the range of 3% to 30%. In this embodiment, the area of the inclined plate 1 in the unit volume of the reactor 5 is set as 10m 2 Inclined board / 1m 3 Pool capacity, the ratio of the sum of th...

Embodiment 2

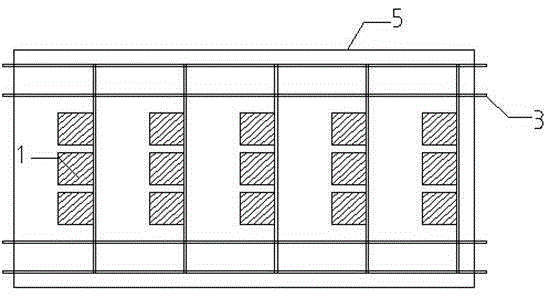

[0015] Embodiment 2: as Figure 4 As shown, the form of the inclined plate group 4 in the aerobic reactor 5 can be various, and a plurality of inclined plates 1 can be fixed in the reactor 5 through the support rods 2 in the horizontal direction. And the formation of aerobic granular sludge can play the same role. Other setting parameters are the same as embodiment 1.

[0016] In an aerobic reaction tank 5, a sloping plate selection culture device is installed according to embodiment 1 or embodiment 2, and the inoculated sludge is put into the tank so that the initial sludge concentration is within the range of 3500 ~ 4500mg / L, and the tank is passed into the well by the water inlet pipe. The sewage to be treated by the oxygen reaction tank 5 makes the sludge aggregate together while degrading the pollutants, and accelerates the formation of aerobic granular sludge.

[0017] After the aerobic reaction tank 5 was operated for 4 to 5 days, initial granular sludge with a partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com