Patents

Literature

67results about How to "Guaranteed Low Temperature Performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

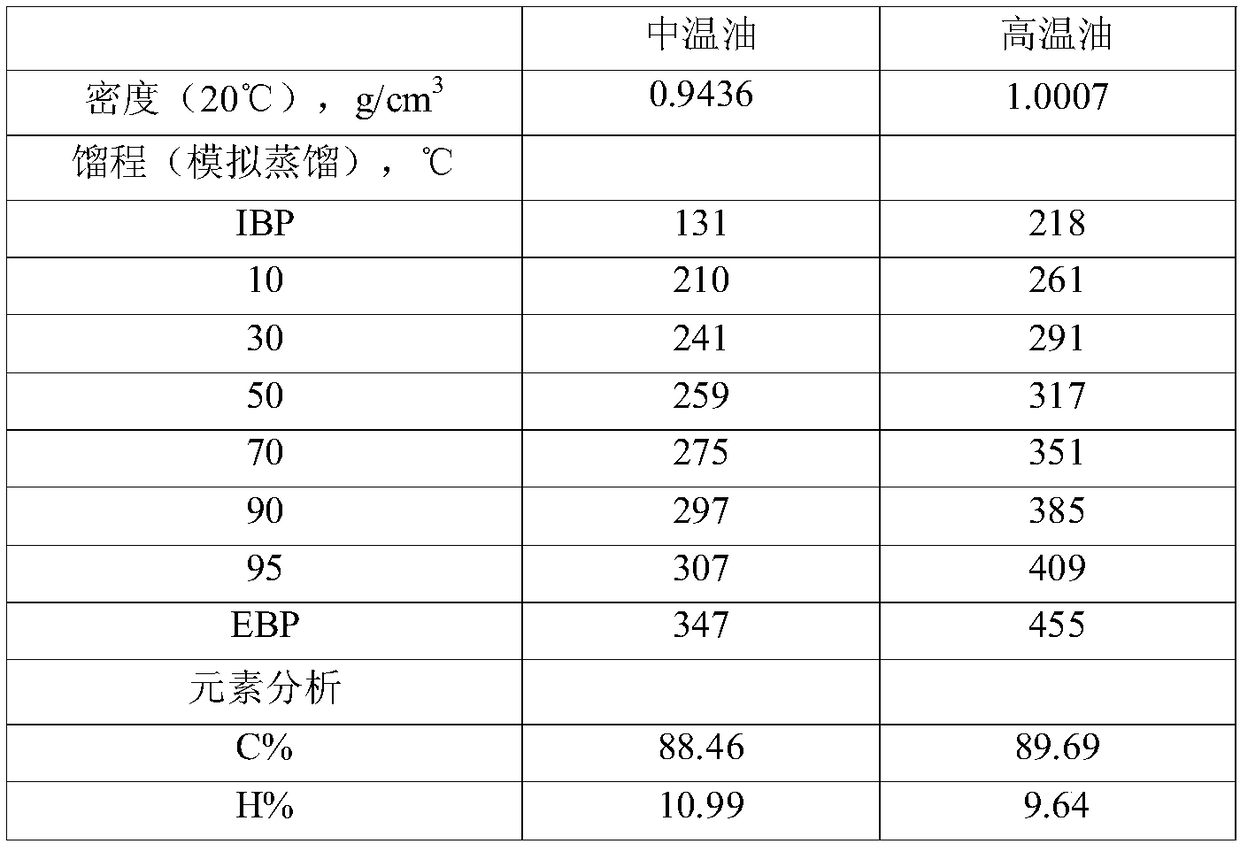

Method for hydrogenation of medium-low temperature coal tar to produce large-specific weight aviation kerosene

ActiveCN103789034AImprove featuresExcellent carbon deposition performanceTreatment with hydrotreatment processesKeroseneFractionation

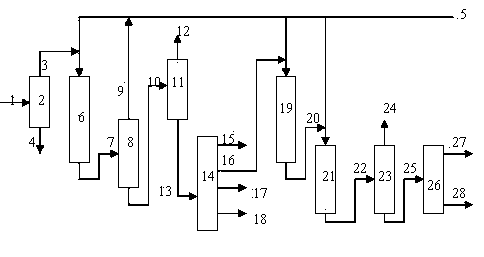

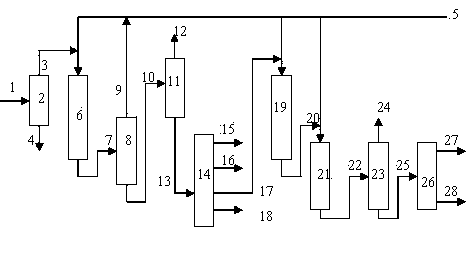

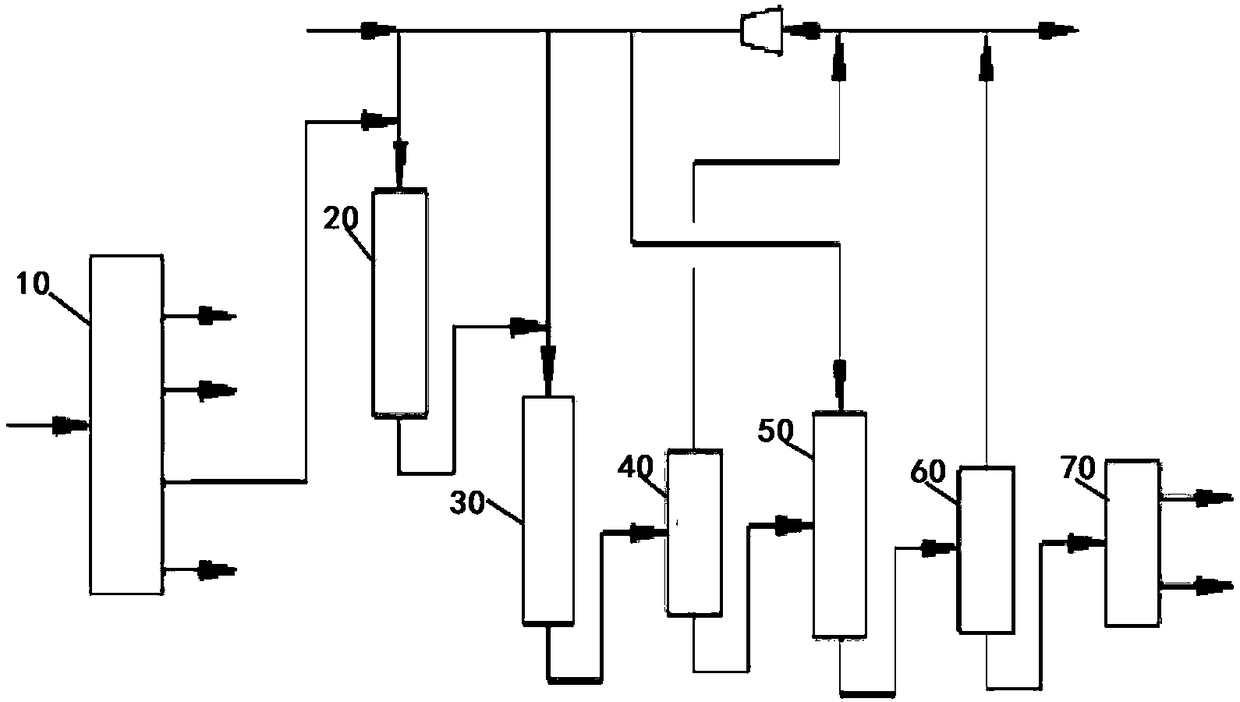

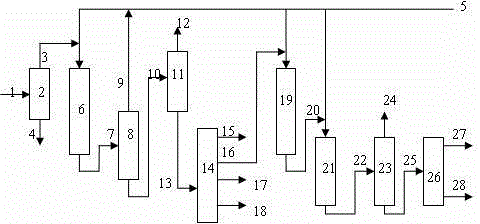

The invention discloses a method for hydrogenation of medium-low temperature coal tar to produce large-specific weight aviation kerosene. The method includes: fractionating the medium-low temperature coal tar to obtain light fraction and heavy fraction, mixing the light fraction with hydrogen and leading the mixture into a hydrotreating reaction area to contact a hydrogenation protective catalyst and a hydrofining catalyst in order to undergo hydrogenation reaction; separating the hydrofining effluent, making the obtained liquid phase product enter a fractionating tower; bringing the 140-290DEG C kerosene fraction obtained by fractionation into a hydro-upgrading reaction area where a hydro-upgrading catalyst containing amorphous aluminium silicon and modified Y zeolite is adopted, and performing hydro-upgrading reaction in the presence of hydrogen; subjecting the hydro-upgrading effluent into a hydrofinishing reaction area to undergo hydrofinishing reaction, and separating the hydrofinishing product to obtain the large-specific weight aviation kerosene. The method provided by the invention adopts the medium-low temperature coal tar as the raw material to maximumly produce the large-specific weight aviation kerosene with the advantages of high density, volume, high volume calorific value, low aromatic hydrocarbon content, and good low temperature performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for Enhancing High Temperature and Low Temperature Resistance of Aluminum Electrolytic Capacitors

InactiveCN102280257AGuaranteed low temperature stabilityRaise the ratioElectrolytic capacitorsPhosphorous acidPhosphoric acid

The invention discloses a method for enhancing the high temperature resistance and low temperature resistance of an aluminum electrolytic capacitor, which includes the preparation of an electrolyte, and the electrolyte includes the following raw materials in parts by weight: main solvent: 48-80%; auxiliary solvent: 10-32%, solute : 15-30%, additives: 0.3-3.2%, wherein, the solvent composed of the main solvent and the auxiliary solvent is a liquid with low saturated vapor pressure; the solute is tetramethylammonium maleate, ammonium adipate, triethylamine, One or more of 1,2-dimethylimidazolium phosphoric acid and phosphorous acid. Due to the selection of solvents with low saturated vapor pressure, the ratio of solutes is increased to ensure that the electrolyte does not condense at low temperature and the solutes do not precipitate; adding hydrogen absorbing agents and water suppressing agents reduces the internal pressure of the product; adding inhibitors and low leakage agents, The occurrence of high-temperature characteristic defects such as too fast recovery of electric leakage is prevented; the invention can also effectively ensure the low-temperature stability of the electrolyte, and provide guarantee for the stable operation of the LED driving power supply.

Owner:ZHAOQING BERYL ELECTRONICS TECH

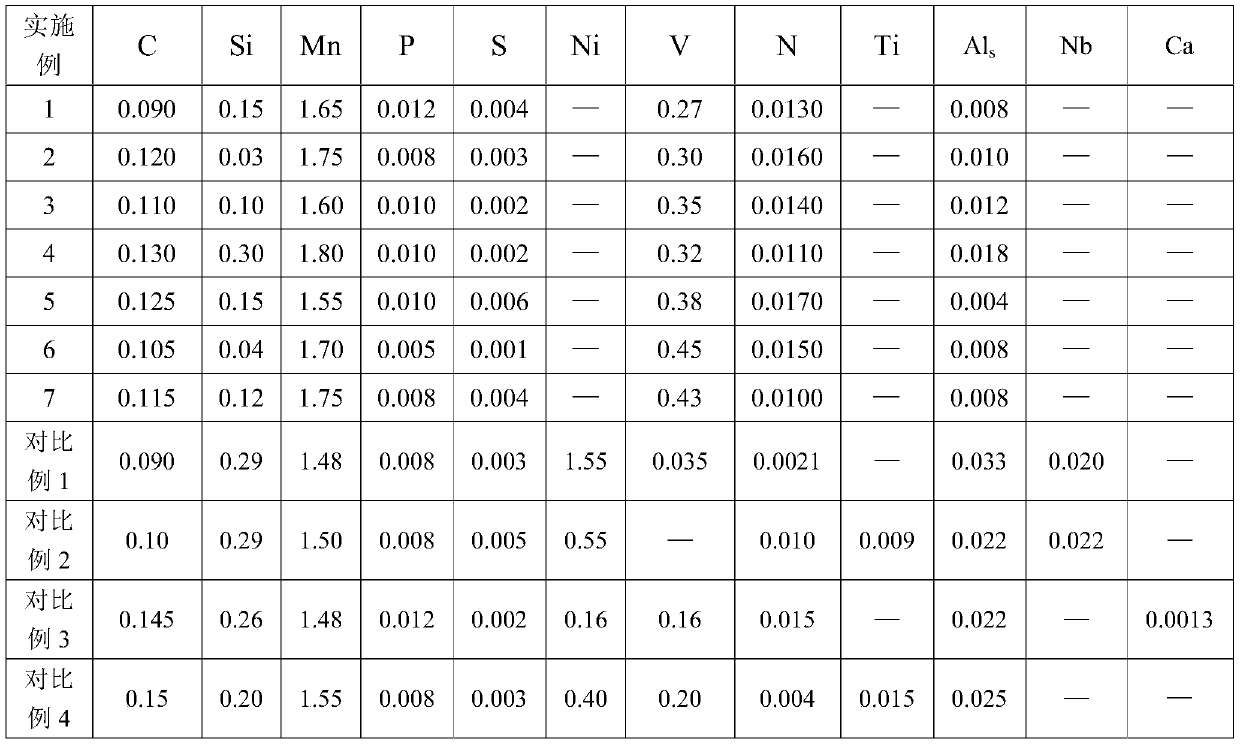

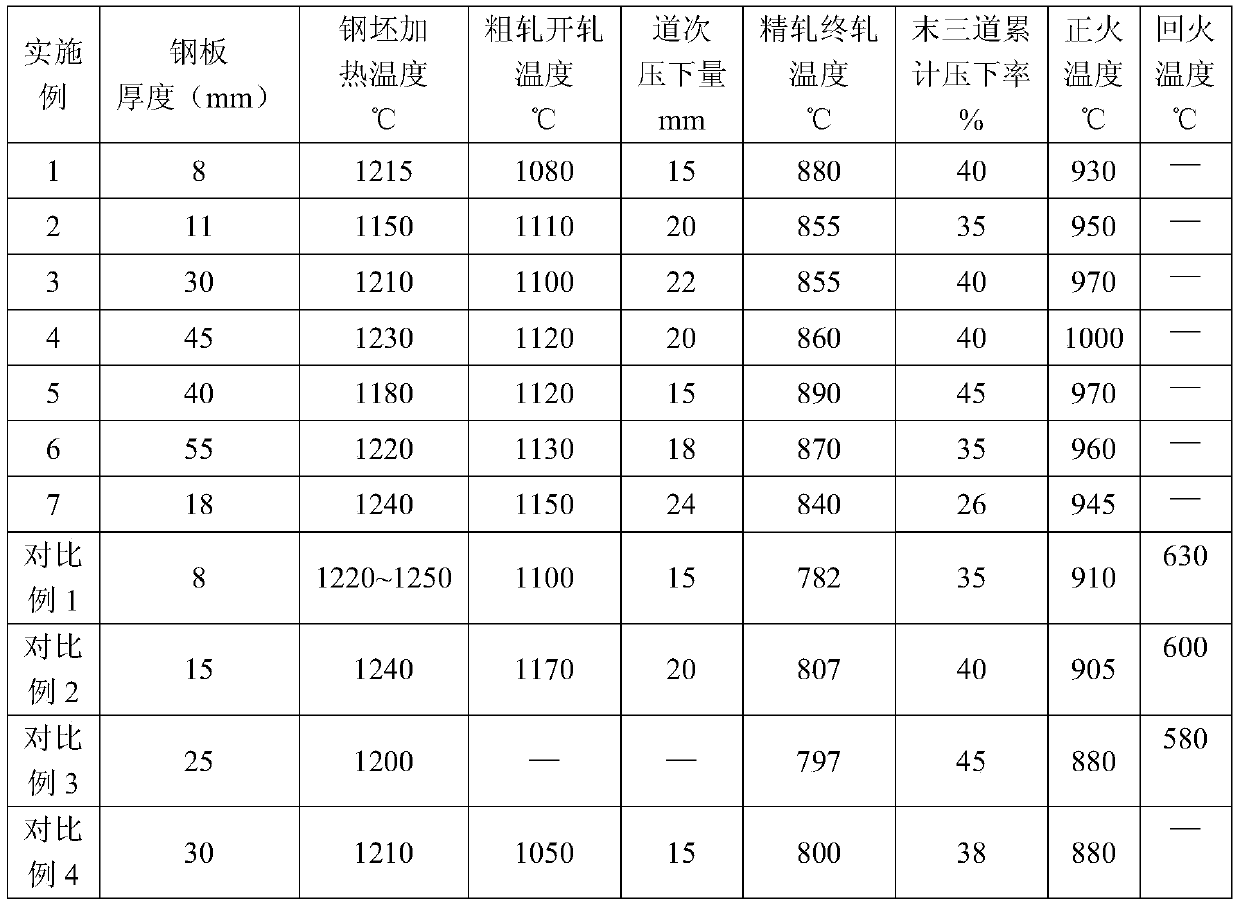

Steel plate for low-temperature pressure container and manufacturing method thereof

