Process for controlling medium and lower limit Mn content R350HT steel rail flash welding joint structure

A technology for R350HT and welded joints, which is applied in the field of controlling the microstructure of the R350HT rail flash welded joint with the lower limit Mn content, can solve the problems of increasing the martensite content in the joint, and achieve the effect of simple control process and good prospect of popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

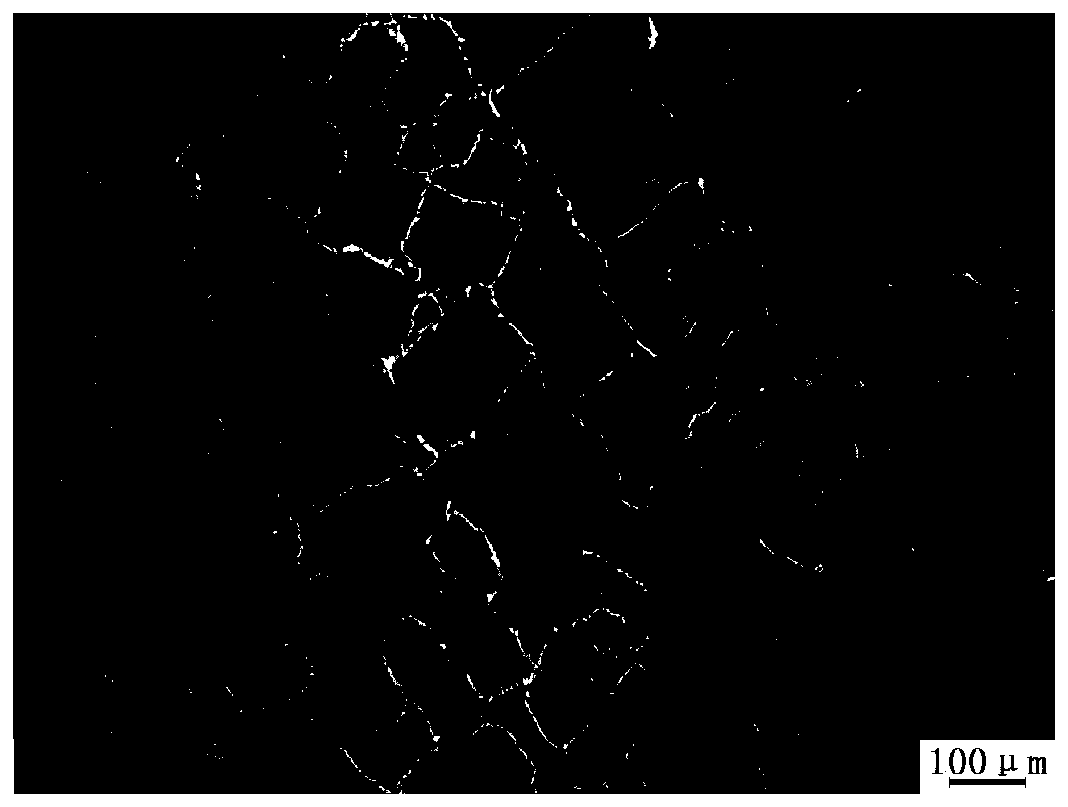

Image

Examples

Embodiment 1

[0029] The heat input is 5.6MJ, the flash welding process is 12.8mm, and the mass fraction of Mn is 0.85%, and the mass fraction of Cr is 0.10%. wt%, Cr 0.10~0.11wt%, Rm≥1175MPa, A≥9%, tread hardness ≥350HB) for flash welding. After the flash welding is completed, directly place the joint in the air to cool down to room temperature naturally.

[0030] According to the EN 14587.2 standard, the joints obtained by the above welding process and post-welding treatment method were inspected and analyzed. The microstructure of the rail head and the rail foot on the center plane of the joint was pearlite, and no harmful structures such as martensite were found; except for softening The hardness of the joints outside the area is all within the range of the average hardness of the base metal -30HV~+60HV; the three-point bending static bending test is 2000kN continuously, and the maximum deflection is 26.3mm; the three-point support physical fatigue test is 5 million times unbroken, and ...

Embodiment 2

[0032] The flash welding process with heat input of 5.0MJ and upsetting amount of 12.0mm is adopted, and the European standard R350HT heat-treated steel rail with a mass fraction of Mn of 0.95% and a mass fraction of Cr of 0.10% (C content is in the middle and lower limits, Si≤0.30 wt%, Cr 0.10~0.11wt%, Rm≥1175MPa, A≥9%, tread hardness ≥350HB) for flash welding. After the flash welding is completed, directly place the joint in the air to cool down to room temperature naturally.

[0033] According to the EN 14587.2 standard, the joints obtained by the above welding process and post-welding treatment method were inspected and analyzed. The microstructure of the rail head and the rail foot on the center plane of the joint was pearlite, and no harmful structures such as martensite were found; except for softening The hardness of the joints outside the area is all within the range of the average hardness of the base metal -30HV~+60HV; the three-point bending static bending test is ...

Embodiment 3

[0035] The heat input is 7.0MJ, the flash welding process is 14.5mm, and the mass fraction of Mn is 0.91%, and the mass fraction of Cr is 0.11%. wt%, Cr 0.10~0.11wt%, Rm≥1175MPa, A≥9%, tread hardness ≥350HB) for flash welding. After the flash welding is completed, directly place the joint in the air to cool down to room temperature naturally.

[0036] According to the EN 14587.2 standard, the joints obtained by the above welding process and post-welding treatment method were inspected and analyzed. The microstructure of the rail head and the rail foot on the center plane of the joint was pearlite, and no harmful structures such as martensite were found; except for softening The hardness of the joints outside the area is within the average hardness of the base metal -30HV~+60HV; the three-point bending static bending test is 2000kN continuously, and the maximum deflection is 26.5mm; the three-point support physical fatigue test is 5 million times unbroken, and all indicators ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com