Mixed non water electrolyte additive for improving battery high-temperature performance

A non-aqueous electrolyte, high-temperature performance technology, applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problem of loss of low-temperature performance, and achieve the goal of inhibiting expansion, ensuring high-temperature performance, and meeting battery performance effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

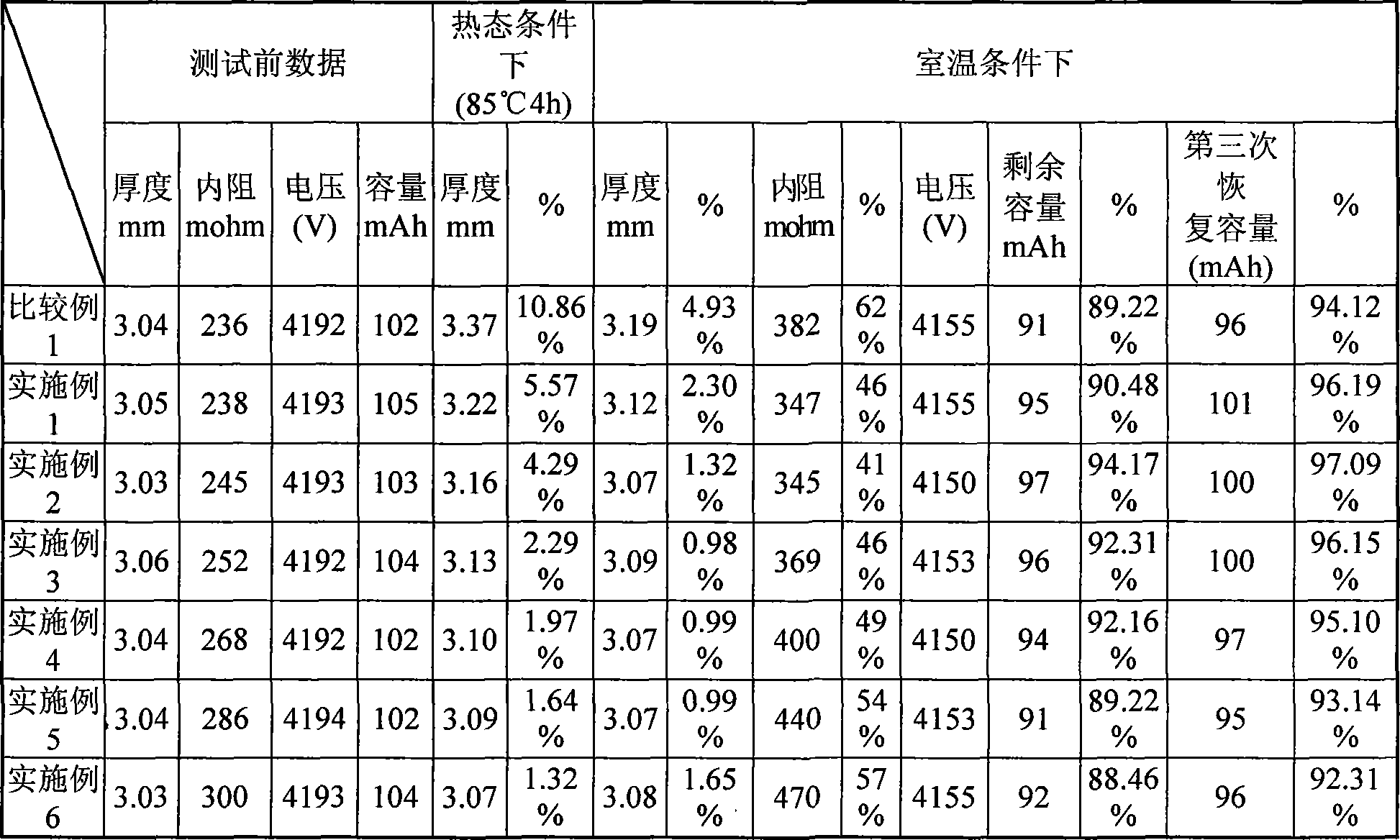

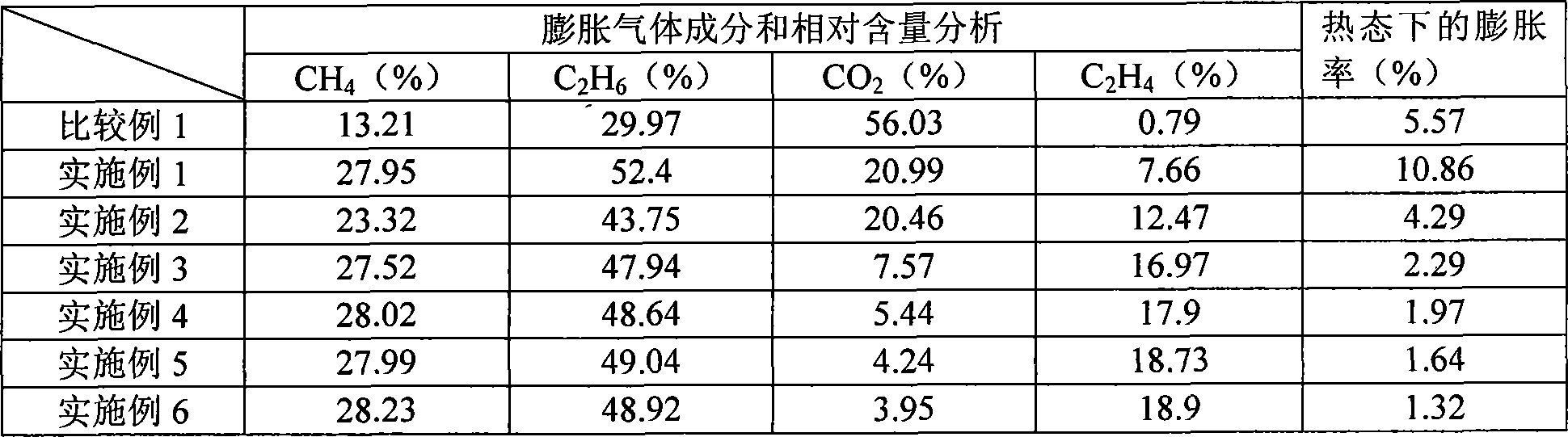

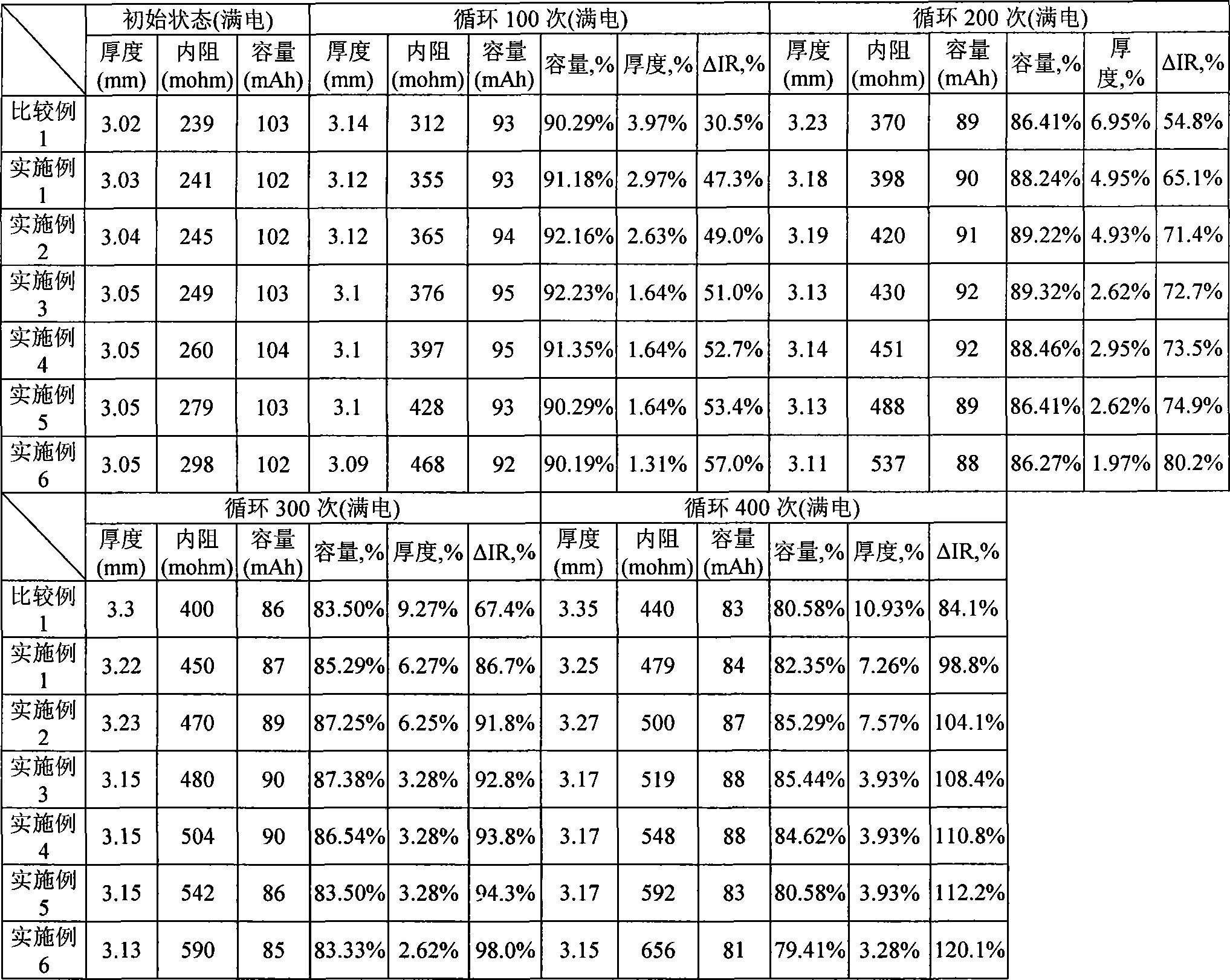

Embodiment 1

[0014] The composition of the non-aqueous electrolyte: EMC / EC / PC=55:40:5 (ratio by weight), the solute is LiPF6, and the concentration is 1mol / L. In 100 parts by weight of non-aqueous electrolyte, add 3 parts of PS and 1 part of VC to form a general additive. Then 0.5 parts of VEC and 0.1 parts each of PPACA and ethyl acetate were added thereto.

Embodiment 2

[0016] The composition of the non-aqueous electrolyte: EMC / EC / PC=55:40:5 (ratio by weight), the solute is LiPF6, and the concentration is 1mol / L. In 100 parts by weight of non-aqueous electrolyte, add 3 parts of PS and 1 part of VC to form a general additive. Then 1.0 part of VEC and 0.1 parts each of PPACA and ethyl acetate were added thereto.

Embodiment 3

[0018] The composition of the non-aqueous electrolyte: EMC / EC / PC=55:40:5 (ratio by weight), the solute is LiPF6, and the concentration is 1mol / L. In 100 parts by weight of non-aqueous electrolyte, add 3 parts of PS and 1 part of VC to form a general additive. Then 1.0 part of VEC and 0.2 parts each of PPACA and ethyl acetate were added thereto.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com