ActiveCN107937805AImprove mechanical propertiesGood welding performanceChemical compositionEconomic benefits

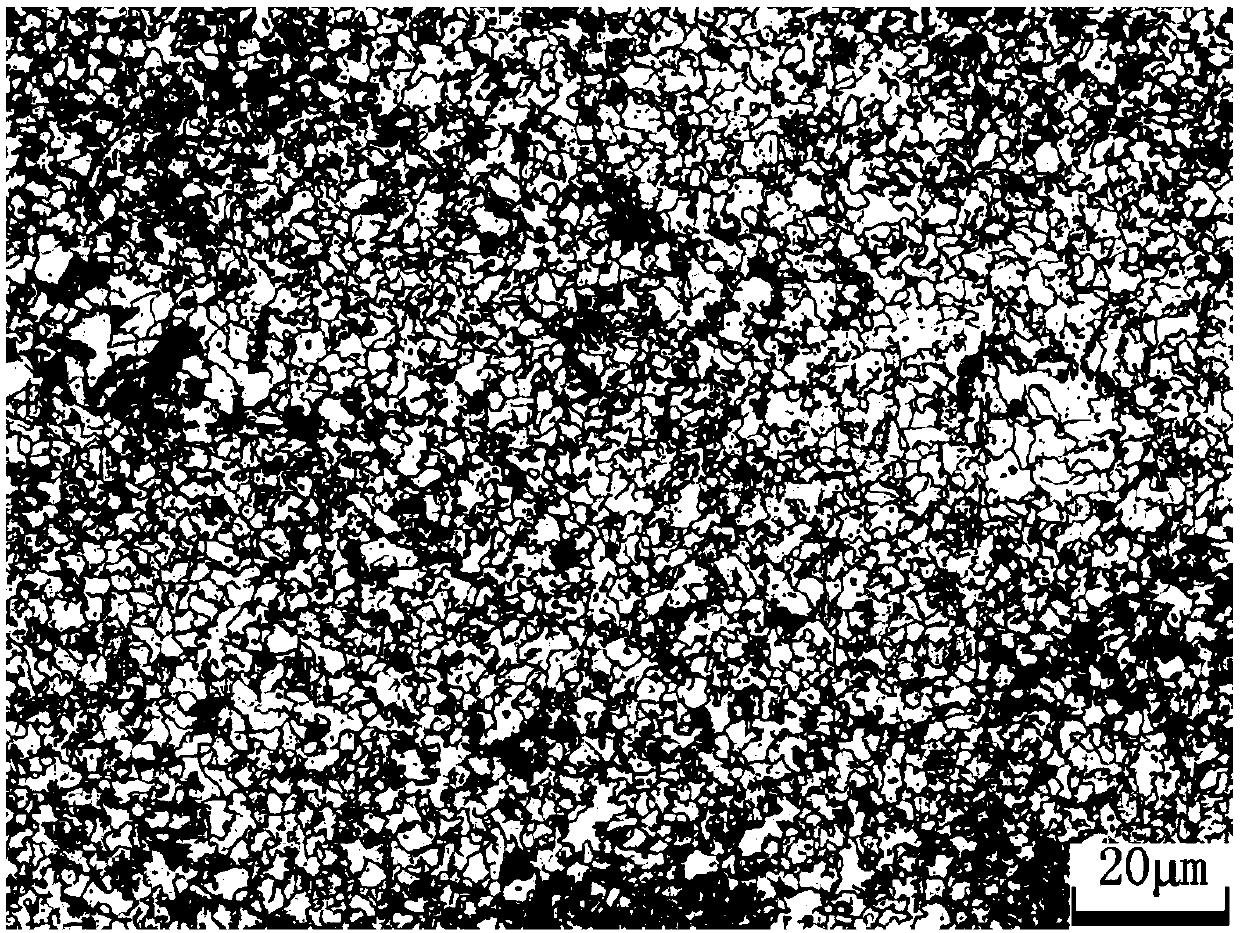

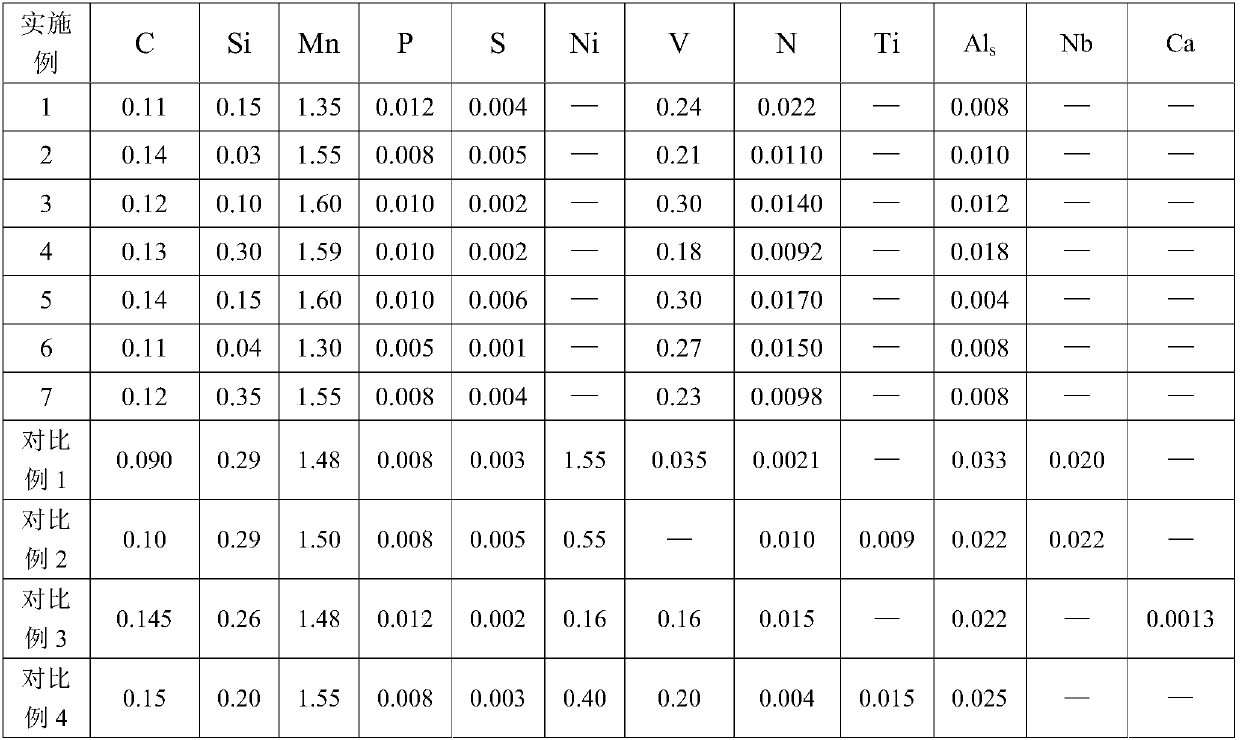

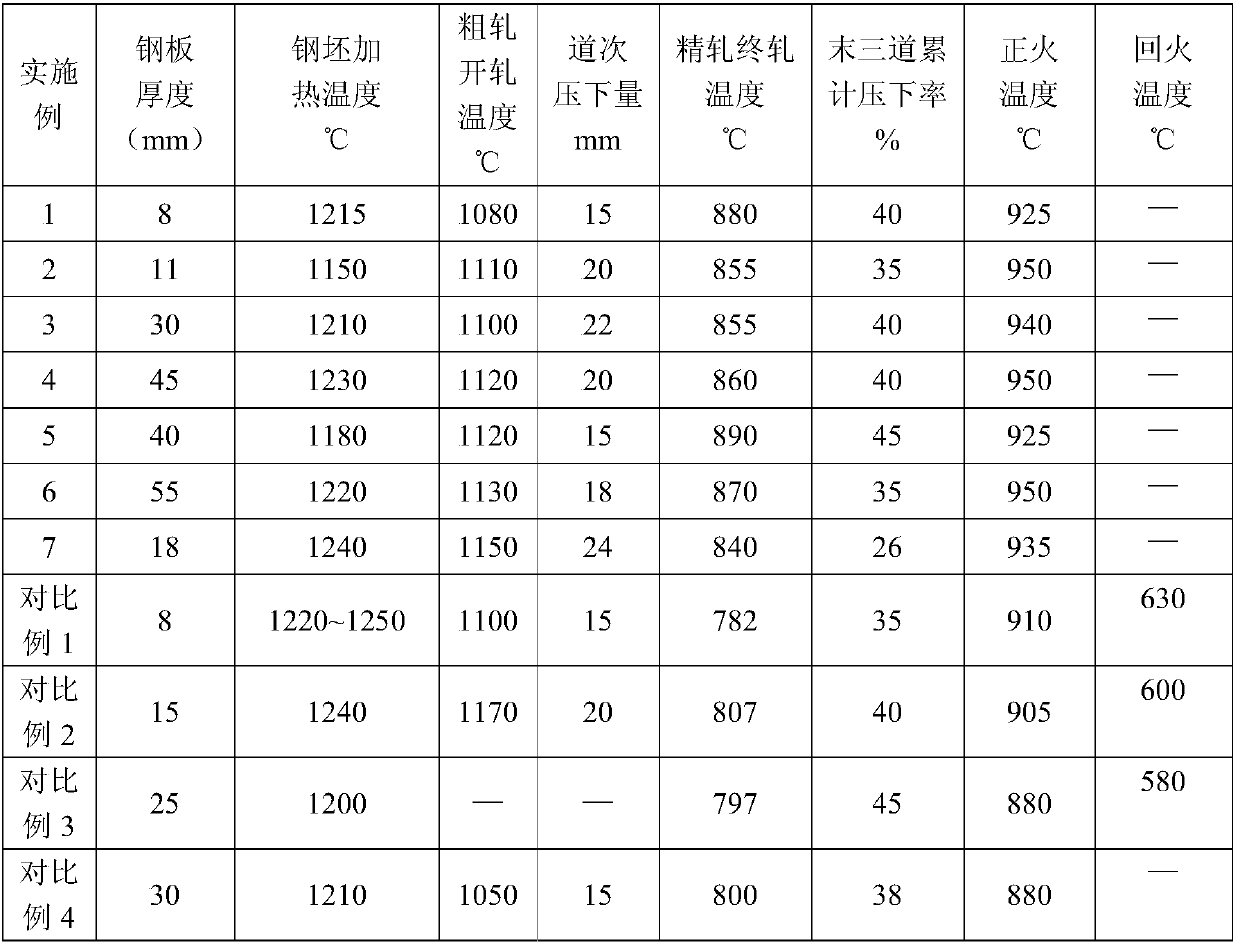

The invention discloses a steel plate for a low-temperature pressure container and a preparation method of the steel plate, the steel comprises the chemical components of, by weight, 0.110-0.140% of C, less than or equal to 0.15% of Si, 1.30-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.21-0.30% of V, 0.0090-0.0220% of N, less than or equal to 0.020% of Alt,and the balance Fe and inevitable impurities, and meanwhile, the components satisfy the conditions that V / C is greater than or equal to 1.6 but smaller than or equal to 2.8 and V / (C+Si) is greater than or equal to 0.9 but smaller than or equal to 1.25 simultaneously. According to the steel plate for the low-temperature pressure container and the manufacturing method thereof, the steel strength ishigh, the low-temperature impact toughness is good, KV<2> is greater than or equal to 100 J at -70 DEG C, an excellent manufacturing material is provided for the low-temperature pressure container, afoundation is laid for the large scale and light weight of the movable type pressure container, and the carrying efficiency and the economic benefit of the movable type pressure container are greatlyimproved.

Owner:武汉钢铁有限公司

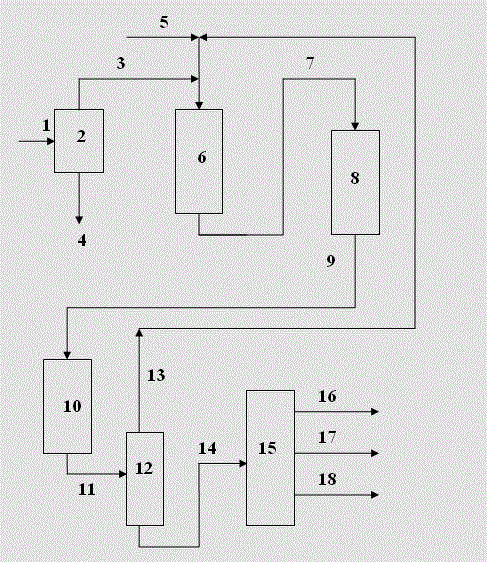

Method for hydrogenation of medium-low temperature coal tar to produce refrigerator oil base oil

ActiveCN103789032AImprove featuresImprove the lubrication effectTreatment with hydrotreatment processesBase-materialsFractionationRefrigerated temperature

The invention discloses a method for hydrogenation of medium-low temperature coal tar to produce refrigerator oil base oil. The method includes: fractionating the medium-low temperature coal tar to obtain light fraction and heavy fraction, mixing the light fraction with hydrogen and leading the mixture into a hydrotreating reaction area to contact a hydrogenation protective catalyst and a hydrofining catalyst in order to undergo hydrogenation reaction; separating the hydrofining effluent, making the obtained liquid phase product enter a fractionating tower; bringing the 320-350DEG C diesel fraction obtained by fractionation into a hydro-upgrading reaction area where a hydro-upgrading catalyst containing amorphous aluminium silicon and modified Y zeolite is adopted, and performing hydro-upgrading reaction in the presence of hydrogen; subjecting the hydro-upgrading effluent into a hydrofinishing reaction area to undergo hydrofinishing reaction, and separating the hydrofinishing product to obtain the refrigerator oil base oil. The method provided by the invention adopts the medium-low temperature coal tar as the raw material to produce the refrigerator oil base oil with the characteristics of good low-temperature fluidity, corrosiveness, intersolubility with refrigerant and oxidation stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

