Sleeving method of inner and outer containers of LNG (Liquefied Natural Gas) storage tank

A technology of inner container and outer container, which is applied to the field of inner container of liquefied natural gas cryogenic storage tank is fitted into outer container, which can solve the problems of difficulty in fitting and support setting and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

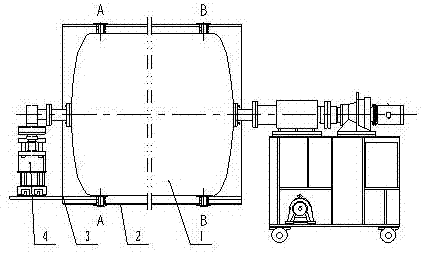

[0024] In this embodiment, one end of the outer container is welded. The upper four support structures of the A-A support section and the B-B support section are opened on the outer container, and the lower four support structures are not opened on the outer container. The fitting method is as follows, see the attachment for details Figure 2-9 .

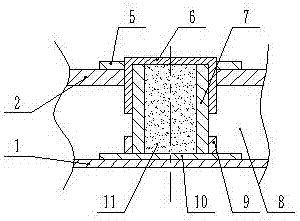

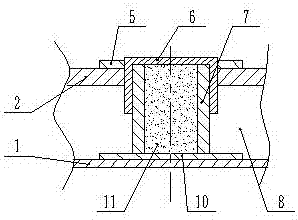

[0025] 1. Preparation of the outer container: as attached Figure 6 As shown, the head 12 and the outer cylinder 13 are welded together by double-sided welding, and the two support sections of the eight support structures are the A-A support section close to the head 12 and the B-B support section close to the fitting entrance of the outer container, wherein The support structure of the A-A support section is a sliding support, image 3 It is a schematic diagram of the upper sliding support structure of the A-A support section, and the two support points on the upper part of the outer container are opened; Figure 5 It is a schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com