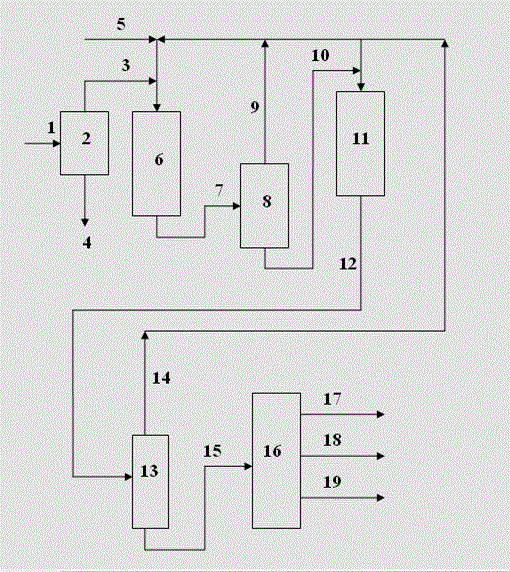

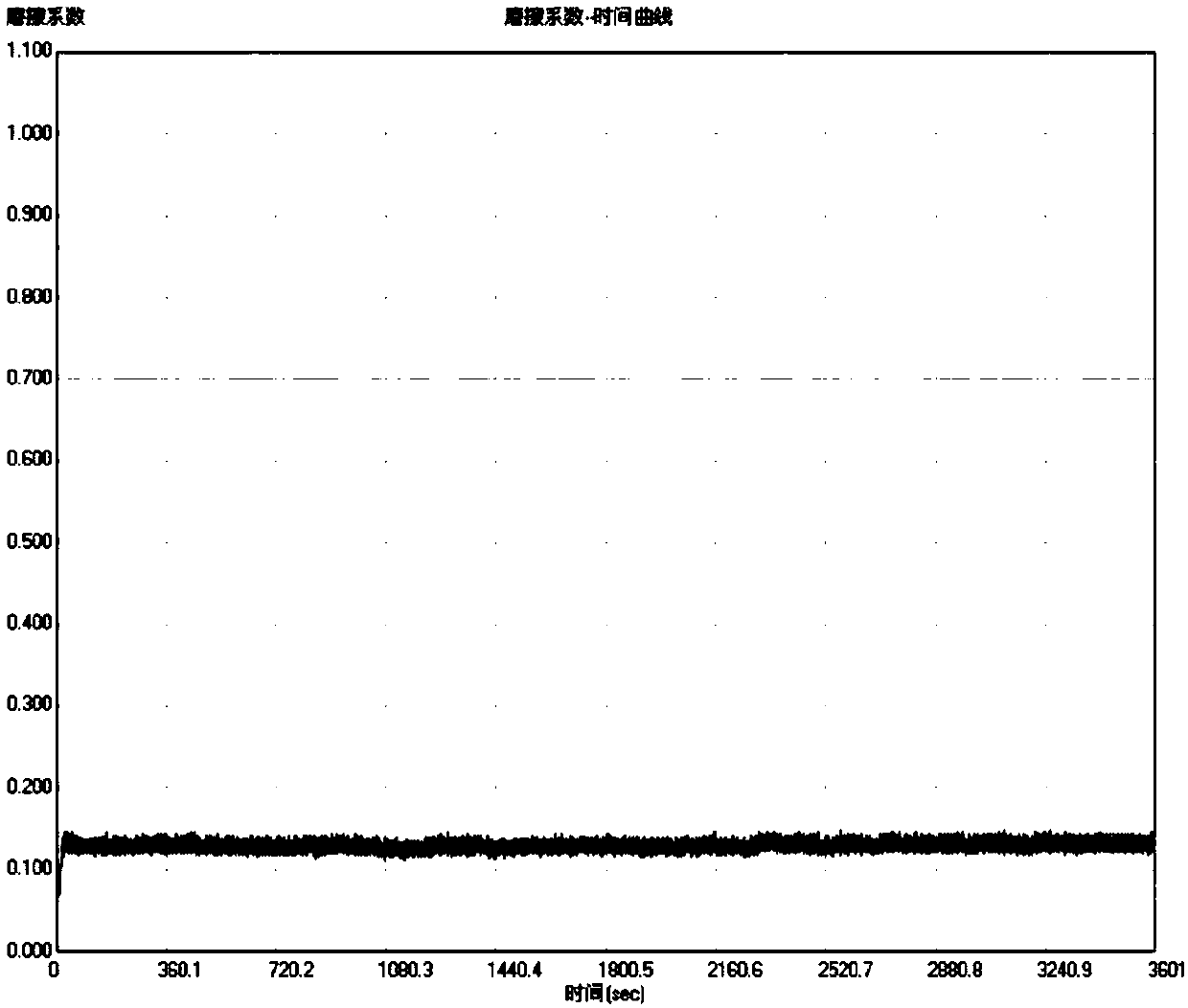

Production method for environment-friendly rubber filling oil

ActiveCN104593065ALow hydrogenation activityHigh content of hydrogenated componentsTreatment with hydrotreatment processesHydrogenAmorphous silicon

The invention discloses a method for producing environment-friendly rubber filling oil base oil through hydrogenation of catalytic slurry oil. The method comprises the following steps: fractionating the catalytic slurry oil so as to obtain a light fraction and a heavy fraction and allowing the light fraction to be mixed with hydrogen, then enter a hydrotreating reaction zone and successively contact with a hydrogenation protection catalyst, a hydrorefining catalyst and a hydroupgrading catalyst A for hydrogenation; allowing hydrogenation effluent to enter a hydroupgrading reaction zone where a hydroupgrading catalyst B containing amorphous silicon aluminum and modified Y zeolite and an after-refining catalyst are used, carrying out hydroupgrading reaction in the presence of hydrogen and saturating olefin produced in the process of hydroupgrading at the lower part of the hydroupgrading reaction zone; and separating hydroupgrading products so as to obtain environment-friendly rubber filling oil. The method provided by the invention uses the catalytic slurry oil as a raw material and can produce the environment-friendly rubber filling oil with good low-temperature fluidity, intersolubility with rubber, oxidation stability, safety and environmental protection property.

Owner:CHINA PETROLEUM & CHEM CORP +1

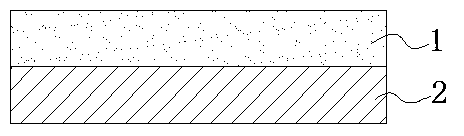

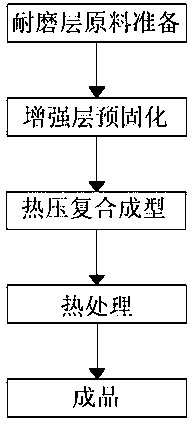

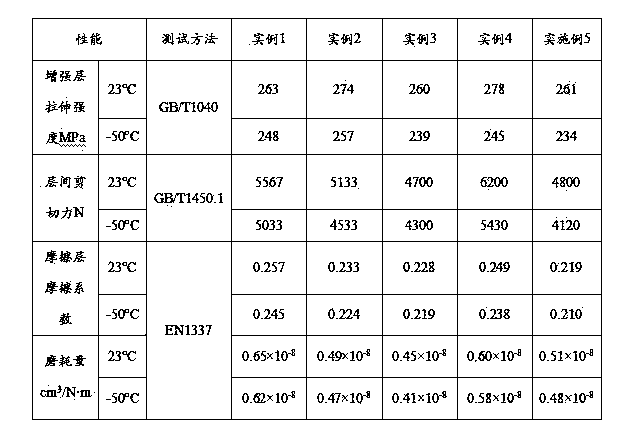

Composite friction plate and preparation method thereof

ActiveCN103694485ASolve the problem of low shear strengthGuaranteed Low Temperature PerformanceGlass fiberWear resistant

The invention discloses a composite friction plate and a preparation method thereof. The composite friction plate comprises a wear resistant layer and a reinforcement layer, wherein the wear resistant layer is composed of the components: adhesive resin, a fiber reinforced material and a friction performance adjusting material; and the reinforcement layer is composed of the component: glass fiber cloth reinforced phenolic resin. By using the composite friction plate, the problem of low shear strength between the wear resistant layer and the reinforcement layer in the composite friction plate is effectively solved, and the low temperature performance of the composite friction plate is ensured; and in addition, the composite friction plate is simple in production process, high in production efficiency and stable in product quality so as to be widely applied to the fields such as railways, subways, military industry, engineering machines and the like with relatively high requirements for mechanical strength and friction performance.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Water-proof sealing grease for optical instrument and preparation method thereof

The invention relates to the field of optical auxiliary materials, in particular to a water-proof sealing grease for an optical instrument and a preparation method thereof. The grease, actually a mixture, is characterized by comprising the raw materials in part by weight ratio: two kinds of silicone oils with kinematic viscosities of 0.65-3000 cst and 3000-500000 cst at 25 DEG C, a lipid solubility additive, a plasticizer, and an inorganic gelling agent. The method comprises the following steps: adding the two kinds of silicone oils with kinematic viscosities of 0.65-3000 cst and 3000-500000 cst at 25 DEG C, the lipid solubility additive and the plasticizer in a mixing tank for mixing for 0.5-3 h at the speed of 30-1000 r / min, adding the inorganic gelling agent after the mixture is uniformly mixed for further uniformly mixing, pouring into a plate for spreading, placing in a vacuum drying box for heating 3-8 h, taking out for cooling to an ambient temperature, grinding 3-5 times, and packing if passing the detection. The grease is used for the sealing and lubricating of the optical instruments, has good water resistance, does not dissolve in the water environment, dose not disperse, is strong in air tightness, small in volatility and good in lubricity, has the advantages of no corrosion to metal and glass and has high and low temperature resistance.

Owner:云南光电辅料有限公司

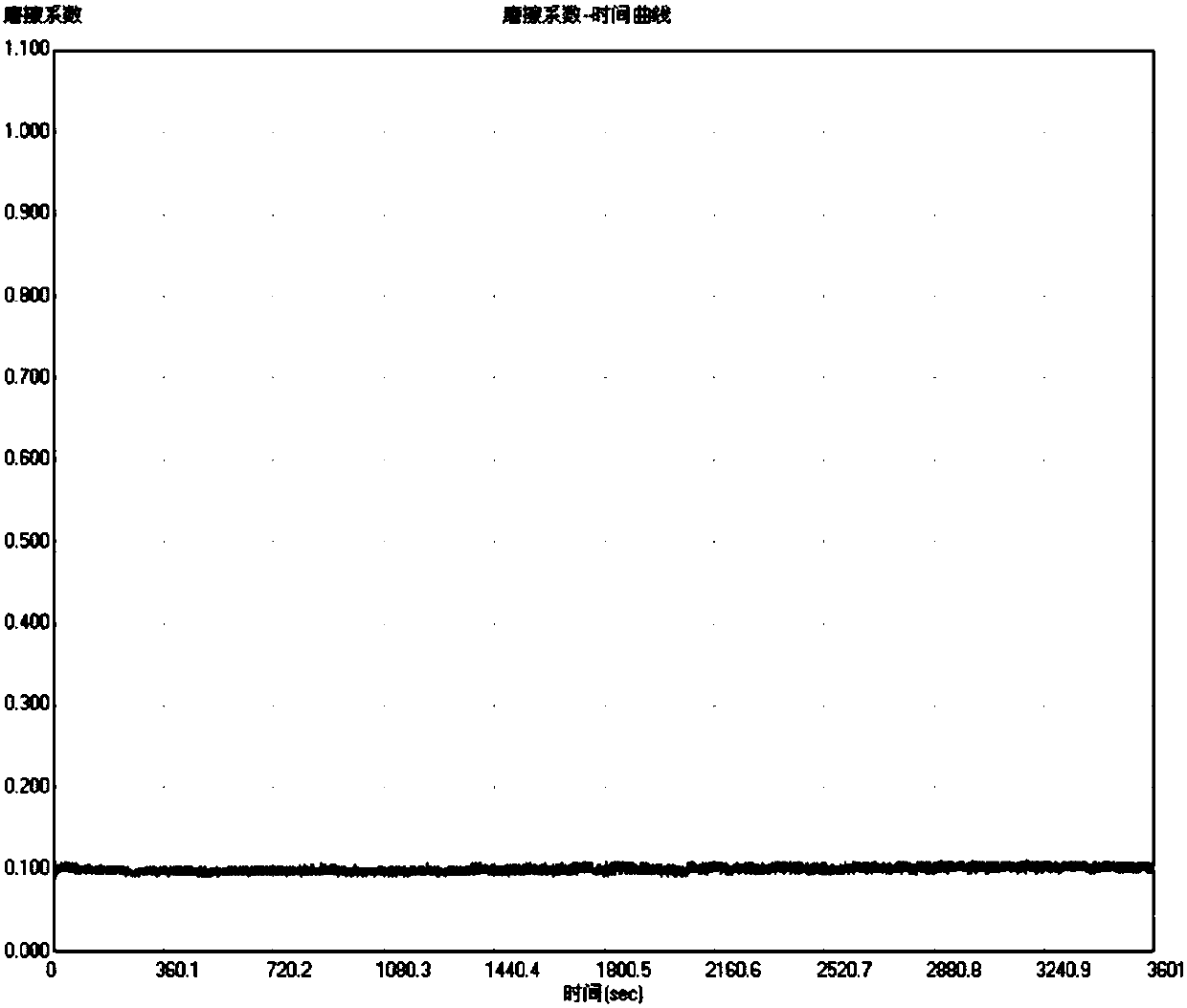

Method for producing white rubber filling oil base oil from catalytic slurry oil

ActiveCN104593067ALow hydrogenation activityHigh content of hydrogenated componentsTreatment with hydrotreatment processesHydrogenation reactionFractionation

The invention discloses a method for producing white rubber filling oil base oil through catalytic slurry oil hydrogenation. The method comprises the following steps: catalytic slurry oil is subjected to fractionation, such that a light fraction and a heavy fraction are obtained; the light fraction is mixed with hydrogen, and the mixture enters a hydrogenation treatment reaction zone; the mixture sequentially contacts a hydrogenation protection catalyst, a hydro-refining catalyst and a hydro-upgrading catalyst A, such that a hydrogenation reaction is carried out; a hydrogenation treatment effluent enters a hydro-upgrading reaction zone; a hydro-upgrading catalyst B containing amorphous silica-alumina and modified Y zeolite is adopted in the hydro-upgrading reaction zone, and a hydro-upgrading reaction is carried out under the existence of hydrogen; a hydro-upgrading effluent enters a hydro-finishing reaction zone, and is subjected to a hydro-finishing reaction; and a hydro-finishing product is separated, such that the rubber filling oil base oil is obtained. According to the invention, the catalytic slurry oil is adopted as a raw material, and can be used for producing the white rubber filling oil base oil with good low-temperature fluidity, good intersolubility with rubber, and good oxidation stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing environment-friendly rubber filling oil from medium-low temperature coal tar

ActiveCN104593066ALow hydrogenation activityLow modification activityTreatment with hydrotreatment processesHydrogenation reactionFractionation

The invention discloses a method for producing producing environment-friendly rubber filling oil from medium-low temperature coal tar. The method comprises the following steps: medium-low temperature coal tar is subjected to fractionation, such that a light fraction and a heavy fraction are obtained; the light fraction is mixed with hydrogen, and the mixture enters a hydrogenation treatment reaction zone; the mixture sequentially contacts a hydrogenation protection catalyst, a hydro-refining catalyst and a hydro-upgrading catalyst A, such that a hydrogenation reaction is carried out; a hydrogenation treatment effluent is separated such that gas and water are separated; an obtained liquid-phase product enters a hydro-upgrading reaction zone; a hydro-upgrading catalyst B containing amorphous silica-alumina and modified Y zeolite and a hydro-finishing catalyst are adopted in the hydro-upgrading reaction zone, and a hydro-upgrading reaction is carried out under the existence of hydrogen; olefin produced during the hydro-upgrading process is saturated at the lower part of the hydro-upgrading reaction zone; and the obtained hydro-upgrading product is separated, such that the environment-friendly rubber filling oil is obtained. According to the invention, the medium-low temperature coal tar is adopted as a raw material, and can be used for producing the environment-friendly rubber filling oil with good low-temperature fluidity, good intersolubility with rubber, good oxidation stability, good safety and good environment friendliness.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of rubber asphalt mixture

InactiveCN101462849AImproved adhesion and high temperature performanceGuaranteed Low Temperature PerformanceSolid waste managementRubberized asphaltPetroleum

The invention discloses a method for preparing a rubber asphalt mixture. The method comprises the following steps: adding tyre rubber powder into the road petroleum asphalt, and carrying out the stirring and reaction for 45 to 120 minutes to prepare the rubber asphalt; and adding N,N'-ethidence dioleamide into the heated stone material in the mineral aggregate, stirring the mineral aggregate evenly, then adding the rubber asphalt into the mineral aggregate, and stirring the mixture evenly to obtain the composite modified rubber asphalt mixture finished product. The obtained rubber asphalt mixture can simultaneously improve the high temperature performance and bonding performance of the rubber asphalt mixture.

Owner:TONGJI UNIV

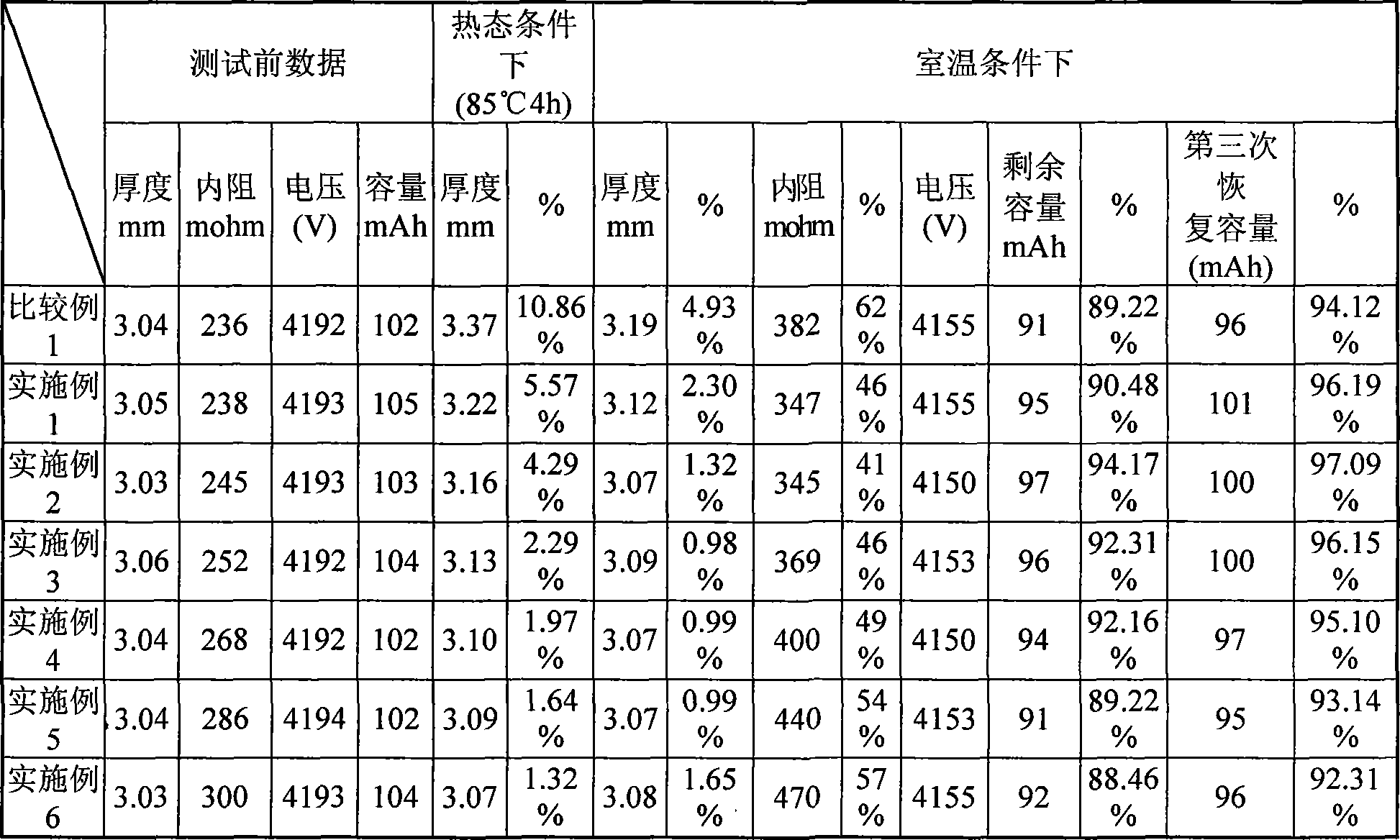

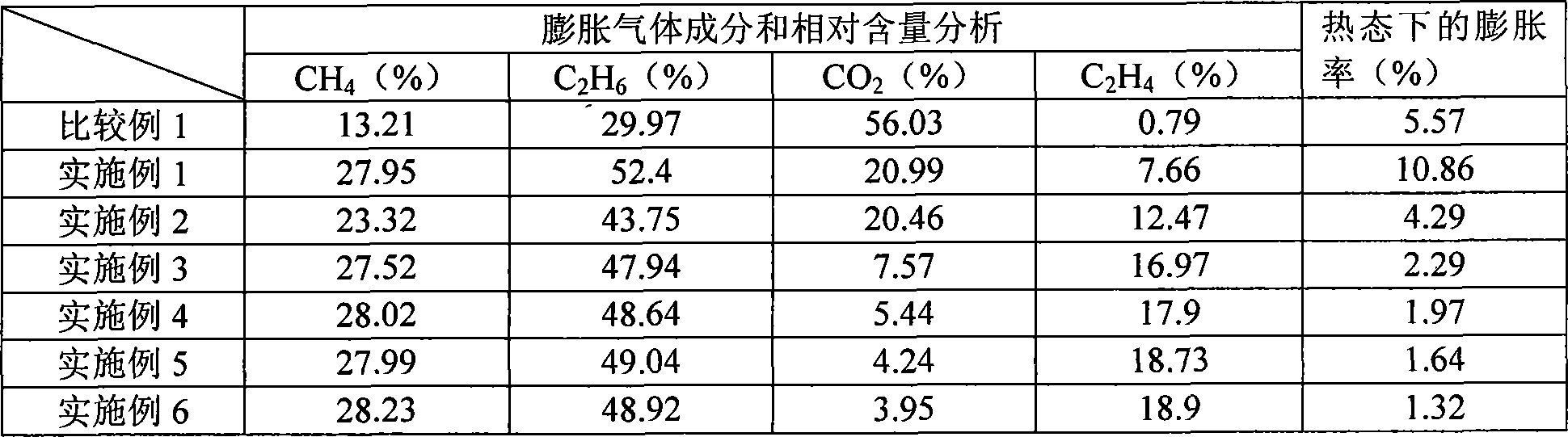

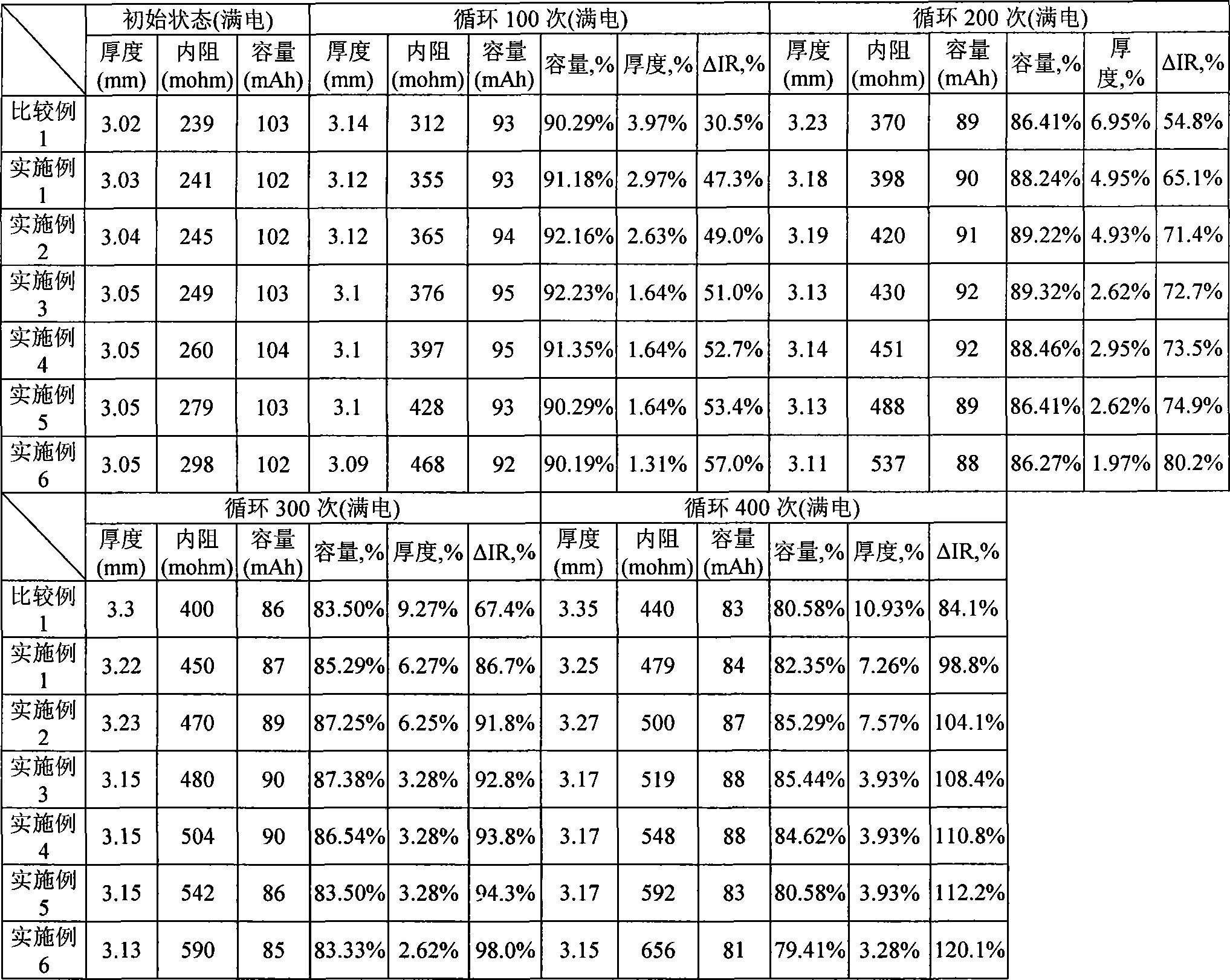

Mixed non water electrolyte additive for improving battery high-temperature performance

InactiveCN101170200AInhibit swellingIncrease capacityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsAcetic acidHigh temperature storage

The invention relates to a mixed type non-water electrolytic solution additive used for improving high temperature performance of a cell, which is characterized in that the additive comprises mixture of 1-propenyl phosphonic cyclic acid anhydride, ethyl acetate, as well as vinyl enthylene elayl carbonic ester, and is dissolved in the non-water electrolytic solution; the ratio of addition of the 1-propenyl phosphonic cyclic acid anhydride and the weight share of the non-water electrolytic solution is 0.05-5.0:100; the ratio of weight shares of the ethyl acetate and the non-water electrolytic solution is 0.05-5.0:100; the ratio of addition of the vinyl enthylene elayl carbonic ester and the non-water electrolytic solution is 0.05-5.0:100. The 1-propenyl phosphonic cyclic acid anhydride in the component of the invention can effectively inhibit expansion in the process of high-temperature storage and circulation through inhibit CO2 generated effect; at the same time, the vinyl enthylene elayl carbonic ester can improve the cell capacity under the conditions of high-temperature storage and circulation through effectively protecting SEI membrane. The addition agent can effectively improve the cell performance on high-temperature storage and high-temperature circulation, as well as make the cell maintain good low-temperature electric discharge characteristic.

Owner:TIANJIN LISHEN BATTERY

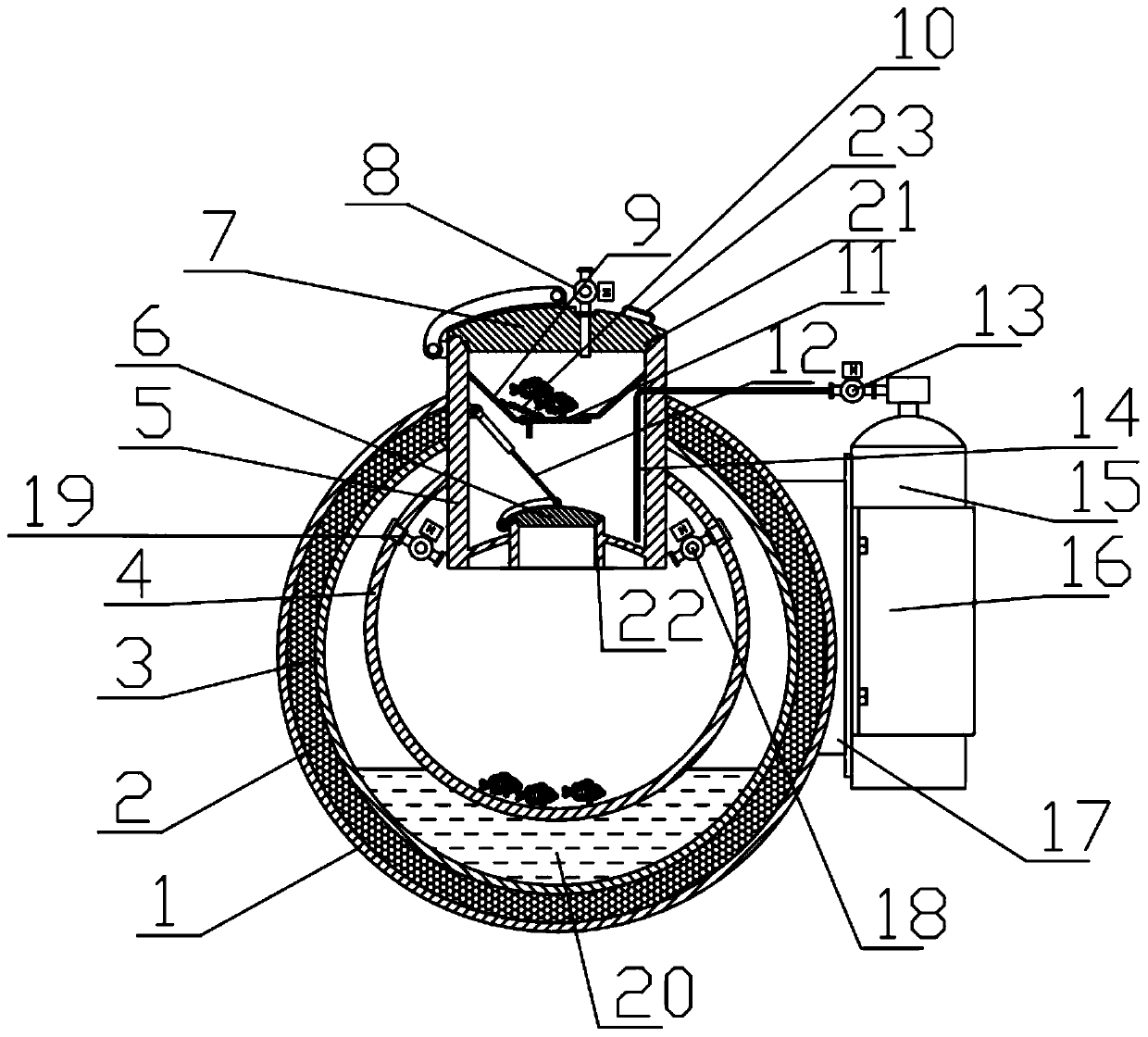

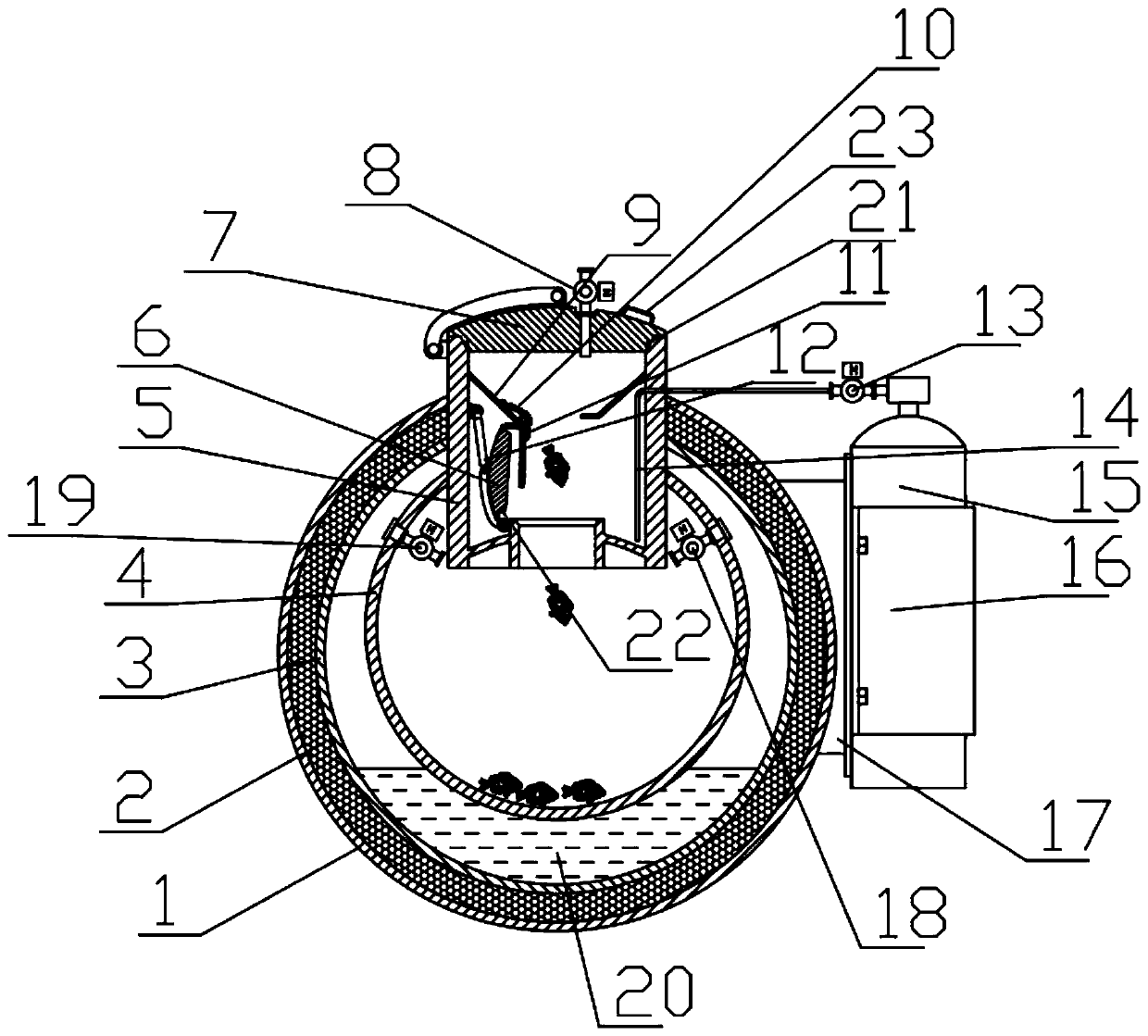

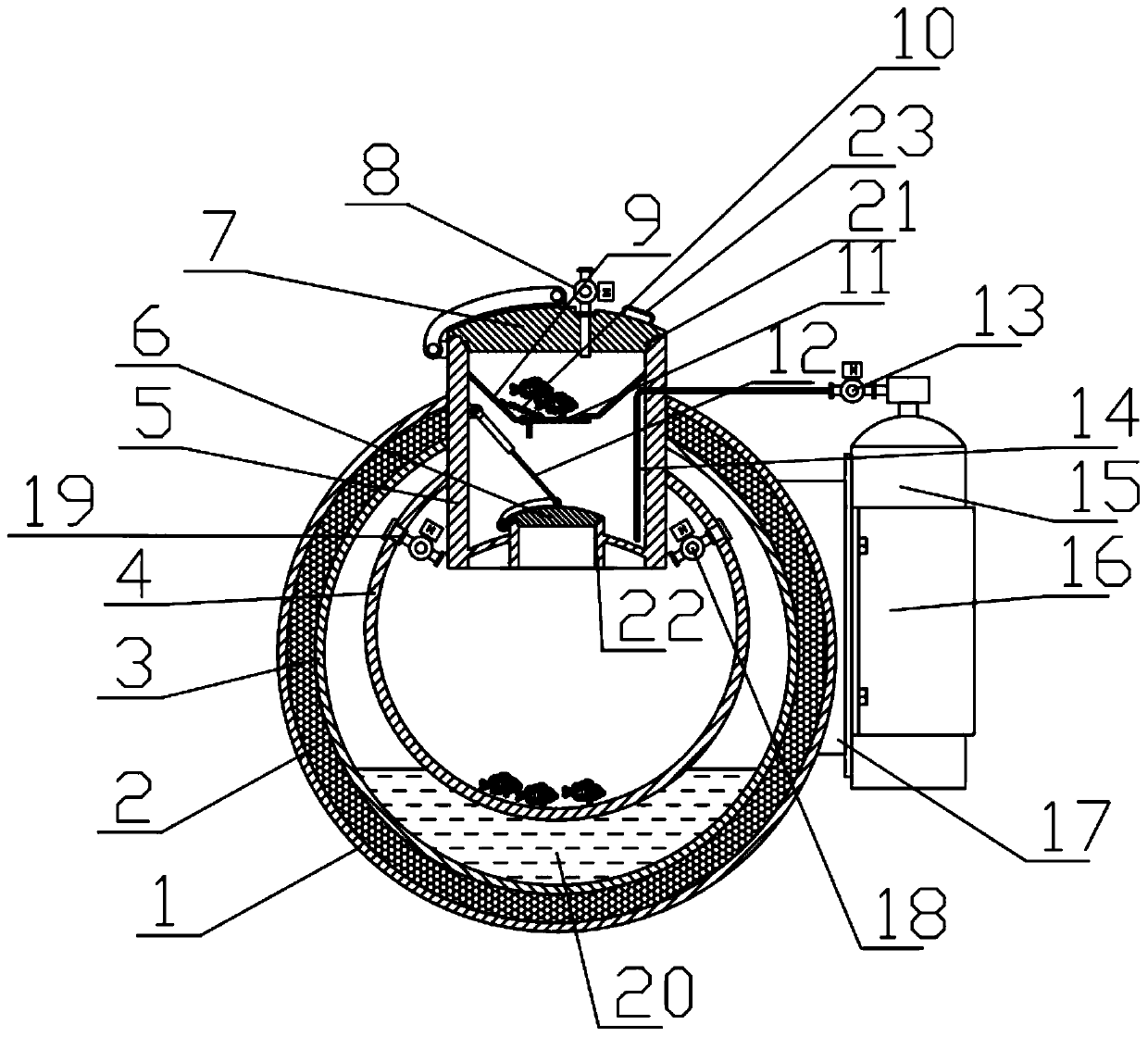

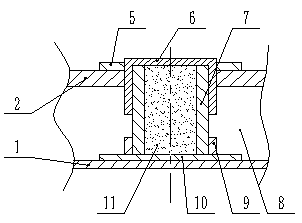

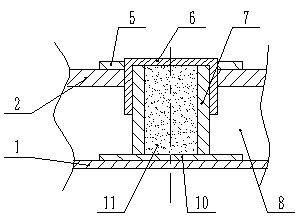

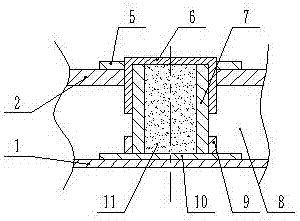

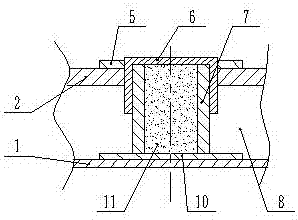

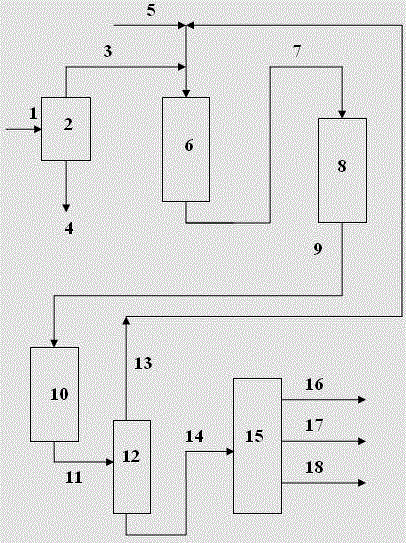

Biont low-temperature preservation device for deep submergence vehicles

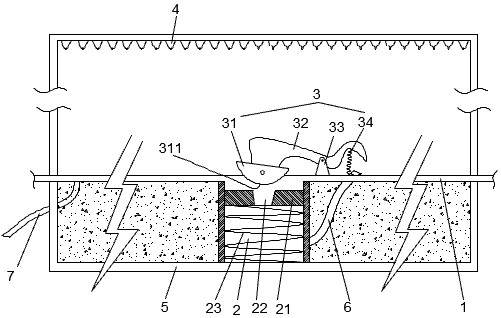

ActiveCN109911412AAchieve transferSolve cryopreservationClosuresDomestic cooling apparatusHydraulic cylinderEngineering

The invention relates to a biont low-temperature preservation device for deep submergence vehicles. The biont low-temperature preservation device for the deep submergence vehicles comprises a pressure-resistant surrounding wall with a hollow cylinder structure, a bottom hatch cover is arranged at the bottom in the pressure-resistant surrounding wall through a supporting frame structure, a hydraulic cylinder driving the opening and closing of the bottom hatch cover is arranged between the middle position outside a hatch of the bottom hatch cover and the inner wall of the pressure-resistant surrounding wall, the upper part of the inner wall surface of the pressure-resistant surrounding wall is provided with a conical guide cylinder, the bottom surface of the conical guide cylinder is provided with a tray through pin shafts, the tray is downwards opened, a baffle block is arranged at one end of the bottom of the tray, the upper part of the tray is connected with the inner wall surface ofthe conical guide cylinder through a tension spring, the top surface of the pressure-resistant surrounding wall is provided with a top hatch cover through a hinge mechanism, and the top hatch cover isprovided with an electric sea suction valve. The outer wall surface of the pressure-resistant surrounding wall is sequentially provided with, from outside to inside, an outer-layer pressure-resistantshell, an intermediate-layer pressure-resistant shell and an inner-layer pressure-resistant shell which are all in a hollow spherical structure. The biont low-temperature preservation device for thedeep submergence vehicles is reliable in working.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

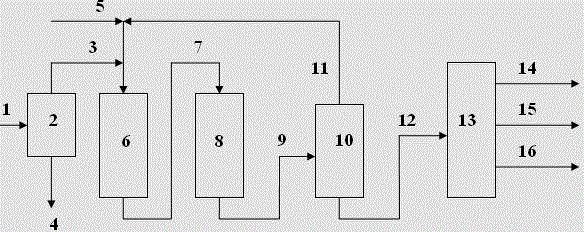

Transformer oil base oil and preparation method thereof

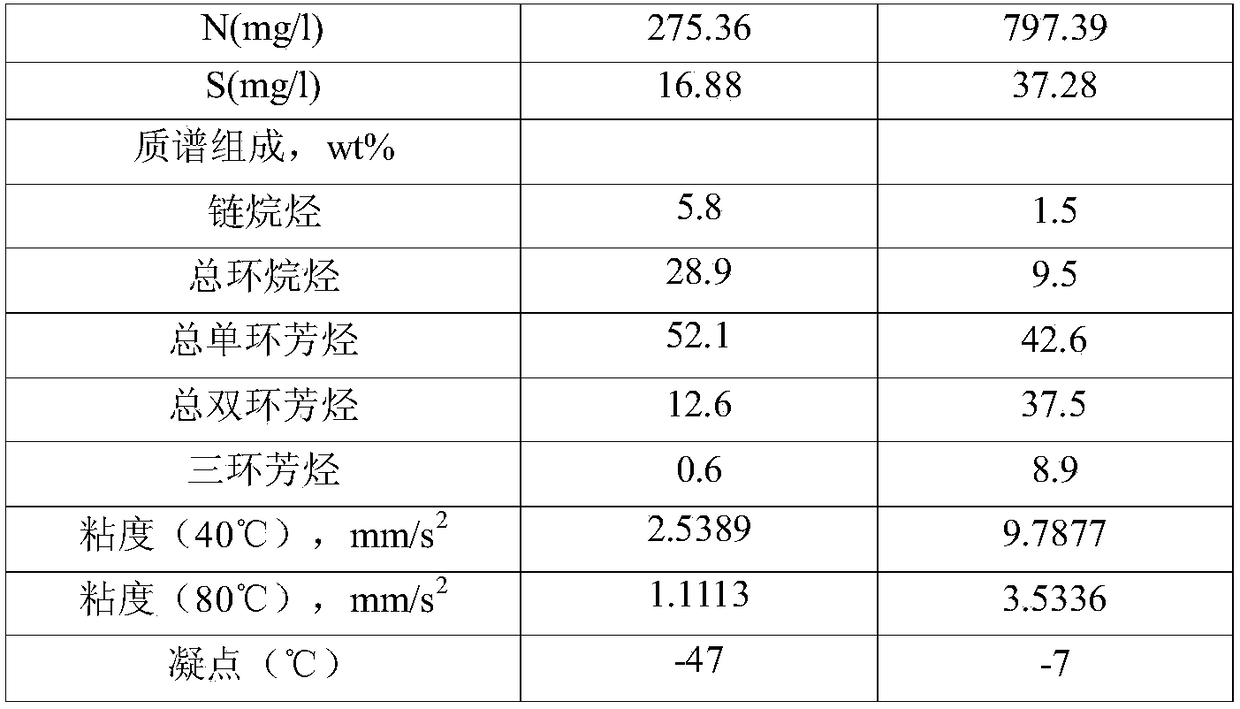

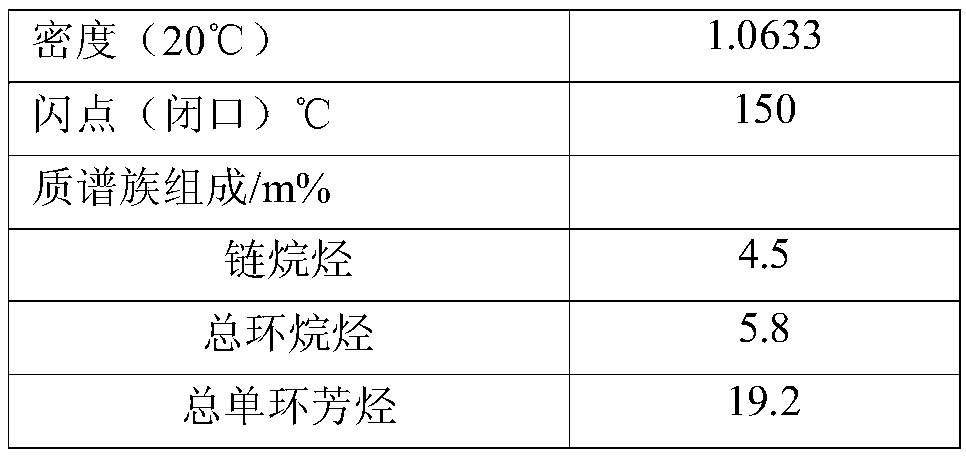

ActiveCN108977224AExtend the industrial chainReduce water contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsAlkaneDistillation

The invention provides a transformer oil base oil and a preparation method thereof. The preparation method comprises the following steps: 1) fractionating a coal direct liquefied oil to obtain a diesel fraction, wherein the distillation range of the diesel fraction is 290-330 DEG C; 2) performing hydrotreating reaction on the diesel fraction to obtain a hydrogenation product; 3) subjecting the hydrogenation product to a hydro-upgrading reaction to obtain a first transformer oil base oil; 4) subjecting the first transformer oil base oil to a hydrogenation replenishing reaction to obtain a second transformer oil base oil; wherein the coal direct liquefied oil comprises oil A and oil B, wherein the volume ratio of the oil A to the oil B is (1:1) to (1:10), wherein the oil A and the oil B bothcontain a certain amount of chain alkane, cycloalkane, monocyclic aromatic hydrocarbon, bicyclic aromatic hydrocarbon and tricyclic aromatic hydrocarbon, the sum of the contents of the components isequal to 100%. The preparation method has short process flow, low energy consumption, high target product yield and excellent performance.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Material for piston rod in ultra-low temperature reciprocating compressor and surface reinforcing method of material

ActiveCN107828945AGuaranteed room temperatureGuaranteed Low Temperature PerformanceMolten spray coatingEngineeringQuenching

The invention discloses a material for a piston rod in an ultra-low temperature reciprocating compressor and a surface reinforcing method of the material and belongs to the technical filed of materials of ultra-low temperature moving parts and surface reinforcing in equipment manufacturing industries. The material of the piston is obtained by means of the method that 1Ni9 steel forge pieces serveas a raw material and are sequentially subjected to performance heat treatment, finishing and stable treatment, wherein as for the performance heat treatment process, normalizing treatment is conducted at the temperature of 890-910 DEG C, primary quenching is conducted at the temperature of 810-830 DEG C, secondary quenching is conducted at the temperature of 660-680 DEG C, and tempering treatmentis conducted at the temperature of 570-590 DEG C. The surface of the material of the piston is sprayed with a WC-Co coating through a supersonic flame spraying technology. The material of the pistonrod and the coating quality meet the performance requirements of the parts under the ultra-low temperature, the difficult problem of selecting of the materials of the main parts such as the piston rodof the ultra-low temperature reciprocating compressor equipment and the surface reinforcing method is solved, and the foundation is laid for future better and quicker development of natural gas and hydrocarbon liquefaction, storage and conveying device equipment in China.

Owner:沈阳鼓风机集团往复机有限公司

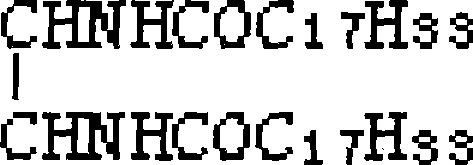

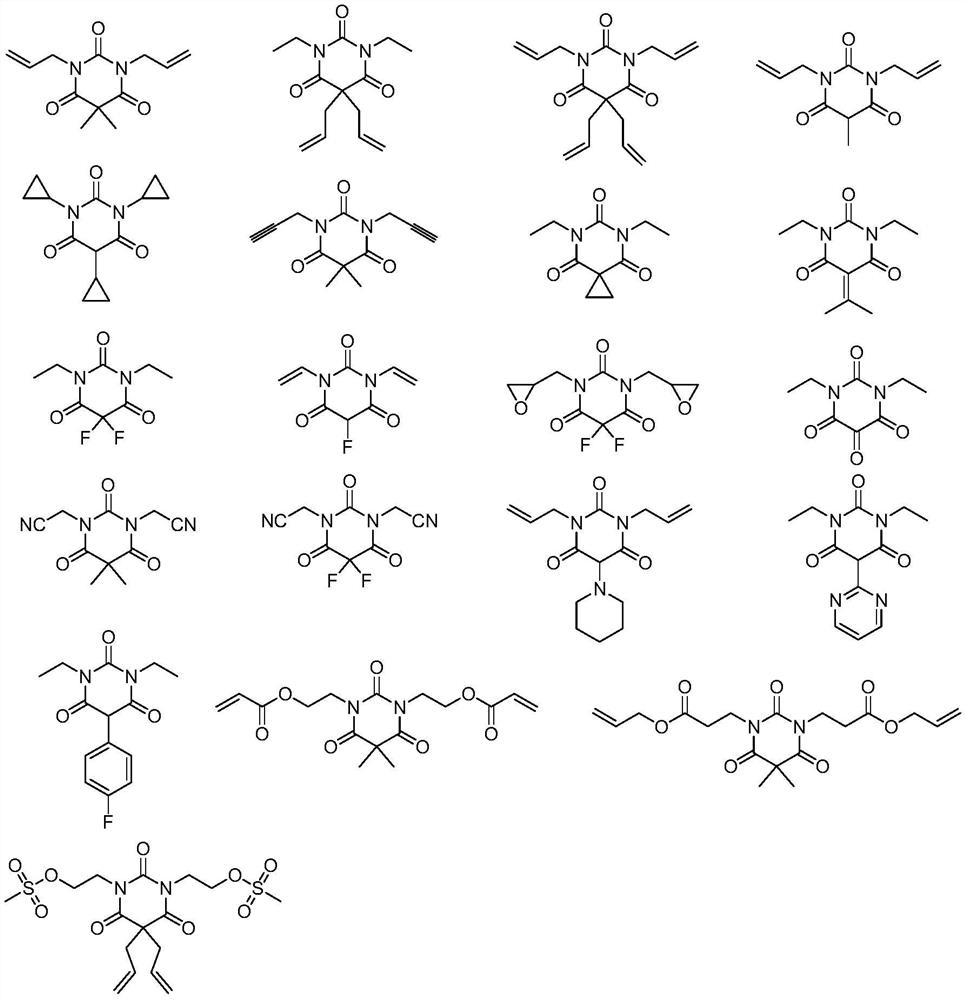

Additive for non-aqueous electrolyte of lithium ion battery and preparation method and application thereof

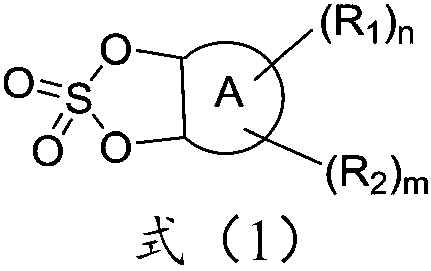

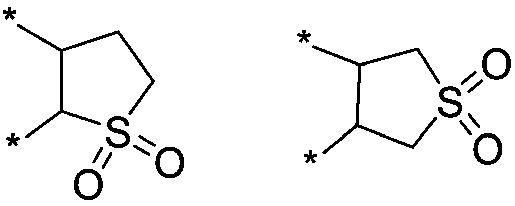

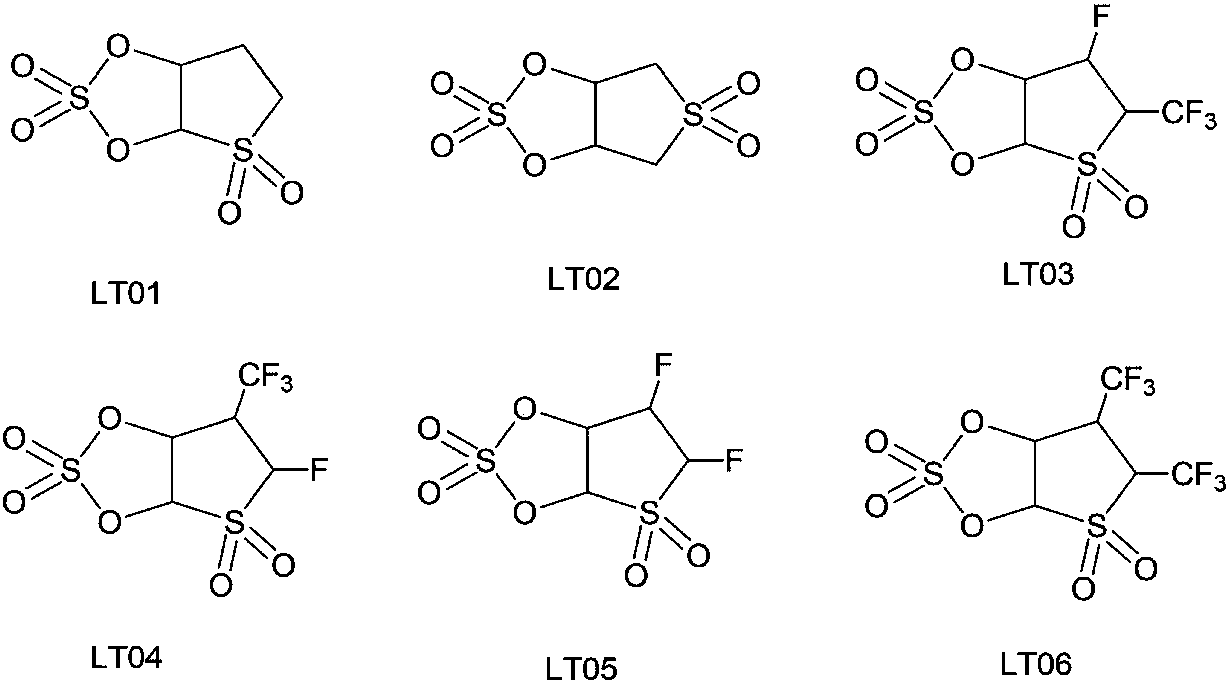

InactiveCN108550914AInitial capacity dropReduce bloatFinal product manufactureElectrolyte accumulators manufacturePhysical chemistryCharge discharge

The invention proposes an additive for a non-aqueous electrolyte of a lithium ion battery and preparation method and application thereof. The additive has the following molecular structure shown in aformula (1), wherein R1 and R2 respectively express fluoro group or trifluoromethyl, n and m are respectively 0, 1 or 2, A is selected from one of the following structures shown in the specification,and * expresses connection sites. After the additive is applied into the electrolyte of the lithium ion battery, the reduction of the initial capacity of the battery can be prevented, the initial discharging capacity is improved, the battery expansion after high-temperature placing is reduced, the charge-discharge performance of the battery is improved, and the cycle frequency is increased.

Owner:VALIANT CO LTD

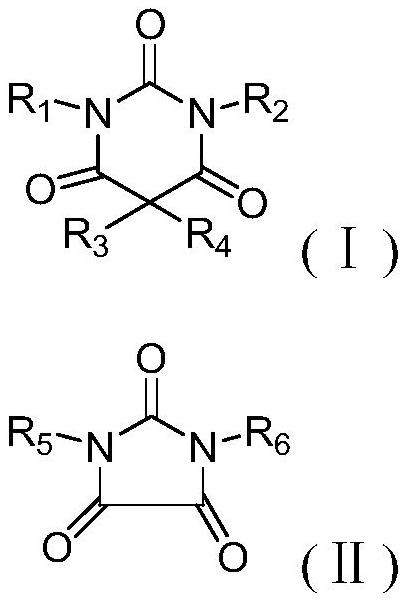

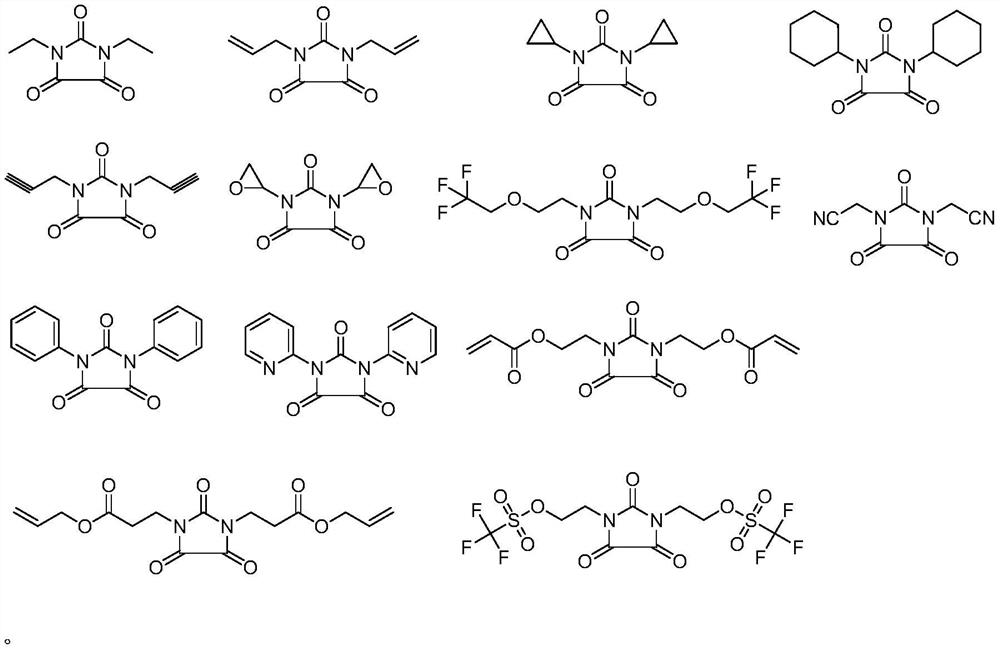

Lithium ion battery electrolyte

PendingCN114430068AImprove high temperature storage performanceImprove cycle performanceOrganic chemistrySecondary cells servicing/maintenanceOrganic solventLithium-ion battery

The invention relates to a lithium ion battery electrolyte which comprises a lithium salt, an organic solvent, a ureide compound, a boron-containing compound and a functional additive. The lithium ion battery electrolyte contains the unique combination of the ureide compound and the boron-containing compound, and the ureide compound can preferentially form a film at a negative electrode and is matched with other low-impedance film-forming additives to form a film, so that the low-temperature performance and the cycle performance are ensured. Meanwhile, the ureide compound has a stabilizing effect on the high-nickel positive electrode, and the high-temperature storage performance of the battery is improved. The boron-containing compound can stably form a film at a negative electrode, boron atoms have a modification effect on a positive and negative electrode interface film, the film impedance is reduced, and the cycle performance and low-temperature performance of the battery are improved. According to the lithium ion battery electrolyte, the high-temperature storage performance, the low-temperature performance and the cycle performance of a high-nickel positive electrode lithium ion battery can be improved.

Owner:SHENZHEN YANYI NEW MATERIALS CO LTD

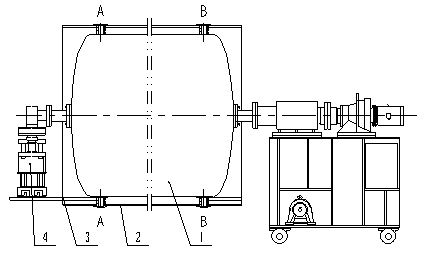

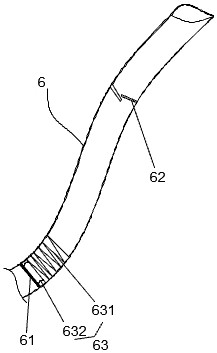

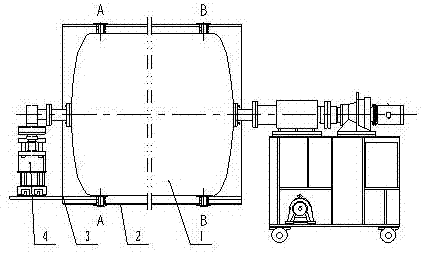

A kind of nesting method of inner and outer container of LNG storage tank

ActiveCN107477353BGuaranteed Low Temperature PerformanceGuaranteed lifeVessel manufacturingNon-pressured vesselsGlass fiberEngineering

The invention discloses a sleeving method of inner and outer containers of an LNG (Liquefied Natural Gas) storage tank. The sleeving method comprises the steps of (1) preparing an outer container; (2) preparing an inner container; (3) preparing for sleeving; and (4) sleeving. Holes are formed in upper support points of the A-A and B-B support sections of the outer container, backing plates II are welded on lower support points of the A-A and B-B support sections of the outer container, an outer support ring is welded on a lower support point of the A-A section, and a glass fiber reinforced plastic support is inserted. Backing plates and an inner support ring are welded on support points of the inner container. The inner container is fixedly connected with a counterweight container, a connecting steel pipe is lifted, and the inner container is moved to sleeve. When the B-B section of the inner container reaches an inlet, the outer support ring sleeves the outer surface of the glass fiber reinforced plastic support filled with heat insulating materials, the glass fiber reinforced plastic support is pressed into the lower inner support ring, and the outer support ring and the glass fiber reinforced plastic support are supported to sleeve together with the inner container. In a specified position, the inner container falls so as to compress the glass fiber reinforced plastic support. The outer support ring of the B-B section is welded on the backing plate II, and then the upper support structure is welded, so that sleeving is completed. According to the sleeving method, the full penetration rate of the outer container is increased, leakage points of the outer container are reduced, and the vacuum leakage rate of an interlayer between the inner and outer containers is reduced.

Owner:XINXING ENERGY EQUIP

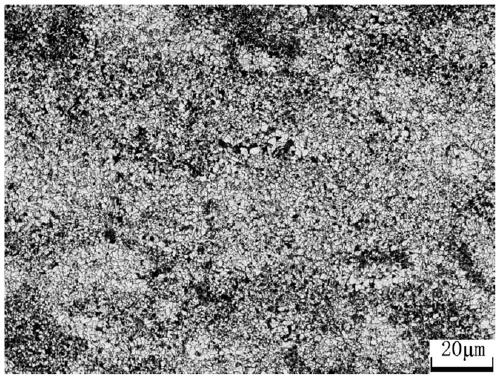

High-toughness steel plate for low-temperature pressure vessel and manufacturing method thereof

ActiveCN107937804BImprove mechanical propertiesGood welding performanceChemical compositionEconomic benefits

The invention discloses a steel plate used for a high-tenacity low-temperature pressure vessel and a manufacturing method thereof. Steel comprises the following chemical components including, by weight, 0.090-0.130% of C, not greater than 0.15% of Si, 1.40-1.80% of Mn, not greater than 0.012% of P, not greater than 0.004% of S, 0.27-0.45% of V, 0.010-0.020% of N, not greater than 0.020% of Alt andthe balance Fe and inevitable impurities; and meanwhile, V / C is greater than or equal to 3 and smaller than or equal to 4, and V / (C+Si) is greater than or equal to 1.2 and smaller than or equal to 3.The steel provided by the invention is high in strength and good in low-temperature impact toughness, the minus 60 DEG C KV2 is greater than or equal to 80 J, an excellent manufacturing material is provided for the low-temperature pressure vessel, a foundation is laid for enlargement and lightweight of the low-temperature pressure vessel, furthermore, the carrying efficiency of the movable pressure vessel is greatly improved, and the economic benefit of the movable pressure vessel is greatly increased.

Owner:武汉钢铁有限公司

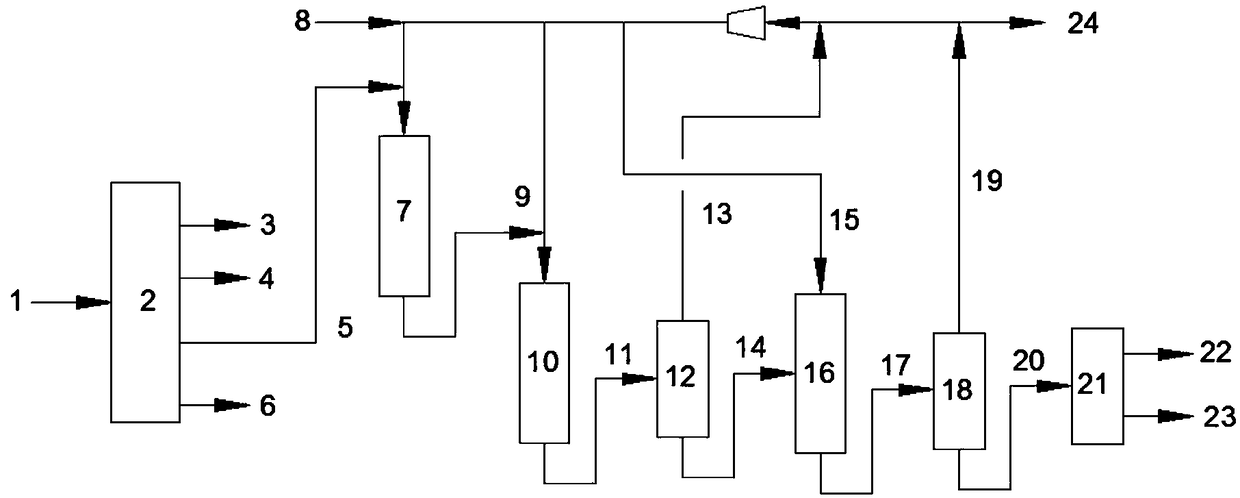

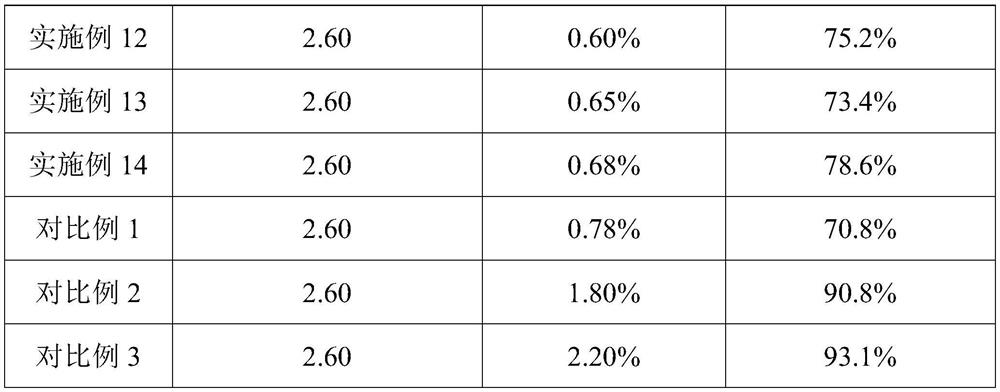

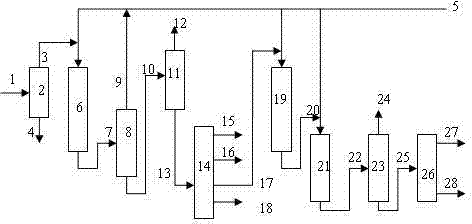

Method and device for producing base oil of naphthene base refrigerating machine oil

ActiveCN109321273AExtend the industrial chainReduce water contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsPulp and paper industryBase oil

The invention provides a method and device for producing base oil of naphthene base refrigerating machine oil. The method for producing the base oil of the naphthene base refrigerating machine oil comprises the steps that S1, direct coal liquefied oil is subjected to fractional distillation, and a first fraction at the temperature of 330-360 DEG C is obtained; S2, the first fraction is subjected to hydrofining, and a first refined product is obtained; and S3, the first refined product is subjected to hydro-upgrading, and the base oil of the naphthene base refrigerating machine oil is obtained.The coal direct liquefied oil serves as a production raw material in order to solve the problem that the product raw materials are in shortage in the prior art, the fraction at the temperature of 330-360 DEG C is obtained through fractional distillation, and the base oil of product the naphthene base refrigerating machine oil can be economically and efficiently obtained by conducting hydrofiningand hydro-upgrading on the fraction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Asphalt mixture with superstrong anti-rutting performance

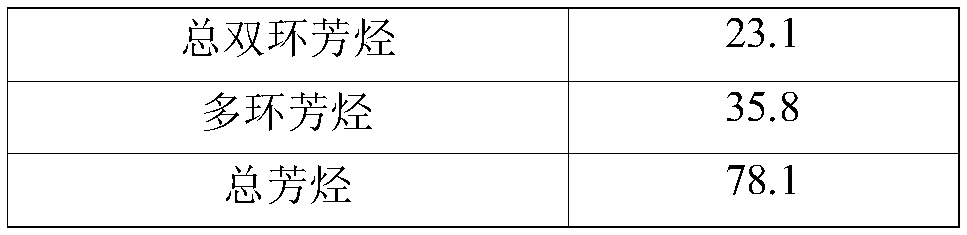

InactiveCN104743966AExcellent resistance to rutting deformation at high temperatureExtended service lifeHeavy dutyAsphalt

The invention relates to an asphalt mixture with superstrong anti-rutting performance, and particularly relates to an asphalt mixture which has especially excellent anti-rutting performance at a high temperature, and is especially applicable to the field of heavy-duty traffic. The asphalt mixture comprises aggregate, cement, modified asphalt and an anti-rutting agent, and the aggregate comprises crude aggregate and fine aggregate; and the specifications of the aggregate are respectively 19-26.5mm, 11-19mm, 5-11mm, 3-5mm and 0-3mm, and the ratios of the aggregates and the cement accounting for total mass of the aggregates and cement is 12:33:25:10:18:2. The preparation method of the asphalt mixture comprises the following steps: 1) preparing modified asphalt; 2) mixing the aggregates with cement, and adding the anti-rutting agent; and 3) weighing the modified asphalt obtained in the step 1), which accounts for 4.38% of the mass of the aggregates and the cement, and placing into a mixing cylinder and stirring for 40-45s, to obtain the asphalt mixture with superstrong anti-rutting performance. The water stability and low-temperature performance can meet the requirement of an expressway, and the high-temperature stability performance is especially excellent.

Owner:JSTI GRP CO LTD

Precision casting bearing steel

InactiveCN106119729AGood corrosion resistance, wear resistance and temperature resistanceCorrosion-resistant, wear-resistant and temperature-resistantUltimate tensile strengthWear resistance

The invention discloses precision casting bearing steel, which is prepared from the following components in percent by weight: 0.95-1.02% of C, 0.15-0.25% of Si, 0.55-0.75% of Mn, 0.03-0.05% of S, 14-17% of Cr, 0.01-0.02% of P, 0.020-0.035% of Al, 0.30-0.40% of N, 0.8-1.0% of Mo, and the balance of Fe and inevitable impurities. The performances such as corrosion resistance and wear resistance of the bearing steel in the prior art cannot meet the use requirements, but in the present invention, C, N, Cr and Mo are reasonably proportioned, such that the material has very good corrosion resistance, wear resistance and temperature resistance, as well as mechanical property and fatigue strength.

Owner:娄土岭

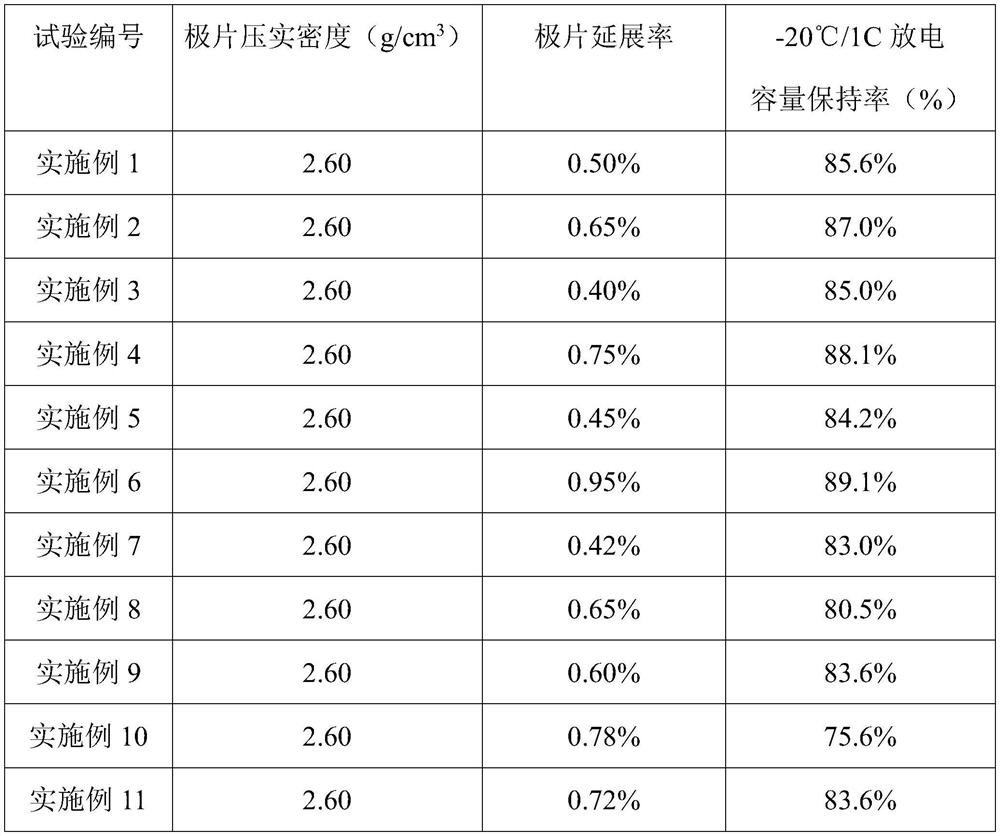

Lithium iron phosphate material, preparation method thereof and lithium ion battery

ActiveCN114843487AImprove conductivitySolve densitySecondary cellsPositive electrodesCarbon coatingLithium iron phosphate

The invention relates to a lithium iron phosphate material, a preparation method thereof and a lithium ion battery, the preparation method comprises the following steps: (1) mixing iron phosphide and first mixed powder, and sanding to obtain a doped precursor; (2) mixing a carbon source and the second mixed powder, carrying out secondary granulation, and roasting to obtain a coated precursor; and (3) mixing the doped precursor obtained in the step (1) and the coated precursor obtained in the step (2), and calcining to obtain the lithium iron phosphate material, wherein the step (1) and the step (2) are not divided into a sequence; the first mixed powder and the second mixed powder respectively and independently comprise phosphorus iron lithium mixed powder. According to the preparation method provided by the invention, organic combination of carbon coating and doping is adopted, the lithium iron phosphate material with excellent low-temperature performance and high compaction is obtained, and the problem that high volume density and low-temperature rate performance of lithium iron phosphate are incompatible is solved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Method for hydrogenation of medium-low temperature coal tar to produce refrigerator oil base oil

ActiveCN103789032BImprove featuresImprove the lubrication effectTreatment with hydrotreatment processesBase-materialsFractionationRefrigerated temperature

The invention discloses a method for hydrogenation of medium-low temperature coal tar to produce refrigerator oil base oil. The method includes: fractionating the medium-low temperature coal tar to obtain light fraction and heavy fraction, mixing the light fraction with hydrogen and leading the mixture into a hydrotreating reaction area to contact a hydrogenation protective catalyst and a hydrofining catalyst in order to undergo hydrogenation reaction; separating the hydrofining effluent, making the obtained liquid phase product enter a fractionating tower; bringing the 320-350DEG C diesel fraction obtained by fractionation into a hydro-upgrading reaction area where a hydro-upgrading catalyst containing amorphous aluminium silicon and modified Y zeolite is adopted, and performing hydro-upgrading reaction in the presence of hydrogen; subjecting the hydro-upgrading effluent into a hydrofinishing reaction area to undergo hydrofinishing reaction, and separating the hydrofinishing product to obtain the refrigerator oil base oil. The method provided by the invention adopts the medium-low temperature coal tar as the raw material to produce the refrigerator oil base oil with the characteristics of good low-temperature fluidity, corrosiveness, intersolubility with refrigerant and oxidation stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrogenation of medium-low temperature coal tar to produce transformer oil base oil

ActiveCN103789019BImprove featuresIntegrity guaranteedTreatment with hydrotreatment processesBase-materialsFractionationChemistry

The invention discloses a method for hydrogenation of medium-low temperature coal tar to produce transformer oil base oil. The method includes: fractionating the medium-low temperature coal tar to obtain light fraction and heavy fraction, mixing the light fraction with hydrogen and leading the mixture into a hydrotreating reaction area to contact a hydrogenation protective catalyst and a hydrofining catalyst in order to undergo hydrogenation reaction; separating the hydrofining effluent, making the obtained liquid phase product enter a fractionating tower; bringing the 280-320DEG C diesel fraction obtained by fractionation into a hydro-upgrading reaction area where a hydro-upgrading catalyst containing amorphous aluminium silicon and modified Y zeolite is adopted, and performing hydro-upgrading reaction in the presence of hydrogen; subjecting the hydro-upgrading effluent into a hydrofinishing reaction area to undergo hydrofinishing reaction, and separating the hydrofinishing product to obtain the transformer oil base oil. The method provided by the invention adopts the medium-low temperature coal tar as the raw material to maximumly produce the transformer oil base oil with the advantages of high density, volume, high volume calorific value, low aromatic hydrocarbon content, and good low temperature performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrogenation of medium-low temperature coal tar to produce large-specific weight aviation kerosene

ActiveCN103789034BImprove featuresExcellent carbon deposition performanceTreatment with hydrotreatment processesKeroseneFractionation

The invention discloses a method for hydrogenation of medium-low temperature coal tar to produce large-specific weight aviation kerosene. The method includes: fractionating the medium-low temperature coal tar to obtain light fraction and heavy fraction, mixing the light fraction with hydrogen and leading the mixture into a hydrotreating reaction area to contact a hydrogenation protective catalyst and a hydrofining catalyst in order to undergo hydrogenation reaction; separating the hydrofining effluent, making the obtained liquid phase product enter a fractionating tower; bringing the 140-290DEG C kerosene fraction obtained by fractionation into a hydro-upgrading reaction area where a hydro-upgrading catalyst containing amorphous aluminium silicon and modified Y zeolite is adopted, and performing hydro-upgrading reaction in the presence of hydrogen; subjecting the hydro-upgrading effluent into a hydrofinishing reaction area to undergo hydrofinishing reaction, and separating the hydrofinishing product to obtain the large-specific weight aviation kerosene. The method provided by the invention adopts the medium-low temperature coal tar as the raw material to maximumly produce the large-specific weight aviation kerosene with the advantages of high density, volume, high volume calorific value, low aromatic hydrocarbon content, and good low temperature performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Energy-saving satellite bin combined refrigeration house

ActiveCN111692802AAchieve reuseSmall supplementary needsLighting and heating apparatusStationary refrigeration devicesWater pipeWater storage tank

The invention discloses an energy-saving satellite bin combined refrigeration house. The energy-saving satellite bin combined refrigeration house comprises a material area and further comprises a water storage tank arranged below the material area, a sliding groove formed below the water storage tank, in communication with the water storage tank and internally provided with xylitol, a water pressing piece arranged in the sliding groove and a water pressing piece driving structure used for driving the water pressing piece to move; a water spraying area with a plurality of water spraying heads is arranged above the material area, the water spraying heads are connected with the sliding groove through water pipes, a vertically-through through hole is formed in the water pressing piece, the water pressing piece driving structure comprises a pressing head, a sealing part is arranged on the pressing head and used for blocking the through hole when the water pressing piece is pressed to act. According to the energy-saving satellite bin combined refrigeration house, when the refrigeration house is powered off, low-temperature cooling water formed by dissolving xylitol in water repeatedly scours food to reduce the temperature of the food, so that the food in the refrigeration house is prevented from deteriorating and rotting due to high temperature, sufficient repair time can be won formaintenance personnel, and the cooling water sprayed out of the water spraying heads flows through the material area and returns to the water storage tank again; the cooling water can be recycled, thewater supplement requirement is small, water resource waste is little, xylitol serves as a non-toxic organic matter, and the problem of food safety cannot be caused.

Owner:福州市金政捷制冷设备有限公司

Preparation of rubber asphalt mixture

InactiveCN101462849BGuaranteed Low Temperature PerformanceGuaranteed fatigue performanceSolid waste managementPolymer sciencePetroleum

The invention discloses a method for preparing a rubber asphalt mixture. The method comprises the following steps: adding tyre rubber powder into the road petroleum asphalt, and carrying out the stirring and reaction for 45 to 120 minutes to prepare the rubber asphalt; and adding N,N'-ethidence dioleamide into the heated stone material in the mineral aggregate, stirring the mineral aggregate evenly, then adding the rubber asphalt into the mineral aggregate, and stirring the mixture evenly to obtain the composite modified rubber asphalt mixture finished product. The obtained rubber asphalt mixture can simultaneously improve the high temperature performance and bonding performance of the rubber asphalt mixture.

Owner:TONGJI UNIV

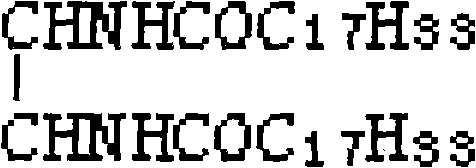

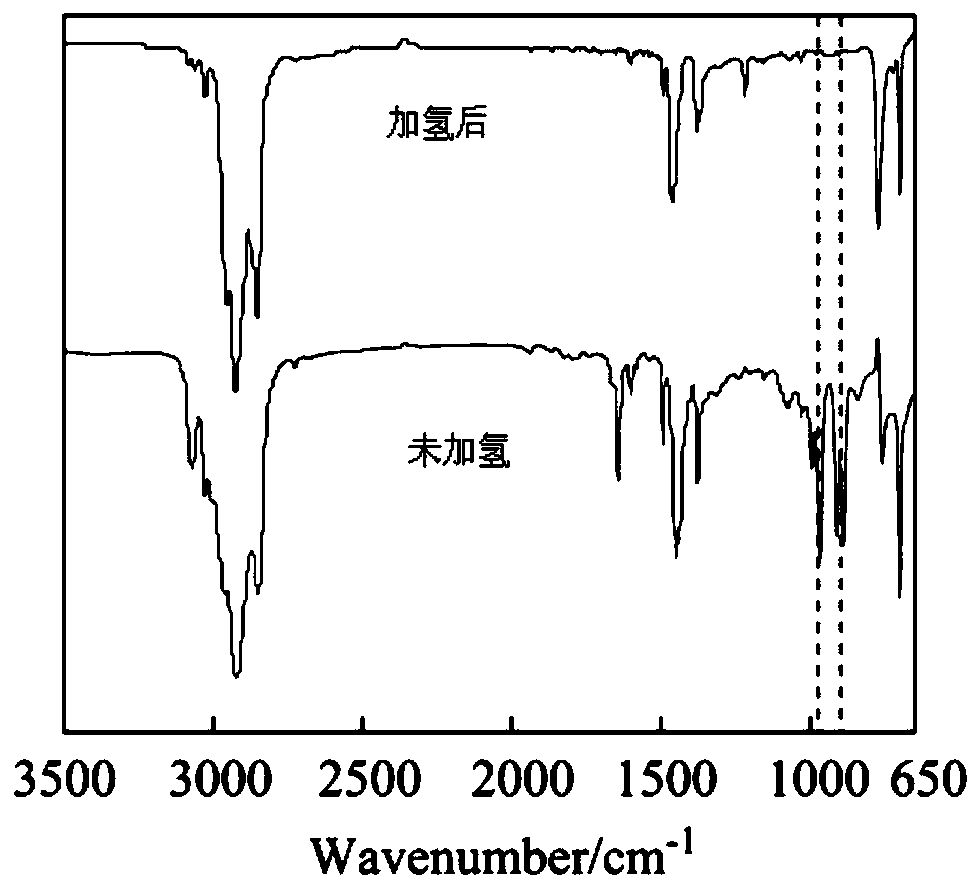

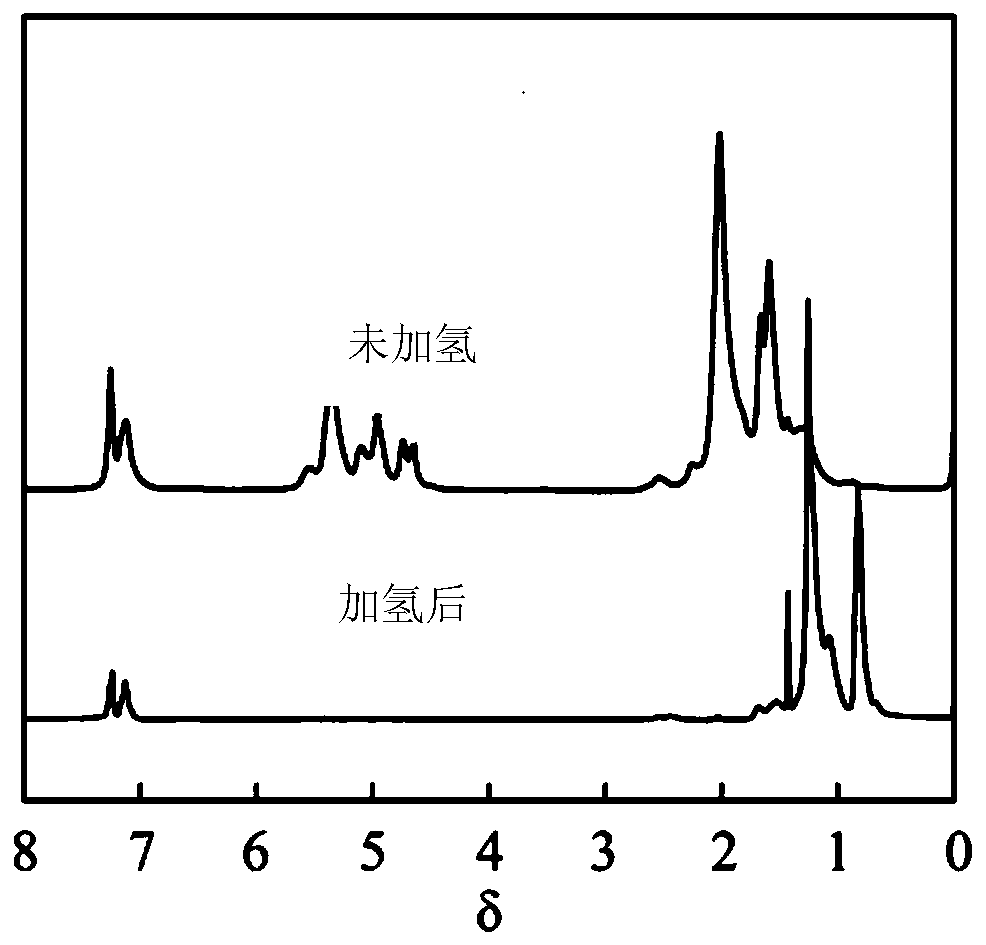

A kind of asymmetric polystar polymer and its preparation method and application

InactiveCN107663265BHigh degree of branchingGuaranteed cryogenic pumping performanceAdditivesPolymer scienceOil viscosity

The invention provides an asymmetrical poly star polymer as well as a preparation method and application thereof, and belongs to the field of a high-molecular polymer. The polymer has a structural general formula of (S1)nT(S2)m, wherein S1 is X1-(EP)a; X1 is polydivinylbenzene cores; EP is polyisoprene arms; a is the arm number; the value range of the a is 3 to 20; S2 is X2-(EB)b; the X2 is polydivinylbenzene cores; EB is polybutadiene arms or the polyisoprene arms; b is the arm number; the value range of the b is 3 to 20; the m and the n are positive integers; the value ranges of the m and the n are both 1 to 20; T is a coupling agent. The invention also provides a preparation method of the asymmetrical poly star polymer. The invention also provides application of the asymmetrical poly star polymer as a lubricating oil viscosity index improving agent. The low-temperature performance is ensured; meanwhile, the high-temperature thickening capability of a viscosity index agent is furtherimproved; the use range is wide; the application to various kinds of basic oil can be realized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Sleeving method of inner and outer containers of LNG (Liquefied Natural Gas) storage tank

ActiveCN107477353AGuaranteed Low Temperature PerformanceGuaranteed lifeVessel manufacturingNon-pressured vesselsGlass fiberEngineering

The invention discloses a sleeving method of inner and outer containers of an LNG (Liquefied Natural Gas) storage tank. The sleeving method comprises the steps of (1) preparing an outer container; (2) preparing an inner container; (3) preparing for sleeving; and (4) sleeving. Holes are formed in upper support points of the A-A and B-B support sections of the outer container, backing plates II are welded on lower support points of the A-A and B-B support sections of the outer container, an outer support ring is welded on a lower support point of the A-A section, and a glass fiber reinforced plastic support is inserted. Backing plates and an inner support ring are welded on support points of the inner container. The inner container is fixedly connected with a counterweight container, a connecting steel pipe is lifted, and the inner container is moved to sleeve. When the B-B section of the inner container reaches an inlet, the outer support ring sleeves the outer surface of the glass fiber reinforced plastic support filled with heat insulating materials, the glass fiber reinforced plastic support is pressed into the lower inner support ring, and the outer support ring and the glass fiber reinforced plastic support are supported to sleeve together with the inner container. In a specified position, the inner container falls so as to compress the glass fiber reinforced plastic support. The outer support ring of the B-B section is welded on the backing plate II, and then the upper support structure is welded, so that sleeving is completed. According to the sleeving method, the full penetration rate of the outer container is increased, leakage points of the outer container are reduced, and the vacuum leakage rate of an interlayer between the inner and outer containers is reduced.

Owner:XINXING ENERGY EQUIP

A method for producing white rubber extension oil base oil from catalytic oil slurry

ActiveCN104593067BLow hydrogenation activityHigh content of hydrogenated componentsTreatment with hydrotreatment processesHydrogenation reactionFractionation

The invention discloses a method for producing white rubber filling oil base oil through catalytic slurry oil hydrogenation. The method comprises the following steps: catalytic slurry oil is subjected to fractionation, such that a light fraction and a heavy fraction are obtained; the light fraction is mixed with hydrogen, and the mixture enters a hydrogenation treatment reaction zone; the mixture sequentially contacts a hydrogenation protection catalyst, a hydro-refining catalyst and a hydro-upgrading catalyst A, such that a hydrogenation reaction is carried out; a hydrogenation treatment effluent enters a hydro-upgrading reaction zone; a hydro-upgrading catalyst B containing amorphous silica-alumina and modified Y zeolite is adopted in the hydro-upgrading reaction zone, and a hydro-upgrading reaction is carried out under the existence of hydrogen; a hydro-upgrading effluent enters a hydro-finishing reaction zone, and is subjected to a hydro-finishing reaction; and a hydro-finishing product is separated, such that the rubber filling oil base oil is obtained. According to the invention, the catalytic slurry oil is adopted as a raw material, and can be used for producing the white rubber filling oil base oil with good low-temperature fluidity, good intersolubility with rubber, and good oxidation stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com